Anthony Danko, Ph.D.

Naval Facilities Engineering Command (NAVFAC)

Engineering and Expeditionary Warfare Center (EXWC)

Treatment Technologies for PFAS Site Management

2

Presentation Overview

• Evaluating Remediation Technologies

• Sorption

• In Situ Technologies

• Dealing with Investigation-Derived Waste (IDW)

• Wrap-Up

FRTR 2018: PFAS Emerging Characterization and Remedial Technologies

3

Summary of Available Technologies – Drinking Water Treatment

Technology Category Technology Maturity/Availability

Sorption

Activated Carbon* Commercialized, can be purchased from vendors

Anion Exchange Resin* Commercialized, can be purchased from vendors

Biochar Field Pilot Scale, not commercially available

Zeolites/Clay Minerals Commercialized, can be purchased from vendors

Membrane Filtration

Reverse Osmosis and

Nanofiltration

+

Commercialized, can be purchased from vendors

Coagulation Specialty Coagulants Full Scale application being conducted by researchers

Redox Change Electrochemical Field Pilot Scale, not commercially available

Other Sonochemical Field Pilot Scale, not commercially available

Evaluating Remediation Technologies

* Technologies that will be discussed

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

4

Summary of Available Technologies – Soil Treatment

Technology Category Technology Maturity/Availability

Sorption and Technologies

Modified Carbon* Commercialized, can be purchased from vendors

Minerals/Modified Minerals* Commercialized, can be purchased from vendors

Excavation Disposal

To Landfill Commercialized

To Incinerator Commercialized

Thermal Field Pilot Scale, commercially available

* Technologies that will be discussed

Evaluating Remediation Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

5

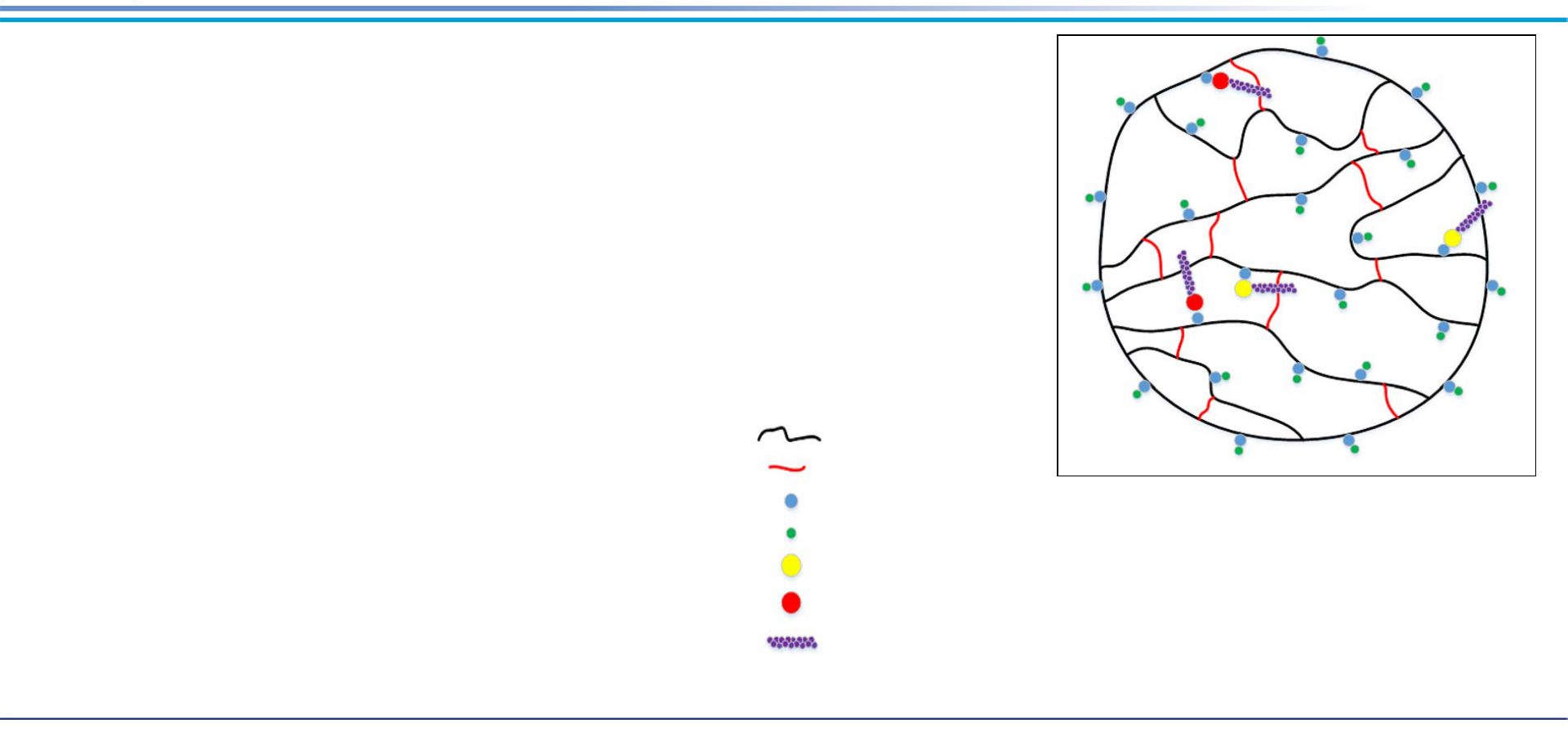

Consider Effect of Prior Remediation for Co-Contaminants on PFAS

• Benzene plume

• Oxygen injections at yellow

• Elevated levels of PFAA at location of historical and present

benzene plume – lacking in areas with no O

2

injections

• Fourfold difference in Kd between PFHxA and PFOA yet

their plume overlapped – likely due to in situ transformation

of precursors

• Navy currently conducting similar study under NESDI

Reference Evidence of Remediation-Induced Alteration of Subsurface Poly- and Perfluoroalkyl Substance Distribution at a

Former Firefighter Training Area Meghan E. McGuire, Charles Schaefer, Trenton Richards, Will J. Backe, Jennifer A. Field,

Erika Houtz,, David L. Sedlak, Jennifer L. Guelfo, Assaf Wunsch, and Christopher P. Higgins

Evaluating Remediation Technologies

Plume

Extent

2002

Treatment

Building

Treatment

Discharge

Most Recent

Burn Pit Area

Direction of

Groundwater Flow

Plume

Extent

2011

IRT

Pond 001

0 ft 150 ft 300 ft 450 ft

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

6

Pump-and-Treat

• At drinking water wellhead

• At point of use

• To control plume size/spread

• At base boundary to prevent plume migration

Only practical treatment for groundwater available

Key

Point

Wellhead Treatment

Point of Entry Treatment

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

7

Granular Activated Carbon (GAC)

Material

• Made from bituminous coal or coconut

• Highly porous, large surface area

Application

• Typically used in packed-bed flow-through vessels

• Operate in series (lead-lag) or parallel

• Virgin or Reactivated GAC

http://store.ecologixsystems.com/detail/index.cfm?nPID=294

Sorption

Reagglomeration

Coal Blend Pulverizing Agglomeration Crushing Baking Activation Screening

Finished

Product

Even Activation

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

8

Granular Activated Carbon (cont.)

Mechanism

• Adsorption on surface process, physical mass transfer

• No chemical degradation or transformation

Effectiveness

• Capable of 90 to >99% removal efficiency

• Individual PFAS have different GAC breakthrough times

–e.g., GAC capacity for PFOS>PFOA

• Influent conc. for <5 Carbon PFAS typically lower

• High DOC reduces effectiveness

Reference -Yu, Q., R. Zhang, S. Deng, J. Huang, G. Yu, 2009.

"Sorption of perfluorooctane sulfonate and perfluorooctanoate

on activated carbons and resin: Kinetic and isotherm study."

Water Research, 43, 1150-1158.

PFAS <5 carbons shorter

breakthrough times

Key

Point

Sorption

Activated Carbon

hemi-micelle

micelle

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

9

Reactivation of PFAS Contaminated Granular Activated Carbon

Thermal Reactivation Process

• Reactivation temperature 1,300°F

• PFAS pyrolysed to carbon char

• Lower CO

2

footprint than making virgin GAC

• Reactivated carbon just as effective as virgin carbon

Reactivation furnace

under negative

pressure and

nitrogen

environment

Furnace off gas

passed through after

burn to destroy

organics

Emission stream

passed through

chemical scrubber to

remove acid gases

Final treatment

through baghouse

filters to remove

particulate matter

Process is expensive and energy intensive

Key

Point

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

10

PFBS (ppb)

RSSCT PFOA Breakthrough Curves

10 Minutes Empty Bed Contact Time (EBCT)

Removal of PFBS Using

Filtrasorb

®

vs. Coconut

1.2

1

0.8

0.6

PFOA (ppb)

0.4

0.2

0

0 20,000 40,000 60,000 80,000 100,000 120,000 140,000 160,000 180,000 200,000

0

0 20,000 40,000 60,000 80,000 100,000 120,000

200

180

160

140

120

100

80

60

40

20

Bed Volumes Treated (BV)

Bed Volumes Treated (BV)

Filtrasorb

®

Coconut 12x40

Feed

Virgin

Filtrasorb

®

Coconut

12x40

Coconut

8x30

Feed

PFOA

50% Feed

PFOA

Reagglomerated coal

significantly outperformed

coconut

Reagglomerated coal

significantly outperformed

coconut

70 ppt EPA Health Advisory Exposure Limit

Bituminous vs. Coconut Carbon

Bituminous carbon appears to perform better than coconut carbon

at this specific site

Key

Point

NEWMOA PFAS Technical Workshop – Activated Carbon

Don Ivey and John Matthis May 2017

Sorption

Background TOC 1.42 mg/L

Simulated Empty Bed

Contact Time (EBCT)

10 minutes

Concentration of PFOA 920 ng/L (ppt)

Background TOC 0.16 mg/L

Simulated Empty Bed

Contact Time (EBCT)

10 minutes

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

11

Case Study – Point of Entry Treatment – Vermont Residences

• PFOA contamination from

textile coating at

CHEMFAB

®

• 541 samples from private

wells

• Bottled water delivered to

residents

• 11 homes connected to

municipal water

• 255 POET systems

installed

Sorption

Non-Detect (ND)

20-100 ppt

100-1,000 ppt

>1,000 ppt

Landfill Monitoring

Factory

Landfill

Wastewater Treatment Plant

Town Water Sample

Water Line

Village Boundary (VCGI)

Sampling Boundary

6/22/16 Sampling Extension

5/24/16 Sampling Extension

Town Boundary

<20 ppt (VDH Advisory)

1 0

MILES

LAYERS PFOA

BOUNDARIES

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

12

Case Study – POET Vermont

• Initially sampled once per month for 3 months

• Influent, midpoint and effluent

• Influent PFOA Concentration >1,000 ppt: sample every 3 months

• Influent PFOA Concentration >200 ppt to <1,000 ppt sample every 6 months

• Influent PFOA Concentration <200 ppt every 12 months

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

13

Case Study POET Vermont – Results

• Influent concentrations vary from <20 ppt

to 4,600 ppt

• Volume treated per unit from 50 gal over

one month to 37,000 gal over 3 months

• Pre and post filter replaced every 4 months

• UV lap replaced every 12 months

• GAC replacement assumed every 2 years

• Swap lead and lag tank then ship GAC

media to vendor

Reference: Lessons Learned on Vermont POET Installations and

Operations at Residences Impacted by PFASs. Richard Spiese.

Sorption

TOC Concentration (ppm, mg/L)

PFC Concentration (ppt, ng/L)

Simulated Days of Operation

Simulated Days of Operation vs. PFCs and TOC

PFC/TOC Customer ACT Data

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0

50

100

150

200

250

300

350

400

0.0 100.0 200.0 300.0 400.0 500.0 600.0

PFHpA PFHxA PFOA Feed PFHpA Feed PFHxA Feed PFOA TOC Removal Feed TOC

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

14

Case Study – NAS Brunswick, ME GWETS

• Former Naval Air Station in Brunswick, ME, BRAC 2011

• Treating CVOCs at GWETS using air stripping and GAC (vapor and liquid phase)

• Recovered over 500 kg VOCs since 1995; removal now limited by back diffusion rate,

asymptotic range

• 1,4-Dioxane addressed by addition of HiPOx

®

unit

• PFAS removed via liquid-phase GAC

–PFOA breakthrough determines changeout

–Shorter-chain PFAS, carboxylates, break through

earlier

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

15

Case Study – NAS Brunswick, ME GWETS – Results

Sorption

1.00

PFOS Concentration (µg/L)

0.90

0.80

0.70

0.60

0.50

0.40

0.30

0.20

0.10

0.00

PFOS – Plant Influent

Sample Date

PFOS – Plant Effluent

PFOS – HiPOx

®

Effluent

PFOS – USEPA HA

PFOS – GAC Mid-point

Carbon change-out

11/2/2015 2/10/2016 5/20/2016 8/28/2016 12/6/2016 3/16/2017 6/24/2017 10/2/2017 1/10/2018

Carbon Change-out 11/10/15

Lead Vessel: Coconut Carbon

Lag Vessel: F600

Carbon Change-out 10/12/16

Lead Vessel: F600

Figure 1: PFOS Concentrations

GWETS Carbon Change Out PFC Monitoring

Former Naval Air Station Brunswick, Brunswick, ME

PFOA – Plant Influent

11/2/2015

3.5

3

2.5

2

1.5

1

0.5

0

PFOA Concentration (µg/L)

2/10/2016 5/20/2016 8/28/2016 12/6/2016 3/16/2017 6/24/2017 10/2/2017 1/10/2018

Sample Date

PFOA – Plant Effluent

PFOA – HiPOx

®

Effluent

PFOA – USEPA HA

PFOA – GAC Mid-point

Carbon change-out

Carbon Change-out 11/10/15

Lead Vessel: Coconut Carbon

Lag Vessel: F600

Carbon Change-out 10/12/16

Lead Vessel: F600

Figure 2a: PFOA Concentrations

GWETS Carbon Change Out PFC Monitoring

Former Naval Air Station Brunswick, Brunswick, ME

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

16

Case Study – NAS Brunswick, ME GWETS – Results (cont.)

Sorption

11/2/2015

0.160

0.140

0.120

0.100

0.080

0.060

0.040

0.020

2/10/2016 5/20/2016 8/28/2016 12/6/2016 3/16/2017 6/24/2017 10/2/2017 1/10/2018

Sample Date

PFOA–Plant Effluent

PFOA–USEPA HA

PFOA–GAC Mid-point

Carbon change-out

Carbon Change-out 11/10/15

Lead Vessel: Coconut Carbon

Lag Vessel: F600

Carbon Change-out 10/12/16

Lead Vessel: F600

Figure 2b: PFOA Concentrations (Carbon Vessels Only)

GWETS Carbon Change Out PFC Monitoring

Former Naval Air Station Brunswick, Brunswick, ME

0.000

PFOA Concentration (µg/L)

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

17

Case Study – NAS Brunswick, ME GWETS – Results (cont.)

Sorption

11/2/2015

0.160

0.140

0.120

0.100

0.080

0.060

0.040

0.020

2/10/2016 5/20/2016 8/28/2016 12/6/2016 3/16/2017 6/24/2017 10/2/2017 1/10/2018

Sample Date

PFBA – Plant Influent

PFBA – HiPOx

®

Effluent

PFBA – GAC Mid-point

Carbon change-out

Carbon Change-out 11/10/15

Lead Vessel: Coconut Carbon

Lag Vessel: F600

Carbon Change-out 10/12/16

Lead Vessel: F600

Figure 3: PFBA Concentrations

GWETS Carbon Change Out PFC Monitoring

Former Naval Air Station Brunswick, Brunswick, ME

0.000

PFOA Concentration (µg/L)

Sample Date

PFBA – Plant Effluent

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

18

Ion Exchange

Material

• Synthetic neutral co-polymeric media (plastics)

with positively-charged exchange sites

• Can be regenerated (produces waste stream)

or single use (must be disposed of properly)

Application

• Removes anionic PFAS binding to negatively-

charged functional group

• Lead-lag including combination of single use

and regenerated

Reference: Steve Woodward John Berry Brandon Newman. 2017. Ion Exchange Resin for PFAS

Removal and Pilot Test Comparison to GAC. Remediation Journal Volume 27, Issue 3 Pages 19–27

Sorption

Polystyrene polymer chain

Fixed ion exchange group, e.g., quaternary ammonium, —

≡N

+

, for anion IEX

Divinylbenzene crosslink

Exchangeable counter ion, e.g., chloride ion, Cl-, for anion IEX

Sulfonate group, —SO

3

-

, of PFAS (e.g., PFOS), replacing exchangeable counter ion

Carboxylate group, —CO

2

-

, of PFAS (e.g., PFOA), replacing exchangeable counter ion

PFAS carbon-fluorine tail adsorbing to polystyrene polymer chain or divinylbenzene

crosslink via Van der Waals forces

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

19

Ion Exchange (cont.)

Mechanism

• Acts as ion exchange resin and adsorbent resin

• Positively charged anion exchange media

• Removes negatively-charged PFAS from water

Effectiveness

• Reaction kinetics faster than GAC

• Operating capacity higher than GAC

• Breakthrough varies for different PFAS

• Less frequent media change-outs

Sorption

% Removal from GAC (5.6 min EBCT) vs.

Ion Exchange (1.4 min EBCT)

Ion Exchange

Bituminous GAC

% Removal After Treating 146 days

PFOS PFHxS PFOA PFBS PFHpA PFHxA

Anion-Exchange Resin

hemi-micelle

micelle

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

20

Considerations When Using Ion Exchange

• Type and concentration of inorganic ions in groundwater affect PFAS capacity of resin

• Bench-scale tests recommended to determine most effective resin

• More cost-effective at higher concentrations

• Organic matter may foul resin

• Co-contaminants compete for resin site

• Site-specific testing should be performed

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

21

Regeneration of Ion Exchange Resins

• Brine solution can desorb anionic head of PFAS from resin

• Organic solvent-like methanol or ethanol can desorb C-F tail

• Surfactants with both nonionic and anionic properties can be used as regenerants

• Most successful has been organic solvents and sodium chloride

• The solution used to regenerate may then need to be concentrated to minimize the

volume of waste

Shipped back to vendor for regeneration

Key

Point

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

22

Case Study – Comparison of GAC with Ion Exchange at Pease AFB

• Historic use of AFFF for firefighting training

• Ion Exchange – ECT Sorbix A3F

• Note 6:2 FS 2

nd

highest concentration PFAS

• GAC – Calgon Filtrasorb

®

400 (F400)

Reference: Steve Woodard John Berry Brandon Newman. 2017 Ion Exchange Resin for PFAS Removal and Pilot Test Comparison to GAC. Remediation Journal Volume 27, Issue 3 Pages 19–27

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

23

Case Study – Comparison of GAC with Ion Exchange at Pease AFB (cont.)

GAC

• 4 vessels in series

• Each containing 9 gal F400

• Each vessel 5 min EBCT, overall 20 min EBCT

• Samples collected at influent and after each

vessel weekly for 8 weeks

• At 1.8 gpm treated 100,486 gal water

(11,165 bed volumes)

Ion Exchange

• 3 vessels in series

• Each containing 9 gal resin

• Each vessel 2.5 min EBCT, overall 7.5 min EBCT

• At 3.6 gpm treated 422,645 gal water (46,961 BVs)

• Samples collected routinely at influent and effluent

Sorption

GROUNDWATER

IN

CARTRIDGE

FILTERS

CARTRIDGE

FILTERS

GROUNDWATER

OUT

SOLVENT

RECOVERY

REGENERANT

SUPPLY

GAC1 GAC2 GAC3 GAC4

IX1 IX2 IX3

TRANSFER

PUMP

TRANSFER

PUMP #1

TRANSFER

PUMP #2

SP

SP

SP

SP

SP SP SP SP

SP SP SP

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

24

Case Study – Comparison of GAC with Ion Exchange at Pease AFB (cont.)

GAC

Ion Exchange

Entire Pilot-Scale Setup

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

25

Case Study – Comparison of GAC with Ion Exchange at Pease AFB (cont.)

PFOS PFOA

Sorption

Influent

Lead Resin (2.5-min EBCT)

Lag Resin (5-min EBCT)

Lead GAC (5-min EBCT)

Lag GAC (10-min EBCT)

USEPA HA: PFOA+PFOS

Bed Volumes

10,000 20,000 30,000 40,000 50,000 0

0.001

0.01

0.1

1

10

100

Concentration (µg/L)

Influent

Lead Resin (2.5-min EBCT)

Lag Resin (5-min EBCT)

Lead GAC (5-min EBCT)

Lag GAC (10-min EBCT)

USEPA HA: PFOA+PFOS

Bed Volumes

0.001

0.01

0.1

1

10

100

10,000 20,000 30,000 40,000 50,000 0

Concentration (µg/L)

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

26

Case Study – Comparison of GAC with Ion Exchange at Pease AFB (cont.)

PFBA PFBS

Sorption

Avg. Influent

Bed Volumes Treated

5,000 10,000 15,000 20,000 25,000 0

0

0.5

1

1.5

2

2.5

0.2

0.4

0.6

0.8

1

1.2

Concentration (µg/L)

Concentration (µg/L)

Resin GAC Avg. Influent Resin GAC

5,000 10,000 15,000 20,000 25,000 0

Bed Volumes Treated

0

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

27

Case Study – Comparison of GAC with Ion Exchange at Pease AFB (cont.)

• Three regeneration trials using proprietary blend of organic solvent and brine

Step 1

Purge lead vessel with

1 BV 10% brine to

prime resin for

regeneration

Step 2

Pump 10 BV

regenerant through

resin counter flow

Step 3

Pump 10 BV potable

water to rinse resin

counter flow

Step 4

Return resin vessel to

full service

TOTAL PFAS

Regenerant Solution Recovery

• Distill off solvent fraction into regenerant tank for reuse,

left with concentrated brine PFAS fraction

• OR conduct superloading – process concentrated brine

PFAS solution through adsorption media then recycle

brine solution

Sorption

1.0

2.0

3.0

4.0

5.0

6.0

Concentration (µg/L)

Lead Resin – Virgin

2,000 4,000 6,000 8,000 0

Bed Volumes Treated

0

Lead Resin – Regenerated

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

28

Case Study – Comparison of GAC with Ion Exchange at Pease AFB (cont.)

• Both GAC and Ion Exchange Resin can remove PFOS and PFOA from groundwater to

below EPA LHA

At 5 min. contact time

• Resin treated 8X more BV than GAC before breakthrough of PFOS observed

• Resin treated 6X more BV than GAC before breakthrough of PFOA observed

• Resin removed 1.66 mg PFAS per gram of resin whereas GAC removed 0.40 mg

PFAS per gram GAC

• Resin could be regenerated in the field

Sorption

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

29

In Situ Stabilization (ISS)

• Use of amendments for adsorbing and stabilizing PFAS in soil and groundwater

• GAC, stabilizers, and modified minerals (organoclays)

• Commercially available

• Additional amendments being developed

• Critical to monitor soil leachate to determine treatment effectiveness

• Limited full-scale application in U.S. (more overseas)

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

30

Activated Carbon for In Situ Water Treatment – PlumeStop

®

Material

• Colloidal activated carbon

• 1-2 µm sized particles of carbon suspended in water

by organic polymer dispersion chemistry

Application

• In situ sorbent technology sorbs PFOS and PFOA

from aqueous phase

• Treats dissolved-phase contaminants

• Applied by low-pressure injections

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

31

Activated Carbon for In Situ Water Treatment – PlumeStop

®

(cont.)

Mechanism

• Coats surface of soil

• Contaminants in dissolved phase then sorb to carbon

• Does not destroy PFAS, immobilizes PFAS in place

• Occupies just 0.1% soil pore volume

Effectiveness

• Reduces aqueous concentration to below 70 ng/L

• Radius of Influence can be up to 25 ft

• Can be applied as multiple barriers perpendicular to plume

In Situ Technologies

RITS 2018: PFAS Remediation: Technologies, Guidance, and Application

A Scanning Electron Microscope (SEM) Image of

Sand Grains With and Without a Coating of Carbon

32

In Situ Soil Treatment – Aluminum-Based Sorbent – Rembind Plus

®

Material

• Aluminum hydroxide, activated carbon, organic matter, and kaolinite

Application

• Apply to soil in ~2 to 5% by weight

• Adjust to 30% moisture content

• Binding occurs in 24 hours

• Pilot tested for water treatment

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

33

In Situ Soil Treatment – Aluminum-Based Sorbent – Rembind Plus

®

(cont.)

Mechanism

• Aluminum hydroxide binds to functional head of PFAS by electrostatic interactions

• Activated carbon and organic matter binds to tail via by hydrophobic interactions and

Van der Waals forces

In Situ Technologies

Large complex organic humus molecule

consisting of chains and rings of mainly

carbon and hydrogen atoms

Organic Matter

Activated Carbon

Aluminum Hydroxide

(Amorphous)

Electrostatic

Interactions

Physical

Binding

Hydrophobic Interactions

Van der Waals

Point of zero charge > pH 9.1

Carboxyl

group

Phenolic

hydroxyl

group

Alcoholic

hydroxyl

group

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

34

Aluminum-Based Sorbent for GW Case Study – Air Force Site

• Historical use of AFFF at site

• Full-scale GAC system: two 20,000-lb GAC vessels in

operation to remove PFOS/PFOA from groundwater

• Goal of pilot study to evaluate sorption capacity of

RemBind Plus

®

In Situ Technologies

Influent Concentrations

Concentration (ng/L)

6000

5000

4000

3000

2000

1000

0

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

35

Aluminum-Based Sorbent for GW Case Study – Air Force Site (cont.)

• 30-gal batch reactor pilot test set up next to GAC system

• 30 gal of contaminated water mixed 1.135 kg aluminum-

based sorbent for one hour and allowed to settle overnight

• Next day treated GW moved to effluent tank and

contaminated GW added to tank with amendment without

replacing amendment

• Run for 2 weeks treating 280 gal water

• Monitored for 53 PFAS compounds and TOP assay

• TOC also monitored

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

36

Aluminum-Based Sorbent for GW Case Study – Air Force Site – Results

• 18 PFASs detected frequently

• Removal ranged from 80 to 100% after 155 gal

• Slight decrease in removal beyond 155 gal

In Situ Technologies

Top Assay Influent

PFAS Concentration

(nmole/L)

Total PFOA PFOS PFSAs Precursors

35

30

25

20

15

10

5

0

PFAS precursors unable

to be directly analyzed

Inf-Pre TOPA

Inf-Post TOPA

PFOA Sorbed

PFOS Sorbed

Pre-Treatment PFOS

% PFOS Removal

Pre-Treatment Concentration (µg/L)

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

3000

2500

2000

1500

1000

500

0

Sorbed Mass (µg/kg)

0 50 100 150 200 250 300

0 50 100 150 200 250 300

Groundwater Volume (gal)

Groundwater Volume (gal)

PFOS Removal (%)

100

95

90

85

80

75

70

65

60

55

50

% PFOS Removal

Cumulative Removed PFOA and PFOS

(µg/kg-RemBind Plus

®

) from Groundwater

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

37

Types of IDW

Liquid Waste

• Purge water from groundwater sampling

• Concentrated AFFF

Solid Waste

• Well installation waste (soil cuttings)

• Soil cuttings from core sampling

• Spent GAC

• Spent ion exchange resin

• Soil from excavations

Dealing with Investigation-Derived Waste (IDW)

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

38

Challenges with Handling IDW

• PFAS are considered non-hazardous (can be disposed of in any landfill)

• Landfill refusal to accept PFAS waste

• Potential for future liability

• Risk of landfill leachate

Dealing with Investigation-Derived Waste (IDW)

Consideration should be given to taking liquid waste to existing onsite

GWETS if available

Key

Point

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

39

Considerations for Liquid IDW

• If PFAS concentrations are below regulatory levels, water may be considered to be

disposed to sanitary sewer/POTW

• At sites where there is a PFAS GWETS, purge water should be considered to be

treated in that system with operator approval

• Purge water may be considered to be passed through a drum of GAC, held in a

receiving tank pending analysis

• If below regulatory values, GW may be able to be discharged to the sanitary

sewer/POTW

• Purge water may be able to be sent to an off-site treatment facility willing to accept it

Dealing with Investigation-Derived Waste (IDW)

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

40

Considerations for Liquid IDW

• Currently sending to a landfill or a treatment facility may be the only choice

• As treatment becomes more common, the soil cuttings may be treatable on-site

(e.g., thermal)

• PFAS waste is non hazardous*, so 90 day rule does not apply

• Option – retain material on site as treatment approaches and policies are developed

• EXWC conducting research on treatment for IDW and source zone soils

Dealing with Investigation-Derived Waste (IDW)

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

41

Key Points

• GAC may be the only practical treatment for groundwater to date

• PFAS <5 carbons much shorter breakthrough times

• Bituminous carbon appears to perform better than coconut carbon

• Ion exchange resin may be better at removing PFAS and can be regenerated but may be more

expensive

• In situ treatment technologies PlumeStop

®

, RemBind Plus

®

and MatCARE™

limited field

demonstrations in U.S.

Wrap-Up

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

42

Select References

• ITRC PFAS Remediation Factsheet

• PFAS Remediation Whitepaper (Internal Navy Document)

• Andres Arias Espana, Victor, Megharaj Mallavarapu, and Ravi Naidu. 2015. “Treatment technologies

for aqueous perfluorooctanesulfonate (PFOS) and perfluorooctanoate (PFOA): A critical review with

an emphasis on field testing,” Environmental Technology and Innovation, 4, 168-181.

• Du, Ziwen, Shubo Deng, Yue Bein, Qian Huang, Bin Wang, Jun Huang, and Gang Yu. 2014.

“Adsorption behavior and mechanism of perfluorinated compounds on various adsorbents – A

review,” Journal of Hazardous Materials, 274, 443-454.

• Zhu, Runliang, Qingze Chen, Qing Zhou, Yunfei Xi, Jianxi Zhu, and Hongping He. 2016. “Adsorbents

based on montmorillonite for contaminant removal from water: A review,” Applied Clay Science, 123,

239-258.

• Merino, Nancy, Yan Qu, Rula Deeb, Elisabeth L. Hawley, Michael R. Hoffmann, and Shaily

Mahendra. 2016. “Degradation and Removal Methods for Perfluoroalkyl and Polyfluoroalkyl

Substances in Water,” Environmental Engineering Science, 33, 615-649.

Wrap-Up

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

44

Questions and Answers

Wrap-Up

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

45

Backup Slides

Wrap-Up

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

46

Mechanism of Sorption – Electrostatic Interaction

• Interaction between negative and positive charges

• Strong negative charged shell around CF chain due to fluorine atoms and functional

group

• Electrostatic bond mainly at functional group sue to stronger negative charge

• To promote electrostatic bond increase ionic strength, ensure pH is not too alkaline

• Example seen in organoclays

Reference Du, Ziwen, Shubo Deng, Yue Bein, Qian Huang, Bin Wang,

Jun Huang, and Gang Yu. 2014. “Adsorption behavior and mechanism of

perfluorinated compounds on various adsorbents – A review,”

Journal of Hazardous Materials, 274, 443-454.

Sorption

Electrostatic Attraction

PFC molecule

Divalent cation

Positively charged site

Negatively charged site

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

47

Mechanism of Sorption – Hydrophobic Interactions

• Occurs at the electronegative CF chain

• Longer chain more hydrophobic

• Leads to formation of micelles

• Is often stronger than electrostatic repulsion (between negatively-charged tail and

negatively-charged sorbent)

Sorption

Hydrophobic Interaction

PFC molecule

Positively

charged site

Electrostatic Repulsion

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

48

Property MatCARE™

Bulk Density (kg m

-3

) 608

Particle Density (kg m

-3

) 1,677

Porosity (%) 40

Pore Volume (kg m

-3

) —

Particle Size 77.4% between 2,000 and 1,180 µm

Surface Area (m

2

g

-1

) 31.91

Reversible Swelling (%) 2.5

Moisture Holding Capacity (%) 50.28

In Situ Soil Treatment Modified Organoclay Sorbent – MatCARE™

Material

• Palygorskite-based material modified with

oleylamine, i.e., amine modified clay sorbent

Application

• Applied to soil at 10% w/w

• Water content of soil 60%

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

49

In Situ Soil Treatment Modified Organoclay Sorbent – Soil Treatability Studies

• Four soils from fire training areas at overseas Air Force Bases

• Air-dried, homogenized, and passed through 2-mm sieve

• pH, organic carbon content, and PFOS concentration

• 1 kg of each soil adjusted to 60% moisture, amendment added at 10 g per 100 g soil

• PFOS-spiked treatment also included (10 ml of PFOS stock solution) then mixed

• 10 g sample, 3x/yr

• Water extraction

In Situ Technologies

Physico-Chemical Properties of the Soil

Soils pH TOC (%) PFOS (nmol g

-1

) Texture

Solvent Extracted Water Extracted Sand (%) Silt (%) Clay (%) Textural Class

A 4.8 0.96 3.66 0.52 52.63 25.62 21.74 Sandy clay loam

B 4.9 1.97 148.72 21.13 43.21 21.42 35.37 Clay loam

C 8.1 0.29 32.33 4.72 75.15 9.11 15.74 Sandy loam

D 6.5 2.03 18.52 1.86 57.04 10.93 32.03 Sandy clay loam

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

50

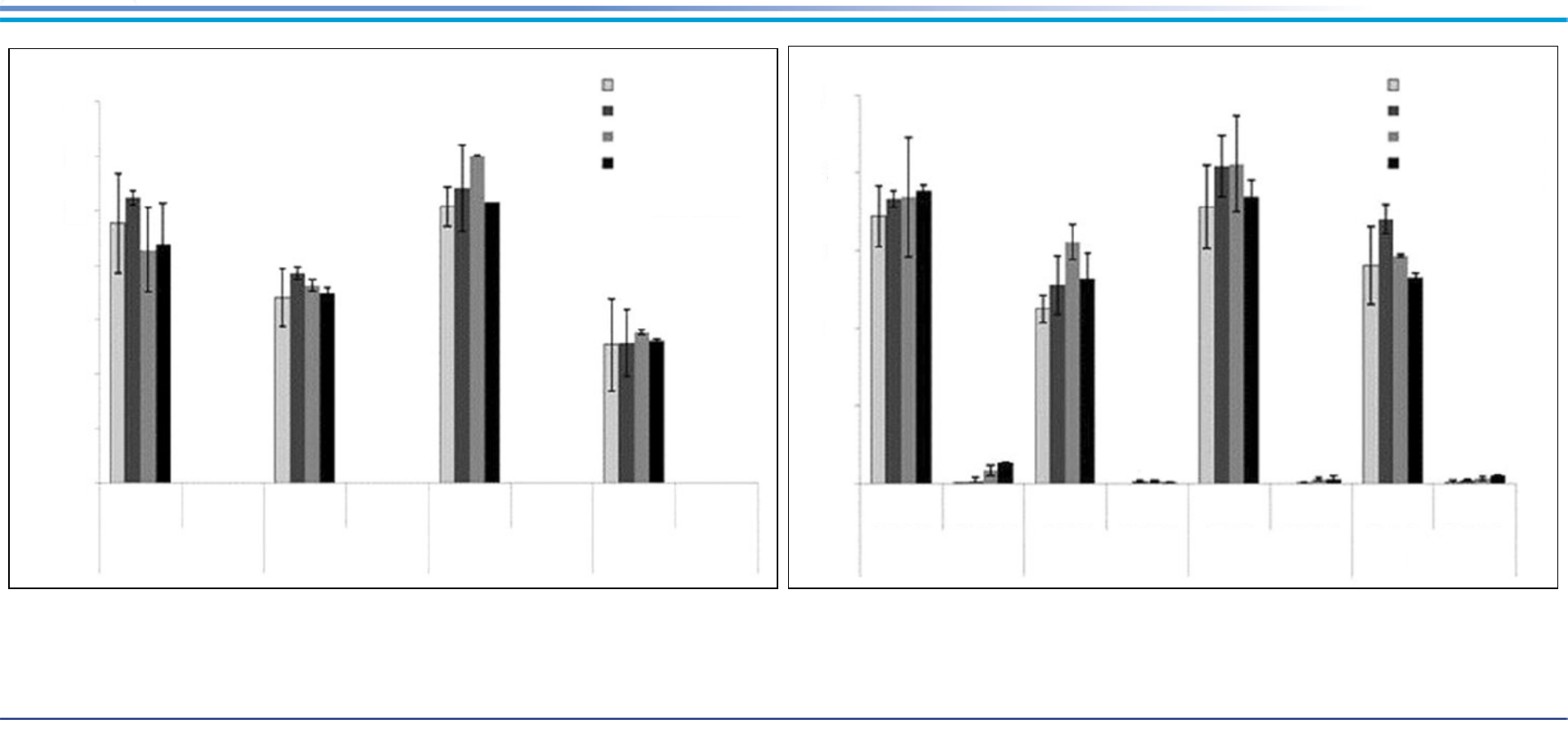

In Situ Soil Treatment Modified Organoclay Sorbent – Results

In Situ Technologies

25

°

C

no spike

25

°

C

spike with 0.2 mmol/kg PFOS

Control

Sorbent

Control

Sorbent

Control

Sorbent

Control

Sorbent

Soil A

Soil B

Soil C

Soil D

Control

Sorbent

Control

Sorbent

Control

Sorbent

Control

Sorbent

Soil A

Soil B

Soil C

Soil D

% Release

% Release

14

12

10

8

6

4

2

0

25

20

15

10

5

0

a

a

1st quarter

2nd quarter

3rd quarter

4th quarter

1st quarter

2nd quarter

3rd quarter

4th quarter

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

52

Aluminum-Based Sorbent for GW Case Study – AF Site – Future Work

Verify amendment sorption capacity

Optimize dosage to meet EPA Health Advisory

Monitor effectiveness on short-chain PFAS and PFAA precursors

Conduct regeneration trials using proprietary wash solutions

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

53

Aluminum-Based Sorbent for Full-Scale Soil Treatment Case Study

• Airport contaminated with PFAS

• Replacing asphalt – excavated 900 tons of PFAS-contaminated soil

In Situ Technologies

Aviation Rescue and Fire Fighting Services

Damaged Asphalt

Aircraft Taxiway

Damaged

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

54

Aluminum-Based Sorbent for Full-Scale Soil Treatment Case Study (cont.)

• 900 tons of contaminated soil

• PFOS total concentration <5.7 mg/kg

• PFOS leachable concentration <180 µg/L (by USEPA Method 1311)

In Situ Technologies

Aircraft Taxiway

Construction of New Apron PFAS-Contaminated Soil

~900 tonnes

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

55

Aluminum-Based Sorbent for Full-Scale Soil Treatment Case Study (cont.)

• Transported 900 tonnes of soil to municipal waste landfill site

• Treated hotspots with 10% RemBind

®

• Validated samples at accredited lab

• Obtained EPA approval for disposal in a purpose-built burial cell

In Situ Technologies

RemBind

®

Capping

RemBind

®

Layer

Waste

2500

10500

2000

Soil Disposal Area

1

2

1

2

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

56

Aluminum-Based Sorbent for Full-Scale Soil Treatment Case Study (cont.)

Laying the Amendment Capping Layer Finished Lined Burial Cell

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

57

Aluminum-Based Sorbent for Full-Scale Soil Treatment Case Study (cont.)

• Soil Leachate after Treatment

Activity

Approximate

Cost (US)

Cost per Ton

(900 Tons)

Landfill disposal fees $63,500 $67

Investigation, bench trials, mixing, and reagent supply

$47,500 $50

Total $111,000 $117

In Situ Technologies

Hotspot 1

(µg/L)*

Hotspot 2

(µg/L)*

Compliance Limit

(µg/L)*

PFOS <0.01 <0.01

0.2

PFOA <0.01 <0.01

6:2 Fluorotelomer sulfonate <0.1 <0.1

8:2 Fluorotelomer sulfonate <0.2 <0.2

*Soil leachate concentrations as measured by TCLP at pH 5

• Project Costs

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

58

Aluminum-Based Sorbent for Full-Scale Soil Treatment Case Study (cont.)

• A water authority in Cape

Cod, MA treated soil with

amendment in the bottom

of an excavation before

backfilling to mitigate the

risk of PFAS leaching in

a drinking water source

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

59

96% reduction

PFOS

90% reduction

PFOS

99% reduction

PFOS

98% reduction

PFOS

In Situ Technologies

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

60

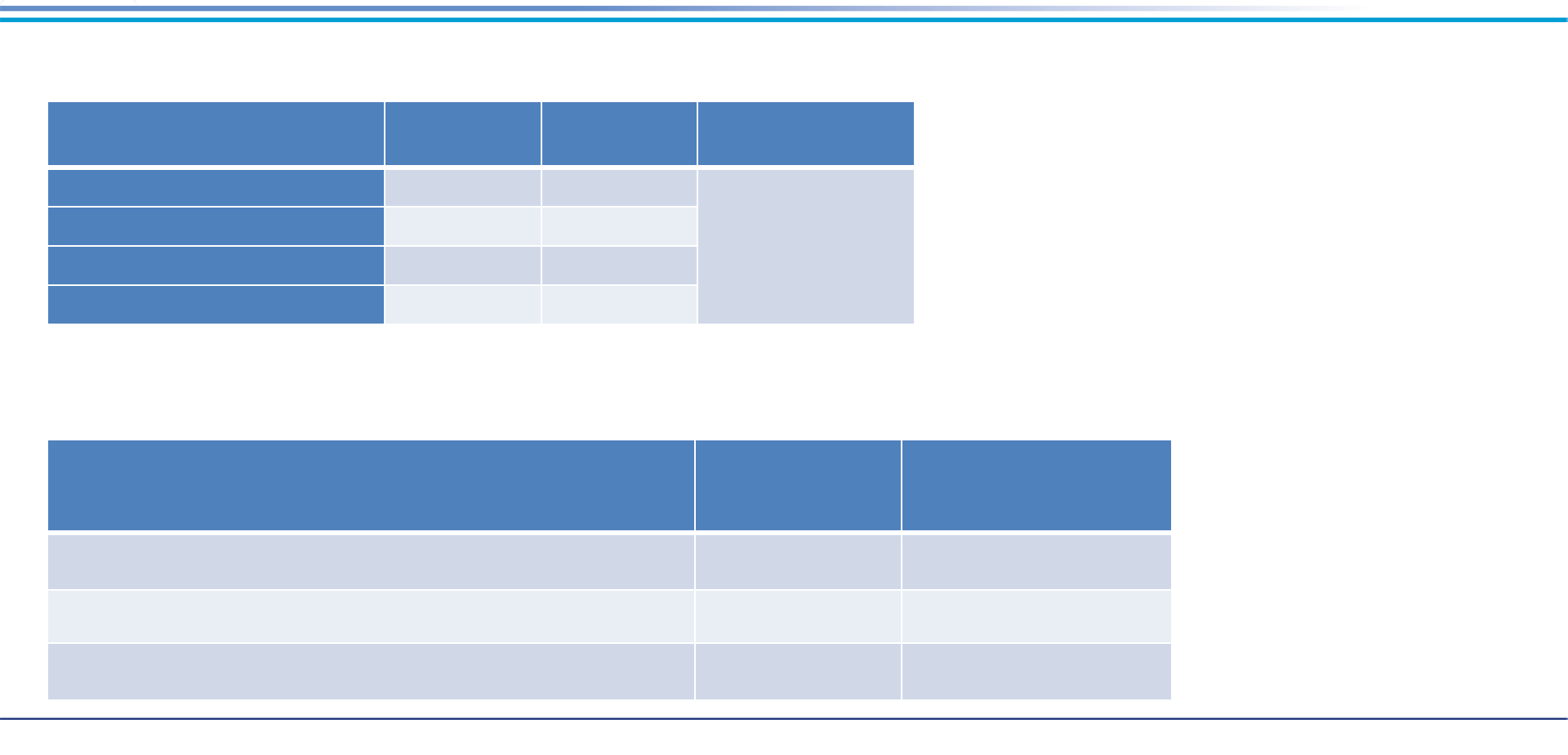

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

SERDP PFAS Projects*

Project PI

Field Demonstration and Life Cycle Comparison of Ex-Situ Treatment Technologies for Poly- and

Perfluoroalkyl Substances (PFASs) in Groundwater

Alice Fulmer, Water Research

Foundation

Rational Design and Implementation of Novel Polymer Adsorbents for Selective Uptake of

PFASs from Groundwater

Dr. Damian Helbling, Cornell University

Ex Situ Treatment of PFAS Contaminated Groundwater Using Ion Exchange with Regeneration

Dr. Mark Fuller, CB&I Federal Services

Remediation of PFAS Contaminated Groundwater Using Cationic Hydrophobic Polymers as

Ultra-High Affinity Sorbents

Dr. Reyes Sierra-Alvarez, University of

Arizona

Regenerable Resin Sorbent Technologies with Regenerant Solution Recycling for Sustainable

Treatment of PFASs

Dr. Timothy Strathmann, Colorado

School of Mines

An Electrocoagulation and Electrooxidation Treatment Train to Degrade Perfluoroalkyl

Substances and Other Persistent Organic Contaminants in Groundwater

Dr. Dora Chiang, AECOM

Treatment of Legacy and Emerging Fluoroalkyl Contaminants in Groundwater with Integrated

Approaches: Rapid and Regenerable Adsorption and UV-Induced Defluorination

Dr. Jinyong Liu, University of California,

Riverside

*Not a complete list

61

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

SERDP PFAS Projects*

Project PI

Removal of Complex Mixtures of Perfluoroalkyl Acids from Water Using Molecularly Engineered

Coatings on Sand and Silica

Dr. Paul Edmiston, The College of

Wooster

Combined In Situ/Ex Situ Treatment Train for Remediation of PFAS Contaminated Groundwater

Dr. Michelle Crimi, Clarkson University

Electrochemical Oxidation of Perfluoroalkyl Acids in Still Bottoms from Regeneration of Ion

Exchange Resins

Dr. Qingguo Huang, University of

Georgia

Electrically Assisted Sorption and Desorption of PFASs

Dr. Douglas Call, North Carolina State

University

Development of Coupled Physicochemical and Biological Systems for In Situ Remediation of

Perfluorinated Chemical and Chlorinated Solvent Groundwater Plumes

Dr. Kurt Pennell Brown University

Molecular Design of Effective and Versatile Adsorbents for Ex Situ Treatment of AFFF-Impacted

Groundwater

Dr. Mandy Michalsen, U.S. Army Corps

of Engineers

In situ Remediation of Aqueous Film Forming Foams and Common Co-Contaminants with the

Dual Approach of Chemical Oxidation and Bioremediation

Dr. Lisa Alvarez-Cohen

University of California at Berkeley

*Not a complete list

62

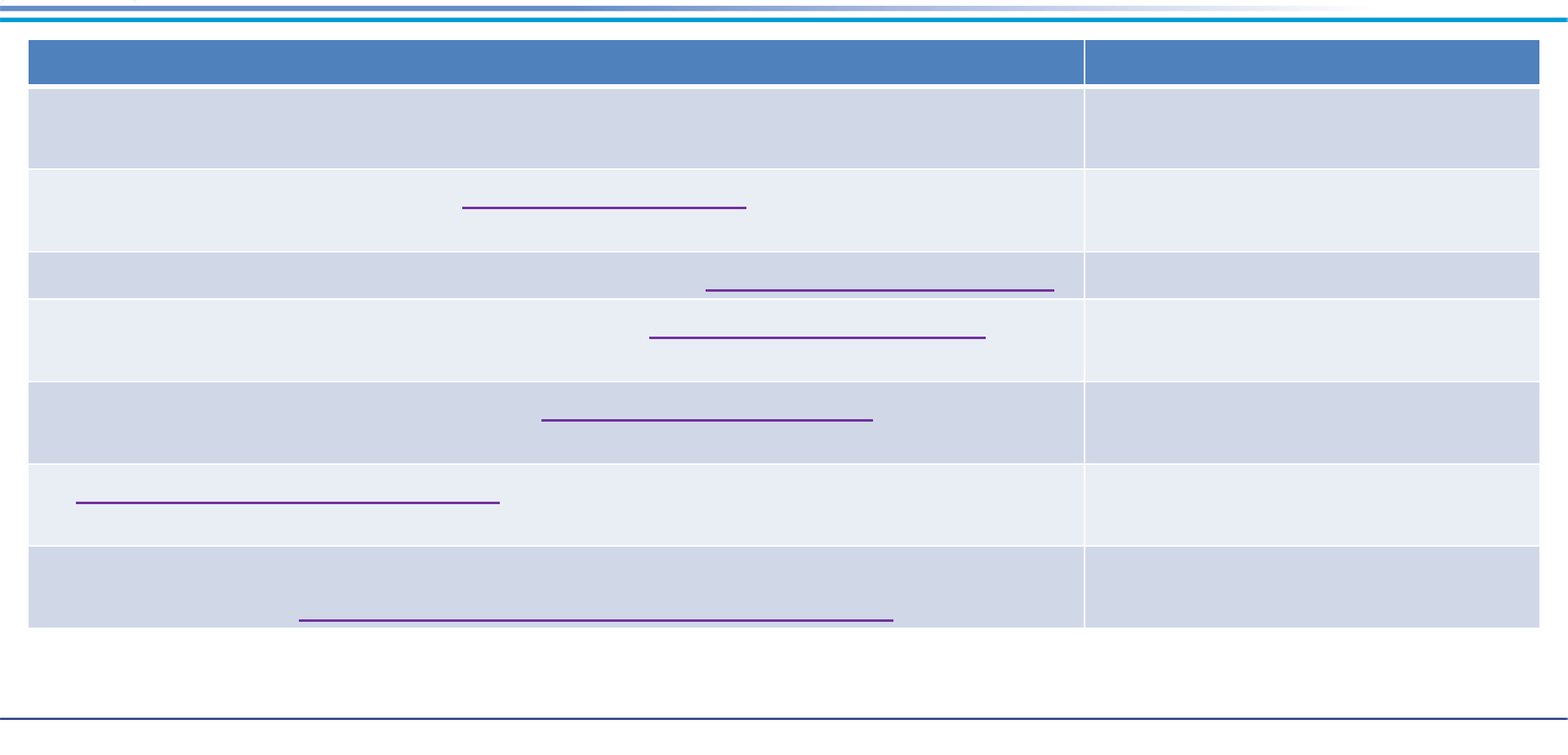

FRTR 2018: PFAS Emerging Contaminants and Remediation Technologies

ESTCP PFAS Projects*

Project PI

Field Demonstration to Enhance PFAS Degradation and Mass Removal Using Thermally-Enhanced

Persulfate Oxidation Followed by Pump-and-Treat

Dr. John Kornuc

NAVFAC EXWC

Characterization of the Nature and Extent of Per- and Polyfluoroalkyl Substance (PFASs) in

Environmental Media at DoD Sites for Informed Decision-Making

Dr. John Kornuc

NAVFAC EXWC

*Not a complete list