Fundamentals of Asset Management

Step 10. Build Asset Management Plan

A Hands-On Approach

Fundamentals of Asset Management 2

Tom’s bad day…

Fundamentals of Asset Management 3

Asset Mgmt Plan;

Policies and

Strategy;

Annual Budget

AM plan 10-step process

Develop

Asset

Registry

Assess

Performance,

Failure Modes

Determine

Residual

Life

Determine

Life Cycle &

Replacement

Costs

Set Target

Levels of

Service (LOS)

Determine

Business Risk

(“Criticality”)

Optimize

O&M

Investment

Optimize

Capital

Investment

Determine

Funding

Strategy

Build AM

Plan

Fundamentals of Asset Management 4

Recall View 4: Management framework

Asset Management

Business Processes

Operating Budget

Asset Management

Plans

Capital Budget

Strategic Initiatives

Annual Budgets

Fundamentals of Asset Management 5

Asset decision framework

Big picture

Whole portfolio

perspective

• Trends

• Macro forces

Policy framework

Budget arena

Micro view

Event based

Specific asset focus

Case-by-case decision

points

Maintain? Repair? Refurbish? Replace? Augment?

Fundamentals of Asset Management 6

Tom’s Jones Street asset management plan: Key

points

State of the facility

• Facility is well into mature stage of life cycle

• Most imminent major failure mode—capacity

• Assume two years before peak design flow is

exceeded—growth

• Additional capacity can not be feasibly added

• Physical state is very poor, especially pumps and motors

• Asset is largely at 75% to 90% physical life consumed

Required LOS

• Stop SSOs

• Meet Whispering Oaks flow requirements

Critical assets

• Roof

• Power

• Controls

• Pump assemblies

Fundamentals of Asset Management 7

Tom’s Jones Street asset management plan: Key

points

O&M/CIP investment strategies

• Keep lift station running for two years, then decommission

• All replacement equipment sized for reuse in new lift station

• Move to predictive maintenance (set up monitoring intervals) for dynamic

(mechanical/electrical) equipment based on root cause

• Run to failure with effective reactive response plan for rest

• Assure that reactive response plan provides for continuous functioning

(bypass/supplemental power/supplemental pump)

Toward a funding strategy

• Identify O&M budget requirements to fund interim O&M strategy

• Prepare valid capital budget/project to replace lift station

• Prepare business case and present to Council

Fundamentals of Asset Management 8

Steps in developing your AMP

1. Existing levels of service (LOS)

• Regulatory

• Customer-related

• Internal operations

2. Assess existing assets

• Physical details

• Condition/remaining life

• Performance

• Capacity (current, ultimate)

3. Predict demand, LOS

• Capacity, demands

• Levels of service

• Performance risk

4. Predict failure mode

• Capacity (due to growth)

• LOS

• Mortality

• Efficiency

Fundamentals of Asset Management 9

Steps in developing your AMP, cont.

5. Predict capital program

• Growth, augmentation

• Renewal, reliability

• New LOS

• Business efficiency

6. Predict O&M

• Growth (additional flows)

• New assets LOS

• Age of overall portfolio

7. Predict future expend. model

• Capital, debt service

• Operations

• Maintenance

• Administration

8. Predict future income model

• Rates

• Charges

• Other sources

• Total

Fundamentals of Asset Management 10

Steps in developing your AMP, cont.

9. Ask: Are customers

willing to pay?

12. Return to 1;

revise AMP

items as

necessary

11. Review program options (reduce cost)

• Reduce LOS

• Improve efficiency

• Dispose of under-utilized and under-performing assets

• Manage demand for service (pricing, regulation)

• Alter maintenance or operations

• Accept higher residual risk

• Rationalize project work in order of risk

No

10. Execute

Yes

Fundamentals of Asset Management 11

The Enterprise Asset Management Plan

Executive

Summary

Levels of Service

Section - 2

State of the Assets

Section - 1

Growth & Demand

Section - 3

Business Improvement Plan

Section - 8

Management

Strategies

Section - 6

Lifecycle Management

Section - 4

Augmentation

O&M Renewal

Risk Profile

Section - 5

Financial Planning

Section - 7

Fundamentals of Asset Management 12

The enterprise asset management plan

Fundamentals of Asset Management 13

The Enterprise Asset Management Plan—asset

system summary

1. Asset Profile

Metering & Diversion Structure

A total of six influent trunk lines bring influent into the metering and diversion

structure at Plant No. 1. This structure contains magnetic flow meters, pH

meters and electro-conductivity meters along with gates that can be raised or

lowered to move flows from one trunk-line to another as necessary. A portion

of the influent can also be diverted to Plant No. 2 through an interplant pipeline

to regulate flow into Plant No. 1.

Headworks #1 & #2

There are two Headworks at Plant 1, which have a total rated pump capacity of

210 mgd with 130 mgd of stand by. Headworks #2 can be increased by

another 70 mgd in the future by addition of another pump. It has two support

generation units with a power rating of 1000 KW. Headworks #2 is the newest

and is the operated system and Headworks #1 is the standby system. Three

key processes for Headworks are bar screens, influent pumps, and grit

removal.

Screening Station (Bar screens)

Flow from the Metering and Diversion Structure is routed to the influent

channel for the mechanically-cleaned bar screens at Headworks #2. There are

four individual bar screen channels containing automatically cleaned screens.

Two of the screens are operated and the other two are standby. The structure

contains space to accommodate two additional screens in the future.

Main Sewage Pumps

After passing through the Headworks #2 bar screens, wastewater flows into the

Influent Pump Station wet well. The Influent Pump Station lifts screened

wastewater to the influent channel serving the grit removal chambers. There

are four 70 mgd variable speed pumps at Headworks #2 and two 30 mgd

constant speed pump at Headworks #1, which services as stand by pumps. A

sluice gate in this wet well can be opened to allow screened wastewater to flow

to the Headworks #1 Influent Pump Station wet well if required allowing the wet

wells at Headworks #2 and Headworks #1 to act as one large wet well under

extreme wet weather conditions.

Grit System (Grit Removal)

There are five aerated grit removal chambers at Headworks #2 and two at

Headworks #1 that are standby. The purpose of these is to remove inorganic

solids that are present in the wastewater. The removal of this grit helps

prevent clogging in pipes, protects mechanical equipment, and reduces the

amount of material that collects in the sludge digesters. Each grit chamber

contains four grit collection hoppers. Grit is removed from the chambers using

telescoping valves that continuously discharge grit slurry by gravity to

classifiers. Grit from the classifiers discharged to the conveyor belt carrying

screens normally or to a separate grit bin for off-site disposal. Flow from the

Headworks #2 grit removal chambers is collected in an effluent channel that

discharges to the Primary Influent Distribution Structure (Splitter Box).

Splitter Box

The splitter structure discharges to the Primary Clarifier Basin # 1 to 5 through

a 72 inch-diameter pipeline and/or to the rectangular PCB # 6 to 15 through

two 90 inch-diameter pipelines. Splitting is accomplished using the sluice

gates.

2. Demand Profile and Performance

Table 1 Peak, Average and Standby Design Capacities

System

Sub System(s)

Design Capacity

(Min, max, peak and/or

average)

Actual

Performance

Metering & Diversion Structure

Max. Flowrate 490 MGD

Hydrogen Peroxide

Max. Pressure 150 psi

Sunflower Pump Station

30 MGD duty

30 MGD standby?

Headworks No. 1

30 MGD duty

Main Sewage Pumps

30 MGD duty

30 MGD standby

Grit Removal

2 chambers

Headworks No. 2

210 MGD duty

Main Sewage Pumps

280 MGD duty

70 MGD standby

Bar Screens

4 units (+allowance for 2

units to be constructed)

234 MGD max

1 unit standby

Grit System

Grit Chambers

87 MGD duty

25 MGD standby

5 tanks

2 tanks standby

Grit Washers

Hydraulic 1800 gpm

Overflow Rate 12,000

gpd/ft2

1 duty and 1 standby

Grit Storage Capacity

2 days

Splitter Box

325 MGD

Odor Control Facilities

(Bleach)

3 @ 24000 cfm duty

1 @ 24,000 cfm standby

Feed Pumps

3 @ 11.3 gph duty

1 @ 20 gph standby

Recirculation Pumps

4 @ 600-700 gpm duty

4 @ 600-700 gpm

standby

Muriatic Acid Scrubbing

Cleaning Pumps

1 @ 30 gpm duty

1 @ 30 gpm standby

Trunk Line Scrubbers

1 * Caustic

1 * Biotower

24,000 CFM duty

24,000 CFM standby

Insufficient

performance

Ferric Chloride

Feed Pump

3 @ 200 gph duty

1 @ 200 gph standby

Hydrogen Peroxide

Headworks

4 duty (See 10H-120,

Pump information)

4 standby pumps

Flowrate Capacity 85

gpm

Pressure 116 psi

Splitter Box

Max. Flowrate Capacity

325 gpd

Max. Pressure 150 psi

Support Generators

Power Rating 1000 KW

Scrubbers Headworks

2 on trunk lines

3. Failure Mode

Table 2 Failure Summary

Rating

Process

Area

Condition

Capacity

Function

Reliability

Efficiency

Metering & Diversion

Structure

10A

2

Headworks #1

10B

5

5

Headworks #2

10C

3

4. Key Issues for Further Investigation

General

Project I-10 to increase flow to Plant 1 by 40 MG/D

Metering & Diversion Structure

Concerns about the reliability and accuracy of meters exist due to meter

failures. Proper operation of the meters is important because treatment

costs are allocated to the various revenue areas based on influent meter

readings.

Headworks No. 1

Questions have been raised as to the ability of the headworks to operate

properly under emergency conditions.

Headworks No. 2

Grit Chamber No. 2 is out of service.

6. Investment Program

Table 3 5-Year Summary

Investment

(thous.)

Total

Projected

Budget

Cost

to

date

2005-

06

2006-

07

2007-

08

2008

-09

P1-105

4,920

240

393

320

3,430

537

Total

4,920

240

393

320

3,430

537

Table 4 O&M Cost Summary

Cost (thous.)

2002-

03

2003

-04

2004

-05

2005

-06

2006

-07

Maintenance

208

Operations

1108

5. Current Program

Study

TBA

TBA

Planning

TBA

TBA

Design & Construction

P1-105 - Headworks Rehabilitation and Expansion at Plant No. 1

This project rehabilitates and refurbishes process equipment and

infrastructure within the Plant 1 Headworks facility, to ensure that the

facility continues to be operational. Several studies have been conducted

on the Headworks facility and a number of non-critical items have been

identified for repair and upgrade. The bulk of the project includes

upgrades to existing bar screens, an additional bar screen, a screenings

compressor, improvements to the grit removal facilities, improvements to

the power distribution system including three new larger emergency

generators, and miscellaneous process, mechanical, structural and I&C

upgrades.

This project is in keeping with industry practices as required for reliable

and dependable plant operations. The capital budget identified on this

sheet is based on the non-critical items necessary to ensure the facility

continues to function and conforms to the ultimate layout of the facility.

The FY 2004/05 budgets for P1-71 and P1-105 have been reallocated

after further evaluation of critical and non-critical work. P1-105 will

address increases in the facilities capacity to meet expected increases in

wastewater flow projected in the 2001 Interim Strategic Plan Update.

P1-71 - Headworks Rehabilitation/Refurbishment

The scope of work consists of rehabilitating and refurbishing the VFDs for

the main sewage pumps and the cable trays and wiring from the VFDs to

the pumps. An evaluation of the pumping capacity of Headworks No. 2 at

Plant 1 conducted in 2001. Capacity issues will not be addressed through

this project as capacity upgrades are being handled through a separate

project (Ellis Avenue). There are other potential tasks items for this project

which includes: a grit characterization study based on a computer model,

gate operators, and installation of ventilation in Headworks 1 to meet

NFPA 820. Other tasks that were previously part of this project have been

moved to Job No. P1-105.

This project is in keeping with industry practices as required for reliable

and dependable plant operations. These reliability of these VFDs must be

restored by late 2008 such that Plant 1 may reliably accept diverted flow

from Plant 2 during Plant 2 Headworks changeover.

P1-104 – Regional FOG Control Collection at Plant 1

J71-8 – Headwork Scrubbing Replacement

Management Strategies

TBA

Fundamentals of Asset Management 14

Detail, left page

1. Asset Profile

Metering & Diversion Structure

A total of six influent trunk lines bring influent into the metering and diversion

structure at Plant No. 1. This structure contains magnetic flow meters, pH

meters and electro-conductivity meters along with gates that can be raised or

lowered to move flows from one trunk-line to another as necessary. A portion

of the influent can also be diverted to Plant No. 2 through an interplant pipeline

to regulate flow into Plant No. 1.

Headworks #1 & #2

There are two Headworks at Plant 1, which have a total rated pump capacity of

210 mgd with 130 mgd of stand by. Headworks #2 can be increased by

another 70 mgd in the future by addition of another pump. It has two support

generation units with a power rating of 1000 KW. Headworks #2 is the newest

and is the operated system and Headworks #1 is the standby system. Three

key processes for Headworks are bar screens, influent pumps, and grit

removal.

Screening Station (Bar screens)

Flow from the Metering and Diversion Structure is routed to the influent

channel for the mechanically-cleaned bar screens at Headworks #2. There are

four individual bar screen channels containing automatically cleaned screens.

Two of the screens are operated and the other two are standby. The structure

contains space to accommodate two additional screens in the future.

Main Sewage Pumps

After passing through the Headworks #2 bar screens, wastewater flows into the

Influent Pump Station wet well. The Influent Pump Station lifts screened

wastewater to the influent channel serving the grit removal chambers. There

are four 70 mgd variable speed pumps at Headworks #2 and two 30 mgd

constant speed pump at Headworks #1, which services as stand by pumps. A

sluice gate in this wet well can be opened to allow screened wastewater to flow

to the Headworks #1 Influent Pump Station wet well if required allowing the wet

wells at Headworks #2 and Headworks #1 to act as one large wet well under

extreme wet weather conditions.

Grit System (Grit Removal)

There are five aerated grit removal chambers at Headworks #2 and two at

Headworks #1 that are standby. The purpose of these is to remove inorganic

solids that are present in the wastewater. The removal of this grit helps

prevent clogging in pipes, protects mechanical equipment, and reduces the

amount of material that collects in the sludge digesters. Each grit chamber

contains four grit collection hoppers. Grit is removed from the chambers using

telescoping valves that continuously discharge grit slurry by gravity to

classifiers. Grit from the classifiers discharged to the conveyor belt carrying

screens normally or to a separate grit bin for off-site disposal. Flow from the

Headworks #2 grit removal chambers is collected in an effluent channel that

discharges to the Primary Influent Distribution Structure (Splitter Box).

Splitter Box

The splitter structure discharges to the Primary Clarifier Basin # 1 to 5 through

a 72 inch-diameter pipeline and/or to the rectangular PCB # 6 to 15 through

two 90 inch-diameter pipelines. Splitting is accomplished using the sluice

gates.

2. Demand Profile and Performance

Table 1 Peak, Average and Standby Design Capacities

System

Sub System(s)

Design Capacity

(Min, max, peak and/or

average)

Actual

Performance

Metering & Diversion Structure

Max. Flowrate 490 MGD

Hydrogen Peroxide

Max. Pressure 150 psi

Sunflower Pump Station

30 MGD duty

30 MGD standby?

Headworks No. 1

30 MGD duty

Main Sewage Pumps

30 MGD duty

30 MGD standby

Grit Removal

2 chambers

Headworks No. 2

210 MGD duty

Main Sewage Pumps

280 MGD duty

70 MGD standby

Bar Screens

4 units (+allowance for 2

units to be constructed)

234 MGD max

1 unit standby

Grit System

Grit Chambers

87 MGD duty

25 MGD standby

5 tanks

2 tanks standby

Grit Washers

Hydraulic 1800 gpm

Overflow Rate 12,000

gpd/ft2

1 duty and 1 standby

Grit Storage Capacity

2 days

Splitter Box

325 MGD

Odor Control Facilities

(Bleach)

3 @ 24000 cfm duty

1 @ 24,000 cfm standby

Feed Pumps

3 @ 11.3 gph duty

1 @ 20 gph standby

Recirculation Pumps

4 @ 600-700 gpm duty

4 @ 600-700 gpm

standby

Muriatic Acid Scrubbing

Cleaning Pumps

1 @ 30 gpm duty

1 @ 30 gpm standby

Trunk Line Scrubbers

1 * Caustic

1 * Biotower

24,000 CFM duty

24,000 CFM standby

Insufficient

performance

Ferric Chloride

Feed Pump

3 @ 200 gph duty

1 @ 200 gph standby

Hydrogen Peroxide

Headworks

4 duty (See 10H-120,

Pump information)

4 standby pumps

Flowrate Capacity 85

gpm

Pressure 116 psi

Splitter Box

Max. Flowrate Capacity

325 gpd

Max. Pressure 150 psi

Support Generators

Power Rating 1000 KW

Scrubbers Headworks

2 on trunk lines

Fundamentals of Asset Management 15

Detail, right page

3. Failure Mode

Table 2 Failure Summary

Rating

Process

Area

Condition

Capacity

Function

Reliability

Efficiency

Metering & Diversion

Structure

10A

2

Headworks #1

10B

5

5

Headworks #2

10C

3

4. Key Issues for Further Investigation

General

Project I-10 to increase flow to Plant 1 by 40 MG/D

Metering & Diversion Structure

Concerns about the reliability and accuracy of meters exist due to meter

failures. Proper operation of the meters is important because treatment

costs are allocated to the various revenue areas based on influent meter

readings.

Headworks No. 1

Questions have been raised as to the ability of the headworks to operate

properly under emergency conditions.

Headworks No. 2

Grit Chamber No. 2 is out of service.

6. Investment Program

Table 3 5-Year Summary

Investment

(thous.)

Total

Projected

Budget

Cost

to

date

2005-

06

2006-

07

2007-

08

2008

-09

P1-105

4,920

240

393

320

3,430

537

Total

4,920

240

393

320

3,430

537

Table 4 O&M Cost Summary

Cost (thous.)

2002-

03

2003

-04

2004

-05

2005

-06

2006

-07

Maintenance

208

Operations

1108

5. Current Program

Study

TBA

TBA

Planning

TBA

TBA

Design & Construction

P1-105 - Headworks Rehabilitation and Expansion at Plant No. 1

This project rehabilitates and refurbishes process equipment and

infrastructure within the Plant 1 Headworks facility, to ensure that the

facility continues to be operational. Several studies have been conducted

on the Headworks facility and a number of non-critical items have been

identified for repair and upgrade. The bulk of the project includes

upgrades to existing bar screens, an additional bar screen, a screenings

compressor, improvements to the grit removal facilities, improvements to

the power distribution system including three new larger emergency

generators, and miscellaneous process, mechanical, structural and I&C

upgrades.

This project is in keeping with industry practices as required for reliable

and dependable plant operations. The capital budget identified on this

sheet is based on the non-critical items necessary to ensure the facility

continues to function and conforms to the ultimate layout of the facility.

The FY 2004/05 budgets for P1-71 and P1-105 have been reallocated

after further evaluation of critical and non-critical work. P1-105 will

address increases in the facilities capacity to meet expected increases in

wastewater flow projected in the 2001 Interim Strategic Plan Update.

P1-71 - Headworks Rehabilitation/Refurbishment

The scope of work consists of rehabilitating and refurbishing the VFDs for

the main sewage pumps and the cable trays and wiring from the VFDs to

the pumps. An evaluation of the pumping capacity of Headworks No. 2 at

Plant 1 conducted in 2001. Capacity issues will not be addressed through

this project as capacity upgrades are being handled through a separate

project (Ellis Avenue). There are other potential tasks items for this project

which includes: a grit characterization study based on a computer model,

gate operators, and installation of ventilation in Headworks 1 to meet

NFPA 820. Other tasks that were previously part of this project have been

moved to Job No. P1-105.

This project is in keeping with industry practices as required for reliable

and dependable plant operations. These reliability of these VFDs must be

restored by late 2008 such that Plant 1 may reliably accept diverted flow

from Plant 2 during Plant 2 Headworks changeover.

P1-104 – Regional FOG Control Collection at Plant 1

J71-8 – Headwork Scrubbing Replacement

Management Strategies

TBA

Fundamentals of Asset Management 16

The asset management improvement plan section

OCSD Asset Management Improvement Program

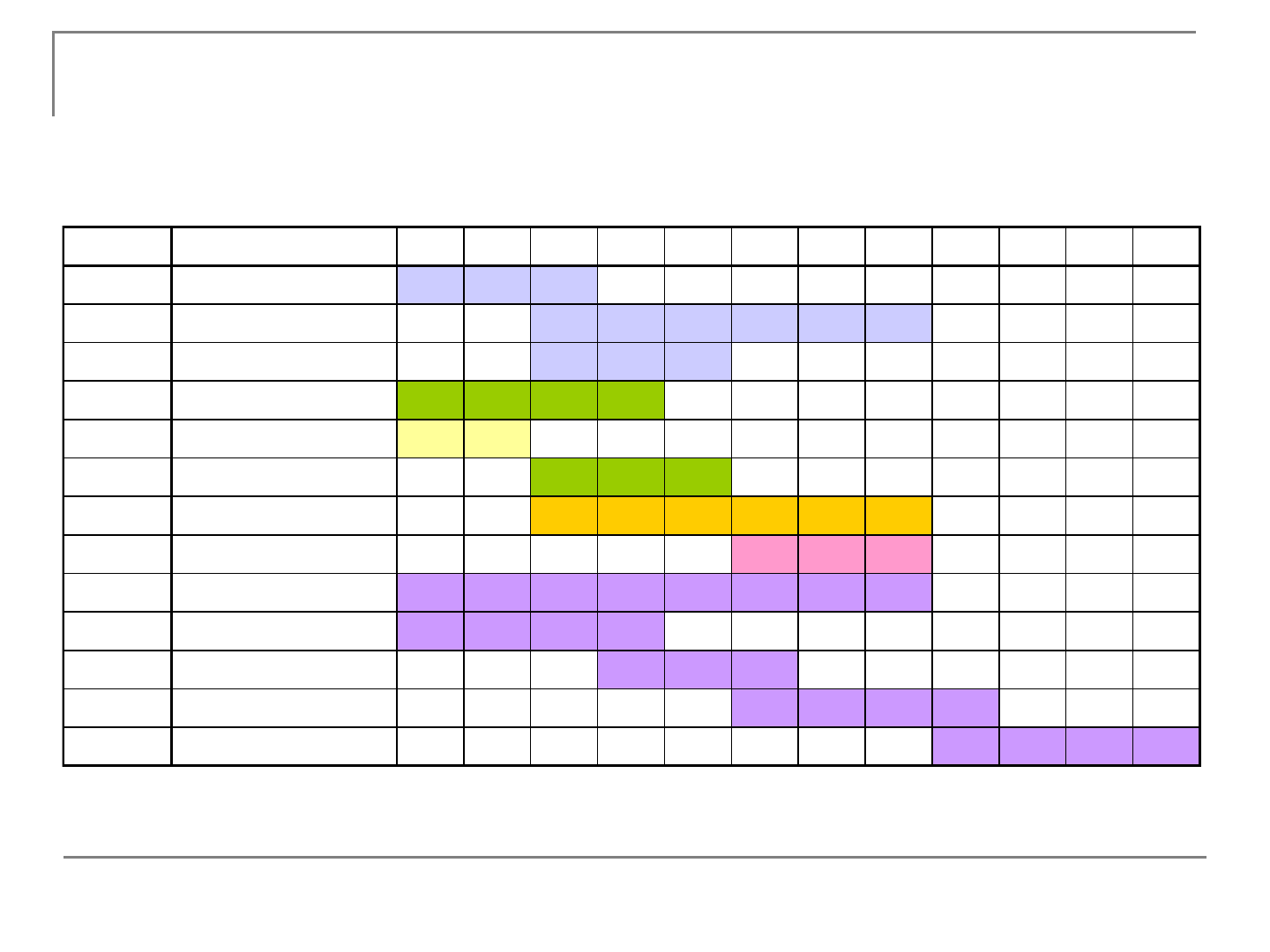

Staff Lead Program 2005/06 Budget - Overall Timeline

Project No. Project Name June July Aug Sept Oct Nov Dec Jan Feb Mar April May

11 & 12

Data Standards Asset Registers

(GHD) CMMS

8

AMIS Function Applications and

Strategy

(GHD)

13

Condition Assessment Guidelines

(GHD)

2

CIP Validation Stage 4

(JB)

4

BRE Collections

(NA)

5

BRE Plant

(JB)

6

LOS Stage 2

(JH)

7

4 Box Model

(DS)

1

Asset Management

Plan 2

(AMT-DS)

10

ORDM / LLCCA

(AMT-DS)

9

Risk Policy

(AMT-DS)

14

Organizational Alignment

(AMT-DS)

3

Reliability Centered Management

(AMT-DS)

Note: (GHD) Initials in brackets denotes Project Managers

Fundamentals of Asset Management 17

Example: Organizational AM strategies

No.

Description

Remarks /Deliverables

Benefits

1

Asset Management

Plan 2006

Increase confidence level rating with

better accurate data on condition and

performance, more defined

management strategies, improve

future predictions on changed levels

of service overall results / outputs etc

including rate modeling. Complete

updated asset management plan

analysis and assess improvements

made. Links and inputs from most

projects.

Asset Management

Plan output

improvements.

Improved Confidence

Level Rating.

Improved Business

Risk Exposure

assessments, funding

and rate models,

operations and

maintenance budgets.

Expenditure prediction

Tool enhancements

and improved Business

Risk Exposure

modeling.

2/10

Capital

Improvement

Program Validation

Stage 4 (2005/06)

Add life cycle costs, Business case

analysis methodology, including

improved maintenance budgets

/options and improve risk model to full

economic cost and Triple Bottom

Line. Link / integrate this process to

the start of the asset creation

gateways system. Improve analytical

budget setting process.

Significant benefits

derived for 2004

program ($25M in

capital) and over $50M

in life cycle costs.

Improved ability to

rank and prioritize

projects.

Greater understanding

of Business Risk

Exposure.

Higher confidence /

justification in the

projects proceeding.

Improved ability to

justify deferral.

Fundamentals of Asset Management 18

The AM “charter”

Fundamentals of Asset Management 19

The AM charter

Asset Inventory We will know the assets that we own,

or for which we have legal responsibility, and will

maintain an accurate computerized asset register

developed around an asset hierarchy that supports

advanced asset management functions.

Fundamentals of Asset Management 20

The AM charter

Condition Assessment We will gather, record, and

analyze condition assessment data; store and analyze

it using user friendly computerized systems; design

these systems to support high confidence level asset

related decision making; and create a comprehensive

and dynamic condition index.

Fundamentals of Asset Management 21

The AM charter

Maintenance We will retain a detailed maintenance

policy, and operate a user friendly, accurate, and

comprehensive enterprise asset management system

(that includes a Computerized Maintenance

Management System) to ensure that the assets,

facilities, and systems perform to their design criteria

and meet their design lives.

Fundamentals of Asset Management 22

Telling the story—institutionalization

• Annual budget process

• Annual report

Fundamentals of Asset Management 23

Key points from this session

Key Points:

AM focuses relentlessly on

providing sustained

performance at the lowest

life-cycle cost to the

organization

AM is both a way of thinking

and a set of specific practices

The more we understand

about our assets, the better

we can mange them

Understanding our assets

starts with asking the right

questions

Associated Techniques:

The Enterprise Asset

Management Plan

The Total Enterprise Asset

Management Improvement

Program

Best AM Practices; Best

Appropriate Practices

The Five Core AM Questions

The 10 Step Process to an

asset management plan

What does my asset management plan look like?

Fundamentals of Asset Management 24