AD ALTA JOURNAL OF INTERDISCIPLINARY RESEARCH

THE EFFECT OF INTERNAL COOLING ON BLOW MOLDED PRODUCTS

a

PAVEL BRDLÍK,

b

PETR LENFELD

Technical University of Liberec, Department of Engineering

Technology, Studentská 2, 464 17, Liberec 1, Czech Republic.

email:

a

pavel.brdlik@tul.cz,

b

petr.lenfeld@tul.cz

This paper was prepared due to the financial support from Student Grant Contest

project 28005 (SGS 28005) from the TUL part within the support of the specific

university research.

Abstract: The article presented deals with the production of blow molding products

where the cooling phase is one of the most important. The method of reducing the heat

energy directly determines the production time and dictates product quality. One very

efficient way to improve the cooling ability, and consequently to reduce production

time, is to implement at this stage internal cooling systems. These systems make it

possible to ensure savings 50% of the production time. This is an interesting result, but

the next important question is how the intensive internal cooling influences product

quality? The aim of this published research is therefore focused on finding an answer

to the question posed. To achieve this target, theoretical research was used to create a

series of experiments which measured and evaluated the microstructure, mechanical,

visual behavior and also the stability of the shape of the product.

Keywords: internal cooling, blow molding process, microstructure, behavior of

products, carbon dioxide

1 Introudction

Extrusion blow molding is the most commonly-used technology

for the production of hollow parts (GARCIA-REJON, 1995).

The process can be divided into three main steps: the formation

of the parison, clamping and inflation of the parison, and the

cooling and solidification of molten form. Of these 3 stages,

definitely the cooling stage takes the longest. This is because the

polymer materials have a low heat transfer coefficient

(ROSAT, 2004). Consequently a number of improvements have

been recorded. Internal cooling is one of the most efficient. The

principle of internal cooling is based on the ability to increase

heat reduction inside the parts of the product. These days there

are several suitable solutions in use. The circulation of air is the

easiest variant, which requires the lowest initial investment. On

the other hand, the resultant increase in production efficiency is

not as high as with the following cooling methods

(HUNKAR, 1973). The use of deep-cooled air (-35°C) is clearly

more efficient (STIPSITS, 1993). An even more efficient

possibility is to connect to a cooling mixture system of

pressurized air and water droplets. This system uses the Joule-

Thomson effect to change water droplets into ice crystals

(MICHAELI, 2007). Another method which uses an atomized

medium to perform the cooling process is the injection of an

inert gas such as carbon dioxide (-78°C) or nitrogen (-196°C).

This cooling variant is by far the most efficient with a possible

process improvement of up to 50% (JORG, 2006). The exact

value depends on the volume of the product, its thickness,

intricacy, injection setting, used gas, and so on. This is of great

interest for producers who are continuously looking to speed up

production. But the issue of product quality must not be

forgotten. Although the quality is a very important part of blow

molding production, there is not a lot of research recorded that

deals with this topic. One of the most interesting studies was

written by Professor Dilhan M. Kalyon et al.. They focused their

research on investigating the influence of different heat transfer

methods on the microstructure, the crystallinity and the

birefringence of the blow-molded article

(KALYON, 1983, 1991). In their study, the changes in the

distribution of density, residual stress and molecular orientation

were observed. S. B. Tan and P.R. Hornsby were part of another

research group. This group explored the effects of cooling rate

on the morphology, shrinkage, warpage and impact properties

(TAN, 2011). Their results indicate that internal cooling could

significantly influence the nature of the products. Hence

experimental measurements were taken to explore the changes to

the microstructure, the mechanical and visual properties and the

shape stability of products by connecting a progressive internal

cooling system to the common blow molding process.

2 Experiment

To investigate the influence of internal cooling on the quality of

blown products, the liquid carbon dioxide injection system was

chosen. This system has the biggest cooling effect due to the

introduction of innovative internal cooling variants and therefore

can produce the most obvious results. The cooling effect is

evaluated on two products of different volume and wall

thickness. They are a seven liter container with a 4mm average

wall thickness and a 0,5 liter bottle with a wall thickness of

1,5mm (figure 1). The conclusions can be generally applied. The

next important decision was the selection of test material. From

the polymers used, polyolefin was selected. This is because

polyolefin is by far the most common material in the production

of hollow products. Two variants were selected. The first one is

a common linear, high-density semi-crystal copolymer called

PE-Liten BB 29 and the second one is a homopolymer,

PP-Mosten EH 0.1. Production took place on 2 classic, single

station, pneumatic, blow-molding machines: a GM 750

(0,5l product) and a GM 5000 (7l product) at the company

G D K spol. s.r.o. The concept of the planned experimental

measurements is shown in Table 1. In first part, the common

blow molding process running at the maximum production limit

was measured. The speed of production was restricted by the

demolding temperature. Next, the carbon dioxide cooling system

was connected to the common blowing process. The CO2 was

injected for 50% of the total cooling time. The last part of the

experiment was to assess the increase in productivity

corresponding to the

used period of CO2

loading.

Thermographic

pictures and test

specimens were taken

from each setting to

additionally analyze

the microstructure,

mechanical and visual

properties, and also the

stability of the shape

of the product. Several

different areas of the

form were selected to

involvement

differences across the

product. The specific

areas are shown in

figure 1.

Tab.1 Process parameters of the experiment

Products

Melt temperature

Cooling temperature

of mold

Critical cycle time of

blow molding setting

Cooling time of blow

mold cooling system

Machine time

Time of injection of

liquid CO2

Increase of efficiency

(evaluated form

max. temperature)

Increase of

productivity

0,5l

190

°C

5°C

22s

16s

4s

8s

43%

45%

7l

190

°C

5°C

95s

80s

10s

40s

17%

21%

3 Results and discussion

The morphology and consequently also the material properties of

the polymer are strongly affected by the thermal-kinetic

conditions during the process of solidification. This is because

the initial temperature and intensity of cooling determine the

number, size and distribution of spherolites, which determine the

Evolution of

tensile test

Evaluation of

density

Fig. 1 Examined products

- page 138 -

AD ALTA JOURNAL OF INTERDISCIPLINARY RESEARCH

mechanical, visual and other properties of the semi-crystal

polymer (KREBS, 2006). The thermal reduction phase of the

cooling process is therefore of enormous important. Blow

molding production is a complicated non-isothermal, cyclic

process with two cooling interfaces. These are the interface

between the polymer and the mold and the interface between the

air and the polymer (ROSAT, 2004). If they are compared it is

evident that their cooling ability is not the same. The inflated

parison touches the cold wall of the mold, initiating the intensive

heat transfer (500 W/m2 K). On the other side of cooling

interface, the heat transfer between the still air and the polymer

(free convection) is very low (20 Wm2 K). These differences in

cooling rates could cause the non-uniform structure throughout

the wall thickness, as well as changes of density, molecular

orientation, birefringence, shrinkage or even warpage

(KALYON, 1983, 1991, TAN, 2011).

3.1 Structure

The microstructure of the polymer is composed of deposited

(crystals) and amorphous fragments. Their rate is specified as

percentage of crystalline. The quantity of fragments created is

mainly influenced by the ability of the material to crystallize, but

the thermal-kinetic conditions also have a considerable impact

(KREBS, 2006). For example, if slower cooling is applied, it

gives the spherolites more time to grow than with faster cooling

and the result is the creation of fewer, but bigger spherolites.

Conversely, using more intensive cooling causes the creation of

more, but smaller spherolites (KREBS, 2006). For blow molding

process, this means that by intensively cooling the effective

interface, polymer/ mold, a large number of small spherolites

should be created. Low heat transfer of the effective interface,

air/ polymer, gives the spherolites enough time to grow to larger

sizes. The difference in morphology increases with increasing

product thickness and a faster cooling rate of the mold (external

cooling system). How does this influence the connection to a

progressive internal cooling method? From the theoretical

statement introduced above, it can be assumed that the

spherolites would be smaller and the structure more uniform.

The influence of the different cooling rates at both interfaces on

the microstructure across the product was observed using

polarization microscopy. The results, which are shown in

figure 2, showed that no structural changes were noted. This

result was found for all tested samples of both of the examined

materials. The explanation could be found through

experimentation of the cooling settings. Water at five degrees

centigrade is circulated in the mold, which is the lowest

recommend temperature to produce the product without causing

rejection (through the effect of sweating). If a higher cooling

temperature or a thicker product were tested, the results could be

different.

PP-Mosten EH 0.1

PE-Liten BB 29

Fig. 2 The distribution of microstructure

3.2 Density

As previously mentioned, the microstructure is defined. But,

how was the percentage of crystals changed? The easiest test for

crystalline changes is the determination of the density. The

crystal fragments contain macro-molecules which are closer

together than the macro-molecules in amorphous locations.

Consequently these areas have a higher density (KREBS, 2006).

The increase in density then clearly indicates an increase in the

percentage of crystals. To explore the changes in density, and

hence crystal percentage, three areas on each product were

examined (figure 1). Different temperatures were recorded in

these locations. This could cause different thermal-kinetic

conditions and therefore different crystal percentages. The

results which are showed in figure 3 confirmed this theory.

Higher densities were recorded in locations with higher

measured temperature. Connection to a liquid carbon dioxide

injection system brings about an increase in cooling efficiency.

The products were re-tested using a lower temperature and the

test specimens reached lower density. But by increasing

productivity the demolding temperature was increased and

therefore the density was similar to the first experimental

measurements. This discovery allows us to declare that

increasing productivity does not change the percentage of

crystals.

Fig. 3 Average values of measured density with standard

deviation

3.3 Mechanical properties

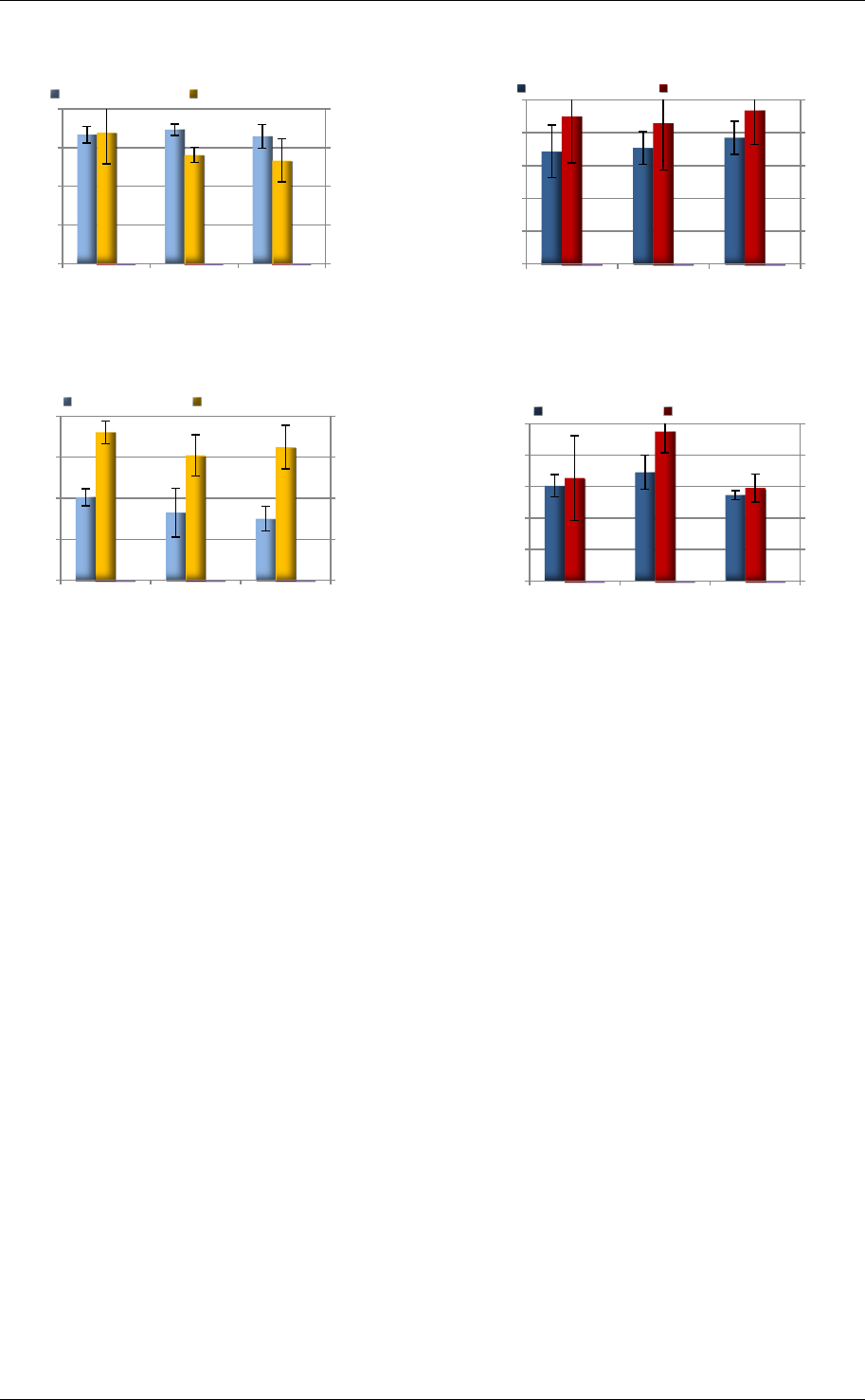

For the evaluation of mechanical properties of semi-crystal

polymers, it is necessary to know that crystal fragments have

different mechanical properties from amorphous ones. Their

closer ordering leads to higher adhesive forces. Consequently,

the increasing percentage of crystals leads to increased strength,

mechanical stiffness and hardness by several degrees of

toughness. The amorphous segments are possible to imagine as

joints about which the crystals can rotate by deformation. It

contributes to improving toughness and elongation

(KREBS, 2006).With respect to the results of density and the

declared theory that, as the density (percentage of crystals) was

changed by more intensive cooling, so the mechanical properties

could be changed too. The tensile test didn´t confirmed this

premise, as can be seen in the figure 4 and figure 5. The

differences between the results are very small and could be with

relation to reached values of standard deviations neglected.

898,0

901,0

904,0

907,0

910,0

common cooling

cooling with

CO2

productivity

increasing

Density

PP-Mosten EH 0.1

7 liter product

0,5 liter product

940

942

944

946

948

common cooling

cooling with

CO2

productivity

increasing

Density

PE-Liten BB 29

7 liter product

0,5 liter product

Out side interface

Inside interface

Out side interface

Inside interface

- page 139 -

AD ALTA JOURNAL OF INTERDISCIPLINARY RESEARCH

3.4 Visual properties

The visual properties of semi-crystal polymers can be evaluated

with the help of birefringence (KALYON, 1983). Professor

Dilhan M. Kalyon proved in his publications that the distribution

of birefringence is a function of the distance from the outer

surface. “The rapid cooling rates at the interface polymer/ mold

induce the retention of the orientation and generate high values

of birefringence (especially at low initial parison temperature)”

(KALYON, 1991). Conversely, the low heat transfer at the

interface air/polymer causes a decrease in the orientation of the

macromolecules and gives rise to negligible birefringence

values. This means that the birefringence deceases from a

maximum at the outer surface to a minimum at the inner surface

(KALYON, 1983). The measured rate and distribution of

birefringence for the experimentally created, cooling variant did

not show any significant variations. This behavior corresponds

with the earlier conclusion concerning the structure across the

product.

3.5 Warpage

Warpage is directly related to residual stress which is built up by

locally varying strain fields during solidification of the polymer.

Non-uniform cooling therefore causes temperature variations,

strain gradients and lead to an uneven residual stress, which

induces a bending moment in the part. The bending moment

leads to warpage of the part in order to balance the residual

stress (TAN, 2011). It can be supposed that increasing the

external cooling rate will increase the unbalanced residual stress.

As a consequence, the induced bending moment and the part

warpage also increase. On the other hand, increasing the cooling

ability at the air/ polymer interface should decrease the potential

warpage or distortion during molding because the thermal heat

transfer is more uniform on both sides (TAN, 2011). Because the

structure is uniform and no-residual stress was detected, warpage

distortion is not an issue. Comparison of the shape stabilities of

the products confirmed this association.

4 CONCLUSIONS

The aim of this article is to investigate the influence of an

internal cooling method on the structure, the mechanical and

visual properties and the stability of shape of semi-crystal

products. Theoretical research states that differences in thermal

conductivity at the polymer/ mold interface and the air/ polymer

interface could lead to a non-uniform structure throughout the

product regarding wall thickness, as well as changes of density,

molecular orientation, birefringence, shrinkage and even

warpage. Improving the cooling ability of inner surfaces should

ensure more uniform structure and a decrease in potential

warpage or distortion in the mold. Consequently the use of a

progressive internal cooling method should have a positive

effect. Experimental examination of the changes in heat transfer

on the internal interface did not show any changes in the

structure. This is probably because a very intense cooling setting

of the mold was applied which caused fast and uniform cooling

of the structure. The question is how the structure would look

with thicker products or materials with higher thermal-kinetic

requirements for crystallization. The crystal percentage

decreased with the more intensive cooling setting. However, no

differences were noted with increased productivity. Neither in

the evaluation of shape stability of the product nor in its visual

behavior and mechanical properties were any significant

differences of tested variants observed. This allows us to state

that using the liquid carbon dioxide injection system for 50% of

the total cooling period brings about an increase in efficiency of

21% in a 7l container, and 45% in 0,5l container and it does not

cause any structural, mechanical or visual changes, nor were

there any product shape differences in either of the tested

polyolefins (PP, PE).

Literature:

1. GARCIA-REJON, A. Advances in Blow Moulding Process.

Rapra Technology Limited, Shrewsbury, p. 3, 17-30. 1995.

5,0

6,3

7,5

8,8

10,0

9

14

19

24

29

Common

cooling

Cooling with

CO2

Productivity

increasing

Unite tensile strain

[

%

]

Tensile stress

[

Mpa

]

Yeld point in tension

Tensile stress Unite tensile strain

9,0

9,5

10,0

10,5

11,0

14

15

16

17

18

Common

cooling

Cooling with

CO2

Productivity

increasing

Unite tensile strain

[

%

]

Tensile stress

[

Mpa

]

Yeld point in tension

Tensile stress

Unite tensile strain

500

540

580

620

660

700

30

32

34

36

38

40

Common

cooling

Cooling with

CO2

Productivity

increasing

Unite tensile strain

[

%

]

Tensile stress

[

Mpa

]

Ultimate strenght

Tensile stress

Unite tensile strain

690

730

770

810

850

890

22

24

26

28

30

32

Common

cooling

Cooling with

CO2

Productivity

increasing

Unite tensile strain

[

%

]

Tensile stress

[

Mpa

]

Ultimate strenght

Tensile stress

Unite tensile strain

Fig. 4 Results of tensile test for PP-Mosten EH 0.1

Fig. 5 Results of tensile test for PE-Liten BB29

- page 140 -

AD ALTA JOURNAL OF INTERDISCIPLINARY RESEARCH

2. ROSAT, D. V. ROSAT, A.V. DiMathia, D.P. Blow

Moulding Handbook. Munchen, p. 227-257, 2004. ISBN 1-

3446-22017-8.

3. HUNKAR, D. B. Coolin Blow –Molded Bottles From the

Inside Out. Journal of Plastic Engineering. vol . 29, p. 25-

27, 1973, ISSN: 0091-9578.

4. STIPSITS, B. Using -30°C Internal Cooling Air to Achieve

Faster Extrusion Blow Molding Machine Cycle Via the CAC

– Compressed Air Cooling System. 9

th

Annual High

Performance Blow Molding Conference, New Jersey, USA,

Conference Proceedings, p. 253-262, 1993.

5. MICHAELI, W., BRUMER, T. Reduction o Cooling Time

by Using Atomized Watter in Blow Molding. ANTEC 2007,

Ohio, USA, Conference Proceedings. vol. 4, p. 2137-2141,

2007, IBSN 978-1-60423-24-1.

6. JORG, CH. Carboxyl dioxide cooling method may take the

waiting out of plastic parts. Journal of Automotive

Engineering, p. 40-41, 2006, ISSN 2008-9899.

7. KALYON D. M., KAMAL,M.R. Heat Transfer and

Microstructure in Extrusion Blomolding. Journal of Polymer

Engineering and Science. vol . 23, no. 9, p. 503-509, 1983,

ISSN 1548-2634.

8. KALYON D. M., JEONG S. Yu. Microstructure

Development in Blow Molded Amorphous Engineering

Plastic. Journal of Plastic, Rubber and Composites

Processing and Applications. vol .15, no. 2, p. 95-101,

1991, ISSN 0959-8111.

9. TAN, S.B, HORNSBY P.R, MCAFEE M.B, KEARNS

M.P., MCCOURT M.P. Internal Cooling in Rotational

Molding – a Review. Journal of Polymer Engineering and

Science. vol . 51, p. 1683-1692, 2011, ISSN 1548-2634.

10. KREBS, J. Teorie zpracování nekovových materiálů.

Liberec: Technická univerzita v Liberci, p.20-30, 48-55, 90.

2006, ISBN 80-7372-133-3.

Primary Paper Section: J

Secondary Paper Section: JP

- page 141 -