HAL Id: hal-01703248

https://hal.science/hal-01703248

Submitted on 5 Mar 2019

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of sci-

entic research documents, whether they are pub-

lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diusion de documents

scientiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Simulation of the two stages stretch-blow molding

process: Infrared heating and blowing modeling

Maxime Bordival, Fabrice Schmidt, Yannick Le Maoult, Vincent Velay

To cite this version:

Maxime Bordival, Fabrice Schmidt, Yannick Le Maoult, Vincent Velay. Simulation of the two stages

stretch-blow molding process: Infrared heating and blowing modeling. NUMIFORM 2007 - 9th Inter-

national conference on numerical methods in industrial forming processes, Jun 2007, Porto, Portugal.

pp.519+. �hal-01703248�

Simulation of the Two Stages Stretch-Blow Molding

Process: Infrared Heating and Blowing Modeling

M. Bordival, F.M. Schmidt, Y. Le Maoult, V. Velay

CROMeP - Ecole des Mines d’Albi Carmaux - Campus Jarlard - 81013 Albi cedex 09 - France

Abstract. In the Stretch-Blow Molding (SBM) process, the temperature distribution of the reheated perform affects

drastically the blowing kinematic, the bottle thickness distribution, as well as the orientation induced by stretching.

Consequently, mechanical and optical properties of the final bottle are closely related to heating conditions. In order to

predict the 3D temperature distribution of a rotating preform, numerical software using control-volume method has been

developed. Since PET behaves like a semi-transparent medium, the radiative flux absorption was computed using Beer

Lambert law. In a second step, 2D axi-symmetric simulations of the SBM have been developed using the finite element

package ABAQUS

®

. Temperature profiles through the preform wall thickness and along its length were computed and

applied as initial condition. Air pressure inside the preform was not considered as an input variable, but was

automatically computed using a thermodynamic model. The heat transfer coefficient applied between the mold and the

polymer was also measured. Finally, the G’sell law was used for modeling PET behavior. For both heating and blowing

stage simulations, a good agreement has been observed with experimental measurements. This work is part of the

European project "APT_PACK" (Advanced knowledge of Polymer deformation for Tomorrow’s PACKaging).

Keywords: Stretch-blow molding process (SBM), heat transfer modeling, blowing simulation, G’sell law.

PACS: 44.05.+e; 44.40.+a; 83.60.St;

INTRODUCTION

In a typical Stretch-Bow Molding (SBM) process, a

Polyethylene Terephthalate (PET) preform is heated in

an infrared (IR) oven to its forming temperature

(around 100°C), and brought into contact with a mold

of the desired shape. In such a process, the quality of

the final bottle is closely related to heating conditions.

Indeed, the preform temperature distribution has a

strong effect on the blowing kinematic (stretching and

inflation), and consequently on the thickness

distribution of the final part. Temperature also affects

the orientation induced by stretching, which, in turn,

affects mechanical and optical properties of the bottle

[1]. Temperature is therefore one of the most

important parameters in SBM. However, its

measurement remains a delicate task, especially in the

thickness direction. Some experimental methods, such

as IR thermography allows to measure the surface

temperature during heating, but not its profile through

the material thickness [2]. Recently the use of

thermocouples inserted in the preform thickness was

investigated in [3]. On the other hand, numerical

methods are increasingly used. Researchers

implemented models into commercial finite-element

packages like ANSYS

®

[4], FORGE3

®

[5], or

developed their own software [6-8] with the aim of

predicting the three-dimensional temperature

distribution in the preform. Finally, some studies

focused on the development of numerical optimization

strategies for the SBM. Automatic preform shape

optimization was proposed in [9], while optimization

of heating system design was investigated in [10]. The

objective was to target a uniform temperature profile

along the preform length.

The simulation of the blowing step has been also

the subject of significant researches within the last two

decades. Few studies focused on the feasibility of 3D

temperature-displacement simulations [5, 11]. But on

the whole, researchers proposed 2D axi-symmetric

models, with different material laws. A review is

proposed in [5]. It can be noticed that the air pressure

inside the preform is generally applied as a boundary

condition, which can lead to unrealistic results [12].

Moreover, temperature distribution through the

preform wall thickness is generally omitted.

In this work, a simulation of the two stage SBM

process is proposed. The 3D temperature distribution

of a rotating preform was computed taking into

account all the process conditions, and the real oven

design. In a second step, this temperature distribution

(particularly through the wall thickness) was applied

as initial condition for the simulation of the blowing

step. For that, the finite element commercial package

ABAQUS

®

was used. Thanks to a thermodynamic

model, the air pressure inside the preform is

automatically calculated during simulation. Following

sections focus on presenting each model.

PREFORM HEATING MODELING

In the SBM process, heating devices are often

composed by a set of halogen lamps associated to

aluminum reflectors. The preform translates through

the oven, and is animated by a rotational movement to

provide a uniform temperature along its

circumference. Radiation emitted by the IR lamps is

partially absorbed through the preform thickness,

before being diffused in each space direction.

Additionally, the preform tends to be cooled by air

venting. In other words, preform reheating results from

a combination between conductive, convective, and

radiative heat transfers.

Heat Balance Equation

The evolution versus time of the preform

temperature is governed by the following heat balance

equation:

( )

rp

qTk

dt

dT

c ⋅∇−∇⋅∇=

ρ

(1)

Where T = temperature, t = time, ρ = density, c

p

=

specific heat, k = thermal conductivity, q

r

= radiative

heat flux density. In order to solve this equation in 3D,

a finite volume discretization is adopted. For that, the

preform is meshed into hexahedral elements called

control volumes. Equation (1) is integrated over each

control volume and over the time, to obtain the

following integro-differential formulation:

( )

( )

dtdnq

dtdnTkdtd

t

T

c

t

r

tt

p

Γ

−Γ∇=Ω

∂

∂

∫∫

∫∫∫∫

∆ Γ

∆ Γ∆ Ω

.

.

ρ

(2)

where Ω = control volume, Γ = surface of a control

volume. Unknown temperatures are computed at the

cell centre of each element. While the internal side of

the preform is supposed to be adiabatic, the following

boundary condition is applied to the external one:

( )

(

)

44

∞∞

−+−=

∂

∂

− TTTTh

n

T

k

PPETPc

P

σε

(3)

Where h

c

= natural heat transfer coefficient, ε

PET

=

PET mean emissivity, σ = Stefan-Boltzman constant,

T

p

= preform surface temperature at external side, T

∞

=

ambient temperature. The method used for estimating

PET mean emissivity is fully detailed in [2]. This

boundary condition takes into account two types of

thermal exchanges. The first one is due to the cooling

by natural convection, the second one to the own

emission of the preform. These exchanges are

particularly important during the cooling stage.

Radiative Transfer Modeling

Over the spectral band corresponding to the IR

lamps emission (0.38-10µm), PET behaves like a

semi-transparent body. This involves that the radiative

heat flux is absorbed inside the wall thickness of the

preform, and can not be simply applied as a boundary

condition. The radiation absorption must be taken into

account through the divergence of the radiative heat

flux, previously presented in the heat balance equation.

This term represents the amount of radiative energy

absorbed per volume unit; it is also more commonly

called radiative source term. The computation of this

source term can not be carried out without a precise

understanding of radiative transfer properties,

including its spectral and directional dependencies.

Researchers proposed different numerical methods in

order to compute the radiative source term, like

raytracing [5] or zonal method [6]. The method used in

this work is divided into two steps:

First of all, radiative heat fluxes reaching the

preform surface are computed. For that, IR lamps are

meshed into surface elements of which the

contribution is taken into account via view factors

computation. Moreover, IR lamps are assumed to

behave like isothermal grey-bodies. Their emission is

then defined by the Planck’s law [13]. Finally, incident

fluxes are calculated with the following equation:

(

)

(

)

(

)

tit

i

iip

TLSFq

λλλλ

περ

∑

−= 1

0

(4)

Where ρ

λ

= PET reflexion coefficient, F

ip

= view

factor between the lamp element i and the preform, S

i

= surface area of the lamp element, ε

tλ

= tungsten

emissivity, L

λ

= Planck’s intensity of the lamp i at the

filament temperature T

ti

.

In a second time, the radiation absorption is

computed according to the Beer-Lambert law (under

the assumption of the non-scattering cold medium

[13]):

(

)

(

)

xqxq

λλλ

κ

−

=

exp

0

(5)

Where q

λ

(x) = spectral radiative heat flux density at

the location x, q

λ0

= incident spectral radiative heat

flux density, κ

λ

= PET spectral absorption coefficient

(in m

-1

).

Finally, the radiative source term is computed

according to the following equation:

( )

λκ

λ

κ

λ

λ

λ

deqxq

x

r

−

∆

∫

−=⋅∇

0

(6)

Application - Results and Discussion

Software previously presented was used to simulate

the reheating of a rotating preform with the processing

conditions used on the laboratory blowing machine.

The oven is composed of six halogen lamps (1 kW

power), with ceramic and back aluminum reflectors.

After 50 s heating, the preform is cooled down by

natural convection during 10 s. The natural convection

coefficient was calculated using the empirical

correlation of Churchill and Chu [14]. Its value was

estimated to 7 W.m

-2

.K

-1

. Percentages of nominal

power of each lamp are reported TABLE 1. The

preform rotating speed is equal to 1.2 rps.

TABLE 1. Process parameters of the IR oven

P1

(%)

P2

(%)

P3

(%)

P4

(%)

P5

(%)

P6

(%)

t

heat

(s)

t

cool

(s)

100 100 18 5 50 100 50 10

The preform used is 18.5 g weight, 2.58 mm

thickness. The Material is PET TF9 grade (IV=0.74).

An illustration is displayed FIGURE 1.

FIGURE 1. 18.5 g preform – PET T74F9 (IV=0.74).

Temperature measurements were performed in

order to validate simulations. As it was demonstrated

in [2], PET behaves like an opaque body over the 8-12

µm spectral band. For this reason, an AGEMA 880

LW IR camera, functioning within the long wave

spectral band 8-12 µm, has been chosen. This choice

makes possible to affirm that the camera measures a

surface temperature. PET mean emissivity was also

measured by following the protocol fully detailed in

[2]. Its value is equal to 0.93.

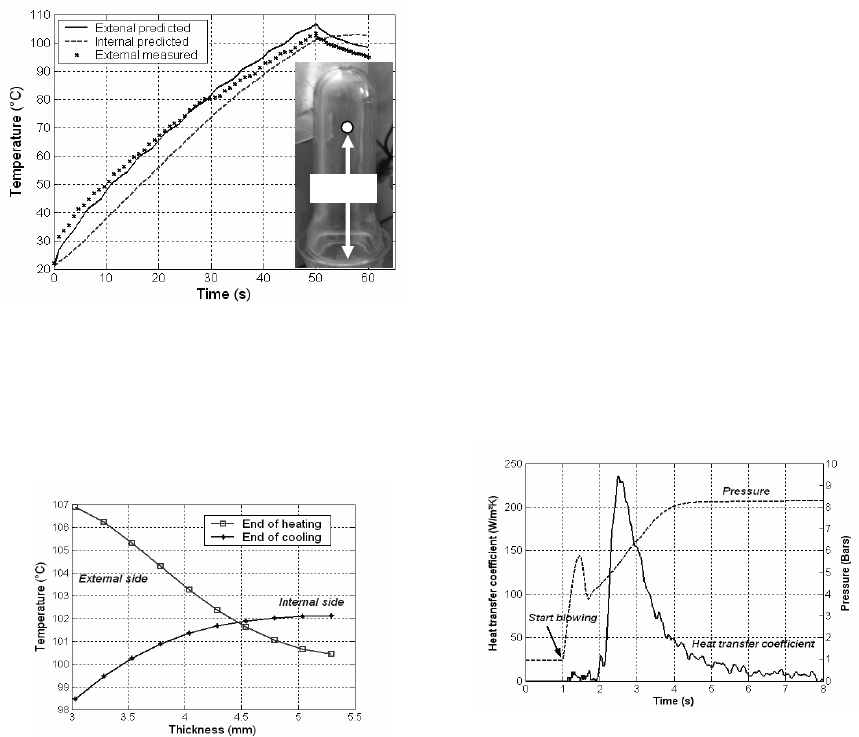

FIGURE 2 illustrates the external temperature

distribution computed with the IR heating software, as

well as the measured temperature cartography.

FIGURE 2. External temperature distribution after cooling –

A: measured – B: simulated.

In the aim of achieving more precise comparisons,

the temperature profile along the preform length (at the

end of the cooling step) is represented FIGURE 3. A

good agreement between simulations and

measurements can be observed, since the global error

is less than 10%.

FIGURE 3. External temperature profile along the preform

length after 10 s cooling.

FIGURE 4 illustrates the variation of temperature

versus time on a single point, located at 47 mm from

the neck of the preform (this point was chosen because

it corresponds to the node located at the middle height

of the mesh). This curve shows clearly the effect of the

cooling stage. Indeed, it is interesting to notice that

after 3 s of cooling (also called inversion time),

temperature on internal side becomes higher than on

the external one. This phenomenon can be easily

Pressure

sensor

A

B

explained: while natural convection tends to cool the

external side, the internal one is heated by heat

conduction. In the SBM process, this point remains

crucial. Indeed, there can be a significant difference

between the inside and outside hoop stretch ratios. In

order to ensure a good uniformity of the stress

distribution through the thickness of the bottle, it is

necessary to deliberately develop a non-uniform

temperature profile throughout the preform before

stretch and blowing.

FIGURE 4. Variation of temperature versus time.

Finally, FIGURE 5 shows clearly that the

temperature distribution through the thickness is not

linear, but exponential. It can be seen that the

temperature difference is around 4°C at the end of the

thermal conditioning step. This value is of course

strongly related to the cooling conditions.

FIGURE 5. Temperature profiles through the preform wall

thickness. Same location as FIGURE 4.

As a conclusion, results demonstrated the

efficiency of the model developed in CROMeP.

Infrared heating software remains a robust tool,

allowing a better understanding of the effect of process

parameters on temperature profiles, particularly

through the preform wall thickness. It could also be

used in order to optimize heating systems [10].

However, a precise understanding of the effect of

temperature on the blowing stage is necessary. For

that, numerical model devoted to the simulation of the

blowing stage was developed. Following section

focuses on giving the key points about this model.

BLOW-MOLDING SIMULATION

Simulations of the SBM process were developed

using the commercial finite element package

ABAQUS

®

. In this study, the objective is to simulate

the process within the same conditions as on the

CROMeP blowing machine, which means: simple

mold for 50 cl water bottle and no stretch rod. A

special attention was given to the measurement of each

initial and boundary condition, namely temperature, air

pressure, and heat transfer coefficient between the

preform and the mold.

Boundary Conditions

As it was mentioned previously, the preform

temperature distribution was measured and calculated

in order to be applied as initial condition.

The heat transfer coefficient between the polymer

and the mold was measured using a sensor developed

for this study. Its peak value was estimated to 230

W.m

-2

.K

-1

, as illustrated FIGURE 6. The method used

for this measurement is fully detailed in [15]. This

coefficient is of prime interest since it affects

drastically the cooling time of the plastic bottle.

FIGURE 6. Heat transfer coefficient and air pressure.

Variation versus time of the air pressure inside the

preform was measured using a Kulite sensor (FIGURE

1). As illustrated FIGURE 6, the air pressure follows

typical variations. In the first time, the pressure

increases sharply. As soon as the pressure is sufficient

to blow the preform, air volume inside the bottle

increases and consequently the pressure drops. While

preform internal volume remains constant, the pressure

reaches gradually its nominal value. This typical

evolution of air pressure gives a good representation of

47 mm

the blowing kinematic. G. Menary [12] has shown that

it is unrealistic to apply the pressure directly as a

boundary condition. Indeed, the pressure drop would

conduct to a deflation of the preform, and not to the

rapid inflation observed experimentally. In this study,

air pressure is not considered as an input variable, but

is automatically computed thanks to the

thermodynamic model “fluid element” available in

ABAQUS

®

. This model is based on the perfect gas

law. Pressure measurements are only used for

validating simulations.

Material Behavior

PET behavior was modeled with the following

visco-plastic G’sell material model [16]:

( )

( )

( )

−

−

=

+−−

=

t

t

a

t

m

TT

Fwith

h

T

WF

T

k

K

1

exp

sinhexp

exp1exp

2

1

0

ε

β

ε

β

εσ

&

(7)

Where

σ

= equivalent Cauchy stress,

ε

&

=

equivalent strain rate,

ε

= cumulated strain, m =

sensitivity to strain rate, (K,k

0

) = consistence. This

model takes into account both temperature and strain

rate dependencies, as well as the strain hardening

which appears for large deformations. It presents the

advantage to be numerically stable and relatively easy

to implement. However this phenomenological

behavior law is reserved to a small range of

temperature and strain rate. Moreover, it does not take

into account the viscoelasticity of the material.

Constitutive parameters have been identified using an

inverse method (non-linear constrain algorithm called

Sequential Quadratic Programming) from equi-biaxial

tensile tests performed in Queen University of Belfast.

The thermo-dependency was identified by [16] from

shear tests on PET T74F9. This model has been

implemented within ABAQUS

®

via a Fortran

subroutine known as user creep.

Blow Molding FEM Model

In order to avoid long computation times, an axi-

symmetric model has been chosen. This approach is

possible since both preform and mold designs are axi-

symmetric, as well as kinematic boundary conditions.

The preform was meshed into 46 quadratic shell

elements (96 nodes), with five integration points

through its thickness in order to take into account the

temperature gradient. The mold used is a prototype

developed at CROMeP. It produces 50 cl bottle. This

one has been assumed to be rigid and isothermal.

Indeed, for one SBM cycle, its temperature increase is

about 1°C [14]. In order to compute the heat transfer

between the polymer and the mold, a coupled

temperature-displacement model was chosen in

ABAQUS

®

Standard (implicit time integration

scheme). The viscous dissipation was not calculated.

However it could have an important effect on the

preform temperature, and consequently on the blowing

kinematic. As mentioned previously, no stretch rod is

modeled. Finally, the contact between the preform and

the mold is assumed to be stick.

Results and Discussion

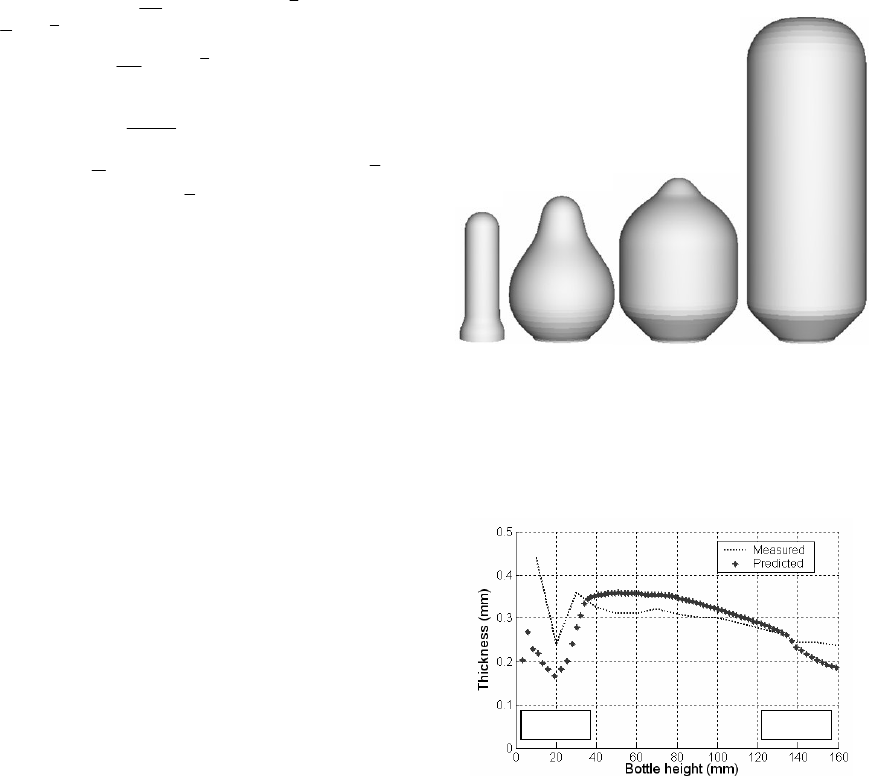

FIGURE 7 illustrates the intermediate preform

shapes versus time.

FIGURE 7. Simulation of the preform shape evolution.

Measurements of the thickness distribution of the

final part were performed on bottles forming on the

CROMeP blowing machine. Comparison with

simulation results are illustrated FIGURE 8.

FIGURE 8. Wall thickness distribution of the bottle.

t=0 s t=0.66 s t=1 s t=1.5 s

Botton

Neck

A good agreement is observed (around 15 % error

on the mean thickness). We can notice that the

measured thickness distribution is probably not

optimal from an industrial point of view. This is due to

the preform design used in this study, which is

probably not adapted to this type of bottle shape.

Thanks to the thermodynamic model used in this

study, it is possible to compare numerical and

experimental blowing kinematics, by comparing the

evolution of air pressure.

It can be seen FIGURE 9 that the pressure

computed by the numerical model is not exactly the

same as the measured one. However, tendencies are

respected.

FIGURE 9. Computed and measured air pressure.

FUTURE WORK

Future work will aim to consolidate the model

presented in this study. It is well known that PET

behavior remains the key point for improving the

model. Since the pressure curve gives a good

representation of the blowing kinematic, it could be

envisaged to couple the model to an optimization

algorithm in order to identify automatically the

constitutive parameters of the material law, by

minimizing the difference between the measured

pressure, and the calculated one. It is also crucial to

investigate the influence of temperature distribution

through the preform thickness on the blowing

kinematic and on the thickness distribution of the final

bottle. A sensitivity study can also be envisaged

concerning the heat transfer coefficient mold/polymer,

in order to prove its effect on the blowing.

ACKNOWLEDGMENTS

This study was conducted within the frame of 6th

EEC framework. STREP project APT_pack; NMP –

PRIORITY 3. www.apt-pack.com. Special thanks to

Logoplaste Technology for manufacturing the

preforms and Tergal Fibre for supplying the material,

and QUB for giving tensile test results. Authors thank

also V. Lucin for its contribution to this work.

REFERENCES

1. G. Venkateswaran and al, Advances in Polymer

Technology 17, 237-249 (1998).

2. S. Monteix and al, QIRT Journal 1, 133-149 (2004).

3. H.-X. Huang and al, Polymer Testing 25, 839-845 (2006).

4. H.-X. Huang and al, SPE ANTEC Tech Papers 12 (2005).

5. C. Champin and al, SPE ANTEC Tech Papers 51 (2005).

6. W. Michaeli and al, SPE ANTEC Tech Papers 30 (2004).

7. S. Monteix and al, Journal of Materials Processing

Technology 119, 90-97 (2001).

8. L. Martin and al, Proceedings of ANTEC, New York,

1999, pp. 982-987.

9. F. Thibault and al, SPE ANTEC Tech Papers 16 (2005).

10. M. Bordival and al, 9th ESAFORM conference on

material forming, Glasgow (UK), 2006, pp. 511-514.

11. S. Wang and al, International Journal for Numerical

Methods in Engineering 48, 501-521 (2000).

12. G. Menary and al, 10th ESAFORM conference on

material forming, Zaragoza (Spain), 2007.

13. M. Modest, Radiative Heat Transfer, McGraw-Hill, Inc

(1993).

14. F. P. Incropera, Fundamentals of Heat and Mass

Transfer, John Wiley & Sons, p 546.

15. M. Bordival and al, 10th ESAFORM conference on

material forming, Zaragoza (Spain), 2007.

16. E. Gorlier, "Caractérisation rhéologique et structurale

d'un PET. Application au procédé de bi-étirage soufflage

de bouteilles", Ph.D. Thesis, ENSMP, 2001.

.