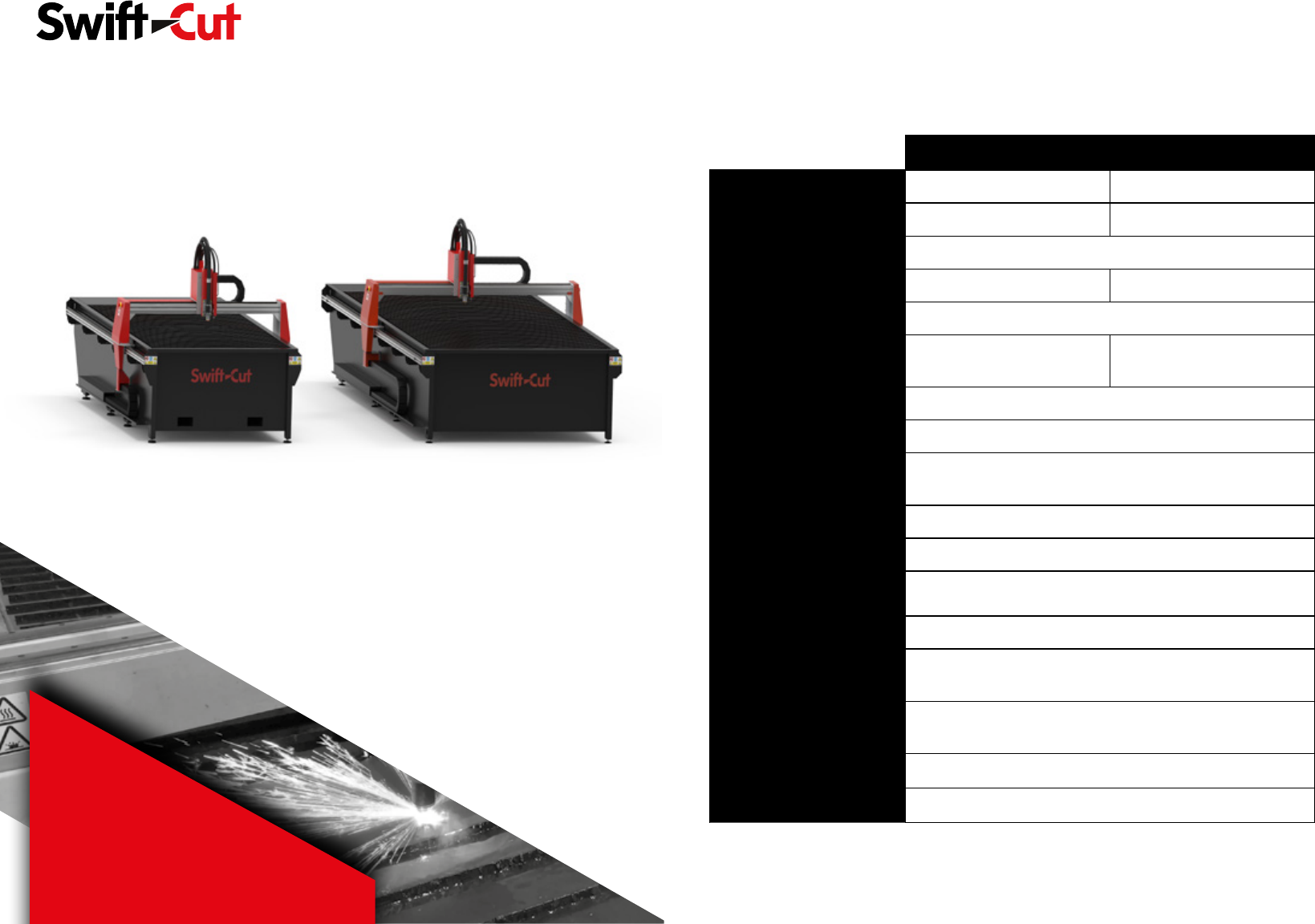

CNC PLASMA CUTTING SYSTEM

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

Why choose

a Swift-Cut XP?

The Swift-Cut XP is cutting edge in its design and more

durable than ever. Designed with production cutting

in mind up to 32mm* (1.25”) and with an edge start

capacity up to 50mm* (2”) the XP range of tables is

supplied with AC servo motors across all axes for

improved performance and accuracy.

*in conjunction with the Hypertherm MaxPro 200 cutting mild steel

Introducing the

Swift-Cut XP

The brief was simple, take all that we learnt with our

best selling Swift-Cut Pro plasma machine and build it

bigger, stronger and more powerful than ever before.

The outcome is a range of two heavy duty CNC plasma

cutting machines built to withstand the rigours of all day

cutting whilst still remaining incredibly affordable.

swift-cut.com

Key

Features

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

OPERATORS

CONSOLE

Ergonomic operators

console with touch

screen and keyboard/

mouse inputs.

HEAVY DUTY BASE

Fully welded reinforced

base provides the

required support and

rigidity when cutting

thick material

GANTRY BEAM

Lightweight but rigid gantry

beam supports twin x-axis linear

rails, it also gives you the ability

to cut 200mm box sections.

PROTECTION

COVERS

Protect key

components against

the harsh cutting

environment.

BREAKAWAY HEAD

Ensures the torch is

protected in the event

of a part collision.

INTELLIGENT TORCH HEIGHT CONTROL

Never have to set up torch height control yourself.

Automatic voltage sampling provides repeatable cut

quality and increased consumable life compared to

conventional Torch Height Control systems.

MAXPRO200

Plasma system

LINEAR RAIL

Precision linear rail on all axes

combined with AC digital

servos delivers exceptional

positioning accuracy.

ENCLOSED

DRAG CHAINS

Fully enclosed

drag chains

protect cables

against damage

from molten

material.

HEAVY DUTY

GANTRY

Heavy duty gantry

end castings with

machined faces

provide a precise and

stable platform for

the cutting head.

TABLE BED OPTIONS

The water table bed option (only

available on the XP 3000 (XP 510) offers

ecient fume suppression reducing

the need for external fume extraction.

Alternatively the zoned downdraft table

option captures fumes and particulate

from beneath the cutting area.

ENGRAVING TOOL

The SwiftMARK engraving tool

allows you to mark and cut

in one operation, meaning no

more outsourcing or moving

your project from one machine

to another (optional extra).

SOFTWARE

Easy to use

SwiftCAM Advanced

and SwiftCNC

software included as

standard

FLOATING INITIAL

HEIGHT SENSE

Reliable touch off

sensing system for

accurate pierce heights.

Swift-Cut tables are ruggedly built,

easy to use, have great accuracy

and most importantly, give an

excellent cut.

Alan Bradford, Plasmatech

Main Key Features:

| Intelligent Torch Height Control (ITHC) means

less set up and the perfect cutting height every time

| 360 degree breakaway head stops any damage

to the torch or work piece in the event of a part

collision

| SwiftCAM and SwiftCNC software included

as standard

| Advanced CAM software with auto nest facility

included with every package

| Downdraft and water table cutting bed options

available on the XP 3000 (XP 510). Available as

down draft only on XP 4000 (XP 613)

| Designed, engineered, and fully supported by the

Swift-Cut team

| Freestanding operators console can be positioned

at any point around the table

| A choice of six plasma power sources with

capacities from 3mm to 32mm (0.12” to 1.25”)

| Smooth and precise AC servo motors across all axis

| Mixed gas cutting and water cooled torch available

on Hypertherm MaxPro 200 plasma power source

The Swift-Cut XP is our heavy

duty, production-ready CNC plasma

cutting machine

How have we built such a durable plasma cutting machine at such an

affordable price point?

Our Swift-Cut XP machine has been designed, prototyped, built, and

tested by our own in-house engineering team. Nothing on this machine is

ineffectual; so at the design stage, if it doesn’t improve the performance,

functionality and durability , then it simply won’t make the cut!

swift-cut.com

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

Plasma is one of the world’s most popular cutting

methods and for good reason: it strikes the perfect

balance between cut quality, cut speed, and cost.

Hypertherm thermal arc plasma systems are trusted

and used by more businesses and people than any

other brand. They are considered the best plasma

cutting tools available today and are seamlessly

integrated with the Swift-Cut XP range.

Easy to use and

feature packed

Swift-Cut are renowned for making feature rich, yet

easy to use cutting machines, and our Swift-Cut XP

is no exception. With our touchscreen HMI, wireless

keyboard & mouse, and both standard and advanced

screens for operators with varying experience, you

will be cutting with condence in no time. Features

like Cut Recovery, Plate Alignment, Sheet Trim, 89

shape parametric library and auto nesting all come as

standard.

SwiftCAM Software

Swift-Cut’s easy to use software guarantees that

anyone with a basic knowledge of using computers

will be capable of operating the CNC plasma cutting

system. Minimal training required means the

machine will be operational almost immediately,

maximising output from the start.

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

How have we built a plasma cutting

machine that’s so durable whilst

maintaining a compact footprint?

We wanted our XP range to have the strength and rigidity to withstand

production cutting of materials up to 32mm (1.25”) in thickness, whilst

maintaining a footprint that wasn’t much bigger than our Pro plasma

range. When we look at the market, it is easy to over engineer a machine

and add size and unnecessary weight in an ever increasing footprint. Our

design team wanted to keep things straight forward so we ensured any

additional strength and weight added did not affect the loading of material

and transporting/positioning the machine. Custom internal structures were

created to guarantee the capability and durability of the machine for now

and the future.

Very few companies are who they say

they are, but Swift-Cut promised a

quality product and then backed it up

Full Metal Solutions

Why choose

Swift-Cut?

We are one of the prominent suppliers of CNC plasma cutting machines

in the world and our reputation for providing value for money, quality

machinery and exceptional service is rst class. Each machine goes

through rigorous testing before leaving our facilities, to ensure our

customers get the machine they have been promised. Swift-Cut’s name is

synonymous with quality cutting, and we’re proud of the contribution we are

making to the global CNC cutting industry.

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

swift-cut.com

Technical

Specications

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

XP 3000 (XP 510)

3000mm x 1500mm

cutting area (10’ x 5’)

4000 (XP 613)

4000mm x 2000mm

cutting area (13’ x 6.5’)

Table Specications & Features

The Swift-Cut XP has been designed by our skilled team of engineers to provide an all-encompassing plasma

cutting solution with industry leading features as standard and is available in 2 sizes.

Table Specications

XP 3000 (XP 510) XP 4000 (XP 613)

Footprint

3710mm x 2030mm (12.2' x 6.6') 4720mm x 2465mm (15.5' x 8.1')

Table weight

1500kg (3300lbs) 2600kg (5732lbs)

Height

1780mm (70”)

Cutting envelope

3000mm x 1500mm (10' x 5') 4000mm x 2000mm (13' x 6.5')

Z-Axis travel

150mm (6”)

Maximum supported

material load

1150kg (2500lbs) 2050kg (4450lbs)

Input voltage

110-230v (6A-4A)

Speed

12m/min (472ipm)

Linear positional

accuracy

0.2mm/m (0.002"/ft)

Repeatability

0.4mm/m (0.005"/ft)

Ballbar circularity

0.3mm/m (0.003"/ft)

Drive description

400W AC Servo motor assembly, 20mm linear rail on X & Y axis. 100W

servo drive system on Z axis. Anti-backlash gearbox

Gantry height

210mm (8.2")

Maximum material

thickness

32mm (1.25")

Maximum cut capacity of

box section

150mm (6")

Input air pressure

7- 7.5 BAR (100 - 110 PSI)

Flow rate

300 LPM (10 CFM)

swift-cut.com

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

Standard

JPEG/DXF/DWG import capable

Import .dxf or .dwg les or convert .jpg images for cutting

Automatic Lead in/out

Software automatically applies lead in/out for quicker programming

Automatic nesting

Automatically nests parts for economical sheet usage

Part in part nesting

Automatically nest parts in scrap areas to fully utilise sheet

Advanced Drawing Importer

Built in system to clean, scale or delete items within problematic

drawings

Parametric shape library

89 congurable shapes

SwiftCAM Software (features)

swift-cut.com

Ease of use was a major deciding

factor. The software is very user

friendly and requires little prior

computer skills.

Delmer Yomer, Wellspring Components, USA

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

Operator console spec

• Touchscreen HMI with wireless keyboard

and mouse control

• Footprint – 610mm x 600mm (23” x 23”)

• Height – 1430mm (56”)

• Weight – 46kg (100lbs)

• Operating system – Windows 10, 64 bit

• Software included – SwiftCAM, SwiftCNC

• Remote support application installed as standard

swift-cut.com

The Swift-Cut machines are capable

of so much, the only limitation is

your imagination

ASE Engineering

SwiftCNC Software (features)

G-Code Browser

Allows the user to start cutting from any individual prole within the G-code

Cut recovery

This function allows the user to start from any position along the cut path

whilst maintaining cut accuracy and reducing material waste

Direct Cut Control

Remote control of settings for Hypertherm Powermax plasma systems

• Automatic control of cutting amps

• Automatic control of air pressure

• Automatic control of cut mode

• Read fault codes from the operator’s console

• Continuous arc mode - A simple unique solution allowing operators

to cut wire mesh and perforated materials with the Hypertherm

Powermax plasma systems

Basic and advanced displays

Basic view for beginners and advanced view for more experienced

operators

Sheet alignment

Simply use the plasma shield to reference the two bottom corners of the

sheet and the software will automatically adjust your part(s) or nest to the

new angle. This will ensure the plasma arc will not ‘run off’ the material as it

travels up the cutting bed

Sheet trim

Easily trim off scrap material. Options to go between 2 or 3 points on the

material

G-code Favourites

Save up to 5 G-code les for quick loading

G-Code queue

Queue up to 5 G-Code les for quick loading

Datum store

Don’t lose a datum point again, this system stores your last datum point so

even if you lose power, you will not lose your position

Congurable datum points

Set up to 5 datum points anywhere on the cutting bed. This can be used

to reduce setup times when using jig xtures or to set custom parking

positions

Dry-run mode

View the plasma torch movement, cutting order and speed in real time

before you switch on the pump, so any problems are found and corrected

without wasting material unnecessarily

Touchscreen display

Seamlessly switch between the wireless keyboard and mouse or the

touchscreen display

Graphical toolpath display

Visual representation of where you are on the toolpath

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

swift-cut.com

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

Cutting Power Options

Plasma Source: Hypertherm

Air Spec

• Clean, dry air supply that should meet ISO8573-1 class 1.2.2.

• Input air pressure – 7- 7.5 BAR (100-110 PSI)

• Flow rate – 300 LPM (10 CFM)

Options

• SwiftMARK engraving tool

• Zoned Downdraft (DD) or Water Table (WT)*

• Powermax consumable kits

• SwiftCAM Advanced software

• Compressor options available

• Air dryer options available

• 3 stage compressed air ltration

• Filtered extraction or extractor fan options for Downdraft machines

• Anti-rust solution

• Anti-fungal tablets

• Wireless or hardwired internet connections

*(WT) only available on XP 3000

Max pierce capacity Mild steel Stainless steel Aluminium Duty cycle 100% duty cycle

Powermax 45 XP* 12mm (1/2”) 12mm (3/8”) 10mm (3/8”) 50% 32Amps

Powermax 65 SYNC™ 16mm (5/8”) 12mm (1/2”) 12mm (1/2”) 50% 46 Amps

Powermax 85 SYNC™ 19mm (3/4”) 16mm (5/8”) 16mm (5/8”) 60% 66 Amps

Powermax 105 SYNC™ 22mm (7/8”) 20mm low use (3/4”) 20mm (3/4”) 80% 94 Amps

Powermax 125 25mm (1”) 20mm (7/8”) 25mm (7/8”) 100% 125 Amps

MAXPRO200 32mm (1.25″) 25mm (1”) 25mm (1.25″) 100% 200 Amps

* Single phase option available

Swift-Cut aftercare is second to none

We take as much pride in helping our customers after

the sale as we do when we are making the sale, and

every aspect of the user being able to get the absolute

best from their Swift-Cut Pro has been thought about.

Whether you need remote assistance, advice, or an

engineer’s visit, we will always make sure that you are

getting the very best in aftercare.

There are a number of options to choose from when you

come to decide how you wish to maintain your machine,

and with over forty years combined experience in

plasma and waterjet cutting, we have great knowledge

when it comes to cutting on many different grades and

types of material.

To enable us to support and train our global customers

and sales partners, Swift-Cut has invested heavily in

technology that allows us to provide remote services by

using Smartphone, Tablet and Wearable Technology via

collaborative software tools to train, assist and diagnose

the problem with precision and in less time. The My

Swift-Cut app allows us to provide real-time video

support which minimises time spent on the job and

keeps machine downtime to a minimum.

We offer interactive online service kits which are

designed to keep your cutting table running at its best,

with the minimal amount of downtime. As part of the

package, our support team will dial in remotely and talk

you through the service procedure, step-by-step.

In addition to the standard warranties that come with

all our cutting tables, if you feel you need more, you

can purchase extended warranties which can cover all

aspects of support, parts or both, giving you even more

peace of mind. Contact a member of our team

for further details.

Swift-Cut has enabled us to diversify

from our primary business into an area

we would never have ventured into.

Leightec

Swift-Cutter CNC family

Here at Swift-Cut we build long-standing relationships with our customers,

with many buying multiple machines from us over time.

Once you buy a Swift-Cut table, you become part of our family, we’ll share

what you do and let you know what other Swift-Cutters are up to.

Our social media pages are an interactive platform where we hope our

customers feel at home, or check out our Swift-Cutters Case Studies

page on our website for more idea of what your fellow Swift-Cutters are

up to and how they get the very best from their machines.

If you require any further

help or information please

visit swift-cut.com

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

Frequently

Asked Questions

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

swift-cut.com

How much does it cost

to run?

There are many variables which can affect running

costs, including type and thickness of material being

cut, so its dicult to put an exact hourly cost down. It is

widely recognised though if you take into consideration

power, compressed air, consumables and routine

maintenance, CNC plasma operating costs are lower

than laser cutting and much lower than waterjet.

What power is required?

The table (inc. console) requires a single phase 110-

230v (6A-4A) supply. The Hypertherm Powermax

45XP requires either a 230v or 415v (32A) supply. The

Hypertherm Powermax 65, 85 and 105 requires a 415v

(32A) supply. The Hypertherm Powermax 125 requires

a 415v (64A) supply. The Hypertherm MaxPro 200

requires a 415v (100A) supply.

Do I need a compressor?

An air compressor is an essential component of the

CNC plasma cutting system. Air plays a crucial part

in ensuring the best quality cut and the reliability of

the machine and plasma power source. It needs

to be dry and free of any contaminants like oil. The

amount of cutting you intend to do will determine what

compressor is best for your needs. As a minimum

we would always recommend you install a 3 stage air

ltration unit close to the cutting table to lter the air

before it enters the plasma power source and table

hardware. We can both advise and supply the best

compressed air setup for your business.

Do I need a downdraft

table (DD) or water table

(WT) to capture the fume?

It all depends on your particular application. Downdraft

tables are slightly more expensive to purchase than

water tables and require connection to either a ltration

unit or extraction fan. The additional equipment adds

extra noise, but they are easier to clean and your only

option if cutting aluminium or stainless steel most of

the time. Water tables are less expensive and quieter,

but more dicult to clean and are not recommended for

certain materials.

What materials will it cut?

CNC plasma cutting can only be used for materials

that are conductive. The three most popular materials

are mild steel, stainless steel and aluminium however

other metals and alloys such as copper, brass, titanium,

hardox, inconel and cast iron can all be cut, albeit you

may experince reduced edge quality due to the melting

temperature of some of those metals.

How accurate is it?

Our XP plasma tables are accurate to within +/- 0.4mm

(0.005”/ft)

Can I have a

demonstration?

Yes, of course! We have dedicated experince centres

in many locations around the world. We can also

carry out personalised remote demonstrations over

Zoom, TeamViewer, Microsoft Teams and WhatsApp

platforms. You can bring parts or drawings with you to

cut out, or we can create something for you which best

represent your particular application.

Is training included?

Training is always included as standard with all our

Swift-Cut machines. This is on a one-to-one basis and

our support engineers will ensure you are comfortable

with operating your new Swift-Cut before the session

ends. This can be done either remotely, which is free

of charge, or on-site*

I’m new to CNC and not

that condent on a

computer, is it easy to use?

We have designed our software to be extremely user

friendly. It is a simple step-by-step process to layout

(nest) your drawing or parametric shape, and create

your g-code ready for cutting. Our SwiftCNC software

has both basic and advanced screen layouts which the

user can switch between as their condence grows.

*Additional charges may apply.

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

What’s the difference

between pierce capacity

and edge start capacity?

When we talk about CNC plasma power source

capacity, we quote pierce capacities. This is the

maximum thickness of material the plasma can pierce if

it was to start within the sheet.

Pierce Start

The pierce needs to happen quickly to reduce the

chance of the molten metal blocking the consumables

in the end of the plasma torch and stopping the cut.

Edge Start

It is possible however (although more dicult to setup)

to start from the edge of the sheet. Because the risk

of blocking the consumables is reduced, the material

thickness can increase. Edge starting can also give

longer consumable life.

swift-cut.com

SWIFT-CUT XP | CNC PLASMA CUTTING SYSTEM

How do I get drawings on

the table?

You can bring your DXF/DWG drawings into the

SwiftCAM software either from les saved locally or

on USB memory drive. Open the folder location where

the le is saved and select the lename you want to

import. Alternatively you can bring in JPEG images via

the same method and then use the advanced image

importer function to clean, scale or delete elements of

the drawing. Once imported, simply follow the step-by-

step process to nest your parts onto your sheet.

Can I use my own plasma

power source?

Swift-Cut plasma machines seamlessly integrate with

Hypertherm plasma power sources and torches. If you

already have a Hypertherm plasma, depending on age,

we can advise the necessary parts required (if any) to

connect it to one of our machines.

Can it cut box section?

No problem at all. We have lots of customers cutting

box section on our Pro plasma machines. The

maximum height box section permitted on the machine

is 150mm (6”)

How often do consumables

generally last?

Many factors can affect consumable longevity

including air quality, material type, and the amount of

pierces. If the machine is setup correctly and you’re

using clean material, consumables should typically last

1-3 hours. When using the MaxPro 200, consumable

technologies such as LongLife, CoolFlow™ and

TrueFlow™ signicantly increase consumable life to

reduce cost per part

Are the consumables easy

to buy?

All consumables are readily available direct from Swift-

Cut or one of our approved distributors.

How fast will the machine

cut?

Depending on material thickness, the Swift-Cut XP

can typically reach cutting speeds up to 6m/min (236

ipm) in combination with the MaxPro 200 plasma

power source

Are there any rules when it

comes to cutting holes?

This one’s as much of guide as it is a hard and fast

rule! When cutting holes using standard denition

plasma, it’s good to follow the 2D rule. This is where,

in order to maintain good hole quality and tolerance,

you should ensure the smallest hole you want to cut

has an approximate diameter twice that of the material

thickness. i.e. if you have 5mm plate, you should aim

for a hole diameter of around 6mm. All our machines

have software which automatically calculates the

optimum lead-in, cut height and feed rate to ensure

your cut holes look as good as possible

Can I use a hand torch with

my Hypertherm plasma

power source?

You certainly can. If you wish to use a hand torch with

your plasma, simply unplug the machine torch and

CNC connections, and plug in the hand torch. You will

need to place your material on the cutting bed of the

Swift-Cut machine to make use of the earth connection.

Alternatively you can plug in a separate earth lead if you

want to work away from the Swift-Cut. When you’ve

nished hand cutting, just reverse the proceedure.

Can I use my own

CAD program such as

AutoCAD?

You are more than welcome to use any CAD package

you feel comfortable with. As long as you can save the

les in a DXF/DWG format, you can open them in the

SwiftCAM software without any problems..

What are the benets of

mixed gas cutting?

The main benets are reduced angularity, better edge

nish, less dross, improved hole quality and faster cutting

speeds. To achieve these results you would use Oxygen

cutting gas and Air shielding gas on mild steel, and

Nitrogen cutting gas and shielding gas on Stainless Steel

and Aluminium. Mixed gas cutting is only available in

conjunction with the MaxPro 200 plasma power source.

If you require any further

help or information please

visit swift-cut.com

For more information contact

swift-cut.com

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or

by any other means, electronic, mechanical, photocopying or otherwise, without prior permission from

Swift-Cut Automation Ltd. All references in this publication to operating weights, sizes, capacities and

other performance measurements are provided for guidance only and may vary dependent upon the exact

specication of machine. They should not therefore be relied upon in relation to suitability for a particular

application. Guidance and advice should always be sought direct from Swift-Cut or an approved Swift-Cut

partner. Swift-Cut reserves the right to change specications without notice. Illustrations and specications

shown may include optional equipment and accessories. All images are correct at time of publication.

follow us

@

SwiftCutAutomation

@

SwiftCutAutomation

Swift-Cut Automation

Swift-Cut