INNOVATION

OUTLOOK

RENEWABLE

METHANOL

in partnership with

© IRENA 2021

Unless otherwise stated, material in this publication may be freely used, shared, copied, reproduced, printed and/or stored, provided that appropriate

acknowledgement is given of IRENA as the source and copyright holder. Material in this publication that is attributed to third parties may be subject to

separate terms of use and restrictions, and appropriate permissions from these third parties may need to be secured before any use of such material.

ISBN 978-92-9260-320-5

CITATION IRENA AND METHANOL INSTITUTE (2021),Innovation Outlook : Renewable Methanol,

International Renewable Energy Agency, Abu Dhabi.

About IRENA

The International Renewable Energy Agency (IRENA) is an intergovernmental organisation that supports countries in

their transition to a sustainable energy future and serves as the principal platform for international co-operation, a centre

of excellence and a repository of policy, technology, resource and financial knowledge on renewable energy. IRENA

promotes the widespread adoption and sustainable use of all forms of renewable energy, including bioenergy, geothermal,

hydropower, ocean, solar and wind energy, in the pursuit of sustainable development, energy access, energy security and

low-carbon economic growth and prosperity. www.irena.org

About METHANOL INSTITUTE

The Methanol Institute (MI) is the global trade association for the methanol industry, representing the world’s leading

producers, distributors, and technology companies. Founded in 1989 in Washington DC, MI now represents its members

from five oces around world in Washington DC, Beijing, Brussels, Delhi, and Singapore. MI serves its members as the

voice of the methanol industry, representing companies within the membership to governments and businesses around

the world to promote the sustainable growth of the industry. MI focuses on advancing the utilisation of methanol as a

clean fuel in energy-related applications such as land & marine transport, power generation, fuel cells, industrial boilers,

and cook stoves. MI also supports sustainable and renewable process to produce methanol as a carbon-neutral chemical

and fuel. www.methanol.org

Acknowledgements

This report was jointly prepared by the International Renewable Energy Agency (IRENA) and the Methanol Institute (MI).

It was developed under the guidance of Dolf Gielen (IRENA) and Greg Dolan (MI). The contributing authors are Seungwoo

Kang and Francisco Boshell (IRENA), Alain Goeppert and Surya G. Prakash (University of Southern California), and Ingvar

Landälv (Fuels & Energy Consulting) with valuable additional contributions from Paul Durrant (IRENA).

The authors appreciate thetechnicalreviewprovided byDeger Saygin (ShuraEnergy TransitionCenter), Tue Johansson

(A.P. Moller - Maersk), Florian Ausfelder (Dechema), Alexandra Ebbinghaus (Shell), Christopher Kidder (International DME

Association), Choon Fong Shih (University of Chinese Academy of Sciences), Mark Berggren (MMSA), Andrew Fenwick

(Johnson Matthey), Tore Sylvester Jeppersen (Haldor Topsoe), Peter J. Nieuwenhuizen (Enerkem), Acya Yalcin and Jason

Chesko (Methanex).

Valuable review and feedback were also provided by IRENA and MI colleagues, including Herib Bianco, Ricardo Gorini,

Paul Komor, Toshimasa Masuyama, Emanuele Taibi (IRENA), and Tim Chan (Methanol Institute).

The chapters in this outlook were edited by Justin French-Brooks.

Available for download: www.irena.org/publications

For further information or to provide feedback, please contact IRENA atinf[email protected]g

This publication and the material herein are provided “as is”. All reasonable precautions have been taken by IRENA to verify the reliability of the material

in this publication. However,neither IRENA nor any of itsocials, agents, data or other third-party content providers provides a warranty of any kind,

either expressed or implied, and they accept no responsibility or liability for any consequence of use of the publication or material herein.

The information contained herein does not necessarily represent the views of all Members of IRENA. The mention of specific companies or certain

projects or products does not imply that they are endorsed or recommended by IRENA in preference to others of a similar nature that are not mentioned.

The designations employed and the presentation of material herein do not imply the expression of any opinion on the part of IRENA concerning the legal

status of any region, country, territory, city or area or of its authorities, or concerning the delimitation of frontiers or boundaries.

Disclaimer

INNOVATION OUTLOOK: 4

1. Methanol:

•

Methanol is a key product in the chemical industry.

It is mainly used for producing other chemicals such

as formaldehyde, acetic acid and plastics. Around

98million tonnes (Mt) are produced per annum, nearly

all of which is produced from fossil fuels (either natural

gas or coal).

•

The life-cycle emissions from current methanol

production and use are around 0.3gigatonnes (Gt)

CO

2

per annum (about 10% of total chemical sector

emissions).

•

Methanol production has nearly doubled in the past

decade, with a large share of that growth being in

China. Under current trends, production could rise to

500 Mt per annum by 2050, releasing 1.5 Gt CO

2

per

annum if solely sourced from fossil fuels.

•

The cost of producing fossil fuel-based methanol is in

the range of USD 100-250 per tonne (t).

2. Renewable methanol:

•

Renewable methanol can be produced using renewable

energy and renewable feedstocks via two routes:

•

Bio-methanol is produced from biomass. Key

potential sustainable biomass feedstocks

include: forestry and agricultural waste and

by-products, biogas from landfill, sewage,

municipal solid waste (MSW) and black liquor

from the pulp and paper industry.

•

Green e-methanol is obtained by using CO

2

captured from renewable sources (bioenergy

with carbon capture and storage [BECCS] and

direct air capture [DAC]) and green hydrogen,

i.e. hydrogen produced with renewable

electricity.

•

Less than 0.2 Mt of renewable methanol is produced

annually, mostly as bio-methanol. The methanol

produced by either route is chemically identical to

methanol produced from fossil fuel sources.

•

Interest in renewable methanol is being driven by

the need to mitigate climate change by substantially

reducing or eliminating CO

2

emissions, and in particular

by the growing focus on holding the average global

temperature rise to no more than 1.5°C. This implies

achieving net carbon neutral emissions across all

sectors of the economy by mid-century.

•

Low-emission methanol could play a larger role in

decarbonising certain sectors where options are

currently limited – particularly as a feedstock in

the chemical industry or as a fuel in road or marine

transport.

3. Production costs of bio-methanol:

•

Since production is currently low, limited data are

available on actual costs, meaning that potential costs

need to be estimated. The bio-methanol production

cost will depend on the bio-feedstock cost, investment

cost and the efficiency of the conversion processes.

KEY FINDINGS

Methanol plays an important role in the chemical industry, and is an emerging energy fuel

currently mostly produced from fossil fuels. A transition to renewable methanol – derived

from biomass or synthesised from green hydrogen and carbon dioxide (CO

2

) – could expand

methanol’s use as a chemical feedstock and fuel while moving industrial and transport sectors

toward net carbon neutral goals. The cost of renewable methanol production is currently high

and production volumes are low. But with the right policies, renewable methanol could be cost-

competitive by 2050 or earlier.

RENEWABLE METHANOL 5

Biomass and MSW feedstock costs vary between

USD0 and USD17 per gigajoule (GJ).

•

With a lower feedstock cost range of up to USD6/GJ,

the cost of bio-methanol is estimated to be in the range

USD 320/t and USD 770/t, with the range influenced

by differences in the specific projects – including

differences in CAPEX, OPEX and conversion efficiency.

•

With process improvements, the cost range could be

reduced to between USD 220/t and USD 560/t for the

lower feedstock price range up to 6 USD/GJ, with a

correspondingly higher range for the higher feedstock

price range.

•

Production of bio-methanol from the waste streams

of other industrial processes (e.g. black liquor from

paper mills and MSW) in particular offer opportunities

to simplify the feedstock logistics and improve overall

plant economics. Co-production of heat, electricity

or other chemicals could also potentially improve the

economics of bio-methanol production.

•

In the short term biomass could be co-fed into a coal-

based gasifier, or biogas fed into a natural gas-based

methanol plant, so allowing for the gradual introduction

of biomass as a feedstock and making methanol

production more sustainable at a potentially lower cost.

4. Production costs of green e-methanol:

•

The cost of e-methanol depends to a large extent

on the cost of hydrogen and CO

2

. The cost of CO

2

depends on the source from which it is captured, e.g.

from biomass, industrial processes or DAC.

•

The current production cost of e-methanol is estimated

to be in the range USD800-1600/t assuming CO

2

is

sourced from BECCS at a cost of USD10-50/t. If CO

2

is

obtained by DAC, where costs are currently USD300-

600/t, then e-methanol production costs would be in

the range USD1200-2400/t.

•

The future cost of green hydrogen production mainly

depends on the combination of further reductions

in the cost of renewable power generation and

electrolysers, and gains in efficiency and durability.

•

With anticipated decreases in renewable power

prices, the cost of e-methanol is expected to decrease

to levels between USD250-630/t by 2050.

•

As in the case of bio-methanol, co-production of

brown/grey (fossil) and green e-methanol could allow

the gradual introduction of green e-methanol at a

reasonable cost.

5. Benefits and challenges for renewable

methanol:

•

Renewable methanol can be produced from a variety

of sustainable feedstocks, such as biomass, waste

or CO

2

and hydrogen. Its use in place of fossil fuels

can reduce greenhouse gas (GHG) emissions and in

some cases can also reduce other harmful emissions

(sulphur oxides [SOx], nitrogen oxides [NOx],

particulate matter [PM] etc.)

•

It is a versatile fuel that can be used in internal combustion

engines, and in hybrid and fuel cell vehicles and vessels.

It is a liquid at ambient temperature and pressures, and

so is straightforward to store, transport and distribute.

It is compatible with existing distribution infrastructure

and can be blended with conventional fuels.

•

Production of methanol from biomass and from CO

2

and H

2

does not involve experimental technologies.

Almost identical proven and fully commercial

technologies are used to make methanol from fossil

fuel-based syngas and can be used for bio- and

e-methanol production.

•

Currently the main barrier to renewable methanol

uptake is its higher cost compared to fossil fuel-based

alternatives, and that cost differential will persist for

some time to come. However, its value is in its emission

reduction potential compared to existing options.

•

Addressing process differences and facilitating the

scale-up of production and use can help reduce costs,

but will require a variety of policy interventions. With

the right support mechanisms, and with the best

production conditions, renewable methanol could

approach the current cost and price of methanol from

fossil fuels.

INNOVATION OUTLOOK: 6

CONTENTS

KEY FINDINGS .................................................................................................................................................................... 4

CONTENTS ...........................................................................................................................................................................6

ABBREVIATIONS .............................................................................................................................................................. 11

SUMMARY FOR POLICY MAKERS ...............................................................................................................................12

1. CURRENT PRODUCTION AND APPLICATIONS OF METHANOL ................................................................22

1.1. Methanol as a raw material ...................................................................................................................................... 22

1.2. Methanol as a fuel ........................................................................................................................................................25

1.3. Storage, transport and distribution of methanol ........................................................................................... 29

2. PRODUCTION PROCESS AND TECHNOLOGY STATUS .................................................................................32

2.1. Low-carbon methanol ................................................................................................................................................ 33

2.2. Renewable methanol ................................................................................................................................................. 34

Bio-methanol from biomass and MSW ................................................................................................................................... 34

Bio-methanol from biogas ........................................................................................................................................................... 40

Bio-methanol from the pulping cycle in pulp mills ............................................................................................................. 41

Methanol from CO

2

(e-methanol) ............................................................................................................................................. 42

Combination of bio- and e-methanol production .............................................................................................................. 50

3. PERFORMANCE AND SUSTAINABILITY ..............................................................................................................53

3.1. Performance and eciency .................................................................................................................................... 53

Bio-methanol ......................................................................................................................................................................................53

E-methanol ......................................................................................................................................................................................... 54

3.2. Renewable methanol vs alternatives.....................................................................................................................57

3.3. Emissions and sustainability ................................................................................................................................... 59

Emissions ............................................................................................................................................................................................ 59

Sustainability and carbon neutrality ........................................................................................................................................ 63

RENEWABLE METHANOL 7

4. CURRENT COSTS AND COST PROJECTIONS ................................................................................................... 65

4.1. Bio-methanol costs ..................................................................................................................................................... 65

Methanol production from biomass and MSW via gasification .................................................................................... 65

Methanol production from biogas .............................................................................................................................................73

Methanol as by-product from wood pulping ........................................................................................................................75

4.2. E-methanol costs ........................................................................................................................................................ 76

E-methanol production costs – A literature review ............................................................................................................76

4.3. Summary of renewable methanol costs today and in the future ............................................................. 84

5. POTENTIAL AND BARRIERS ..................................................................................................................................87

5.1. Demand .............................................................................................................................................................................87

5.2. Sustainable feedstock ................................................................................................................................................90

Biomass ...............................................................................................................................................................................................90

CO

2

and hydrogen ...........................................................................................................................................................................90

5.3. Impact of renewable methanol on the energy sector .................................................................................... 91

5.4. Drivers ................................................................................................................................................................................ 91

5.5. Barriers ............................................................................................................................................................................. 92

Bio-methanol ..................................................................................................................................................................................... 92

E-methanol ......................................................................................................................................................................................... 93

5.6. Policies and recommendations ..............................................................................................................................94

REFERENCES AND FURTHER INFORMATION ..................................................................................................... 99

ANNEXES ..........................................................................................................................................................................110

Annex 1. Some of the pros and cons of methanol and renewable methanol ..............................................110

Annex 2. Overview of major methanol production processes from various carbon sources. .............. 116

Annex 3. Comparison of renewable methanol with other fuels on a price per unit

of energy basis ....................................................................................................................................................117

Annex 4. Overview of existing or planned facilities and technology providers for

e-methanol and bio-methanol production ............................................................................................. 118

INNOVATION OUTLOOK: 8

Figures

Figure 1. Global methanol demand and production capacity (2001-2019) ................................................ 12

Figure 2. Principal methanol production routes ..................................................................................................... 13

Figure 3. Current and future production costs of bio- and e-methanol. .................................................... 15

Figure 4. Comparison of renewable methanol with other fuels on a price

per unit of energy basis ................................................................................................................................ 16

Figure 5. Global methanol demand in 2019 ..............................................................................................................17

Figure 6. The feedstocks and applications of methanol .................................................................................... 23

Figure 7. Global methanol demand and production capacity (2001-2019) ............................................... 24

Figure 8. Historical methanol sale price (1995-2020) ......................................................................................... 24

Figure 9. Fleet of M100 fuelled taxis in Guiyang City, Guizhou province, China ...................................... 26

Figure 10. Geely M100 truck (2019) in China and M100 truck in Israel (2020). .......................................... 26

Figure 11. Gumpert Nathalie, methanol-fuelled hybrid fuel cell supercar .....................................................27

Figure 12. Palcan hybrid methanol reformer/proton-exchange

membrane fuel cell passenger bus in China .........................................................................................27

Figure 13. Methanol-powered Stena Germanica 50000 DWT ferry

operating between Gothenburg and Kiel ............................................................................................. 28

Figure 14. Ocean-going vessel powered by methanol ......................................................................................... 29

Figure 15. Methanol stations in China ..........................................................................................................................30

Figure 16. M15 dispensing pump alongside gasoline and diesel fuel dispensers

at a filling station, and M100 dispensing pump in Israel .................................................................30

Figure 17. DME filling station and pump in Shanghai, China in 2008 .............................................................. 31

Figure 18. Bio-DME filling station in Sweden in 2011 .............................................................................................. 31

Figure 19. Proposed classification of methanol from various feedstocks ................................................... 32

Figure 20. Gasification-based methanol plant – general scheme ................................................................... 35

Figure 21. Enerkem’s MSW to biofuels (methanol and ethanol) plant in Alberta, Canada. ................... 39

Figure 22. Reformer-based methanol plant – general scheme ......................................................................... 41

Figure 23. Types of hydrogen according to production process ...................................................................... 42

Figure 24. Approaches to e-methanol production through electrolysis and

electrochemical processes ......................................................................................................................... 43

Figure 25. CO

2

feedstock for the production of e-methanol .............................................................................. 44

Figure 26. The “George Olah Renewable CO

2

-to-Methanol Plant” of CRI in Iceland ................................46

RENEWABLE METHANOL 9

Figure 27. 1000 t/y e-methanol demonstration plant in Lanzhou, Gansu Province,

Northwestern China ......................................................................................................................................46

Figure 28. Combined bio- and e-methanol scheme with biomass or MSW as feedstock .................... 51

Figure 29. Combined bio- and e-methanol scheme with biogas as feedstock ........................................ 52

Figure 30. Example of estimates for global renewable CO

2

availability from dierent sources

by the middle of the 21st century ..........................................................................................................56

Figure 31. Volumetric energy content of various fuels ......................................................................................... 58

Figure 32. GHG emissions of methanol produced from various feedstocks (from feedstock

extraction to final use, values from Table 11) .......................................................................................63

Figure 33. Anthropogenic carbon cycle for a circular economy ....................................................................... 64

Figure 34. Global supply curve for primary biomass, 2030................................................................................69

Figure 35. Estimated costs of bio-methanol up to 2050 ..................................................................................... 72

Figure 36. Potential production cost reduction for bio-methanol from biomass

within a 15 to 20 year timeframe .............................................................................................................. 73

Figure 37. Potential production cost reduction for bio-methanol from MSW

within a 15 to 20 year timeframe .............................................................................................................. 73

Figure 38. Production cost for biomethane via gasification and via anaerobic digestion ......................74

Figure 39. Cost of methanol as a function of hydrogen and CO

2

cost ............................................................ 81

Figure 40. Estimated costs of renewable e-methanol up to 2050 depending

on the renewable CO

2

.................................................................................................................................. 83

Figure 41. Current and future production costs of bio- and e-methanol ....................................................85

Figure 42. Comparison of renewable methanol with other fuels on a price

per unit of energy basis ...............................................................................................................................86

Figure 43. Fleet of Geely Emgrand 7 cars operating in Iceland and powered by 100%

renewable methanol, in front of the CRI CO

2

-to-methanol production plant ........................88

Figure 44. Swedish car powered by an M56 mix (56% methanol in gasoline) with

bio-methanol from the LTU Green Fuels plant (in the background) ......................................... 88

Figure 45. Chemrec bioDME pilot plant and Volvo DME-fuelled truck ..........................................................88

Figure 46. Passenger ship MS innogy on Lake Baldeney (Germany) powered by a

hybrid fuel cell system fuelled by renewable methanol ..................................................................88

Figure 47. Current and future methanol production by source ........................................................................89

Figure 48. A hypothetical CFD smoothing returns in a volatile market .........................................................96

INNOVATION OUTLOOK: 10

Tables

Table 1. Pros and cons of methanol and renewable methanol ..........................................................................18

Table 2. Examples of syngas conditioning and cleaning processes ............................................................... 36

Table 3. Gasifier design principles ................................................................................................................................ 37

Table 4. Gasification technologies and their application ..................................................................................... 38

Table 5. Methanol plants co-fed with a mix of natural gas and biomethane .............................................40

Table 6. By-product bio-methanol from wood pulping .......................................................................................41

Table 7. Overview of existing or planned facilities and technology providers for

e-methanol production ....................................................................................................................................47

Table 8. Energy conversion eciencies for certain process units ...................................................................53

Table 9. Selection of renewable and non-renewable sources of CO

2

............................................................55

Table 10. Comparison of various fuel properties .....................................................................................................57

Table 11. GHG emissions of methanol from various sources, ordered by feedstock type .......................61

Table 12. Capital cost for bio-methanol plants .........................................................................................................66

Table 13. Capital cost for gasification-based plants for other products .........................................................67

Table 14. Capital cost element in production cost ...................................................................................................68

Table 15. Feedstock cost element in production cost ............................................................................................69

Table 16. OPEX (excluding feedstock) cost element in production cost ........................................................70

Table 17. Total production cost for bio-methanol from biomass and MSW ...................................................71

Table 18. Total production cost for bio-methanol after potential cost reduction ....................................... 72

Table 19: Impact of feedstock price in production of methanol from methane/biomethane ................75

Table 20. Approximate production cost for bio-methanol from wood pulping ...........................................75

Table 21. Production costs and production capacity of e-methanol reported in the literature ............77

Table 22. Cost of green hydrogen today and in the futures .................................................................................79

Table 23. Cost of CO from various sources .............................................................................................................. 80

Table 24. Estimated costs of renewable methanol up to 2050 ..........................................................................82

Table 25. Capital cost for CO-to-methanol plants ................................................................................................. 84

RENEWABLE METHANOL 11

AGR Acid gas removal

ASU Air separation unit

BECCS Bioenergy with carbon capture and

storage

BECCU Bioenergy with carbon capture and use

BEV Battery electric vehicle

BTX Benzene, toluene and xylenes

(aromatics)

CAPEX Capital expenditure

CCS Carbon capture and storage

CCU Carbon capture and use

CFD Contract for dierence

CH

3

OH Methanol

CI Carbon intensity

CNG Compressed natural gas

CO Carbon monoxide

CO

2

Carbon dioxide

CO

2

-eq Carbon dioxide equivalent

COS Carbonyl sulphide

CPP Coal power plant

CRI Carbon Recycling International

DAC Direct air capture

DME Dimethyl ether

DMFC Direct methanol fuel cell

DWT Deadweight tonnage

ECA Emission Control Areas

e-fuel Electrofuel

EU European Union

EV Electric vehicle

FCV Fuel cell vehicle

FEED Front-end engineering design

FFV Flexible fuel vehicle

FT fuels Fischer-Tropsch fuels

GHG Greenhouse gas

H

2

Hydrogen

HCl Hydrogen chloride

HF Hydrogen fluoride

HF Hydrogen fluoride

HHV Higher heating value

ICE Internal combustion engine

IMO International Maritime Organization

IRR Internal rate of return

LCA Life-cycle analysis

LCFS Low Carbon Fuel Standard

LCM Low-carbon methanol

LHV Lower heating value

LNG Liquefied natural gas

LPG Liquefied petroleum gas

MDI Methylenebis (4-phenyl isocyanate)

MMA Methyl methacrylate

MSW Municipal solid waste

MTBE methyl tert-butyl ether

MTG Methanol-to-gasoline

MTO Methanol-to-olefins

NOx Nitrogen oxides

n/k Not known

OMEs Oxymethylene ethers

OPEX Operating expenditure

PEM Polymer electrolyte membrane

PM Particulate matter

PV Photovoltaic

RED Renewable Energy Directive

RES Renewable energy source

SGAB Sub Group on Advanced Biofuels

SNG Synthetic natural gas

SOx Sulphur oxides

TRL Technology readiness level

TTW Tank-to-wheel

US United States

WGS Water gas shift

WTT Wheel-to-tank

WTW Wheel-to-wheel

UNITS OF MEASURE

EJ Exajoule

GJ Gigajoule

Gt Gigatonne

kg Kilogram

km Kilometre

kt/y Thousand tonnes per year

kW Kilowatt

kWh Kilowatt hour

L Litre

L/d Litres per day

MJ Megajoule

Mt Million tonnes

MtCO

2

Million tonnes of carbon dioxide

MW Megawatt

MWh Megawatt hour

MW

t

Megawatt thermal

m

3

Cubic metre

t Tonne

t/d Tonnes per day

t/y Tonnes per year

ABBREVIATIONS

Figure 1. Global methanol demand and production capacity (2001-2019)

Source: Based on data from MMSA (2020).

INNOVATION OUTLOOK: 12

Methanol is one of the four critical basic chemicals –

alongside ethylene, propylene and ammonia – used to

produce all other chemical products. About two-thirds

of methanol is used to produce other chemicals, such

as formaldehyde, acetic acid and plastics. Methanol use

for the production of polyethylene and polypropylene in

particular has grown significantly, going from almost zero

ten years ago to 25Mt in 2019. The remaining methanol is

mainly used as a fuel for vehicles, ships, industrial boilers

and cooking. Methanol’s use as a fuel – either by itself, as

a blend with gasoline, for the production of biodiesel, or in

the form of methyl tert-butyl ether (MTBE) and dimethyl

ether (DME) – has also grown rapidly since the mid-2000s.

Most methanol is currently produced from natural gas or

coal, with estimated annual life-cycle emissions of 0.3 Gt

CO

2

, around 10% of the total chemical and petrochemical

sector’s CO

2

emissions. Addressing emissions from

methanol production is therefore a key component of

the decarbonisation of the chemical sector and could

contribute to the transport sector where the methanol

can be used as a fuel.

Market status and production process

Worldwide annual production of methanol nearly doubled

over the past decade to reach about 98Mt in 2019. A large

part of that growth came from China through methanol

production from coal. Methanol demand is expected to

continue increasing to reach more than 120 Mt by 2025

(MMSA, 2020; Berggren, 2019) and 500 Mt by 2050 in

IRENA’s Transforming Energy Scenario.

SUMMARY FOR POLICY MAKERS

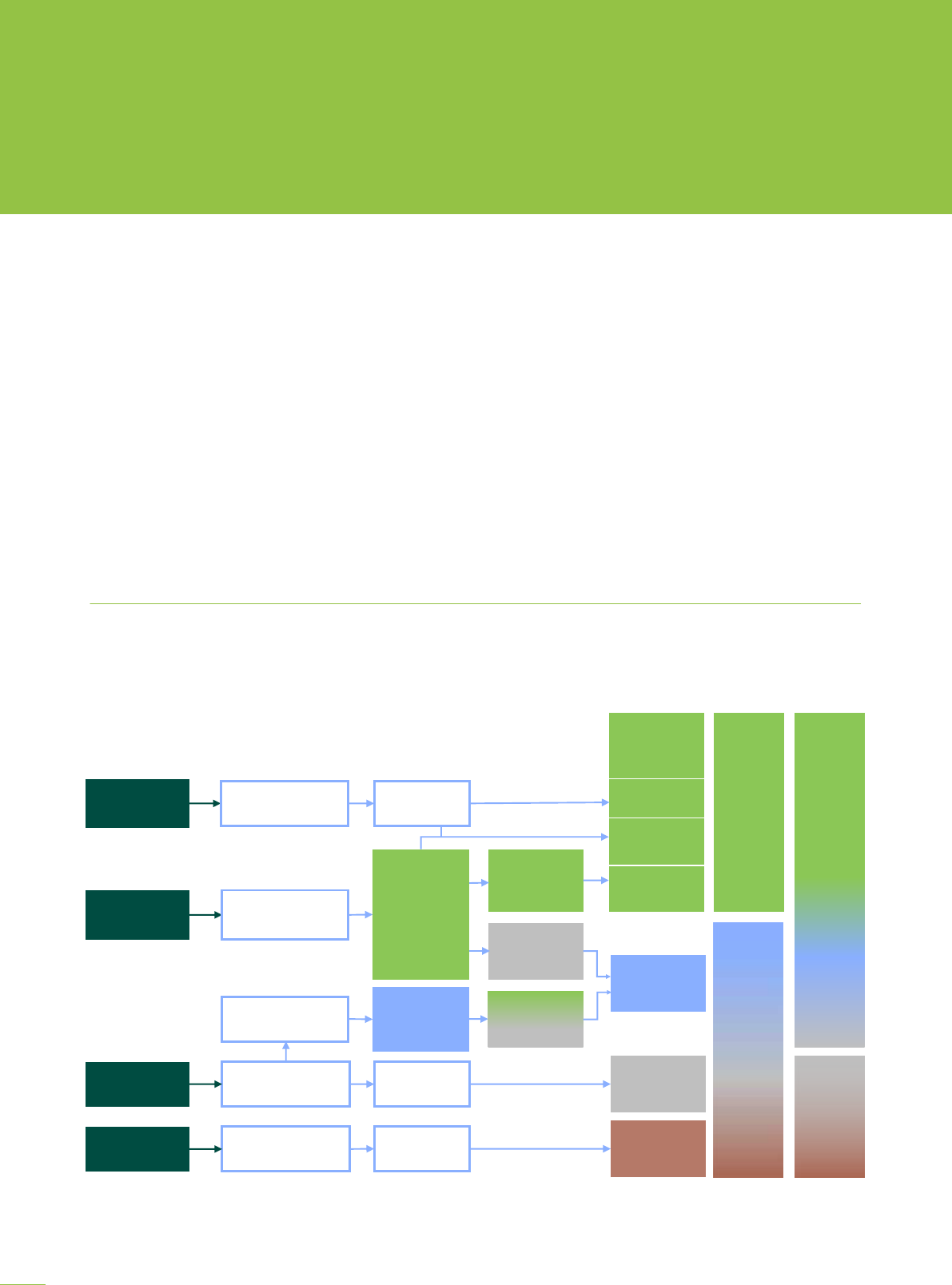

Figure 2. Principal methanol production routes

Renewable CO

2

: from bio-origin and through direct air capture (DAC)

Non-renewable CO

2

: from fossil origin, industry

While there is not a standard colour code for the dierent types of methanol production processes; this illustration of various types of methanol

according to feedstock and energy sources is an initial proposition that is meant to be a basis for further discussion with stakeholders

RENEWABLE METHANOL 13

This is in line with the “well-below 2°C” Paris climate goal

(Saygin and Gielen, forthcoming). Most of the growth

until 2028 is expected to come from the Chinese market,

mainly to be used in the production of olefins, with a

smaller share for gasoline blending, formaldehyde, acetic

acid and MTBE production.

Renewable methanol

Currently, methanol is produced almost exclusively from

fossil fuels. However, methanol can also be made from

other feedstocks that contain carbon, including biomass,

biogas, waste streams and CO

2

(for example captured

from flue gases or through DAC).

Renewable methanol can be produced using renewable

energy and renewable feedstocks via two routes:

•

Bio-methanol is produced from biomass. Key potential

sustainable biomass feedstocks include: forestry and

agricultural waste and by-products, biogas from

landfill, sewage, MSW and black liquor from the pulp

and paper industry.

•

Green e-methanol is obtained from CO

2

captured

from renewable sources (e.g. via BECCS or DAC)

and green hydrogen, i.e. hydrogen produced with

renewable electricity.

To qualify as renewable, all feedstocks and energy

used to produce the methanol need to be of renewable

origin (e.g. biomass, solar, wind, hydro, geothermal).

The methanol produced by either route is chemically

identical to methanol produced from fossil fuel sources.

R

R

e

e

n

n

e

e

w

w

a

a

b

b

l

l

e

e

e

e

l

l

e

e

c

c

t

t

r

r

i

i

c

c

i

i

t

t

y

y

N

N

a

a

t

t

u

u

r

r

a

a

l

l

g

g

a

a

s

s

C

C

o

o

a

a

l

l

Reforming

Gasification

Electrolysis

Carbon capture

and storage (CCS)

CH

3

OH

Blue methanol

CH

3

OH

Grey methanol

CH

3

OH

Brown methanol

Syngas

Syngas

H

2

Blue Hydrogen

CO

2

Non-renewable

B

B

i

i

o

o

m

m

a

a

s

s

s

s

Gasification/

reforming

CH

3

OH

Green methanol

Syngas

CO

2

Renewable

High

carbon

intensity

Low carbon

intensity

Bio-methanol

E-methanol

Bio-

e-methanol

Renewable

CO

2

Non-renewable

Renewable

Non-

renewable

Renewable CO

2

: from bio-origin and through direct air capture (DAC)

Non-renewable CO

2

: from fossil origin, industry

H

2

Green hydrogen

INNOVATION OUTLOOK: 14

Current progress on renewable

methanol production

Less than 0.2 Mt of renewable methanol is produced

annually, from only a handful of plants. Those renewable-

methanol commercial facilities and demonstration

projects focus mainly on using waste and by-product

streams from other industrial processes, which oer the

best economics at present. Suitable feedstocks include:

MSW and low-priced biomass, biogas, waste streams,

and black liquor from the pulp and paper industry.

For example, a commercial-scale plant producing

bio-methanol from bio-methane is in operation in the

Netherlands and a plant producing bio-methanol from

MSW is operating in Canada. In Iceland, e-methanol

is produced by combining renewable hydrogen and

CO

2

from a geothermal power plant. The current

projects benefit from favourable conditions, such as

low feedstock cost (e.g. biogas), strong integration with

conventional industrial processes (e.g. pulp and paper

industry), or very inexpensive renewable electricity

(e.g. geothermal and hydro energy in Iceland).

Depending on appropriate local conditions, there are

other early or niche opportunities for bio-methanol

and e-methanol production (e.g. integrated production

with bio-ethanol from sugarcane, co-feeding biomass

feedstock and fossil fuels, and co-production of heat,

electricity and other chemicals).

The co-feeding of renewable feedstock (e.g. biomass,

CO

2

, green hydrogen, renewable electricity) into natural

gas- or coal-based methanol production facilities

could be a strategy to gradually introduce renewable

methanol production, and reduce the environmental

impact and carbon intensity of conventional methanol

production. The output of these hybrid plants is

sometimes called low-carbon methanol (LCM).

This demand could help with the early scale-up of

electrolysers for hydrogen production, CO

2

capture

processes and other technologies for later large-scale

renewable methanol deployment.

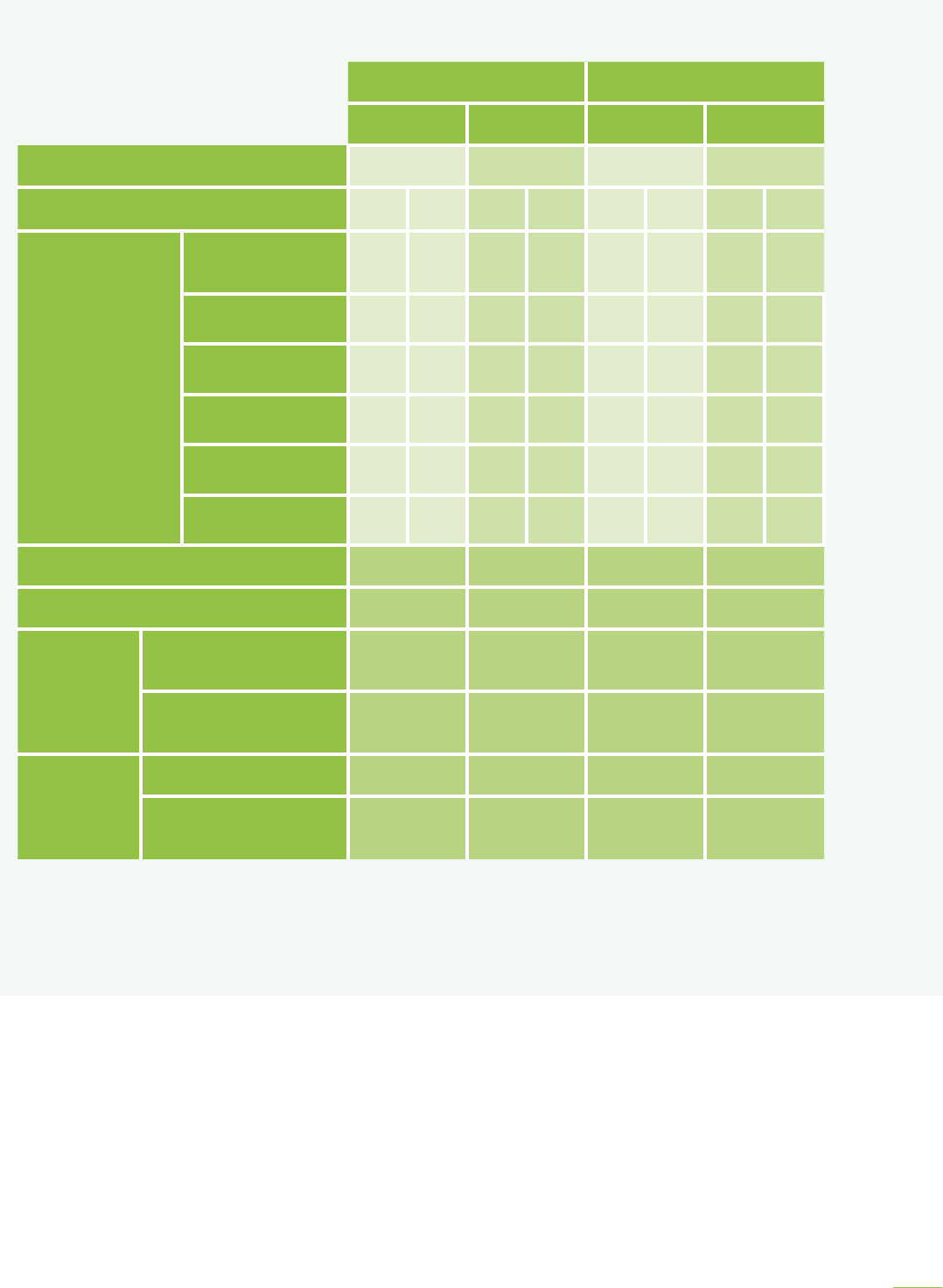

Cost competitiveness of renewable methanol

Renewable methanol production costs are significantly

higher than those of today’s natural gas- and coal-based

methanol production (whose production costs are in

the range of USD 100-250/t). With the lowest-cost

feedstocks and with improvements in production

processes, the cost of producing renewable methanol

from either the gasification of biomass or MSW, or

using CO

2

and renewable hydrogen, could approach the

current cost and price of methanol from fossil fuels, as

illustrated in Figure 3 and Figure 4.

Improving the competitiveness

of bio-methanol

Technology maturity and cost reduction. The gasification

of oil and coal is a well-proven technology with multiple

large units in operation. The application of gasification

technologies to various biomass types and MSW is,

however, in the early commercialisation phase and

requires further development before reaching full

commercial status. In the optimum cases, bio-methanol

is close to competing on cost with fossil fuel-generated

methanol, but it is more expensive, in many cases, by

a factor of up to two. As the cost of the feedstock is

not expected to decrease significantly in the future,

reducing CAPEX will be the largest contributor to

lowering production costs, through economies of

scale and learning curve mechanisms such as process

improvements, improved and more (cost-) eective

plant configurations and plant size.

Sustainable and low-cost biomass feedstocks. The

scale-up of bio-methanol production will depend on the

availability of low-cost biomass feedstock (the share of

feedstock cost in the total production cost can be as high

as 50%). Bio-methanol production requires reliable and

consistent supplies of feedstock. While in some cases

biomass feedstock supplies can be provided locally, many

other projects require more extensive supply chains.

The biomass must be sustainably sourced. Sustainability

assessments and monitoring are needed to consider and

manage the risks of adverse economic, environmental

and social impacts (IRENA, 2020a). The gross maximum

availability of sustainable biomass in the world is

estimated to be 147exajoules in 2030 (IRENA, 2014).

Biomass feedstock costs around the world can vary by up

to 17 USD/GJ depending on the type and the location. The

lowest-cost feedstocks – i.e. below USD6/GJ (EUR20/

megawatt hour) are mainly MSW and residues, and the

availability of these feedstocks is limited. As biomass has

the potential for use in a wide range of options for energy

purposes and for materials, bio-methanol production will

be competing with other applications.

Figure 3. Current and future production costs of bio- and e-methanol

1

Notes: MeOH = methanol. Costs do not incorporate any carbon credit that might be available. Current fossil methanol cost and price are from

coal and natural gas feedstock in 2020. Exchange rate used in this figure is USD1 = EUR0.9.

RENEWABLE METHANOL 15

Improving the competitiveness of e-methanol

Abundant and low-cost green hydrogen. Large-scale

production of e-methanol will depend on the availability

of inexpensive green hydrogen and CO

2

, as well as the

capital cost of the plant. From a cost perspective the

main drivers will be the cost of the renewable power

needed to generate the required H

2

, as well as plant

utilisation rates (especially the electrolysers). Currently,

e-methanol remains costly to produce from these

sources. However, the cost of renewable electricity

produced from wind and solar, which is already

competitive with fossil fuel-generated electricity in most

markets, is predicted to continue decreasing over the

next decades (IRENA, 2020b; IRENA, 2020c). The cost of

e-methanol should therefore also decrease significantly

over the same period. Economies of scale and innovation

in electrolysers will also help reduce costs.

A sustainable and aordable source of carbon. The

necessary CO

2

can be captured from various sources

including power plants and industrial exhaust streams

(e.g. iron, steel and cement production). However, to

be renewable and sustainable, CO

2

has to be obtained

USD/tonne

2 400

1 400

2 200

1 200

2 000

1 000

400

1 800

800

200

1 600

600

0

Current fossil

methanol price

Current fossil

methanol cost

E-methanol - CO

2

from combined

renewable source

E-methanol - CO

2

from DAC only

Bio-methanol < USD 6/GJ

feedstock cost

Bio-methanol USD 6-15/GJ

feedstock cost

Current production

cost levels

Mature production

cost levels

Current production

cost levels

Mature production

cost levels

1 013

884

455

355

764

327

553

227

1620

820

1120

2380

290

630

630

250

A carbon credit of USD 50/t CO

2

would

lower renewable methanol production cost

by about USD 80/t MeOH

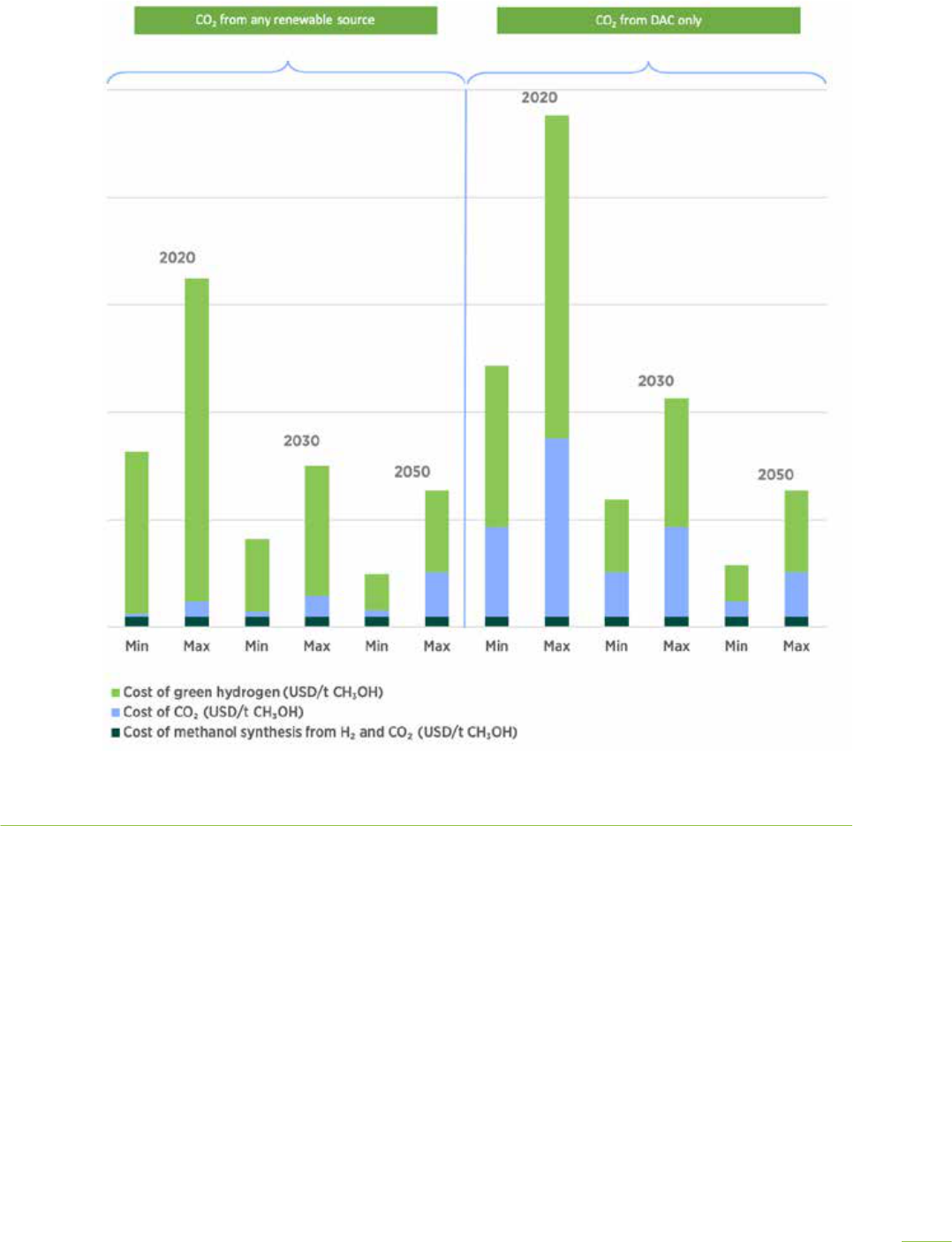

Figure 4. Comparison of renewable methanol with other fuels on a price per unit of energy basis

Notes: Exchange rate used in this figure USD1 = EUR0.9. Fuel costs and prices are averaged over 10years. See Annex 3 for details.

INNOVATION OUTLOOK: 16

from renewable sources such as biomass combustion,

distilleries and biogas. CO

2

capture from these sources

needs to be expanded. The production of e-methanol

from renewable CO

2

sources, especially the least

expensive but most limited ones, might also be in

competition with other carbon capture, use and storage

applications. Ultimately, the capture of CO

2

from air

(DAC) oers the largest potential, but its costs need to

decrease substantially.

The combination of bio- and e-methanol production in

a single facility could be very beneficial. In such a hybrid

plant, the excess CO

2

generated in the production of bio-

methanol can serve as the CO

2

source for the production

of e-methanol with green hydrogen.

Outlook for renewable methanol.

With current global demand for methanol at close to

100 Mt per year and growing, there is a large potential

market for renewable methanol. Methanol, whether from

fossil fuels or renewable sources, has the same chemical

structure: CH

3

OH. As such, renewable methanol could

directly replace fossil methanol in any of its current

uses, e.g. as a feedstock for the production of various

chemicals, materials, plastics and products, and as a fuel

for transport, shipping, cooking, heating and electricity

production. The current expansion of fossil methanol as

a fuel in some applications could also ease the gradual

transition to renewable methanol as the distribution and

transport infrastructure would remain the same.

USD/GJ

0

Current fossil

methanol price

Bio-methanol E-methanol

70

60

100

50

20

90

40

10

80

30

Current production

cost levels

Mature production

cost levels

Gasoline (US Gulf Coast)

Diesel (US Gulf Coast)

Heating Oil No. 2 (New York Harbor)

Jet Fuel (US Gulf Coast)

Gasoline (average US)

Diesel (average US)

Gasoline (average

EU)

Diesel (average EU)

Retail with tax

Before tax

Figure 5. Global methanol demand in 2019

1

Source: Based on data from MMSA (2020)

RENEWABLE METHANOL 17

In addition to existing methanol use, renewable green

methanol could also replace most petroleum-based

hydrocarbons and petrochemicals, either directly or

through methanol derivatives, for a potential market

requiring billions of tonnes of methanol per year.

Production of plastics and aromatics (BTX) from

renewable methanol could, for example, be greatly

expanded. This would facilitate the transition to a

sustainable circular green economy where renewable

methanol is uniquely positioned as a future-proof

chemical feedstock and fuel.

While the expansion of renewable methanol is currently

held back by its higher production cost when compared

to natural gas- and coal-based methanol, renewable

methanol is one of the easiest-to-implement sustainable

alternatives available, especially in the chemical and

transport sectors.

Table 1 summarises the benefits and challenges of

scaled-up renewable methanol use. A more detailed

discussion of the pros and cons of methanol can be

found in Annex 1.

98

million

tonnes

Gasoline blending

14%

Methyl tert-butyl ether (MTBE)

11%

Biodiesel

3%

Dimethyl ether (DME)

3%

Methanol-to-olefins

25%

Formaldehyde

25%

Methyl chloride (chloromethane)

2%

Methylamines

2%

Methanethiol (methyl mercaptan)

1%

Methyl methacrylate (MMA)

2%

Acetic acid

8%

Others

4%

INNOVATION OUTLOOK: 18

Table 1. Pros and cons of methanol and renewable methanol

Pros Cons

+

Can be produced on an industrial scale

from various carbon-containing feedstocks.

Natural gas and coal today; biomass, solid

waste and CO

2

+ H

2

tomorrow

+

Already used to produce hundreds of

everyday industrial chemicals and consumer

products

+

Methanol is a liquid at atmospheric

conditions. This makes it easy to store,

transport and distribute by ship, pipeline,

truck and rail

+

Only relatively inexpensive and minor

modification to existing oil infrastructure

needed for methanol storage and

distribution

+

Versatile fuel for internal combustion

engines, hybrid (fuel/electric) systems and

fuel cells, turbine engines, cookstoves, and

boilers

+

Potential liquid hydrogen carrier

+

Low pollutant emissions: no soot (PM), no

SO

x

, low NO

x

. Low-carbon and renewable

methanol also reduces CO

2

emissions

+

No inherent technical challenges in scaling

up the production of methanol to meet the

needs of the transport or chemical industry

sectors

+

Methanol is readily biodegradable

×

Production of renewable methanol remains

more expensive than fossil methanol

×

Production of renewable methanol needs

to be scaled up

×

Competition for renewable feedstock

(biomass, CO

2

, renewable power, green

hydrogen) with other renewable alternatives

×

Renewable methanol requires investment

support, technology-neutral public policy,

and removal of barriers to access affordable

renewable electricity, CO

2

and biomass

feedstocks

×

Fuel standards for methanol need to be

expanded to allow for wider use in more

countries and for more applications

×

Only about half the volumetric energy

density of gasoline and diesel fuel

×

Corrosive to some metals and incompatible

with some plastics and materials

×

Highly flammable and can lead to explosion

if handled improperly, like gasoline, ethanol

or hydrogen

×

Toxic; can be lethal if ingested

RENEWABLE METHANOL 19

Action areas to foster renewable

methanol production

As with any other alternative to fossil fuels, for renewable

methanol to take o in the chemical sector and as a

renewable fuel, demand and supply have to be stimulated

by suitable policies, regulations and mandates. These

could include, among others, renewable fuel standards,

incentives, carbon taxes, cap-and-trade schemes, long-

term guaranteed price floors, contracts for dierence

(CfD), lower taxes on renewable fuels and feedstocks/

products, information campaigns and eco-labelling.

Life-cycle analyses (LCAs) and other benchmarks will

be needed to weigh up the benefits of each process,

material and fuel.

In the transition to fully renewable methanol production,

the co-production of green and conventional products

with proportionate credit should also be allowed. These

include, for example, LCM technologies where green

hydrogen and CO

2

are added to the process of methanol

production from natural gas.

This would allow for a gradual greening of the methanol

produced while keeping costs low. Once the technologies

(e.g. electrolyser, CO

2

capture) are scaled up and the

cost of renewable power low enough, the share of green

methanol, and credits, could increase.

INNOVATION OUTLOOK: 20

Box 1. How to facilitate the transition to renewable methanol:

Recommendations for industry and governments

1

Ensure systemic investment throughout the value chain, including

technology development, infrastructure and deployment. Methanol

can be utilised in existing internal combustion engines as well as in

more advanced powertrains and chemical production processes.

Conventional grey and blue methanol can be used today, with greater

substitution of green methanol over time. Economies of scale and

improved technologies for renewable methanol production will lead

to competitive pricing for multiple sectors, and must be supported

by targeted investment support in the form of direct subsidies and

loan guarantees for production CAPEX (electrolysers, CO

2

capture, and

synthesis equipment). Industry and government also need to partner

on major cost-lowering and risk-mitigation pilot projects and fuel

infrastructure deployment.

2

Create a level playing field through public policy to facilitate

sector-coupling. Drive investment in renewable electricity from the

power sector and biomass utilisation from the agriculture/forestry sector

that can be scaled up to reduce the OPEX production costs of renewable

methanol. Investment will also be needed in renewable/captured CO

2

through BECCS or DAC. The methanol produced can be used in the

transport and industrial sectors. Each sector may find a dierent pathway

to carbon neutrality, and public policy should encourage synergies by

sector-coupling.

3

Support market forces in the chemical sector, focusing on carbon

intensity in consumer products. Renewable methanol can be an essential

building block for hundreds of products that touch our daily lives,

contributing to a circular economy, benefiting from carbon footprinting

and premium pricing mechanisms.

4

Acknowledge how renewable methanol can contribute to carbon

neutrality in “green deals”, COVID-19 economic recovery packages

and hydrogen strategies. The criteria used to define support strategies for

carbon neutrality must follow inclusive frameworks that include low-carbon

liquid fuels and chemical feedstock such as renewable methanol.

5

Translate the political will for carbon reduction into regulatory

measures and support to facilitate long-term growth. Regulatory

measures for fuel standards/quotas should account for the carbon

intensity of the targeted market, facilitating pricing incentives to provide

stability for sustained growth and investment.

RENEWABLE METHANOL 21

6

Encourage international co-operation on trade strategies to

create jobs and foster competitive new industries for e-methanol in

both producing and consuming regions.

As an e-fuel and e-chemical,

e-methanol can be produced in regions with ample resources of renewable

electricity, using carbon as a carrier in the form of an easily transportable

liquid molecule. Investing in e-methanol production capacity in dierent

countries around the world will diversify energy and feedstock supply and

reduce political risks.

7

Institute policy instruments to ensure equitable tax treatment and

a long-term guaranteed price floor for renewable methanol and other

promising fuels. Fuel excise and other taxes should be based on energy

content and not volume (e.g. USD per kWh, not USD per litre). Energy

tax reductions can be provided for renewable fuels, including renewable

methanol – both bio-methanol and e-methanol. Taxation policy can “make

or break” alternative fuels. A meaningful production support system that

could motivate investment is a contract for dierence (CfD) scheme, in

which advanced renewable fuel production projects bid for, and the winners

are awarded, CfDs in so-called reverse auctions (lowest bid wins).

INNOVATION OUTLOOK: 22

Methanol (CH

3

OH) is a colourless water-soluble liquid

with a mild alcoholic odour. It freezes at -97.6°C, boils

at 64.6°C and has a density of 0.791kilograms (kg) per

cubic metre at 20°C. Methanol is an important organic

feedstock in the chemical industry, with worldwide

annual demand nearly doubling over the past decade to

reach about 98million tonnes (Mt) in 2019 (Figure 6 and

Figure 7), while global production capacity has reached

about 150 Mt (MI, 2020a; MMSA, 2020).

Since 1995, the average contract price for methanol in

Europe has been fluctuating roughly between USD200

and USD400 per tonne (t) when adjusted for inflation

(see Figure 8). Production costs are about USD100 to

USD250/t depending on the feedstock (natural gas or

coal) and the price of that feedstock.

1.1. Methanol as a raw material

Methanol occurs naturally in fruits, vegetables, fermented

food and beverages, the atmosphere and even in space.

Historically methanol was commonly referred to as

wood alcohol because it was first produced as a minor

by-product of charcoal manufacturing, by destructive

distillation of wood. In this process, onetonne of wood

generated only about 10–20litres (L) of methanol (along

with other products).

At the beginning of the 1830s, methanol produced in

this way was used for lighting, cooking and heating

purposes, but was later replaced in these applications

by cheaper fuels, especially kerosene. Interestingly,

up until the 1920s wood was the only source for

methanol. From that point on, industrial production

of methanol from coal was introduced followed by

production from natural gas starting in the 1940s.

This shift to fossil resources allowed for a dramatic

increase in methanol production capacity.

Fast-forward to 2019, of the almost 100 Mt of methanol

produced per year (125 billionL), more than 60% was used

to synthesise chemicals such as formaldehyde, acetic acid,

methyl methacrylate, and ethylene and propylene through

the methanol-to-olefin (MTO) route. These base chemicals

are then further processed to manufacture hundreds

of products that touch our daily lives, from paints and

plastics, to building materials and car parts.

Formaldehyde remains the largest-volume chemical

product derived from methanol and is mainly used to

prepare phenol-, urea- and melamine-formaldehyde

and polyacetal resins, as well as butanediol and

methylenebis(4-phenyl isocyanate) (MDI). MDI foam

is, for example, used as insulation in refrigerators,

in doors, and in motor car dashboards and fenders.

The formaldehyde resins are then predominantly

employed as adhesives in the wood industry in a wide

variety of applications, including the manufacture of

particle boards, plywood and other wood panels.

Among new uses of methanol, the MTO process, as an

alternative to the more traditional production of ethylene

and propylene through petrochemical routes, has seen

tremendous growth in the past 10 years in China for

the production of polyethylene and polypropylene.

From essentially no production through this route in

2010, MTO now accounts for about 25% of global

methanol consumption (MMSA, 2020).

Methanol has many other uses, including as a solvent,

antifreeze, windscreen washer fluid and for denitrification

at wastewater treatment plants (Olah, 2018).

1. CURRENT PRODUCTION AND

APPLICATIONS OF METHANOL

Figure 6. The feedstocks and applications of methanol

1

Sources: Chatterton (2019); Dolan (2020); MMSA (2020).

RENEWABLE METHANOL 23

FeedstockConversionDerivativesMarkets

Natural gas

~65%

Coal

~35%

Biomass & renewables

<1%

Other 5%

DME 3%

Biodiesel 3%

Gasoline blending

and combustion

MMA 2%

Acetic acid 8%

Methylamines 2%

MTBE 11%

Chloromethanes 2%

MTO 25%

Formaldehyde 25%

Methanol synthesis

Appliances

Automotive

Construction Electronics

Fuel Paint Pharma Marine

14%

Figure 7. Global methanol demand and production capacity (2001-2019)

1

Source: Based on data from MMSA (2020).

Figure 8. Historical methanol sale price (1995-2020)

1

Note: Western Europe contract average realised price, FOB Rotterdam.

Source: Based on data from MMSA (2020).

INNOVATION OUTLOOK: 24

Prices

Prices adjusted for inflation (in 2020 $)

RENEWABLE METHANOL 25

1.2. Methanol as a fuel

The use of methanol as a fuel, either by itself, in a blend with

gasoline, for the production of biodiesel, or in the form of

methyl tert-butyl ether (MTBE) and dimethyl ether (DME),

has also grown rapidly since the mid-2000s. Together

these fuel uses now represent about 31% of methanol

consumption. MTBE has been used as an oxygenated

anti-knock fuel additive in gasoline since the 1980s. While

MTBE has been banned in some countries such as the

UnitedStates because of groundwater contamination

issues, its use has been increasing in other regions

including Asia and Mexico. Biodiesel can be obtained by

reacting methanol with fats and oils. However, direct use

of methanol as a fuel has seen the largest growth; from

less than 1% in 2000, the share of methanol consumption

for that purpose has now increased to more than 14%.

Due to its high octane rating, methanol can be used as an

additive or substitute for gasoline in internal combustion

engines (ICEs). Methanol can also be used in modified

diesel engines (Bromberg and Cohn, 2009; Bromberg and

Cohn, 2010), and advanced hybrid and fuel cell vehicles.

Notably, methanol has only about half the volumetric

energy density of gasoline and diesel. If pure methanol

is used as a fuel, adjustments to the tank size have to be

made if a similar range is to be achieved. Direct methanol

fuel cells (DMFCs) can also convert the chemical energy

in methanol directly into electrical power at ambient

temperature (McGrath et al., 2004).

Because methanol does not produce soot, fumes or

odour, it is also widely used in cook stoves (over 5 Mt

in 2018 in China alone) (Dolan, 2020). DME, produced

from methanol by simple dehydration, is a gas that can

be liquefied at moderate pressure, much like liquefied

petroleum gas (LPG). DME as a diesel fuel substitute with

a high cetane rating and producing no soot emissions

(particulate matter [PM]) has also attracted much interest

(Semelsberger et al., 2006; Arcoumanis et al., 2008).

DME can also replace LPG in applications such as

heating and cooking. Up to 20% DME can be blended

with LPG with no or very limited modifications to

existing equipment. Methanol can also be used as a

fuel to produce heat and steam in industrial boilers,

and for electric power generation in gas turbines

(Temchin, 2003; Basu and Wainwright, 2001). More than

1000boiler units in China consumed 2 Mt of methanol

in 2018 (Dolan, 2020).

Methanol has historically been a candidate as an

alternative to conventional crude oil-based fuels. This

was initially the case at the time of crude oil supply

constraints in the 1970s and 1980s. Methanol (fossil) has

a high octane rating, and during the 1980s and 1990s was

widely tested both as a low blend component and as a

pure fuel in large test fleets in many countries, mainly

with the goal of reducing air pollution. This interest was

driven by the knowledge that methanol is relatively

cheap to produce from coal and natural gas, and that it

can be used with only minor modification to the existing

vehicle fleets and distribution infrastructure.

By the late 1990s, various technological advances were

achieving wide acceptance in the automobile industry:

direct fuel injection, three-way catalytic converters,

reformulated gasoline, etc. These reduced dramatically

the emission problems associated with gasoline-powered

vehicles, but decreased at the same time the benefits of

methanol-based fuels. Simultaneously oil prices remained

low meaning that despite being a technical success,

methanol was not a commercial success (Olah et al., 2018).

While the interest in methanol-powered vehicles diminished

in developed countries, China has recently been active in

promoting methanol as a transport fuel, largely to decrease

its dependence on imported fuel. Numerous Chinese

automotive manufacturers are oering methanol-powered

vehicles, including cars, vans, trucks and buses able to run

on M85 (85% methanol, 15% gasoline) and M100 (pure

methanol), as well as methanol/gasoline blends with lower

methanol content (SGS, 2020). Flexible-fuel vehicles able

to run on various mixtures of methanol and gasoline, or

so called GEM fuels (gasoline/ethanol/methanol), are also

available (IRENA, 2019a; Olah et al., 2018; Schröder et al.,

2020). These vehicles cost a similar amount to regular cars.

Methanol can also be used in diesel engines, either by

co-feeding with a small amount of diesel pilot fuel, the

addition of ignition improver (MD95), or the installation

of glow plugs. Use of engines specifically optimised for

methanol that allow for higher compression ratios are

also possible (Schröder et al., 2020). Examples of a fleet

of methanol-fuelled taxis and heavy-duty trucks can be

seen in Figure 9 and Figure 10. China currently consumes

4.8 Mt of methanol per year for road transport (Dolan,

2020). Methanol as a road fuel is also attracting growing

interest in other parts of the world, including Israel, India

and Europe, as well as for other applications such as

trains and heavy machinery (Landälv, 2017).

Figure 9. Fleet of M100 fuelled taxis in Guiyang City, Guizhou province, China

Figure 10. Geely M100 truck (2019) in China and M100 truck in Israel (2020).

Source: Geely (2020); DOR Group (2020).

INNOVATION OUTLOOK: 26

Source: Geely (2020).

Figure 11. Gumpert Nathalie, methanol-fuelled hybrid fuel cell supercar

Figure 12. Palcan hybrid methanol reformer/proton-exchange membrane fuel cell passenger bus in China

Source: Gumpert Aiways (2020).

Source: Palcan Energy Corp. (2020).

RENEWABLE METHANOL 27

While methanol can be used in conventional ICE vehicles,

it can also be a fuel for advanced hybrid and fuel cell

vehicles. In that case methanol is reformed on board a

vehicle to hydrogen, which is fed to a fuel cell to charge

batteries in an electric vehicle (EV) or provide direct

propulsion in a fuel cell vehicle (FCV).

The use of liquid methanol avoids the need for costly

on-board systems able to store and transfer hydrogen

gas safely under extreme pressure (350-700 bar) in

FCVs. To date, methanol is the only liquid fuel that has

been demonstrated on a practical scale in fuel cell-based

transport applications.

The potential for on-board methanol reformers to power

FCVs has been demonstrated in numerous prototypes

constructed and tested by various car companies in the

1990s and 2000s, including Ford, General Motors, Honda,

Mazda, Mitsubishi, Nissan and Toyota (Olah et al., 2018).

In the early 2000s, Daimler introduced the NECAR 5

methanol-powered FCV, which in 2002 was the first FCV

to drive 5000kilometres (km) across the UnitedStates

from coast to coast (Daimler, 2020). Newer models of car

developed by Gumpert Aiways and Palcan Energy are

shown in Figure 11 and Figure 12 (Gumpert Aiways, 2020;

Palcan Energy Corp., 2020), expanding the range of EVs

or FCVs from 300km to over 1000km on a 3-minute

fill-up of methanol fuel.

Source: Stena Line (2020).

INNOVATION OUTLOOK: 28

Maritime transport is another sector that has shown

a growing interest in methanol. Currently more than

20 large ships in operation or on order are powered

by methanol (DNV GL, 2020). The shipping sector is

currently responsible for about 3% of all GHG emissions

and 9% of the GHG emissions associated with the

transport sector (IRENA, 2019b). Maritime shipping

represents 80-90% of international trade. The traditional

marine fuel used in ships is diesel bunker fuel, which is

relatively high in sulphur.

Even with new regulations set by the International

Maritime Organization to reduce the sulphur limit in

marine fuels from 3.5% to 0.5%, ships will still emit

large amounts of sulphur oxides (SO

x

), nitrogen

oxides (NO

x

) and PM into the atmosphere. In addition,

the proliferation of emission control areas (ECAs)

around the world, where emission limits are even

more stringent, requires the use of very low sulphur

fuel oil or marine gasoil, which are much more costly

than traditional heavy fuel oil. Because these are far

costlier to produce, the shipping industry has been

looking for alternatives, among which methanol is a

prime candidate.

Methanol, due to its production process, is sulphur-free

and when burned produces almost no PM (due to the

absence of carbon-carbon bonds) and low amounts of

NOx. A number of demonstration projects have been

looking into methanol for marine use (SGS, 2020).

Conversion of existing large and small ships to methanol

can be achieved easily at a moderate cost (Haraldson,

2015). For new builds, the investment cost is similar to

traditional ships.

Operating on methanol is already economical, especially

in ECAs. Examples of ships running on methanol are

shown in Figure 13 and Figure 14 (MI, 2020b). One

example is the Stena Germanica, a 50000 t, 32000

horsepower ferry operating between Germany and

Sweden that was retrofitted in less than three months to

run on methanol. The world’s largest methanol producer

and distributor, Methanex, also operates part of its fleet

of 50000 deadweight tonnage (DWT) chemical tankers

on dual-fuel MAN engines that can operate on diesel fuel

or methanol. Projects to introduce methanol-powered

fuel cell systems for ship propulsion are also under way

to improve eciency and emissions compared to ICEs

(Chatterton, 2019; Fastwater, 2020).

Figure 13. Methanol-powered Stena Germanica 50000 DWT ferry operating between Gothenburg and Kiel

RENEWABLE METHANOL 29

For aviation purposes methanol could be converted to

kerosene-type aviation fuels using a process similar to

the methanol-to-gasoline (MTG) process (Wang et al.,

2016; Wormslev and Broberg, 2020). Methanol itself is

not usually considered the most suitable fuel due to its

lower volumetric energy density compared to kerosene.

However, methanol could possibly be a candidate for

more advanced hybrid planes using a combination of fuel

cell and battery to run electric turbofans or turboprops

(Soloveichik, 2018). This type of hybrid electric aircraft

would have a number of advantages, including less

pollution, noise and emissions, with energy usage

reduction in the range of 40-60%. This would somewhat

counterbalance the lower energy density of methanol.

This type of hybrid aircraft would be especially suited to

regional flights. Methanol has already been introduced in

drone-type devices to considerably increase their range

and flight time. A tiny methanol combustion motor

charges the battery during flight, allowing for longer

flight times and instant refuelling. DMFCs have also been

successfully tested in unmanned aerial vehicles.

1.3. Storage, transport and

distribution of methanol

In most applications, a liquid energy storage medium

such as methanol would be preferable to a gaseous one.

In the transport sector in particular, a transition from

liquid fossil fuel-derived products (gasoline, diesel fuel,

kerosene etc.) to a renewable and sustainable liquid fuel

would be highly desirable. This would enable the use of

the existing infrastructure with only minor modifications

and at a low cost.

Methanol is already a globally available commodity with

extensive distribution and storage capacity in place.

Millions of tonnes of methanol are transported each month

Source: Waterfront Shipping/MOL (2020).

Figure 14. Ocean-going vessel powered by methanol

Figure 15. Methanol stations in China