AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition 1

AVMA Guidelines for the

Humane Slaughter

of Animals: 2016 Edition

Members of the Panel on Humane Slaughter

Steven Leary, DVM, DACLAM (Chair); Washington University, St Louis, Missouri

Wendy Underwood, DVM, DACVIM (Vice Chair); Eli Lilly and Company, Indianapolis,

Indiana

Raymond Anthony, PhD (Ethicist); University of Alaska Anchorage, Anchorage, Alaska

Douglas Corey, DVM (Equine Working Group); Associated Veterinary Medical Center,

Walla Walla, Washington

Temple Grandin, PhD (Physical Methods Working Group); Colorado State University,

Fort Collins, Colorado

Sharon Gwaltney-Brant, DVM, PhD, DABVT, DABT (Noninhaled Agents Working Group);

Veterinary Information Network, Mahomet, Illinois

Robert Meyer, DVM, DACVAA (Inhaled Agents Working Group); Mississippi State University,

Mississippi State, Mississippi

Joe Regenstein, PhD (Religious/Ritual Slaughter); Cornell University, Ithaca, New York

Jan Shearer, DVM, DACAW (Animals Farmed for Food and Fiber Working Group);

Iowa State University, Ames, Iowa

Stephen A. Smith, DVM, PhD (Aquatics Working Group); Virginia-Maryland College

of Veterinary Medicine, Blacksburg, Virginia

AVMA Staff Consultants

Gail C. Golab, PhD, DVM, MANZCVS, DACAW; Chief Advocacy and Public Policy Officer,

Advocacy and Public Policy SBU

Cia Johnson, DVM, MS; Director, Animal Welfare Division

2 AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition

Copyright © 2016 by the

American Veterinary Medical Association

1931 N. Meacham Road

Schaumburg, IL 60173

The AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition (“work”) is licensed under the Creative

Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License (http://creativecommons.org/licenses/

by-nc-nd/3.0/). You are free to share, copy, distribute, or transmit the work, provided that proper attribution to the

American Veterinary Medical Association is included (but not in any way that suggests that the AVMA endorses you

or your use of the work). You may not use this work for commercial purposes, including without limitation any sale

of the work, or modify or change the work in any way, or creative derivative works from it without the permission

from the American Veterinary Medical Association.

ISBN 978-1-882691-07-4

Version 2016.0.1

AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition 3

Part I—Introduction

I1.

Historical Context, Membership of the Panel,

and Notes on the Current Edition

................. 6

I2. Statement of Use ............................................... 6

I3. Evaluating Slaughter Methods .......................... 6

I4. Stress and Distress, Unconsciousness,

and Pain ............................................................ 7

I5. Animal Behavioral Considerations ................... 9

I6. Human Behavioral Considerations ................... 9

I7. References ....................................................... 10

Part II—History of Regulations, Industry

Guidance and Employee Training

in the United States

H1.

History of Regulation of Slaughter in the

United States ................................................... 11

H2. Enforcement of Humane Slaughter in the

United States ................................................... 11

H3. Auditing by Private Industry .......................12

H3.1 Clear Comments .................................... 12

H3.2 Video Auditing by Industry ................... 13

H4. References ....................................................... 13

Part III—Design of Facilities and

Slaughter Process

D1. Handling Procedures at Slaughter Plants for

Hoofstock ....................................................... 14

D1.1 Step 1—Arrival at the Plant ..................... 14

D1.1.1 Detection of Problems ......................... 14

D1.1.2 Corrective Action for Problems .......... 14

D1.2 Step 2—Unloading ................................... 14

D1.2.1 Detection of Problems ......................... 14

D1.2.2 Corrective Action for Problems .......... 15

D1.3 Step 3—Receiving .................................... 15

D1.3.1 Detection of Problems ......................... 15

D1.3.2 Corrective Actions for Problems ......... 15

D1.4 Step 4—Lairage ........................................ 15

D1.4.1 Detection of Problems ......................... 16

D1.4.2 Corrective Actions for Problems ......... 16

D1.5 Step 5—Handling System......................... 16

D1.5.1 Detection of Problems ......................... 16

D1.5.2 Corrective Actions for Handling

Problems ............................................ 17

D1.6 Step 6—Restraint ..................................... 18

D1.6.1 Detection of Problems ......................... 18

D1.7 Conditions That Cause Welfare

Problems .................................................. 19

D2. Handling

Procedures at Slaughter Plants

for Poultry ...................................................... 19

D2.1 Step 1—Electric Stunning, CAS, and

LAPS: Arrival and Lairage ........................ 19

D2.1.1 Detection of Problems ......................... 20

D2.1.2 Corrective Action for Problems .......... 20

D2.1.3 Handling and Stunning ....................... 20

D2.2 Step 2A—Birds Moved to Stunning Area

and Stunning With CAS and LAPS .......... 20

D2.2.1 CAS Live Unloading ............................ 20

D2.2.2 CAS or LAPS in Transport

Containers .......................................... 20

D2.2.3 Types of CAS and LAPS Chamber

Equipment .......................................... 20

Anesthetized on the Truck .................. 20

Drawers Moved Through a Tunnel ..... 20

LAPS System ....................................... 20

D2.2.4 Detection of Problems With CAS or

LAPS of Poultry .................................. 20

D2.2.5 Correction of Problems With CAS or

LAPS ................................................... 21

D2.3 Step 3A—Removal of Birds From CAS or

LAPS Chamber ......................................... 21

D2.4 Step 2B—Birds Moved to Stunning Area

for Electric Stunning ................................ 21

D2.4.1 Detection of Problems During

Unloading and Shackling for Electric

Stunning .............................................. 21

D2.4.2 Correction of Problems During

Unloading and Shackling For Electric

Stunning ............................................. 21

D2.5 Step 3B—Electric Stunning ...................... 21

D2.5.1 Detection of Problems During

Electric Stunning of Poultry ................ 21

D2.5.2 Correction of Problems With Electric

Stunning ............................................. 21

D3. References

..........................................................

22

Part IV—Techniques

T1.

Atmospheric Methods ..................................... 24

T1.1 Controlled Atmosphere .........................24

T1.1.1 CAS Design .......................................... 25

Detection of Problems ......................... 26

Corrective Action for Problems ............ 26

T1.1.2 Conclusions ......................................... 26

T1.2 Low Atmospheric Pressure ....................... 26

T1.2.1 Conclusions ......................................... 27

T2. Physical Methods ........................................ 28

T2.1 Concussive ............................................. 28

T2.1.1 Penetrating Captive Bolt Guns .......... 28

General Recommendations ............... 28

Detection of Problems ....................... 28

Corrective Action for Problems ......... 28

T2.1.2 Nonpenetrating Captive Bolt Guns ... 29

Detection of Problems ....................... 29

Corrective Action for Problems ......... 29

T2.1.3 Gunshot ............................................ 29

Basic Principles of Firearms .............. 29

Muzzle Energy Requirements ............ 30

Bullet Selection .................................. 30

Firearm Safety ................................... 31

Detection of Problems ....................... 31

Corrective Action for Problems ......... 31

Anatomic Landmarks for Use of the

Penetrating Captive Bolt and Gunshot ...32

CONTENTS

4 AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition

T2.2 Electric...................................................... 33

T2.2.1 Principles ............................................. 34

T2.2.2 Methods ............................................... 35

T2.2.3 Signs of Effective Stunning .................. 35

T2.2.4 General Recommendations ................. 36

Meat Quality ........................................ 36

Cattle ................................................... 36

Pigs and Small Ruminants ................... 36

Poultry ................................................. 37

T2.2.5 Detection of Problems ......................... 38

T2.2.6 Corrective Action for Problems ........... 38

T2.3 Other Physical Methods ........................... 39

T2.3.1 Decapitation ........................................ 39

T2.3.2 Cervical Dislocation ............................ 39

T3. References ....................................................... 40

Part V—Unique Species Issues

U1.

Additional Considerations: Bovine ................. 45

U1.1 Bulls .......................................................45

U1.2 Cull Cows................................................. 45

U1.3 Nonambulatory Cattle ............................. 45

U1.3.1 Downer Cow Syndrome ...................... 46

U1.3.2 The Prevention of Nonambulatory

Cattle and Downer Cow Syndrome .... 46

U1.4 Bob Veal .................................................... 46

U1.5 Fetal Effects .............................................. 47

U2. Additional Considerations: Swine .................. 47

U2.1 Nonambulatory Swine ............................. 47

U2.1.1 Preventing Nonambulatory Swine ...... 48

U3. Handling and Slaughter of Rabbits .................... 48

U3.1 Handling Procedures for Rabbits ............. 48

U4. Slaughter of Food Fish Intended for Human

Consumption ................................................. 50

U4.1 General Considerations ............................ 50

U4.2 Preparation and Environment for Food

Fish Slaughter ............................................ 50

U4.3 Methods of Slaughter for Food Fish ........ 50

Carbon Dioxide........................................ 51

Captive Bolt (Most Commonly

Nonpenetrating; One Step) ...................... 51

Gunshot .................................................... 51

Pithing ...................................................... 51

Manually Applied Blunt Force Trauma

(Cranial Concussion) Followed by

Secondary Kill Step ................................... 51

Decapitation Followed by Secondary

Kill Step ..................................................... 52

Cervical Transection Using a Knife or

Other Sharp Instrument Inserted Caudal

to the Skull to Sever the Spinal Cord and

Cervical Vertebrae, Followed by

Secondary Kill Step ................................... 52

Electrocution ............................................. 52

Exsanguination as a Secondary Kill Step .... 52

Rapid Chilling (Hypothermic Shock;

One Step or Two Step) .............................. 52

U4.4 Conclusions ............................................. 52

U5. Handling and Slaughter of Ratites ..................... 52

U6. Handling and Slaughter of Alligators ................. 54

U7. References ........................................................... 54

Part VI—Design of Facilities and Slaughter

Process for Religious Slaughter

R1. Handling Procedures at Slaughter Plants for

Hoofstock ........................................................ 59

R1.1 Step 1—Arrival at the Plant ...................... 59

R1.2 Step 2—Unloading ................................... 59

R1.3 Step 3—Receiving..................................... 59

R1.4 Step 4—Lairage ........................................ 59

R1.5 Step 5—Handling System ......................... 59

R1.6 Step 6—Restraint ...................................... 59

R1.6.1 Detection of Problems ......................... 59

R1.6.2 Corrective Action for Problems

With Restraint .................................... 59

R1.7 Step 7—Performing the Throat Cut ......... 60

R1.7.1 Detection of Problems ......................... 61

R1.7.2 Painfulness of the Cut ......................... 61

R1.7.3 Time to Lose Consciousness ............... 61

R1.7.4 Aspiration of Blood ............................. 62

R1.7.5 Corrective Action for Problems ........... 62

R2. Auditing Religious Slaughter to Improve

Animal Welfare for Both Kosher and Halal

Slaughter of Cattle, Sheep, or Goats ............... 62

R3. Auditing Religious Slaughter to Improve

Animal Welfare for Both Kosher and Halal

Slaughter of Chickens, Turkeys, and Other

Poultry ............................................................ 63

R4. The Importance of Measurement .................... 63

R5. References ....................................................... 63

CONTENTS

AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition 5

Introduction

In 1963, the AVMA convened the first POE to pro-

vide guidance for veterinarians who perform or oversee

the euthanasia of animals. In 2011, the AVMA POE de-

termined there was a need to address and evaluate the

methods and agents that veterinarians may encounter

when animals are killed under conditions where meet-

ing the POE definition of euthanasia may not be pos-

sible. The guidance contained within this document

relates to the humane slaughter of animals intended for

use as food.

The content of the AVMA Guidelines for the Hu-

mane Slaughter of Animals (Guidelines) reflects the

AVMA’s on-going commitment to ensure that the treat-

ment of animals during every stage of life, including

during the induction of death, is as humane and re-

spectful as possible. While much remains to be learned

about animal pain and consciousness and new evidence

and technological innovation may lead to the adop-

tion of more humane techniques, this edition of the

Guidelines relies on the scientific evidence currently

available. In interpreting that evidence, the POHS was

committed to ensuring, to the best of its ability, that no

unnecessary pain or distress is inflicted on conscious

animals used for food prior to or during slaughter.

These Guidelines are part of a triad of documents on

humane killing—the other two being the AVMA Guide-

lines for the Euthanasia of Animals: 2013 Edition

1

and

the anticipated AVMA Guidelines for the Depopulation

of Animals.

2

The latter half of the 20th century and the first

two decades of the 21st century have seen the prolif-

eration of the scientific study of animals’ welfare to ad-

dress public concerns regarding the ethical treatment of

animals, especially those used in biomedical research

and raised and slaughtered for food.

3

The treatment of

animals is an important subject for public debate and

discussion, especially in light of growing adoption of

intensive forms of agricultural and aquacultural pro-

duction and increased interest in food quality, safety,

and quantity. Additionally, the scientific community

and the public share an interest in the possibility of

substantial cognitive, emotional, psychological, and

social abilities in nonhuman species. Attention to ques-

tions about the moral status of animals has meant that

veterinarians and others have had to demonstrate to

the public due diligence in their professional roles. Ap-

proximately 10% to15% of veterinarians are involved in

promoting the health and welfare of animals that will

eventually become food.

4

Commensurate with increased attention to how

their meat is processed and prepared, the public has

shown greater interest in the quality of life provided for

animals raised for food, including the environments in

which they are raised, how they are handled and man-

aged, and how they are slaughtered and processed for

human consumption. Contemporary slaughter practic-

AVMA Guidelines for the Humane Slaughter

of Animals: 2016 Edition

es are considerably improved over those of times past,

but additional innovation is needed and possible. Care-

ful attention to empirical issues is essential when as-

sessing farming practices and slaughter methods from

an ethical perspective.

The POHS has worked diligently to identify and ap-

ply the best research and empirical information avail-

able to promote the humane slaughter of the species of

animals addressed in this document. Mechanical and

physical methods, electrical methods, and controlled

atmosphere and gas methods are used to bring about

unconsciousness through physical disruption, hypoxia,

neuronal depression, or epileptiform brain activity in

food animals at slaughter. A range of factors, includ-

ing expanded knowledge about the cognitive capabili-

ties of animals, technological and economic conditions,

and social and ethical considerations affecting the sus-

tainability of animal agriculture, the care and manage-

ment of food animals, and food security, will influence

the recommendations in this and future editions of this

document. The AVMA encourages its members to utilize

their scientific knowledge and practical expertise to pro-

tect and promote the health and welfare of all animals.

The Guidelines do not venture into the morality

of killing animals for food. The POHS’s focus was on

what should happen to animals when slaughter is their

ultimate fate. When animals are designated for slaugh-

ter, they should be treated with respect and handled ap-

propriately, and the slaughter process should limit the

harms experienced by these animals. Humane slaughter

methods and agents are designed to bring about rapid

loss of consciousness and, ultimately, a complete loss of

brain function in animals destined for use as food. This

means minimizing (and, where possible, eliminating)

anxiety, pain, and distress associated with terminating

the lives of the following species of animals: hoofstock

(cattle, bison, horses and mules, sheep, goats, swine,

deer, elk), poultry (chickens, turkey, pheasants, ratites,

geese, ducks), fish, alligators, and rabbits. The process

of termination, as defined here, encompasses the period

from which a farmed animal designated for human food

consumption is off-loaded at a slaughter facility until it

is verified to be unconscious and, ultimately, dead and

ready for entry into the food chain.

Abbreviations

CAS Controlled atmosphere stunning

CFIA Canadian Food Inspection Agency

EEG Electroencephalography

FSIS Food Safety and Inspection Service

HMSA Humane Methods of Livestock Slaughter Act

LAPS Low-atmospheric-pressure stunning

LOP Loss of position or posture

LORR Loss of the righting reflex

OIE World Organisation for Animal Health

POE Panel on Euthanasia

POHS Panel on Humane Slaughter

SEP Somatosensory evoked potential

6 AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition

While the POHS is motivated primarily by the sci-

ence and ethics of animals’ welfare, members of the

Panel are also sensitive to adjacent concerns related to

the slaughter of animals. These include, nonexhaus-

tively, public health and safety, food safety and quality,

environmental and economic sustainability, production

adequacy and sustainability, occupational health and

impact on the labor force, international animal welfare

and trade standards, and religious and cultural expecta-

tions. These issues, however, are not the main focus of

this document. The veterinarian’s primary responsibil-

ity of doing what is in the animal’s best interest under

the circumstances (ie, using the most appropriate and

painless slaughter method possible and considering the

context of animals’ welfare in the United States) should

not be displaced by quality, quantity, or economic

arguments.

The AVMA Guidelines for the Euthanasia of Ani-

mals: 2013 Edition should be consulted if individual

animals are deemed inappropriate for the food chain.

The anticipated AVMA Guidelines for the Depopula-

tion of Animals should be consulted in the event that

a zoonotic disease, a foreign animal disease, a natural

disaster, or another concern for population health is the

issue.

I1 Historical Context, Membership of the Panel,

and Notes on the Current Edition

The membership of the POHS included consid-

erable breadth and depth of expertise in the affected

species and environments in which humane slaughter

is performed. These Guidelines represent more than 2

years’ worth of deliberation by more than 15 individu-

als, including veterinarians, animal scientists, and an

animal ethicist. In reviewing the literature and formu-

lating their recommendations, members of the Panel

tapped the expertise ofcolleagues in pertinent fields

and also received invaluable input from AVMA mem-

bers and others during a designated comment period.

The scientific integrity and practical utility of these

Guidelines are a direct result of AVMA members’ input,

as well as suggestions from others concerned about the

welfare of animals used for food and, specifically, tech-

niques used for slaughter.

In these Guidelines, methods, techniques, and

agents used to slaughter animals humanely are dis-

cussed. Illustrations, diagrams, and tables have been

included to assist veterinarians in applying their pro-

fessional judgment. Species-specific information is pro-

vided for terrestrial and aquatic species that are com-

monly farmed and slaughtered for food.

The Guidelines acknowledge that the slaughter of

animals used for food is a process involving more than

what happens to the animal at the time of its death,

and that veterinary responsibilities associated with

slaughter are not limited to the moment or procedure

of killing the animal. In addition to delineating appro-

priate methods and agents for slaughter, the Guidelines

recognize the importance of considering and applying

good preslaughter and animal-handling practices. In-

formation about confirmation of death has also been in-

cluded. While some slaughter methods may be utilized

in euthanasia and depopulation, recommendations

related to euthanasia and depopulation are addressed

specifically in other documents created by their respec-

tive Panels.

I2 Statement of Use

The POHS has developed these Guidelines for use

by members of the veterinary profession who have an

interest in the humane slaughter of hoofstock, poul-

try, rabbits, alligators, and fish. The POHS’s objective

in creating the Guidelines is to provide guidance for

veterinarians about how to prevent pain and distress in

animals that have been designated for slaughter. While

we believe the Guidelines contains valuable informa-

tion that can help assure and improve animals’ welfare

during slaughter, it is important to understand that the

HMSA

5

and its regulations provide final federal author-

ity regarding slaughter practices in the United States.

These Guidelines do not address methods and

techniques involved in the termination of animals

hunted for food (subsistence or otherwise) or animals

raised primarily for their fur or fiber.

Veterinarians experienced in the species of inter-

est should be consulted when choosing a method of

slaughter, especially for those species not covered by

the HMSA (eg, poultry, fish). To minimize distress to

animals and to prevent human injury during slaughter,

methods and agents should be selected that maintain

calm animals. Attention to species-specific anatomy,

physiology, natural history, husbandry, and behavior

will assist in understanding how various methods and

agents may impact an animal during slaughter.

Veterinarians performing or overseeing humane

slaughter should assess the potential for species-specif-

ic distress secondary to physical discomfort, abnormal

social settings, novel physical surroundings, phero-

mones or odors from previously slaughtered animals,

the presence of humans, and other factors. In evaluat-

ing slaughter methods, veterinarians should also con-

sider human safety, availability of trained personnel,

potential infectious disease concerns, conservation or

other animal population objectives, regulatory over-

sight, availability of proper equipment and facilities,

options for carcass disposal, and the potential for sec-

ondary toxicity. Human safety is of utmost importance,

and appropriate safety equipment, protocols, and ex-

pertise must be available before animals are handled.

Advance preparation of personnel must include train-

ing in the stipulated slaughter methods and assurance

of understanding of and sensitivity toward animal wel-

fare indices. Special attention should be paid to unique

species attributes that may affect how animals are

handled, stunned, and rendered unconscious. Once an

animal has been slaughtered, death must be carefully

verified. Slaughter must always be performed in ac-

cord with applicable federal, state, and local laws and

regulations.

I3 Evaluating Slaughter Methods

Some methods of slaughter require physical han-

dling of the animal. The amount of control and the kind

of restraint required will be determined not only by the

species, breed, and size of animal involved, but also

by the level of excitement and prior handling experi-

AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition 7

ence of the animal and competence of the personnel

performing slaughter. Proper handling is vital to mini-

mizing pain and distress in animals and to ensuring the

safety of the person performing slaughter, any bystand-

ers, and other animals that are nearby.

Selection of the most appropriate method of hu-

mane slaughter in any situation will depend on the spe-

cies and number of animals involved, available means

of animal restraint, skill of personnel, and other con-

siderations. Personnel who slaughter animals for food

must demonstrate proficiency in the use of the tech-

nique in a closely supervised environment. Each facility

where slaughter is performed is responsible for appro-

priately training its personnel. Experience in the hu-

mane restraint of the species of animal is critical. Train-

ing should include familiarity with the normal behavior

of the species, an appreciation of how behavior affects

handling and restraint, and an understanding of the

mechanism by which the selected technique induces

loss of consciousness and death.

Death must be verified before invasive dressing be-

gins (or before disposal of the animal for meat-quality

reasons). Personnel must be sufficiently trained to rec-

ognize the cessation of vital signs of different animal

species.

The POHS gave serious consideration to the fol-

lowing criteria in their assessment of the appropriate-

ness of slaughter methods: 1) ability to induce loss

of consciousness followed by death with a minimum

of pain or distress, 2) time required to induce loss of

consciousness and the behavior of the animal during

that time, especially for religious slaughter, 3) reliabil-

ity and irreversibility of the methods resulting in death

of the animal, 4) safety of personnel, 5) compatibility

with intended animal use and purpose (ie, meat con-

sumption), 6) potential psychological or emotional im-

pacts on personnel, 7) ability to maintain equipment

in proper working order, and 8) legal and religious re-

quirements.

These Guidelines do not address every contin-

gency. In circumstances that are not clearly covered by

these Guidelines, a veterinarian experienced with the

species in question should apply professional judgment

and knowledge of clinically acceptable techniques in

selecting a humane method of slaughter or euthanasia

(if required) to end an animal’s life in the best way pos-

sible. The veterinarian should consider whether 1) the

procedure results in the best outcome for the animal,

2) their actions conform to acceptable standards of

veterinary practice and are consistent with applicable

federal, state, and local regulations, and 3) the choice

of slaughter or euthanasia technique is consistent with

her or his professional obligations and ethical commit-

ment to society.

I4 Stress and Distress, Unconsciousness, and Pain

These Guidelines acknowledge that a humane ap-

proach to the slaughter of any animal is warranted,

justifiable, and expected by society. The overall goal

should be to minimize or eliminate anxiety, pain, and

distress prior to loss of consciousness. Therefore, both

the induction of unconsciousness and handling prior

to slaughter must be considered. Criteria for determin-

ing the humaneness of a particular slaughter method

can be established only after the mechanisms of pain,

distress, and consciousness are understood. For a more

extensive review of these issues, the reader is directed

to the AVMA Guidelines for the Euthanasia of Animals:

2013 Edition.

Humane slaughter methods produce unconscious-

ness through four basic mechanisms: 1) physical dis-

ruption of brain activity (eg, blunt cranial trauma,

penetrating captive bolt, gunshot), 2) hypoxia (eg,

controlled low atmospheric pressure for poultry, N

2

, Ar,

exsanguination), 3) direct depression of neurons nec-

essary for life function (eg, CO

2

), or 4) epilepitiform

brain activity (eg, electric stunning). Because loss of

consciousness resulting from these mechanisms can

occur at different rates, the suitability of a particular

agent or method will depend on the species and wheth-

er an animal experiences pain or distress prior to loss of

consciousness.

Distress during slaughter may be created by the

method itself or by the conditions under which the

method is applied and may manifest behaviorally (eg,

overt escape behaviors, approach-avoidance preferenc-

es [aversion]) or physiologically (eg, changes in heart

rate, sympathetic nervous system activity, hypothalam-

ic-pituitary axis activity). Stress and the resulting re-

sponses have been divided into three phases.

6

Eustress

results when harmless stimuli initiate adaptive respons-

es that are beneficial to the animal. Neutral stress results

when the animal’s response to stimuli causes neither

harmful nor beneficial effects to the animal. Distress

results when an animal’s response to stimuli interferes

with its well-being and comfort.

7

Although sympathetic

nervous system and hypothalamic-pituitary axis activa-

tion are well accepted as stress response markers, these

systems are activated in response to both physical and

psychological stressors and are not necessarily associ-

ated with higher-order CNS processing and conscious

experience by the animal. Furthermore, use of sympa-

thetic nervous system and hypothalamic-pituitary axis

activation to assess distress during application of CAS

methods is complicated by continued exposure during

the period between loss of consciousness and death.

1

Ideally, humane stunning and slaughter methods

result in rapid loss of consciousness and the associated

loss of brain function. The perception of pain is defined

as a conscious experience

8

and requires nerve impuls-

es from peripheral nociceptors to reach a functioning

conscious cerebral cortex and the associated subcorti-

cal brain structures. The International Association for

the Study of Pain describes pain as “an unpleasant sen-

sory and emotional experience associated with actual

or potential tissue damage, or described in terms of

such damage. Activity induced in the nociceptor and

nociceptive pathways by a noxious stimulus is not pain,

which is always a psychological state, even though we

may well appreciate that pain most often has a proxi-

mate physical cause.”

9

Pain is therefore subjective in

the sense that individuals can differ in their perceptions

of pain intensity as well as in their physical and behav-

ioral responses to it.

Distress during administration of CO, CO

2

, and

the inert gases N

2

and Ar has been evaluated by use

8 AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition

of behavioral assessment and aversion testing and re-

viewed in the context of euthanasia.

1

It is important to

understand that aversion is a measure of preference,

and while aversion does not necessarily imply that an

experience is painful, forcing animals into aversive situ-

ations creates distress. The conditions of exposure used

for aversion studies, however, may differ from those

used for stunning or slaughter. One of the character-

istics of anesthesia in humans is the feeling that one

is having an out-of-body experience, suggesting a dis-

connection between one’s sense of self and one’s aware-

ness of time and space.

10

Although we cannot know for

certain the subjective experiences of animals, one can

speculate similar feelings of disorientation may contrib-

ute to the observed signs of distress with inhaled meth-

ods. In addition, agents identified as being less aversive

(eg, Ar or N

2

gas mixtures) can still produce overt signs

of behavioral distress (eg, open-mouth breathing) for

extended periods of time prior to loss of consciousness

under certain conditions of administration (eg, gradual

displacement).

11

Unconsciousness, defined as loss of individual

awareness, occurs when the brain’s ability to integrate

information is blocked or disrupted. In animals, loss

of consciousness is functionally defined by LORR, also

called LOP.

8,12,13

This definition is quite useful because

it is an easily observable, integrated whole-animal re-

sponse. Although any physical movement occurring

during anesthesia, euthanasia, slaughter, or depopula-

tion is often interpreted as evidence of consciousness,

cross-species data from the anesthesia literature sug-

gest that both memory formation and awareness are

abolished early in the overall process relative to loss of

reflex muscle activity.

8

Thus, vocalization and nonpur-

poseful movement observed after LORR or LOP with

properly applied CAS methods are not necessarily signs

of conscious perception by the animal. While general-

ized seizures may be observed following effective CAS

methods, these generally follow loss of consciousness;

indeed, anesthesia, coma, and generalized seizures all

represent a loss of consciousness where both arousal

and awareness in humans are low or absent.

14

Loss of

consciousness should always precede loss of muscle

movement.

Although measurements of brain electrical func-

tion have been used to quantify the unconscious state,

EEG data cannot provide definitive answers as to onset

of unconsciousness even when state-of-the-art equip-

ment is used. At some level between behavioral un-

responsiveness and the induction of a flat EEG (indi-

cating the cessation of the brain’s electric activity and

brain death), consciousness vanishes. However, current

EEG-based brain function monitors are limited in their

ability to directly indicate unconsciousness, especially

around the transition point.

15,16

Also, it is not always

clear which EEG patterns are indicators of activation by

stress or pain.

17

Reduction in alpha-to-delta brain wave

ratios coincides with LOP in chickens,

18,19

reinforcing

the usefulness of LOP or LORR as an easily observable

proxy for loss of animal consciousness.

Physical methods that destroy or render nonfunc-

tional the brain regions responsible for cortical inte-

gration (eg, gunshot, captive bolt, cerebral induction

of epileptiform activity in the brain [eg, electric stun-

ning], blunt force cranial trauma, maceration) produce

instantaneous unconsciousness. When physical meth-

ods directly destroy the brain, signs of unconscious-

ness include immediate collapse (LORR or LOP) and

a several-second period of tetanic spasm, followed by

slow hind limb movements of increasing frequency.

20,21

In cattle, however, there is species variability in this re-

sponse. The corneal reflex will also be absent.

22

Signs

of effective electric stunning that induces both epilepti-

form activity in the brain and cardiac arrest are LORR,

loss of menace reflex and tracking of moving objects,

extension of the limbs, opisthotonos, downward rota-

tion of the eyeballs, and tonic spasm changing to clonic

spasm, with eventual muscle flaccidity.

21,23

Physical

methods are inexpensive, humane, and minimize pain

if performed properly, and leave no drug residues in

the carcass. Furthermore, animals presumably experi-

ence less fear and anxiety with methods that require

little preparatory handling. However, physical methods

usually require a more direct association of the opera-

tor with the animals, which can be offensive to, and

upsetting for, the operator. Physical methods must be

skillfully executed to ensure a quick and humane death

because failure to do so can cause significant stress, dis-

tress, and pain. Physical disruption methods are usu-

ally followed by exsanguination to ensure death and

improve meat quality. Exsanguination is also a method

of inducing hypoxia, albeit indirectly.

Controlled atmosphere stunning methods also

depress the cerebral cortical neural system, producing

loss of consciousness accompanied by LORR or LOP.

Purposeful escape behaviors should not be observed

during the transition to unconsciousness. Depending

on the speed of onset of unconsciousness, signs as-

sociated with release of conscious inhibition of motor

activity, (such as vocalization or uncoordinated muscle

contraction) may be observed at LORR or LOP. Signs

of an effective stun when the animal is in deep levels

of anesthesia include LORR or LOP, loss of eye blink

(menace reflex) and corneal reflex, and muscle flaccid-

ity.

24

As with physical disruption methods, CAS meth-

ods are usually followed by exsanguination to ensure

death and improve meat quality.

Decapitation and cervical dislocation are physical

methods of slaughter that require separate comment.

The interpretation of brain electric activity, which can

persist for up to 30 seconds following these meth-

ods,

25–27

has been controversial.

28

As indicated previ-

ously, EEG cannot provide definitive answers as to the

exact onset of unconsciousness. Other studies

26,27,29–31

indicate such activity does not imply the ability to per-

ceive pain and conclude that loss of consciousness de-

velops rapidly.

In summary, the cerebral cortex or equivalent

structures and associated subcortical structures must

be functional for pain to be perceived. If the cerebral

cortex is nonfunctional because of physical disruption,

hypoxia, generalized epileptic seizure, or neuronal de-

pression, pain cannot be experienced. Motor activities

occurring following LORR or LOP, although potentially

distressing to observers, are not perceived by an uncon-

scious animal as pain or distress. Reflexive kicking in

AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition 9

unconscious animals may be mistaken for conscious

activity and can occur even after decapitation, as neu-

rologic circuits involved with walking are located in

the spinal cord.

32

Given that we are limited to applying

slaughter methods based on these four basic mecha-

nisms, efforts should be directed toward educating in-

dividuals involved in the slaughter process, achieving

technical proficiency, and refining the application of

existing methods, including handling conditions prior

to slaughter.

I5 Animal Behavioral Considerations

These Guidelines are concerned with minimizing

animal distress, including negative affective or experi-

entially based states such as fear, aversion, anxiety, and

apprehension, during the slaughter process. They are

also meant to promote human well being and safety as

regards the repeated termination of animals’ lives. Vet-

erinarians and other employees conducting slaughter

should familiarize themselves with preslaughter pro-

tocols and be attentive to species and individual vari-

ability to mitigate distress in both food animals and

human handlers. The method for inducing uncon-

sciousness and the handling and restraint methods as-

sociated with it must be evaluated as an entire system.

33

Physical methods require more handling and restraint

of individual animals, compared with CAS, but they in-

duce instantaneous unconsciousness. Controlled atmo-

sphere stunning does not induce instantaneous uncon-

sciousness, but possible distress during handling may

be reduced. There may be a tradeoff between possible

distress during a longer time to induce unconscious-

ness and the benefits of reduced handling of individual

animals.

Intentional violations of the HMSA must not be tol-

erated. Unintentional pain and/or distress at slaughter

caused by mistakes by personnel or poorly designed fa-

cilities must be addressed promptly. At all stages of the

process of termination, animals should be treated with

respect, and compromises to animal welfare should be

treated as unacceptable if not unlawful. Practitioners

and stockpersons should ensure the following:

• No conscious animal is dragged, shackled, hoisted,

or cut inappropriately. Before invasive dressing (eg,

skinning, leg removal, scalding) begins, all signs

of brainstem function, such as the corneal reflex,

must be abolished.

• Excessive force or frequent use of electric prods

to move animals off trucks, up and down ramps,

or into slaughter facilities or restraint devices is

avoided. Animals should not be forced to move

faster than a normal walking speed. Handlers

should move animals quietly, without using driv-

ing devices that would cause unnecessary pain

and/or distress.

• Nonambulatory or disabled animals are isolated

and moved with suitable equipment (eg, bucket of

a loader, sled) and provided appropriate veterinary

attention. Conscious nonambulatory animals must

never be dragged.

• Terrestrial animals are provided with access to wa-

ter in the lairage pens. Animals should have suf-

ficient room to move in accordance with state, fed-

eral, and local statues, and pens should have room

for all the animals to lie down.

• Slaughter facilities and equipment are well main-

tained to minimize injury or pain to the animals

and employees.

• The induction of unconsciousness (eg, stunning)

causes minimal distress to the animal.

• All personnel are trained in both the application

of stunning methods and behavioral principles of

animal handling.

I6 Human Behavioral Considerations

Food animal veterinarians may be asked to bridge

the physical and psychological divide between current

practices used in the care and management of food ani-

mals and consumers by communicating the realities of

conventional food production. They may also be asked

to provide an ethical accounting and monitoring of ani-

mals’ welfare on the farm, in feedlots, in aqua-farms,

and at slaughterhouses to the public in a transparent

fashion. Food animal veterinarians are encouraged to

increase their awareness of slaughter methods and to

enhance understanding of the science behind the meth-

ods currently used with a view toward the day-to-day

complexities of managing food animals and the range

of challenges facing our contemporary food animal sec-

tor. Likewise, industry agents, veterinarians, caretak-

ers, and others engaged with the slaughter of animals

for food should be encouraged to understand the di-

versity of public concerns and trending societal values

and expectations related to how animals are farmed and

slaughtered for food.

The humane slaughter of animals is a learned skill

that requires training, respect, and self-awareness.

Personnel performing humane slaughter must be

technically proficient. Periodic professional continu-

ing education on the latest methods, techniques, and

equipment available for slaughter is highly encouraged.

Personnel must also possess a temperament that does

not bolster brutality. Self-awareness when it comes to

processing animals for food will help to mitigate com-

passion fatigue and callousness.

The slaughter of individual livestock or poultry by

farm workers who are also responsible for providing

husbandry can substantially impact emotions.

34

There-

fore, appropriate oversight of the psychological well-

being of slaughter employees is paramount to mitigate

guilt, distress, sadness, fatigue, alienation, anxiety, and

behaviors that lack consideration of others or may lead

to harming themselves, animals, or other people. Peo-

ple may have individual differences in how they psy-

chologically react to the job of killing animals.

35

It is

difficult to care about animals when they have to be

killed. This is called the “caring-killing paradox.”

36

Veterinarians and staff who are regularly exposed

to the slaughter process should also be monitored for

emotional burnout, psychological distress, or compas-

sion fatigue and be encouraged to seek appropriate

psychological counseling.

37,38

While integrating good

animal welfare in the food chain, some food animal

practitioners may be torn among serving the best in-

terest of the farmed animal, the human client (indi-

vidual), personal professional interests, and societal

10 AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition

concerns about improving quality of life for animals

and ensuring the availability of safe and affordable ani-

mal protein. More studies on both the impact of ani-

mal slaughter on the personnel performing it and on

attitudes toward the consumption of animals for food

among the general public will go a long way toward

promoting healthier and more respectful human–food

animal relationships.

I7 References

1. AVMA. AVMA guidelines for the euthanasia of animals:

2013 edition. Available at: www.avma.org/KB/Policies/Pages/

Euthanasia-Guidelines.aspx. Accessed Jul 2, 2013.

2. AVMA. AVMA guidelines for the depopulation of animals. Scha-

umburg, Ill: AVMA, 2017;in preparation.

3. Fraser D. Understanding animal welfare: the science in its cultural

context. Ames, Iowa: Wiley-Blackwell, 2008.

4. AVMA website. AVMA market research statistics: AVMA mem-

bership 2008. Available at: www.avma.org/KB/Resources/

Statistics/Pages/Market-research-statistics-AVMA-member-

ship-2008.aspx. Accessed Jul 19, 2014.

5. Humane Methods of Livestock Slaughter Act, 1958. CP.L. 85–

765; 7 U.S.C. 1901 et seg.

6. Breazile JE. Physiologic basis and consequences of distress in

animals. J Am Vet Med Assoc 1987;191:1212–1215.

7. McMillan FD. Comfort as the primary goal in veterinary medi-

cal practice. J Am Vet Med Assoc 1998;212:1370–1374.

8. Antognini JF, Barter L, Carstens E. Overview: movement as an

index of anesthetic depth in humans and experimental animals.

Comp Med 2005;55:413–418.

9. International Association for the Study of Pain. Pain terms.

Available at: www.iasp-pain.org/Taxonomy. Accessed Feb 7,

2011.

10. Alkire MT. General anesthesia. In: Banks WP, ed. Encyclopedia

of consciousness. San Diego: Elsevier/Academic Press, 2009;296–

313.

11. Webster AB, Collett SR. A mobile modified-atmosphere kill-

ing system for small-flock depopulation. J Appl Poult Res

2012;21:131–144.

12. Hendrickx JF, Eger EI II, Sonner JM, et al. Is synergy the rule?

A review of anesthetic interactions producing hypnosis and im-

mobility. Anesth Analg 2008;107:494–506.

13. Zeller W, Mettler D, Schatzmann U. Untersuchungen zur

Betäubung des Schlachtgeflügels mit Kohlendioxid. Fleis-

chwirtschaft 1988;68:1308–1312.

14. Cavanna AE, Shah S, Eddy CM, et al. Consciousness: a neuro-

logical perspective. Behav Neurol 2011;24:107–116.

15. Alkire MT, Hudetz AG, Tononi G. Consciousness and anesthe-

sia. Science 2008;322:876–880.

16. Mashour GA, Orser BA, Avidan MS. Intraoperative aware-

ness—from neurobiology to clinical practice. Anesthesiology

2011;114:1218–1233.

17. Hawkins P, Playle L, Golledge H, et al. Newcastle consensus

meeting on carbon dioxide euthanasia of laboratory animals.

National Centre for the Replacement, Refinement and Reduc-

tion of Animals in Science, 2006. Available at: www.nc3rs.org.

uk/sites/default/files/documents/Events/First%20Newcastle%20

consensus%20meeting%20report.pdf. Accessed Jan 20, 2011.

18. McKeegan DE, Sparks NH, Sandilands V, et al. Physiological re-

sponses of laying hens during whole-house killing with carbon

dioxide. Br Poult Sci 2011;52:645–657.

19. Benson ER, Alphin RL, Rankin MK, et al. Evaluation of EEG

based determination of unconsciousness vs. loss of posture in

broilers. Res Vet Sci 2012;93:960–964.

20. Finnie JW. Neuropathologic changes produced by non-pen-

etrating percussive captive bolt stunning of cattle. N Z Vet J

1995;43:183–185.

21. Blackmore DK, Newhook JC. The assessment of insensibility

in sheep, calves, and pigs during slaughter. In: Eikelenboom G,

ed. Stunning of animals for slaughter. Boston: Martinus Nijhoff

Publishers, 1983;13–25.

22. Gregory NG, Lee JL, Widdicombe JP. Depth of concussion in cat-

tle shot by penetrating captive bolt. Meat Sci 2007;77:499–503.

23. Vogel KD, Badtram G, Claus JR, et al. Head-only followed by car-

diac arrest electrical stunning is an effective alternative to head-

only electrical stunning in pigs. J Anim Sci 2011;89:1412–1418.

24. Grandin T. Improving livestock poultry and fish welfare slaugh-

ter plants with auditing programs. In: Grandin T, ed. Improving

animal welfare: a practical approach. Wallingford, Oxfordshire,

England: CABI Publishing, 2010;160–185.

25. Cartner SC, Barlow SC, Ness TJ. Loss of cortical function in

mice after decapitation, cervical dislocation, potassium chloride

injection, and CO

2

inhalation. Comp Med 2007;57:570–573.

26. Vanderwolf CH, Buzak DP, Cain RK, et al. Neocortical and hip-

pocampal electrical activity following decapitation in the rat.

Brain Res 1988;451:340–344.

27. Mikeska JA, Klemm WR. EEG evaluation of humaneness of as-

phyxia and decapitation euthanasia of the laboratory rat. Lab

Anim Sci 1975;25:175–179.

28. Bates G. Humane issues surrounding decapitation reconsidered.

J Am Vet Med Assoc 2010;237:1024–1026.

29. Holson RR. Euthanasia by decapitation: evidence that this tech-

nique produces prompt, painless unconsciousness in laboratory

rodents. Neurotoxicol Teratol 1992;14:253–257.

30. Derr RF. Pain perception in decapitated rat brain. Life Sci

1991;49:1399–1402.

31. van Rijn CM, Krijnen H, Menting-Hermeling S, et al. Decapita-

tion in rats: latency to unconsciousness and the ‘wave of death.’

PLoS ONE [serial online]. 2011;6:e16514. doi:10.1371/journal.

pone.0016514. Accessed Feb 7, 2011.

32. Grillner S. Human locomotion circuits conform. Science

2011;334:912–913.

33. Grandin T. Making slaughterhouses more humane for cattle,

pigs, and sheep. Annu Rev Anim Biosci 2013;1:491–512.

34. Woods J, Shearer JK, Hill J. Recommended on-farm euthanasia

practices. In: Grandin T, ed. Improving animal welfare: a practi-

cal approach. Wallingford, Oxfordshire, England: CABI Publish-

ing, 2010;194–195.

35. Grandin T. Behavior of slaughter plant and auction employees

towards animals. Anthrozoos 1988;1:205–213.

36. Arluke A. Managing emotions in an animal shelter. In: Manning

A, Serpell J, eds. Animals and human society. New York: Rout-

ledge, 1994;145–165.

37. Meyer RE, Morrow WEM. Euthanasia. In: Rollin BE, Benson GJ,

eds. Improving the well-being of farm animals: maximizing wel-

fare and minimizing pain and suffering. Ames, Iowa: Blackwell,

2004;351–362.

38. Manette CS. A reflection on the ways veterinarians cope with

the death, euthanasia, and slaughter of animals. J Am Vet Med

Assoc 2004;225:34–38.

AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition 11

History of Regulations, Industry Guidance

and Employee Training in the United States

H1 History of Regulation of Slaughter in the United States

The Federal Meat Inspection Act of 1906 (as

amended) requires the USDA to inspect all cattle,

sheep, swine, goats, and horses brought into any plant

to be slaughtered and processed for human consump-

tion;

1

it does not cover poultry. Inspection of poultry

products for human consumption did not become

mandatory until passage of the 1957 Poultry Products

Inspection Act.

1

The 1978 HMSA made mandatory the

humane slaughter and handling of livestock in connec-

tion with slaughter of food animals in USDA-inspected

plants. Animals included under the 1978 Act are cattle,

calves, horses, mules, sheep, goats, swine, and other

livestock. Two methods of slaughter were determined

to be humane under the 1978 Act. The first requires

that livestock be rendered insensible to pain by a sin-

gle blow or gunshot or an electrical, chemical or other

means that is rapid and effective before being shack-

led, hoisted, cast, or cut. The second method is in ac-

cordance with the ritual requirements of any religious

faith that prescribes a method of slaughter whereby the

animal suffers loss of consciousness due to ischemia

caused by the simultaneous and instantaneous sever-

ance of the carotid arteries with a sharp instrument.

Additionally, Section 1906 exempts the handling or

other preparation of livestock for slaughter under the

second method from the terms of the Act. Therefore,

the statutory requirement that livestock are rendered

insensible to pain prior to shackling, hoisting, casting,

or cutting does not apply to the handling or restraint

that is immediately associated with the cut when the

second method of slaughter is being used. Examples of

this type of slaughter include Jewish (kosher) slaughter

and Islamic (halal) slaughter.

2

Currently, the HMSA of 1978 does not cover poul-

try. However, some practices that promote good wel-

fare for poultry are covered by regulatory requirements

for good commercial practices.These regulations can

be found in 9 CFR Part 381.65(b) (Poultry Products

Inspection Act Regulations).

2

Under the Poultry Prod-

ucts Inspection Act, a poultry product is adulterated if,

among other circumstances, it is in whole, or in part,

the product of any poultry that has died by a method

other than slaughter. For example, poultry that are still

breathing on entering the scalder and die from drown-

ing and not from slaughter are considered adulterated

and unfit for human food and are condemned. Further-

more, in 2005, the USDA published a Federal Register

Notice (Docket No. 04-037N) on the treatment of live

poultry before slaughter. The USDA defined a “system-

atic approach” as one in which establishments focus

on treating poultry in such a manner as to minimize

excitement, discomfort, and accidental injury during

the time that live poultry are held in connection with

slaughter.

2

Currently, this approach is voluntary on the

part of industry. A provision in the USDA appropria-

tions act for fiscal year 2001 (P.L. 106-387) amended

the Poultry Products Inspection Act to include manda-

tory FSIS inspection for meat from ratites and quail.

1

Regulations for the inspection of exotic animals

can be found under 9 CFR 352.10. The authority for

the inspection of exotic animals comes from the Agri-

culture Marketing Act of 1946 found in 7 U.S.C. 1621

et seq, which promotes distribution and marketing of

agricultural products (includes exotic species not un-

der the Federal Meat Inspection Act). Exotic animals

that are defined by these regulations are reindeer, elk,

deer, antelope, water buffalo, or bison. This section

includes regulations that address humane handling

during antemortem inspection and stunning practices

to render the animals unconscious that are consistent

with the regulations pertaining to the 1978 HMSA (9

CFR 313.15 or 313.16).

Many countries have set standards for welfare prac-

tices with regard to humane slaughter, and the OIE also

includes standards for the humane conduct of slaugh-

ter in Chapter 7 of its Terrestial Animal Health Code.

3

The impact of such standards has just recently begun

to be felt in global trade. As an example, the Europe-

an Union’s Strategy for the Protection and Welfare of

Animals not only lays a foundation for improving wel-

fare standards in the European Union and making sure

those standards are applied and enforced in all Euro-

pean Union countries, but also expresses intent to ap-

ply equivalent welfare standards to imports from other

countries in the future.

4

H2 Enforcement of Humane Slaughter

in the United States

The FSIS of the USDA is tasked with the enforce-

ment of humane slaughter regulations. In the 1980s

and 1990s, enforcement of humane handling was not

a priority as FSIS focused on improving food safety

though the implementation of hazard-based inspection

systems. This was highlighted in 1997, when a survey

was conducted for the USDA.

5,6

Only three out of 10

beef plants were capable of rendering cattle uncon-

scious with a single shot from a captive bolt. The main

cause of poor captive bolt stunning was lack of mainte-

nance.

6

There were numerous other problems observed

in the 22 beef, pork, lamb, and veal plants that were

surveyed.

5,6

The FSIS recognized a need for improve-

ment and produced a video that served as a correlation

tool for supervisory public health veterinarians.

In 2001, Congress provided the USDA with addi-

tional funding to assist in enforcing the HMSA. This

funding enabled the FSIS to hire 17 district veterinary

medical specialists. The district veterinary medical spe-

cialist is the primary contact for humane handling and

slaughter issues in each district and serves as the liaison

between the district office and headquarters on all hu-

mane handling matters. In addition, in February 2004,

the FSIS began tracking the amount of time inspection

program personnel spend to ensure humane handling

and slaughter requirements are met.

In February 2010, the Government Accountability

Office published a report

7

that expressed concern about

uneven enforcement of humane handling and slaugh-

ter. Enforcement discrepancies were found to be greater

in small plants than in larger plants.

Following the release of that report, in April 2010,

the FSIS established a Humane Handling Enforce-

ment Coordinator position to increase the frequency

12 AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition

with which enforcement and inspection activities are

reviewed. The Humane Handling Enforcement Coor-

dinator coordinates the agency’s implementation and

daily enforcement of humane handling requirements

and provides professional expertise to support inspec-

tors in the field. Additionally, in 2011, the FSIS revised

and combined older directives and notices that defined

egregious animal abuse, providing field inspectors with

clearer guidance that supports more consistent enforce-

ment.

8

In October 2013, the FSIS published a new guid-

ance on the systematic approach to the humane han-

dling of livestock.

9

Proper implementation of this guid-

ance by industry should ensure the humane treatment

of livestock presented for slaughter because the guid-

ance provides establishments with a set of practices that

will assist in minimizing excitement, discomfort, and

accidental injury. The agency will continue to improve

its guidance to ensure the best practices are implement-

ed in establishments.

Food Safety and Inspection Service inspection pro-

gram personnel perform humane handling activities on

an ongoing basis. The FSIS can, and does, take enforce-

ment actions against slaughter plants that do not com-

ply with HMSA or the regulations. The goal is to prevent

suffering of animals while protecting the food supply.

H3 Auditing by Private Industry

A scoring system that was developed for use as part

of a 1997 review became the basis of the voluntary in-

dustry guidelines published by the American Meat In-

stitute.

5,6

The first version was published in 1997, and

the most recent complete version is by Grandin.

10

The

guideline considers five outcome measures. The use of

outcome-based measurements to assess animal welfare

is recommended.

11–13

Following is a summary of the five

major measurements

14

:

1. Percentage of animals rendered unconscious with

a single shot from a captive bolt or percentage of

animals where the electric stunner is placed on the

head in the correct position. The minimum accept-

able scores are 95% first-shot efficacy for captive

bolt and 99% correct positioning for electric stun-

ning.

2. Percentage of animals rendered unconscious before

hoisting to the bleed rail. To pass an audit, 100%

unconsciousness is required on a sample of 100 an-

imals. There is zero tolerance for starting invasive

procedures, such as skinning or leg removal, on an

animal showing any signs of return to conscious-

ness.

3. Percentage of cattle and pigs that remain silent

and do not vocalize (bellow, moo, or squeal) in the

stunning area. To pass an audit, 95% of the cattle or

pigs must remain silent in the stun box or conveyor

restrainer or during restraint for religious slaugh-

ter. Refer to Grandin

10

for more detailed informa-

tion on scoring vocalization. Vocalization scoring

should not be used for sheep.

4. Percentage of animals moved without an electric

prod. The minimum acceptable score is 75% of the

animals moved without use of an electric prod. An

excellent score is 95%.

5. Percentage of animals that remain standing and do

not fall during handling. A score of a fall is given

if the body touches the ground. Restrainer devices

that are designed to trip animals and make them

fall are not acceptable. The minimum acceptable

score is 99% handled with no falling. Falling is

scored in all parts of the facility.

Acts of abuse that should never be tolerated in-

clude, but are not limited to: 1) dragging nonambu-

latory animals; 2) beating animals; 3) poking sensi-

tive areas such as the animal’s eyes, nose, udder, or

anus; 4) deliberately driving animals over the top of

other animals; and 5) deliberately slamming gates on

animals.

In 1999, the use of this scoring system by major

meat-buying customers resulted in great improvements.

A year after McDonald’s Corporation and Wendy’s In-

ternational started using the objective scoring system,

more than 90% of beef plants were able to render 95%

of cattle unconsciousness with a single shot.

15,16

The

use of electric prods and the percentage of animals vo-

calizing were also greatly reduced.

16

The AVMA PHS believes that important elements

for best practice with regard to humane slaughter are:

1) maintenance logs on stunners, 2) training programs

for employees, and 3) auditing using accepted industry

auditing methodologies, such as video auditing.

17

In-

dividual plants can vary on the structure and elements

of their approach, so each plant will need to develop

its ownprogram. Developing best practices for humane

slaughter and handling is similar to writing a hazard

analysis and critical control points plan for food safety.

Industry assessors and auditors should conduct direct

observations to ensure that the plant employees are fol-

lowing their plant’s written program. Best practices for

humane slaughter include procedures that are done in

the plant. There should be records to show that reviews

have been conducted and that procedures are being

followed. Additional critical areas for best practice in-

clude: nonslip floors on unloading ramps and in stun

boxes, electric prod use, and handling of down, non-

ambulatory animals. Many assessors/auditors use the

American Meat Institute objective scoring system to

determine when a plant has a problem.

H3.1 CleAr Comments

When a problem is identified, it is essential that

both FSIS inspectors and private auditing companies

write clear comments describing exactly what they saw.

When return to sensibility is observed, it is essential

to not confuse corneal reflex, nystagmus, and natural

blinking (menace reflex). An animal that has a weak

corneal reflex after electric stunning is usually uncon-

scious, but after captive bolt or gunshot, the corneal

reflex must be absent. An animal that has natural blink-

ing like a live animal in the lairage is definitely sensible.

This applies to all types of stunning methods.

An example of a poor description in an inspection

report would be “rough handling.” An example of a

clear description of an abusive handling incident would

be “intentional electric prod use on sensitive mucosal

areas.” Clear comments are essential so that supervi-

sors may appropriately manage problem behavior. The

AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition 13

FSIS has two excellent examples of clear descriptions of

an egregious situation of inhumane handling in attach-

ments 4 and 5 of Directive 6900.2, revision 2.

17

H3.2 Video Auditing by industry

Two major meat companies have installed video

cameras that are monitored by a private third-party au-

diting company. The use of video auditing helps pre-

vent the problem of employees following correct proce-

dures when they are being watched and then reverting

to inappropriate methods after the inspector or auditor

is gone. Video auditing is most effective when it is done

by a third-party auditor over the Internet. Experience

has shown that internal video auditing programs are

less effective.

H4 References

1. Rawson JM. Issue brief for congress: meat and poultry inspection

issues. Updated August 27, 2002. Washington, DC: Congressio-

nal Research Service, The Library of Congress, 2002. Available

at: www.cnie.org/NLE/CRSreports/IB10082.pdf. Accessed Sep

14, 2012.

2. FSIS. Humane handling of livestock and good commercial prac-

tices in poultry. 2009. Available at: www.fsis.usda.gov/PDF/

FSRE-HH-GCP.pdf. Accessed Sep 14, 2012.

3. OIE. Chapter 7.5. Slaughter of Animals. In: Terrestrial

Animal Health Code, 2015. Available at: www.oie.int/

index.php?id=169&L=0&htmfile=chapitre_aw_slaughter.htm.

Accessed May 25, 2015.

4. Gavinelli A. Developments in AW policies in the EU: every-

one is responsible. Seminar of the European Institute on Ani-

mal Welfare: market-driven animal welfare in the EU and the

US. Available at: www.slideshare.net/EUintheUS/washington-

andrea-1. Accessed Jul 14, 2014.

5. Grandin T. Survey of stunning and handling in federally in-

spected beef, veal, pork, and sheep slaughter plants. Available

at: www.grandin.com/survey/usdarpt.html. Accessed Jul 14,

2014.

6. Grandin T. Objective scoring of animal handling and stunning

practices at slaughter plants. J Am Vet Med Assoc 1998;212:36–

39.

7. Government Accountability Office. Humane methods of

slaughter act. February 2010. Available at: www.gao.gov/

assets/310/300921.pdf. Accessed Oct 17, 2012.

8. FSIS. Facilitator guide for situation-based humane handling train-

ing. Beltsville, Md: FSIS, 2011.

9. FSIS. FSIS compliance guide for a systematic approach to the

humane handling of livestock. Available at: www.fsis.usda.gov/

wps/wcm/connect/da6cb63d-5818-4999-84f1-72e6dabb9501/

Comp-Guide-Systematic-Approach-Humane-Handling-Live-

stock.pdf?MOD=AJPERES. Accessed Feb 19, 2016.

10. Grandin T, American Meat Institute Animal Welfare Commit-

tee. Recommended animal handling guidelines and audit guide: a

systematic approach to animal welfare. Washington, DC: Ameri-

can Meat Institute Foundation, 2012. Available at: www.animal-

handling.org. Accessed Aug 21, 2012.

11. Hewson CJ. Can we assess welfare? Can Vet J 2003;44:749–753.

12. Webster J. The assessment and implementation of animal wel-

fare: theory into practice. Rev Sci Tech 2005;24:723–734.

13. Whay HR, Main DCJ, Guen LE, et al. Assessment of the welfare

of dairy cattle using animal-based measurements: direct obser-

vations and investigation of farm records. Vet Rec 2003;153:197–

202.

14. Grandin T. Auditing animal welfare at the slaughter plants. Meat

Sci 2010;86:56–65.

15. Grandin T. Effect of animal welfare audits of slaughter plants

by a major fast food company on cattle handling and stunning

practices. J Am Vet Med Assoc 2000;216:848–851.

16. Grandin T. Maintenance of good animal welfare standards in

beef slaughter plants by use of auditing programs. J Am Vet Med

Assoc 2005;226:370–373.

17. FSIS. Humane handling and slaughter of livestock. Directive

6900.2, Revision 2. Washington, DC: FSIS, 2011.

14 AVMA Guidelines for the Humane Slaughter of Animals: 2016 Edition

Design of Facilities and Slaughter Process

D1 Handling Procedures at Slaughter

Plants for Hoofstock

d1.1 step 1—ArriVAl At tHe plAnt

The normal process is for the animals to be un-

loaded promptly after a vehicle arrives at the plant. In

the best operations, the vehicles are unloaded within

15 to 60 minutes after arrival, and industry guidelines

recommend a maximum wait time of 60 minutes.

1

This

requires the scheduling of an appointment between the

plant and transporter. Scheduling vehicle arrival times

prevents the problem of too many vehicles arriving at

the same time, which results in long lines and delays at

unloading. During hot weather, delayed unloading can

result in severe animal welfare problems due to heat

stress. Death losses in pigs increase as the internal tem-

perature of the trailer increases.

2

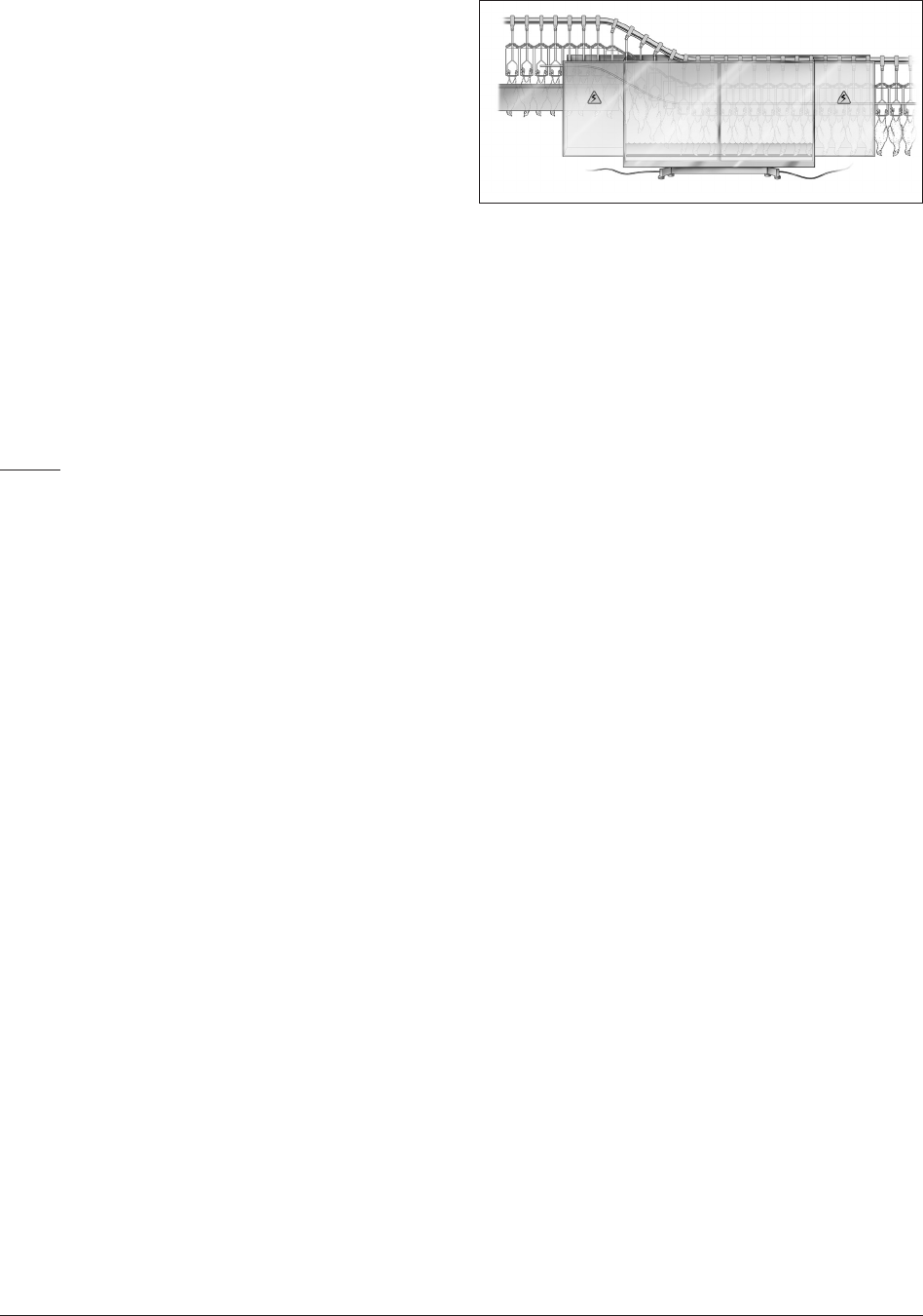

Figure 1 shows the

step-by-step flow of animals through the plant.

D1.1.1 Detection of problems

There have been unfortunate cases where many

cattle or pigs have died while waiting an entire day to

unload. This serious problem is most likely to occur

when there is an emergency condition such as a power

failure or storm, which either shuts down the plant or

makes roads impassable.

D1.1.2 Corrective action for problems

It is best practice to have an emergency program ei-

ther to divert incoming trucks to other slaughter facili-

ties or to unload animals at auction markets, feedlots,

or fairgrounds. This will require a coordinated program

that facilitates immediate cancellation of animal load-

ing on the farm and diverts loads that are en route to

other facilities.

d1.2 step 2—unloAding

When unloading is done correctly, animals will

move off the vehicle in a quiet, orderly manner. Han-

dlers should be quiet and refrain from yelling, whis-

tling, or repeatedly hitting the sides of the vehicle. The

sound of people yelling has been shown to be very

stressful for livestock.

3,4

Electric prods can be complete-

ly eliminated during unloading of most hoofstock and

ducks. The best US sheep plants use trained sheep to

lead the animals off the vehicle.

5

An electric prod may

occasionally be necessary to move pigs out of a vehicle

with multiple decks. Some pigs may be very difficult to

move if they have never had the experience of people

walking through their pens on the farm. Handling ex-

periences on the farm can affect pig movement in the

future.

6–8

Pigs that have become accustomed to people

walking through their pens on the farm will be easier to

move and less likely to pile up when they are handled

at the plant.

5

Use of electric prods on horses is strongly

discouraged; they should only be used as a last resort

when all other options have been exhausted. Accept-

able handling tools for horses include flags and rattle

paddles.

9

D1.2.1 Detection of problems

Industry guidelines advise that if more than 1% of

animals fall during unloading or more than 5% of ani-

mals are unloaded using an electric prod, there is a wel-

fare problem in the unloading area.

10–12

Most plants can