D 154

Department of Agricultural

and Resource Economics

SAMPLE BUDGET FOR BLACKBERRY PRODUCTION UNDER

VARIOUS INTEGRATED PEST MANAGEMENT AND

MARKETING STRATEGIES, 2022

February 2022

Margarita Velandia, Riley Denton, Omar Aza, Tori Marshall, Alicia Rihn

Department of Agricultural and Resource Economics

David Lockwood and Natalie Bumgarner

Department of Plant Sciences

Zachariah Hansen

Department of Entomology and Plant Pathology

The objective of this document is to help users

understand and navigate the sample blackberry

budget created by the University of Tennessee,

available at https://bit.ly/3FJxag4. This sample

budget was created to guide blackberry

producers and those interested in producing

blackberries on the factors to consider when

estimating their production and marketing costs.

Additionally, this sample budget helps users

evaluate changes in costs associated with two

pest management strategies (i.e., none and

conventional fungicide program), and three marketing strategies (i.e., 100 percent ready picked

retail, 50 percent u-pick and 50 percent ready picked retail, 75 percent u-pick and 25 percent

ready picked retail).

The sample budget shows examples of blackberry production costs given specific assumptions.

Therefore, users should modify numbers to accurately portray their actual farm costs. Every farm

is unique; hence, estimated costs will vary depending on soil conditions; blackberry variety;

production practices used; and pest, weed and disease pressure; among other factors. Regardless

of the variation in costs due to farm and location characteristics, blackberry cash flow will be

negative until the crop has matured (Year 3), which means establishment costs will not be

recovered until Year 3

1

.

1

Ernst, T., and Woods, T. “2017 Kentucky Blackberry Cost and Return Estimates.” ID-149, University of Kentucky

College of Agriculture, Food and Environment, Cooperative Extension Service. Available online at

https://bit.ly/31PrVfI

Sample Budget for Blackberry Production

2

Users of the sample budget should note that the input prices used in this document and the Excel

budget tool were current as of January 2022 and are subject to change. Input prices were

collected from a handful of randomly selected businesses; therefore, users are encouraged to

conduct a thorough search when sourcing input suppliers.

Sample Budget Details

This document divides the production of blackberries into three time horizons: pre-planting,

planting and fruiting. A detailed description of the activities involved in each timeline is given

below. The document further discusses the details of fertilizer, fungicide and insecticide

applications, as well as information pertaining to irrigation, labor, machinery, equipment, harvest

and post-harvest activities, and marketing.

Pre-planting (Year 1)

The examples presented in this sample budget are based on 1 acre of blackberries. It is assumed

all preparation activities will happen in Year 1 to allow at least six months to a year for the soil

to reach ideal conditions for blackberry production. For soil preparation and weed destruction, a

disk harrow and 1-shank subsoiler are assumed to be used. The use of herbicide might also be

necessary to destroy weeds. Following the 2021 Southeast Regional Caneberries Integrated

Management Guide

2

, we assume glyphosate would be used to destroy weeds. Although we

assumed 2 quarts per acre of glyphosate at $10.7 per quart

1

, you should read the label for the

application rate. A 100 gallon 3-point hitch boom sprayer pulled by a 50 hp mechanical front-

wheel drive tractor will be used to apply the glyphosate. Whether the sprayer is a tractor

mounted or slides in the bed of an ATV, the vehicle must be capable of maintaining a uniform

ground speed over uneven terrain and a uniform pump speed. Without this, it would be

impossible to calibrate the sprayer for precise application. Backpack and handheld pump-up

sprayers are often used by small growers, but they cannot be calibrated accurately.

Soil tests are necessary for Year 1, as the results from these tests will guide producers on the

requirements to adjust soil fertility conditions. Soil tests are budgeted at $15 per soil test, and we

assumed two soil tests per acre. In Year 1, we assumed a soil probe would be purchased at $108.

Hand labor associated with soil tests is estimated at 0.6 hours per acre. Fertilizer application

along with fungicides and insecticides are discussed in more detail below.

We allocated one hour per acre to mark the rows where blackberry plants will be planted

1

.

We assumed grass would be planted between rows to support equipment used between rows and

avoid soil erosion. We assumed 10 lbs per acre of tall fescue grass seed at $1.89 per lb would be

planted in between rows in Year 1. We estimated the grass seed price by averaging grass seed

prices obtained from various input suppliers in January 2022.

Planting (Year 2)

We assumed grass between rows would be mowed before planting blackberry transplants with a

rotary cutter. We allocated about 2.2 operator labor hours per acre distributed across the planting

2

2021 Southeast Regional Caneberries Integrated Management Guide. Available online at

https://bit.ly/3DJTZyd

Sample Budget for Blackberry Production

3

year to complete this task

3

. Additionally, we assumed glyphosate would be used to destroy

weeds before planting. Although we assumed 1 quart per acre of glyphosate at $10.7 per quart

4

,

you should read the label for the application rate.

When determining row and plant spacing, it is important to remember that these decisions will

determine the number of plants per acre. For the budget, a 12-foot space between rows and a 3-

foot space between blackberry plants is assumed. If you are growing more than one variety, it

would be appropriate to use the same space between rows and plants regardless of the varieties

grown for management purposes. If there is variation in space between rows and plants, mowing

and other activities that require specific equipment sizes may become more complicated or

laborious.

We assumed the blackberry varieties grown are Natchez and Ouachita. Natchez is a semi-erect

thornless variety, while Oachita is an erect thornless variety. These two varieties are high-

yielding, high-quality, and are great for commercial and local markets

5

. The harvesting period

for both varieties is June to August, but Natchez ripens about a week earlier (around June 3) than

Ouashita

6

. Exact harvesting times will vary from year to year and by the location of the

operation. There are no differences in management strategies between the varieties as trellis

systems are recommended for both varieties. There are benefits of combining these varieties

because Natchez is more sensitive to freezing temperatures than Oachita, and therefore

combining the two varieties might help to manage weather risks. Additionally, combining

varieties may create additional marketing opportunities as it extends the marketing season.

When assuming a 3-foot-by-12-foot spacing (i.e., plant space times row space), 1,210 plants at

$4.11 each are transplanted. Blackberry plant prices are estimated by taking the average of plant

prices from nurseries in Indiana and Arkansas. We assumed transplanting happens in early spring

(March) of Year 2. The 1,210-plant density is appropriate for u-pick operations. We allocated 36

labor hours for transplanting blackberry plants into the field

7

. Canes produced from the

blackberry plants in Year 2 (primocanes) will not bear fruit.

For cane support and to keep the fruit off the ground, a wood T-trellis system is assumed to be

used. Trellis systems are useful in maximizing sunlight exposure, air movement and spray

penetration throughout the canopy. Additionally, trellis systems can facilitate planting

management or make harvesting and floricane removal easier. In general, using trellis systems

can maximize yield and minimize labor use. Although we assumed a wood T-trellis system for

this budget, there are various trellis systems options

8

. When choosing a trellis system for your

3

Mississippi State University, 2010 Fruit and Nut Planning Budgets. Available online at

https://bit.ly/3mhUPfT

4

Ernst, T., and Woods, T. “2017 Kentucky Blackberry Cost and Return Estimates.” ID-149, University of

Kentucky College of Agriculture, Food and Environment, Cooperative Extension Service. Available online at

https://bit.ly/31PrVfI

5

University of Arkansas. Blackberry variety information. Available online at https://bit.ly/3EIWnGS

6

Carroll, B. “Commercial Blackberry Production.”HL-6239, Oklahoma State University, Oklahoma Cooperative

Extension Service. Available online at https://bit.ly/3ERTqE0

7

North Carolina State University. “Blackeberru Budget Program 2011”. Available online at

https://bit.ly/3GZZ0VI

8

North Carolina State University. “Trellis Systems.” Available online at https://bit.ly/30FCfqj.

Sample Budget for Blackberry Production

4

operation, it is important to consider construction and material costs, availability of trained labor,

and climate considerations (e.g., risk of blackberry cold injury).

It is important to construct trellises before the first harvest season. The post should be placed

before planting to not disturb the plants, but wires could be installed after planting. We assumed

8-foot wood posts would be used for the trellis system, set 30 feet apart within a row

9

. We

assumed rows would not be longer than 400 feet to help with harvesting efficiency and make

trellis system repair easier. If we assumed 134 plants per row and nine rows, there would be

approximately 13 posts per row, for a total of about 118 posts per acre at $19.6 per post. We

assumed an auger would be used to make holes for post placement. A piece of 2-by-4-inch

pressure-treated wood is assumed to be used for cross arms. We assumed two 8,700-ft, 12.5

gauge high-tensile wire rolls would be used for the trellis system. Other trellis hardware (e.g.,

anchors) is estimated at $288 per acre

10

.

A total of 155 labor hours are assumed during Year 2 or planting year. As previously mentioned,

36 hours are allocated to transplanting. Trellis construction consists of 45 hand labor hours.

Labor associated with hoeing for weed management in Year 2 is estimated at 65 labor hours and

labor hours associated with irrigation are estimated at 0.35 labor hours distributed across the

planting year

10

. We assumed five labor hours per acre would be assigned to tipping. Tipping is

usually done in late June and July.

We assumed soft tipping (i.e., removal of the shoot tip when it is of a small diameter and easily

pinched by hand) would be done during the planting year to allow for lateral branches to grow

and increase fruit yield

11

. Several trips through the planting should be made for tipping, given

that primocanes growth happens at different times during the summer and grow at different rates.

Planting (Years 3 to 8)

After the planting year, a blackberry plant will have primocanes and floricanes (canes that

produce fruit). Primocanes should be pruned. Floricanes should be removed (i.e., cane removal)

from the planting after harvesting. Cane removal after harvesting is important to reduce disease

carryover in the planting. Additionally, cutting off floricanes to the ground level is important for

new primocanes to develop from buds on healthy tissue at or below the soil line

11

. We allocated

7 hours per acre per year for summer pruning and 20 hours per acre per year for cane removal in

Years 3 to 8.

We assumed grass between rows would be mowed with a rotary cutter. We allocated

approximately 2.3 operator labor hours per acre per year for Years 3 to 8 to complete this task.

Labor associated with hoeing for weed management in Years 3 to 8 is estimated at 33 labor

hours per year, and labor hours associated with irrigation are estimated at 0.35 labor hours per

year.

9

North Carolina State University. “Trellis Systems.” Available online at https://bit.ly/30FCfqj.

10

Ernst, T., and Woods, T. “2017 Kentucky Blackberry Cost and Return Estimates.” ID-149, University of

Kentucky College of Agriculture, Food and Environment, Cooperative Extension Service. Available online at

https://bit.ly/31PrVfI

11

Lockwood, D. Pruning and Training Caneberries (Blackberries and Raspberries), SP 284-G. UT Extension.

Available online at

https://bit.ly/3mD88Yh

Sample Budget for Blackberry Production

5

Fertilizer, Fungicides and Insecticides

This section of the document discusses fertilizer application for all three time horizons: pre-

planting, planting and fruiting.

For the pre-planting year (Year 1), it is assumed 800 lbs per acre of 15-15-15 fertilizer at $0.41

per lb are applied. This fertilizer cost serves only as a reference for fertilizer applications as P

(phosphorous) and K (potassium) needs will be determined by the soil test results and will likely

vary greatly from farm to farm.

For the planting year (Year 2), we assumed 40 units of nitrogen (40/0.46= 87 lbs of urea) per

acre would be applied. Half of those units (50 percent) would be applied three weeks to a month

after planting, then another 25 percent 6 to 8 weeks after the last application, and the remaining

25 percent 6 to 8 weeks after the last application. For the fruiting years (Year 3 to 8), we

assumed 60 units of nitrogen (60/0.46 = 130 lbs of urea) would be applied. Half of those units

(50 percent) would be applied at early bloom, and then the other half would be applied in late

July or early August. Ideally, urea should be applied through fertigation for more accuracy. In

this budget, we are assuming urea would be applied with a side spreader, but it is important to

acknowledge that urea has a problem with volatility. Therefore, it is important to remember that

if rain is not forecasted or there is no irrigation, a percentage of the applied urea will be lost.

The intensiveness of pest and disease management in blackberry fields can vary widely due to

several factors, including variety selection, cultural practices, location, and pest and disease

pressures. In situations with minimal pest and disease pressure and/or where cultural practices

are followed to minimize impacts from pests and diseases, blackberries may be produced with

minimal pesticide inputs. However, where pest and disease pressure are high, a regular spray

program may be necessary. The sample budget provides two pest management scenarios: (1) no

fungicide inputs are applied, and (2) a conventional fungicide program is followed. Captan is

included in all sprays as a broad-spectrum tank-mix partner for fungicide resistance management

and to increase the breadth of diseases covered. Pristine, Quilt Xcel and Luna Tranquility are

included as representative examples of fungicides used to manage common blackberry diseases,

including anthracnose, cane blight, powdery mildew, rusts, leaf spots, Botrytis and rosette.

Several other fungicide options are available and can be found in the most recent version of the

Southeast Regional Caneberry Integrated Management Guide

12

.

Table 1. Moderate Disease Pressure IPM Spray Schedules

Spray #

Target Month Application

Input products applied

1

April

Pristine + Captan

2

May

Quilt Xcel + Captan

3

June

Luna Tranquility + Captan

4

July

Quilt Xcel + Captan

* Pristine can only be tank-mixed with Captan for blackberry applications and cannot be tank-

mixed with any other active ingredient. See label for details.

12

2021 Southeast Regional Caneberries Integrated Management Guide. Available online at

https://bit.ly/3DJTZyd

Sample Budget for Blackberry Production

6

Table 2. Moderate Disease Pressure IPM Application Rates per acre and Chemicals’ Prices

Label Rate

Range

Application Rate

Price per application

unit

Pristine

18.5 - 23 oz

21 oz

$0.81/oz

Captan

2.5 lb

2.5 lb

$6.74/lb

Luna Tranquility

13.6 - 27 fl oz

20 fl oz

$3.25/fl oz

Quilt Xcel

14 - 21 fl oz

17.5 fl oz

$1.25/fl oz

Growers should also scout for spotted wing drosophila (SWD) and treat as needed. If SWD is not

present, insecticides do not need to be applied for it. However, if SWD is present, then growers

should spray a labeled insecticide beginning two weeks prior to harvest and continuing with

weekly sprays through the end of harvest. Growers should consult the most recent version of the

Southeast Regional Caneberry Integrated Management Guide

13

for an updated list of insecticides

labeled for SWD management, as well as management recommendations for other common

insect pests.

Machinery and Equipment

We assumed one tractor (i.e., a 50 horsepower four-wheel-drive tractor) would be used to

perform all activities associated with blackberry production. In Table 3, we show estimated

direct (e.g., repair and maintenance, fuel, and labor costs) and fixed costs associated with all

implements, including the tractor’s fixed cost, used for blackberry production in this sample

budget. Fixed machinery costs associated with the tractor and implements were calculated using

the Mississippi State Budget Generator (version 6.0).

Blackberry production costs include an annual fixed cost of $1,100 per acre per year associated

with an 8-by-8-by-8-foot cooling unit used to maintain berry quality and enhance shelf life. This

assumption is based on total purchase, installation and maintenance costs of $7,700

14

. Although

we assumed all cooling system costs are assigned to the blackberry enterprise, it is important to

acknowledge the costs of the system could be allocated to other fruits and vegetables needing

refrigeration and being grown outside of the blackberry harvest window. Additionally, there

might be smaller cooling systems that are a good fit for blackberry production and can result in

cooling system cost savings.

13

2021 Southeast Regional Caneberries Integrated Management Guide. Available online at

https://bit.ly/3DJTZyd

14

Ernst, T., and Woods, T. “2017 Kentucky Blackberry Cost and Return Estimates.” ID-149, University of

Kentucky College of Agriculture, Food and Environment, Cooperative Extension Service. Available online at

https://bit.ly/31PrVfI

Sample Budget for Blackberry Production

7

Table 3. Machinery and Equipment Costs per acre used for Blackberry Production.

Direct Costs

Fixed Costs

Auger

$54.04

$12.08

Disk Harrow

$9.12

$2.35

Grain drill

$12.56

$5.71

Rotary Cutter

$15.88

$4.52

Side Dresser

$24.97

$13.83

Sprayer — Air Blast

$16.69

$16.11

Sprayer — Boom

$2.78

$0.68

Sub-Soiler (1 shank)

$29.29

$7.29

Source: Mississippi State University Budget Generator

Labor and Fuel

Hand labor was estimated at the 2022 US Department of Labor Tennessee Adverse Effect Wage

Rate of $13.89

15

. Operator labor was estimated at $17.42/hour based on the 2020 US Department

of Labor estimates for Tennessee. Diesel prices were estimated at $2.88 per gallon. Hand labor is

associated with soil testing, irrigation check activities, planting, hoeing, pruning, cane removal

and harvesting.

Irrigation

We assumed a trickle irrigation system is used. The establishment cost of the irrigation systems

is estimated at $1,327. The annual variable costs of irrigation are estimated at $248, but they

might fluctuate greatly due to water availability and cost

16

. Trickle irrigation systems are

preferred over overhead irrigation systems because the water is applied to the soil and does not

contact leaves or fruit, which could aggravate disease issues. In general, trickle irrigation systems

use less water and require a lower pump capacity than overhead systems.

Capital

The interest on operating capital was calculated annually at a rate of 4 percent. Operating interest

is assumed to be charged on half of all variable expenses.

Harvest and Post-harvest

We assumed that no crops would be harvested in Years 1 and 2. We assumed plantings would

initiate producing yield in Year 3. We assumed in Year 3, blackberry plants would produce 60

percent of the maximum anticipated yield at crop maturity. We assumed the maximum

anticipated yield at crop maturity would happen in Year 4 and would be 5,000 quarts per acre or

about 4 quarts per plant (Table 4). The yield would likely vary depending on farm and location

characteristics, as well as production practices used. It can exceed the assumed 5,000 quarts per

acre if appropriate production practices are followed.

15

https://www.dol.gov/agencies/eta/foreign-labor/wages/adverse-effect-wage-rates

16

Ernst, T., and Woods, T. “2017 Kentucky Blackberry Cost and Return Estimates.” ID-149, University of

Kentucky College of Agriculture, Food and Environment, Cooperative Extension Service. Available online at

https://bit.ly/31PrVfI

Sample Budget for Blackberry Production

8

Table 4. Estimated Yields by Year of Blackberry Production.

Production

Year

qt/acre

% of full

production

0

0

0%

1

0

0%

2

3,000

60%

3

5,000

100%

4

5,000

100%

5

5,000

100%

6

5,000

100%

7

5,000

100%

We assumed that harvested berries are sorted into 1-quart plastic clamshells at a cost of $0.15 per

plastic container. We assumed the estimated harvest rate for picking blackberries is 30 quarts per

hour. Therefore, we assumed 100 and 165 hours are designated for harvesting activities in Years

3, and 4 to 8, respectively. It is assumed that six to 10 pickers are needed to harvest 1 acre of

blackberries

17

.

Operating costs associated with the refrigeration of blackberries to maintain berry quality and

enhance shelf life is estimated at $36.60 per acre per year.

Marketing

In this sample budget, we assumed the blackberries would be marketed through farmers markets,

on-farm, roadside stands and/or pick-your-own (PYO). The choice of marketing strategies would

depend on various factors, including farm location that would determine the distance to

customers and markets and labor and time availability for marketing activities. The advantage of

marketing blackberries using a PYO strategy is the labor savings associated with reducing

harvesting activities. When blackberries are marketed through PYO, it is important to still have

some labor available to harvest blackberries in the parts of the field that are not harvested by the

customers. It is important for spotted wing drosophila (SWD) control not to have overripe berries

in the field. For u-picked operations, between 300 and 450 customers are needed to harvest 1

acre of blackberries, with semi-erect varieties requiring the highest amount of customers for

harvesting

17

.

There are other considerations and costs associated with using a PYO marketing strategy,

including adequate parking area, restroom facilities, convenient and safe access, and adequate

liability insurance.

Marketing costs were estimated at 10 percent of gross revenue. Gross revenue would depend on

marketing strategies. We assumed blackberries would be sold at $5 per quart for PYO

17

Kaiser, C., and M. Ernst. 2018. “Blackberries.” Center for Crop Diversification, University of Kentucky.

Available online at https://bit.ly/3sMKgFK

Sample Budget for Blackberry Production

9

blackberries and $7 per quart for already-picked blackberries sold on-farm, via roadside stands or

at farmers markets.

Excel Sample Budget

The blackberry sample budget Excel tool is available on the Department of Agricultural and

Resource Economics website at https://bit.ly/3FJxag4. You can see a list of all available

spreadsheets by clicking the mouse right-click button on the arrow pointing to the right on the

bottom left corner of any spreadsheet (see figure below).

In this Excel tool, users can select different scenarios associated with pest management strategies

and marketing strategies in the “General Assumptions” spreadsheet:

1. You can select one of two pest management scenarios: None and Conventional Fungicide

Program. The “None” scenario assumes there will be no disease control (see Tables 1 and

2 above).

2. You can select three strategies to market your blackberries: 1) 100 percent retail (e.g., on-

farm or at farmers markets); 2) 50 percent pick-your-own (PYO) AND 50 percent ready

picked to be marketed on-farm, roadside stands or at farmers markets; 3) 75 percent pick-

your-own (PYO) AND 25 percent ready picked to be marketed on-farm, roadside stands

or at farmers markets.

In the “Labor, Fuel and Interest” spreadsheet, you can change assumptions related to

operator, hand labor and fuel cost, as well as the interest rate.

In the “Yield” spreadsheet, you can change assumptions related to yield in Years 3 to 8.

Sample Budget for Blackberry Production

10

In the “Blackberry Prices” spreadsheet, you can change assumptions related to u-picked and

ready-picked (e.g., on-farm and farmers markets) blackberry prices.

If quantities and details of the “Labor, Fuel and Interest,” “Yield” and “Blackberry Prices”

spreadsheets are modified, original values can be restored when clicking on the “Default”

button on the right of each of these spreadsheets. The “Intro” button allows you to return to

the introductory page.

After making your pest management, marketing strategies, labor, fuel, interest, yield and

price selections, you can evaluate the overall changes in costs and changes in costs per year

in the “Summary Budget” spreadsheet. The “Print” button on this spreadsheet allows the user

to print this one-page summary. The “Intro” button allows you to return to the introductory

page. On the “Summary Budget” spreadsheet, you can click on the first row of the table

“Year X” to see the detailed budget for each year.

The “Blackberry Budget YX” spreadsheets will provide details about costs of production for

Year 1 to Year 8. In these spreadsheets, you will be able to change a few operating/durable

input costs (highlighted in gray). These spreadsheets contain detailed information about the

budget estimations, including machinery and implements fixed and variable costs, and are

designed for those users that would like to better understand budget estimations. The “Year

X Budget Summary” button will allow you to go to the summary budget for each year (i.e.,

“Summary YX”). The “Summary YX” spreadsheets will provide a summary budget for each

year. These summary spreadsheets are appropriate for users who are interested in estimating

overall costs per year, but are not interested in the specific details behind the estimations. In

these spreadsheets, you will be able to change a few operating/durable input costs

(highlighted in gray) and use the individual year budgets function to evaluate your own

production costs per year. The “Summary Budget” spreadsheet will not reflect user changes

in the “Summary YX” spreadsheet because the summary budget cost categories do not match

each year’s budget summary cost categories. You will be able to print each year’s budget

“Summary XY” using the print button. If quantities and details of the sample budget are

modified, original values can be restored when clicking on the “Default” button on the

bottom right of the “Blackberry Budget YX” and “Summary YX” spreadsheets.

Examples of Costs Associated with Various Marketing and Pest Management

Strategies

Using the excel sample blackberry budget, we estimated costs associated with two pest

management strategy scenarios (i.e., none and conventional fungicide program) and one

marketing strategy (i.e., 100 percent ready picked blackberries to be marketed through

farmers markets, roadside stands or on-farm). As you can see in Tables 5 and 6, in Year 2,

the largest expenses are those associated with blackberry plants and the construction of the

trellis system. In Years 3 to 8, the largest expenses are those associated with harvesting and

post-harvesting activities (i.e., post-harvesting costs include marketing costs). The difference

in costs associated with the two pest management scenarios is about $1,800 per acre. Costs

associated with fungicides represented 2.7 percent of total costs for Years 3 to 8.

Sample Budget for Blackberry Production

11

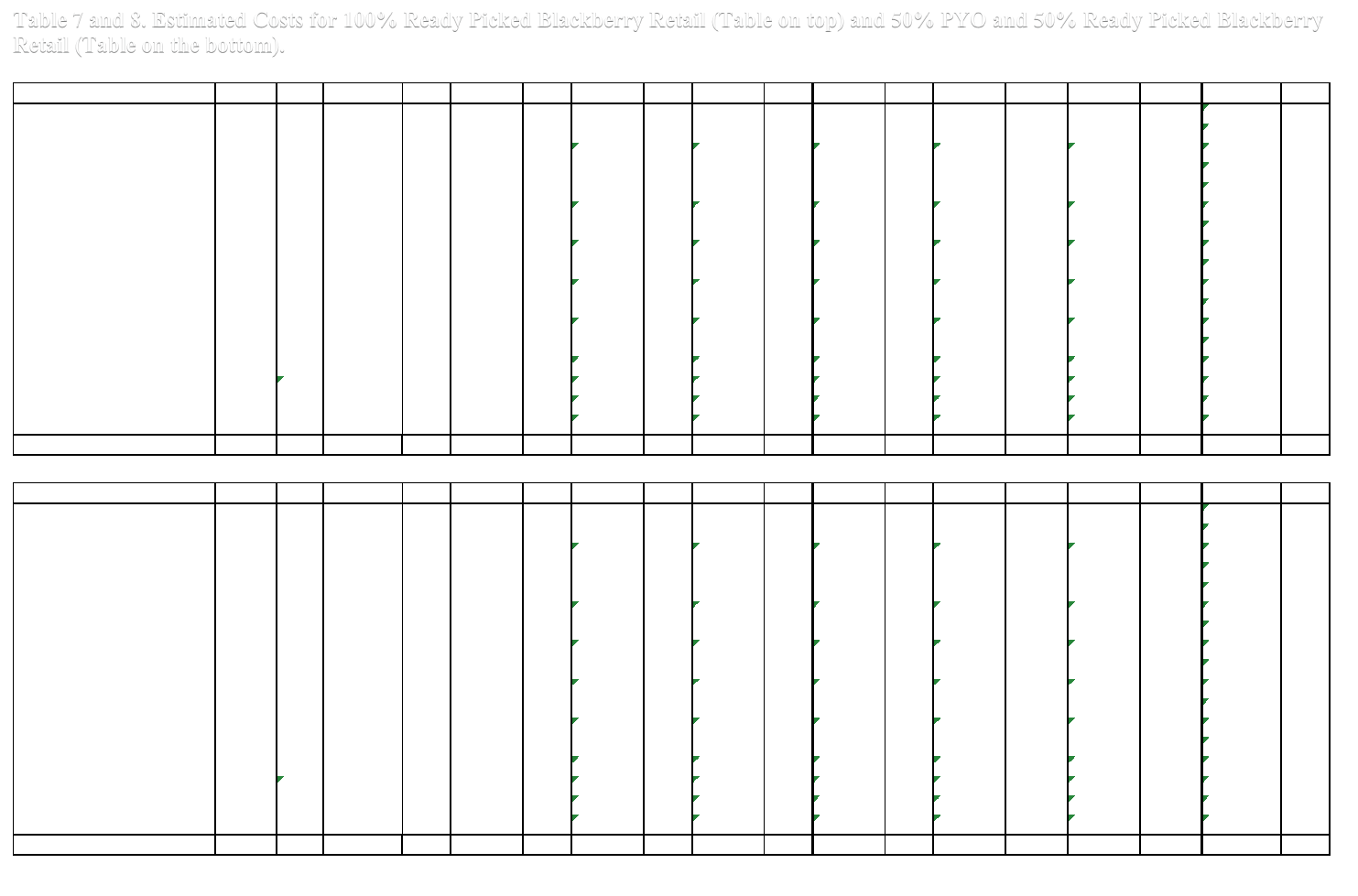

We also evaluated two different marketing strategies using the excel sample blackberry

budget: 1) 100 percent retail (e.g., on-farm or at farmers markets); and 2) 50 percent pick-

your-own (PYO) AND 50 percent ready picked to be marketed on-farm, roadside stands or at

farmers markets. We assume a conventional fungicide program pest management strategy in

both marketing scenarios. As you can see in Tables 7 and 8, when switching from the 100

percent retail scenario to the 50 percent PYO-50 percent retail scenario, harvesting costs go

from representing about 27 percent to 32 percent of total costs to representing about 16

percent to 20 percent of total costs. Regardless of pest management and marketing strategy

used, planting, construction of trellis system, harvesting and post-harvesting costs are the

largest expenses associated with blackberry production.

Sample Budget for Blackberry Production

12

Tables 5 and 6. Estimated Costs for 100% Ready Picked Blackberry Retail, No Fungicide Application (Table on top), Conventional

Fungicide Program (Table on the bottom).

Year 1 % Year 2 % Year 3 % Year 4 % Year 5 % Year 6 % Year 7 % Year 8 %

Total %

Mark Rows 13.89$ 2.3% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 13.89$ 0.0%

Planting -$ 0.0% 5,473.14$ 47.7% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 5,473.14$ 8.5%

Tipping/Prune/Remove Canes -$ 0.0% 69.45$ 0.6% 375.03$ 5.7% 375.03$ 4.1% 375.03$ 4.1% 375.03$ 4.1% 375.03$ 4.1% 375.03$ 4.1% 2,319.63$ 3.6%

Disk 11.03$ 1.9% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 11.03$ 0.0%

Subsoiler 8.79$ 1.5% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 8.79$ 0.0%

Fertilizer 345.78$ 58.5% 90.59$ 0.8% 88.66$ 1.4% 88.66$ 1.0% 88.66$ 1.0% 88.66$ 1.0% 88.66$ 1.0% 88.66$ 1.0% 968.35$ 1.5%

Weed Spray 24.72$ 4.2% 12.36$ 0.1% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 37.09$ 0.1%

Disease Management -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0%

Construct Trellis -$ 0.0% 4,057.65$ 35.4% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 4,057.65$ 6.3%

Hoeing -$ 0.0% 902.85$ 7.9% 458.37$ 7.0% 458.37$ 5.0% 458.37$ 5.0% 458.37$ 5.0% 458.37$ 5.0% 458.37$ 5.0% 3,653.07$ 5.7%

Soil Testing 131.06$ 22.2% -$ 0.0% -$

0.0% -$ 0.

0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 131.06$ 0.2%

Mowing -$ 0.0% 78.56$ 0.7% 78.56$ 1.2% 78.56$ 0.9% 78.56$ 0.9% 78.56$ 0.9% 78.56$ 0.9% 78.56$ 0.9% 549.93$ 0.9%

Seed Grass 39.15$ 6.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 39.15$ 0.1%

Irrigation -$ 0.0% 443.60$ 3.9% 443.60$ 6.8% 443.60$ 4.8% 443.60$ 4.8% 443.60$ 4.8% 443.60$ 4.8% 443.60$ 4.8% 3,105.18$ 4.8%

Harvest -$ 0.0% -$ 0.0% 1,836.42$ 28.0% 3,037.54$ 33.2% 3,037.54$ 33.2% 3,037.54$ 33.2% 3,037.54$ 33.2% 3,037.54$ 33.2% 17,024.14$ 26.4%

Post-harvest -$ 0.0% -$ 0.0% 3,236.60$ 49.4% 4,636.60$ 50.6% 4,636.60$ 50.6% 4,636.60$ 50.6% 4,636.60$ 50.6% 4,636.60$ 50.6% 26,419.60$ 41.0%

Financial 16.65$ 2.8% 340.42$ 3.0% 38.21$ 0.6% 38.21$ 0.4% 38.21$ 0.4% 38.21$ 0.4% 38.21$ 0.4% 38.21$ 0.4% 586.31$ 0.9%

Total Costs 591.07$ 100.0% 11,468.62$ 100.0% 6,555.44$ 100.0% 9,156.57$ 100.0% 9,156.57$ 100.0% 9,156.57$ 100.0% 9,156.57$ 100.0% 9,156.57$ 100.0% 64,398.00$ 100.0%

Year 1 % Year 2 % Year 3 % Year 4 % Year 5 % Year 6 % Year 7 % Year 8 % Total %

Mark Rows 13.89$ 2.3% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 13.89$ 0.0%

Planting -$ 0.0% 5,473.14$ 46.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 5,473.14$ 8.3%

Tipping/Prune/Remove Canes -$ 0.0% 69.45$ 0.6% 375.03$ 5.5% 375.03$ 4.0% 375.03$ 4.0% 375.03$ 4.0% 375.03$ 4.0% 375.03$ 4.0% 2,319.63$ 3.5%

Disk 11.03$ 1.9% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 11.03$ 0.0%

Subsoiler 8.79$ 1.5% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 8.79$ 0.0%

Fertilizer 345.78$ 58.5% 90.59$ 0.8% 88.66$ 1.3% 88.66$ 0.9% 88.66$ 0.9% 88.66$ 0.9% 88.66$ 0.9% 88.66$ 0.9% 968.35$ 1.5%

Weed Spray 24.72$ 4.2% 12.36$ 0.1% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 37.09$ 0.1%

Disease Management -$ 0.0% 257.87$ 2.2% 257.87$ 3.8% 257.87$ 2.7% 257.87$ 2.7% 257.87$ 2.7% 257.87$ 2.7% 257.87$ 2.7% 1,805.12$ 2.7%

Construct Trellis -$ 0.0% 4,057.65$ 34.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 4,057.65$ 6.1%

Hoeing -$ 0.0% 902.85$ 7.7% 458.37$ 6.7% 458.37$ 4.9% 458.37$ 4.9% 458.37$ 4.9% 458.37$ 4.9% 458.37$ 4.9% 3,653.07$ 5.5%

Soil Testing 131.06$ 22.2% -$ 0.0% -$

0.0% -$ 0.

0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 131.06$ 0.2%

Mowing -$ 0.0% 78.56$ 0.7% 78.56$ 1.2% 78.56$ 0.8% 78.56$ 0.8% 78.56$ 0.8% 78.56$ 0.8% 78.56$ 0.8% 549.93$ 0.8%

Seed Grass 39.15$ 6.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 39.15$ 0.1%

Irrigation -$ 0.0% 443.60$ 3.8% 443.60$ 6.5% 443.60$ 4.7% 443.60$ 4.7% 443.60$ 4.7% 443.60$ 4.7% 443.60$ 4.7% 3,105.18$ 4.7%

Harvest -$ 0.0% -$ 0.0% 1,836.42$ 26.9% 3,037.54$ 32.2% 3,037.54$ 32.2% 3,037.54$ 32.2% 3,037.54$ 32.2% 3,037.54$ 32.2% 17,024.14$ 25.7%

Post-harvest -$ 0.0% -$ 0.0% 3,236.60$ 47.5% 4,636.60$ 49.2% 4,636.60$ 49.2% 4,636.60$ 49.2% 4,636.60$ 49.2% 4,636.60$ 49.2% 26,419.60$ 39.9%

Financial 16.65$ 2.8% 347.47$ 3.0% 45.26$ 0.7% 45.26$ 0.5% 45.26$ 0.5% 45.26$ 0.5% 45.26$ 0.5% 45.26$ 0.5% 635.67$ 1.0%

Total Costs 591.07$ 100.0% 11,733.55$ 100.0% 6,820.37$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 66,252.49$ 100.0%

Table 7 and 8. Estimated Costs for 100% Ready Picked Blackberry Retail (Table on top) and 50% PYO and 50% Ready Picked Blackberry

Retail (Table on the bottom).

Year 1 % Year 2 % Year 3 % Year 4 % Year 5 % Year 6 % Year 7 % Year 8 % Total %

Mark Rows 13.89$ 2.3% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 13.89$ 0.0%

Planting -$ 0.0% 5,473.14$ 46.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 5,473.14$ 8.3%

Tipping/Prune/Remove Canes -$ 0.0% 69.45$ 0.6% 375.03$ 5.5% 375.03$ 4.0% 375.03$ 4.0% 375.03$ 4.0% 375.03$ 4.0% 375.03$ 4.0% 2,319.63$ 3.5%

Disk 11.03$ 1.9% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 11.03$ 0.0%

Subsoiler 8.79$ 1.5% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 8.79$ 0.0%

Fertilizer 345.78$ 58.5% 90.59$ 0.8% 88.66$ 1.3% 88.66$ 0.9% 88.66$ 0.9% 88.66$ 0.9% 88.66$ 0.9% 88.66$ 0.9% 968.35$ 1.5%

Weed Spray 24.72$ 4.2% 12.36$ 0.1% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 37.09$ 0.1%

Disease Management -$ 0.0% 257.87$ 2.2% 257.87$ 3.8% 257.87$ 2.7% 257.87$ 2.7% 257.87$ 2.7% 257.87$ 2.7% 257.87$ 2.7% 1,805.12$ 2.7%

Construct Trellis -$ 0.0% 4,057.65$ 34.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 4,057.65$ 6.1%

Hoeing -$ 0.0% 902.85$ 7.7% 458.37$ 6.7% 458.37$ 4.9% 458.37$ 4.9% 458.37$ 4.9% 458.37$ 4.9% 458.37$ 4.9% 3,653.07$ 5.5%

Soil Testing 131.06$ 22.2% -$ 0.0% -$

0.0% -$ 0.

0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 131.06$ 0.2%

Mowing -$ 0.0% 78.56$ 0.7% 78.56$ 1.2% 78.56$ 0.8% 78.56$ 0.8% 78.56$ 0.8% 78.56$ 0.8% 78.56$ 0.8% 549.93$ 0.8%

Seed Grass 39.15$ 6.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 39.15$ 0.1%

Irrigation -$ 0.0% 443.60$ 3.8% 443.60$ 6.5% 443.60$ 4.7% 443.60$ 4.7% 443.60$ 4.7% 443.60$ 4.7% 443.60$ 4.7% 3,105.18$ 4.7%

Harvest -$ 0.0% -$ 0.0% 1,836.42$ 26.9% 3,037.54$ 32.2% 3,037.54$ 32.2% 3,037.54$ 32.2% 3,037.54$ 32.2% 3,037.54$ 32.2% 17,024.14$ 25.7%

Post-harvest -$ 0.0% -$ 0.0% 3,236.60$ 47.5% 4,636.60$ 49.2% 4,636.60$ 49.2% 4,636.60$ 49.2% 4,636.60$ 49.2% 4,636.60$ 49.2% 26,419.60$ 39.9%

Financial 16.65$ 2.8% 347.47$ 3.0% 45.26$ 0.7% 45.26$ 0.5% 45.26$ 0.5% 45.26$ 0.5% 45.26$ 0.5% 45.26$ 0.5% 635.67$ 1.0%

Total Costs 591.07$ 100.0% 11,733.55$ 100.0% 6,820.37$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 9,421.50$ 100.0% 66,252.49$ 100.0%

Year 1 % Year 2 % Year 3 % Year 4 % Year 5 % Year 6 % Year 7 % Year 8 %

Total %

Mark Rows 13.89$ 2.3% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 13.89$ 0.0%

Planting -$ 0.0% 5,473.14$ 46.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 5,473.14$ 10.0%

Tipping/Prune/Remove Canes -$ 0.0% 69.45$ 0.6% 375.03$ 6.7% 375.03$ 5.1% 375.03$ 5.1% 375.03$ 5.1% 375.03$ 5.1% 375.03$ 5.1% 2,319.63$ 4.2%

Disk 11.03$ 1.9% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 11.03$ 0.0%

Subsoiler 8.79$ 1.5% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 8.79$ 0.0%

Fertilizer 345.78$ 58.5% 90.59$ 0.8% 88.66$ 1.6% 88.66$ 1.2% 88.66$ 1.2% 88.66$ 1.2% 88.66$ 1.2% 88.66$ 1.2% 968.35$ 1.8%

Weed Spray 24.72$ 4.2% 12.36$ 0.1% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 37.09$ 0.1%

Disease Management -$ 0.0% 257.87$ 2.2% 257.87$ 4.6% 257.87$ 3.5% 257.87$ 3.5% 257.87$ 3.5% 257.87$ 3.5% 257.87$ 3.5% 1,805.12$ 3.3%

Construct Trellis -$ 0.0% 4,057.65$ 34.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 4,057.65$ 7.4%

Hoeing -$ 0.0% 902.85$ 7.7% 458.37$ 8.2% 458.37$ 6.2% 458.37$ 6.2% 458.37$ 6.2% 458.37$ 6.2% 458.37$ 6.2% 3,653.07$ 6.6%

Soil Testing 131.06$ 22.2% -$ 0.0% -$

0.0% -$ 0.

0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 131.06$ 0.2%

Mowing -$ 0.0% 78.56$ 0.7% 78.56$ 1.4% 78.56$ 1.1% 78.56$ 1.1% 78.56$ 1.1% 78.56$ 1.1% 78.56$ 1.1% 549.93$ 1.0%

Seed Grass 39.15$ 6.6% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% -$ 0.0% 39.15$ 0.1%

Irrigation -$ 0.0% 443.60$ 3.8% 443.60$ 7.9% 443.60$ 6.0% 443.60$ 6.0% 443.60$ 6.0% 443.60$ 6.0% 443.60$ 6.0% 3,105.18$ 5.7%

Harvest -$ 0.0% -$ 0.0% 918.21$ 16.4% 1,518.77$ 20.5% 1,518.77$ 20.5% 1,518.77$ 20.5% 1,518.77$ 20.5% 1,518.77$ 20.5% 8,512.07$ 15.5%

Post-harvest -$ 0.0% -$ 0.0% 2,935.85$ 52.4% 4,135.35$ 55.9% 4,135.35$ 55.9% 4,135.35$ 55.9% 4,135.35$ 55.9% 4,135.35$ 55.9% 23,612.60$ 43.0%

Financial 16.65$ 2.8% 347.47$ 3.0% 45.26$ 0.8% 45.26$ 0.6% 45.26$ 0.6% 45.26$ 0.6% 45.26$ 0.6% 45.26$ 0.6% 635.67$ 1.2%

Total Costs 591.07$ 100.0% 11,733.55$ 100.0% 5,601.41$ 100.0% 7,401.48$ 100.0% 7,401.48$ 100.0% 7,401.48$ 100.0% 7,401.48$ 100.0% 7,401.48$ 100.0% 54,933.42$ 100.0%

Sample Budget for Blackberry Production

14

UTIA.TENNESSEE.EDU

D 154 02/22 Programs in agriculture and natural resources, 4-H youth development, family and consumer sciences, and resource development. University of Tennessee Institute of Agriculture, U.S. Department of

Agriculture and county governments cooperating. UT Extension provides equal opportunities in programs and employment.