``

CORPORATE

HEADQUARTERS

Great Lakes Region, U.S.A.

TECHNICAL REPORT 1

M. JULIA HAVERTY

STRUCTURAL OPTION

ADVISOR: H. SUSTERSIC

12 SEPTEMBER 2014

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 1

Contents

Executive Summary ....................................................................................................................................................... 2

Purpose and Scope ........................................................................................................................................................ 3

General Description of Building ..................................................................................................................................... 4

Structural Overview ....................................................................................................................................................... 5

Brief Description of the Structural System ............................................................................................................... 5

Building Materials ..................................................................................................................................................... 5

Foundation System ................................................................................................................................................... 6

Floor System .............................................................................................................................................................. 9

Typical Floor Bay .................................................................................................................................................... 9

Framing System ....................................................................................................................................................... 11

Lateral System ......................................................................................................................................................... 12

Column Splices ..................................................................................................................................................... 13

Floor to Curtain Wall Connection ........................................................................................................................ 14

Moment Connection to Columns ........................................................................................................................ 15

Design Codes and Standards ....................................................................................................................................... 16

Design Loads ................................................................................................................................................................ 17

National Code for Live Loads and Lateral Loadings ............................................................................................... 17

Gravity Loads ........................................................................................................................................................... 17

Live Loads: ........................................................................................................................................................... 17

Dead Loads: ......................................................................................................................................................... 18

Snow Loads.............................................................................................................................................................. 18

Lateral Loads ........................................................................................................................................................... 18

Wind Loads: ......................................................................................................................................................... 18

Seismic Loads: ...................................................................................................................................................... 19

Soil Loads ................................................................................................................................................................. 19

Load Paths ................................................................................................................................................................... 20

Gravity Load Path .................................................................................................................................................... 20

Lateral Load Path .................................................................................................................................................... 20

Conclusion ................................................................................................................................................................... 21

Appendices .................................................................................................................................................................. 22

Appendix A: ............................................................................................................................................................. 22

Appendix B: ............................................................................................................................................................. 26

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 2

Executive Summary

The Corporate Headquarters, located in the Great Lakes Region of the United States, is a

new 5 story office and retail space designed to serve as new home base for an established and

successful US based company. The building's architecture was designed to mirror its

surrounding buildings, namely, the newer retail area situated directly to the north of the

building. In keeping with that building style, the Corporate Headquarters features a façade of

glass and face brick, construction crews broke ground on the roughly 660,000 SF building in

August 2014 and have a projected completion date of Spring 2016.

A challenge in the design of the Corporate Headquarters is the poor existing soil

conditions on part of the site. To remedy this problem, aggregate piers will be pushed down

below foundation level for the column spread footings and piers to sit upon. In addition to the

spread footings, a large portion of the building’s foundation features slab on grade and a few

grade beams.

The floor system in floors 2-5 is a composite floor framing structure consisting of metal

deck on top of steel wide flange members. Average bays are rectangular and have slight

variation in size although average sizes are around 38’ and beams typically span 40’. The

primary lateral system of the building is HSS braced frames near the building’s core.

The primary loading conditions considered in the design of this structure were live

loads, dead loads, snow loads, wind loads, seismic loads, and soil loads. To consider these

loading conditions, the 2011 Ohio Building Code was set as primary design criteria. 2011 Ohio

Building Code adopts IBC 2009, which references ASCE 7-05.

The following report will provide further information on these topics. Due to security

reasons, location maps are not currently permitted. Further consultation with the owner to

follow for subsequent technical reports.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 3

Purpose and Scope

The purpose of this technical report is to describe the existing structural conditions of

the Corporate Headquarters, located in the Great Lakes Region of the Midwestern United

States.

The scope of this technical report includes descriptions of structural systems, building

materials, applicable building design codes, design loads, and load paths. This report will focus

primarily on a detailed description of the building’s structural system. This includes descriptions

of the foundation, floor system, lateral system, and roof system. Within the foundation system

description, soil conditions will also be discussed.

A full structural analysis of the design of the Corporate Headquarters will be provided in

subsequent technical reports.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 4

General Description of Building

The Corporate Headquarters will be constructed at the South end of an existing retail

park in the Great Lakes Region of the Midwestern United States. It is a five story office a retail

space designed to serve as the new headquarters for an established and successful US based

company. The new 659,000 SF building’s architecture was designed to blend in with the style of

the surrounding buildings in the retail park. Designed in the contemporary “Americana” style,

the Corporate Headquarters will serve as the last component of the retail area and aims to

become the cornerstone of an already thriving community. Ground was broken on the

Corporate Headquarters in August 2014 and the project’s projected completion date is Spring

2016.

The building features an interior courtyard which begins on the third level of the

building and allows workers within the offices to bring the outside in. Additionally, this grassy

courtyard is meant to help enrich the sense of creativity and community within employees. To

achieve this courtyard, the structural design engineer chose to utilize grade beams and braced

frames, as well as aggregate piers below the foundation to help beef up the poor soil

conditions.

The Corporate Headquarters serves as the south port of entry into a retail plaza and will

incorporate retail space on its ground floor. The upper levels are dedicated to larger open

office spaces that allow for spatial transitions and mobility. Pending acquisition of land adjacent

to the site, a bridge will connect the upper floors of the Corporate Headquarters with a parking

structure, as is commonplace in the rest of the retail park. The proposed face brick and curtain

wall façade mimics the “Main Street America” feel of the retail park but speaks to how the

company has evolved throughout the generations to stay classic, but feel current.

Plans and elevations of the project can be found in Appendix A and B.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 5

Structural Overview

Brief Description of the Structural System

The Corporate Headquarters is supported on a foundation comprised of spread footings,

column piers, grade beams, and partial slab on grade. Floors 2-5 of the building are framed

with a composite system of wide flange members and metal deck. Braced frames near the core

of the building are the primary lateral force resisting system and the roof is also a composite

system of wide flange members and metal deck. In the pages to follow, each component will be

explained in more detail.

Building Materials

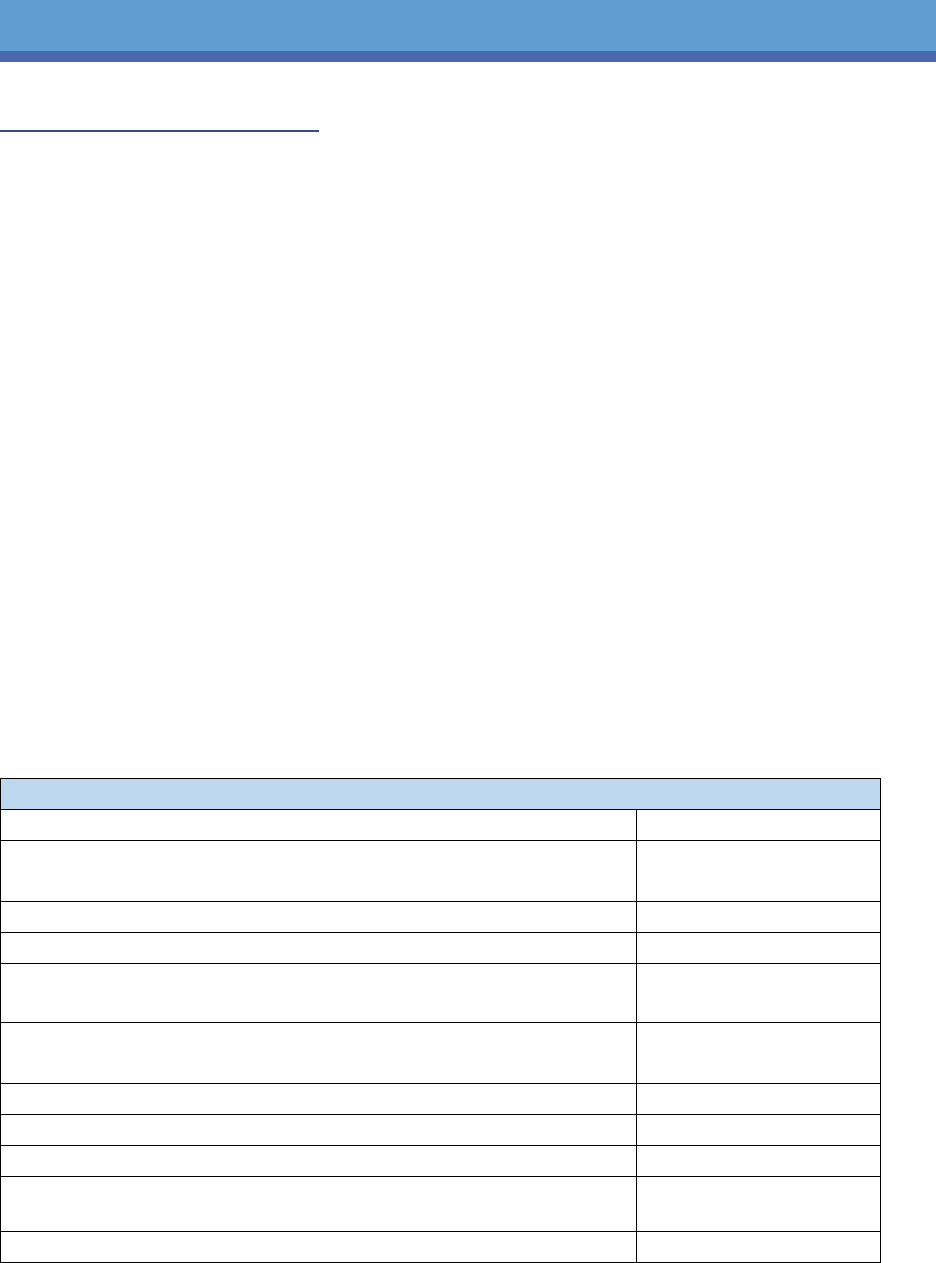

The tables below lists the building materials and specifications used in the design of the

Corporate Headquarters.

Structural Steel

Member

Grade

Wide Flange Shapes & WT Shapes

ASTM A992,UNO

Channels

ASTM A36, UNO

Angles

ASTM A36, UNO

Rectangular and Square Hollow Structural Sections

ASTM A500 GRADE B,

UNO

Round Hollow Structural Sections

ASTM A500 GRADE B,

UNO

Steel Pipe

ASTM A53 GRADE B

Steel Plates

ASTM A36, UNO

High Strength Bolts

ASTM A325 OR A490

Anchor Bolts

ASTM F1554, GRADE 36

AND GRADE 105

Standard Fasteners

ASTM A307

*UNO= unless nothed otherwise in drawings

TABLE X: STURCTURAL STEEL SPECIFICATIONS

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 6

Concrete

Application

Strength

(psi)

Weight

(pcf)

Spread Footings

3500

150

Walls, Piers, Grade Beams

4000

150

Slab on Grade

3500

150

Mud Mat

2000

150

TABLE X: CONCRETE SPECIFICATIONS

Reinforcement

Application

Grade

Deformed Bars

ASTM A615, Grade

60

Deformed Bars (Weldable)

ASTM A706

Welded Wire Fabric

ASTM A185

TABLE X: REINFORCING SPECIFICATIONS

Foundation System

A geotechnical report of the future site of the Corporate Headquarters was performed

by in February 2012 by Geo-Sci, Inc. Following the completion of the report, it was determined

that the soil bearing capacity would not be sufficient to support the weight of the building. In

order to increase the soil capacity, an aggregate pier soil reinforcement systems was utilized

below each free standing column footing. The size of the aggregate pier was determined by the

size of the column footing.

Due to the soil’s sensitivity to both weather and construction activity, it is required that

all footings, both column and wall, be excavated and poured on the same day so as not to

disturb the soil. If this cannot be achieved, a 3” concrete mud mat must be poured over top of

the excavated soil. For ease of constructability, the foundation is comprised of spread footings,

wall footings, column piers, grade beams, partial slab on grade.

This foundation of the Corporate Headquarters required the use of grade beams in order to

transmit the large dead load of the trees planted in the upper level courtyard. This is evident

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 7

due to the placement of the grade beams near the areas with courtyard access, namely, the

southwestern corner of the courtyard and the northwestern corner.

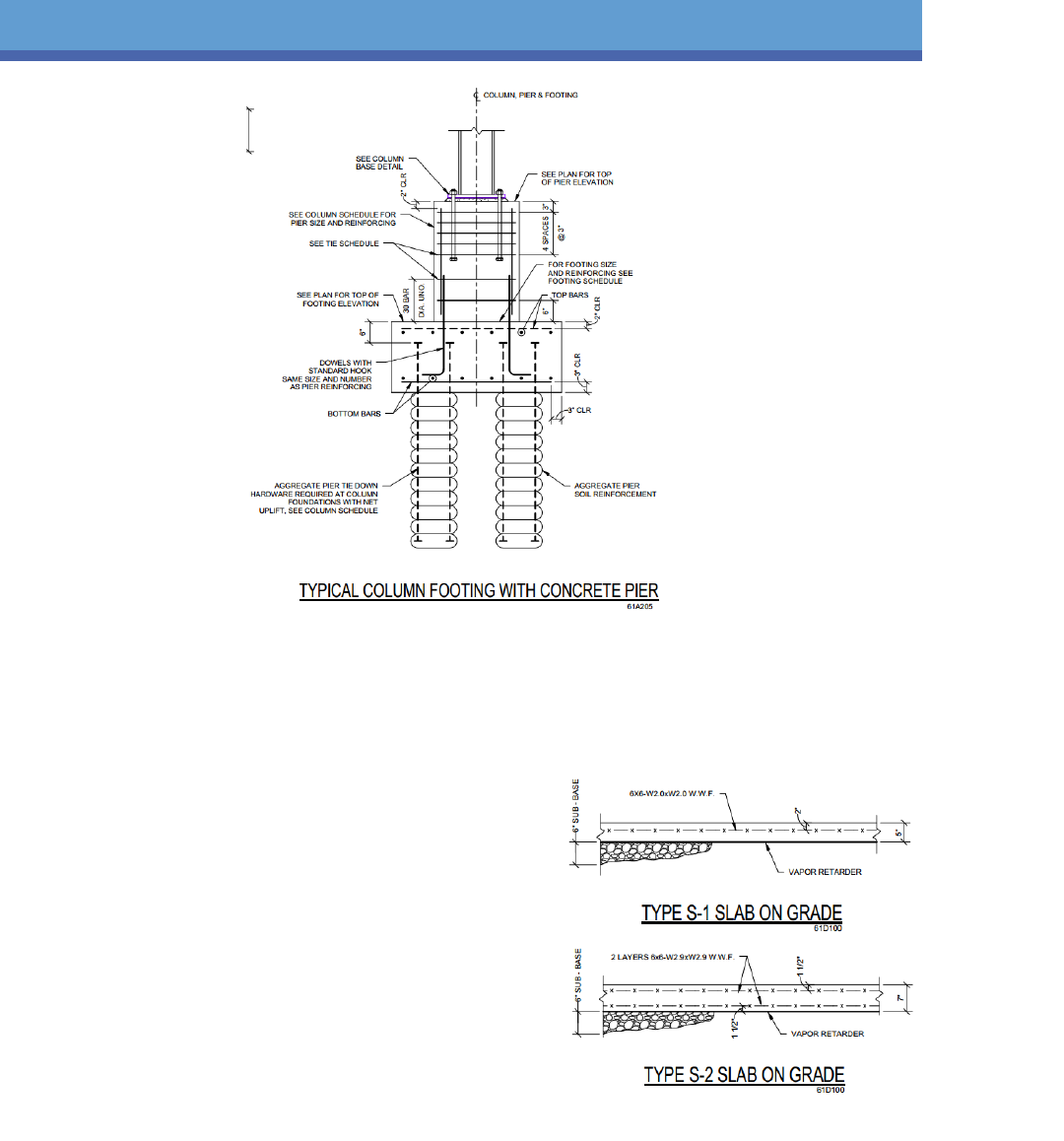

The typical spread footings (Figure 1) are centered under the base of the steel columns and are

placed directly above the aggregate piers used for soil reinforcement. Since there are no

moment frames within the structure of the building, it can be reasonably assumed that the

connections are pinned. For columns that sit on both a spread footing and concrete pier (Figure

2), the connection can also be assumed to be pinned. All spread footings in this building are

required to sit on aggregate piers due to the poor soil quality on the site.

FIGURE 1- TYPICAL STEEL COLUMN AND FOOTING

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 8

FIGURE 2- TYPICAL COLUMN FOOTING WITH CONCRETE PIER

Wall footings are used at all exterior wall locations

along the perimeter of the building, and most of the

building rests on a slab on grade foundation. The

larger slab depth (Type S-2 in) is used throughout

most of the northern half of the building since it is

slightly below grade. Slab Type S-1 is used primarily

near the center of the building, near the area of the

courtyard, and is typical slab on grade construction.

Both slab types can be seen in Figure 3.

FIGURE 3- SLAB ON GRADE DETAILS

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 9

Floor System

The Corporate Headquarter features two different construction assemblies for the floor

system. The first assembly (F-1) features 3 ¼” lightweight concrete with 6x6-W1.4xW1.4 welded

wire fabric reinforcement on top of a 2” 18 gage composite metal deck. Assembly F-2 has 4 ¼”

of lightweight concrete reinforced with 6x6-W2.0xW2.0 welded wire fabric on 3” 16 gage

composite metal deck. The decking runs perpendicular to the wide flange beams.

Typical Floor Bay

Many of the bays in the Corporate Headquarters are rectangular, and shapes only differ

near the edges of the building and the interior courtyard area. A typical beam span is

38’-0” to 40’-0” and a typical bay is between 33’-0” and 38’-0”. Two typical member

sizes used in all levels of floor framing are W21x44 W24x55, with slight variation when

spans are smaller. In the smaller span areas, such as around stair and elevator openings

and the courtyard, W18 shapes and W21 shapes are common. Typical interior girders

for a standard bay are W24x68, and in areas with smaller bays are typically W21 shapes

or lighter W24 shapes. Figure 4 below shows a typical 38’ bay and W24x55 beams.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 10

FIGURE 4: LEVEL 4 FRAMING PLAN SHOWING TYPICAL BAY (S104.D)

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 11

Framing System

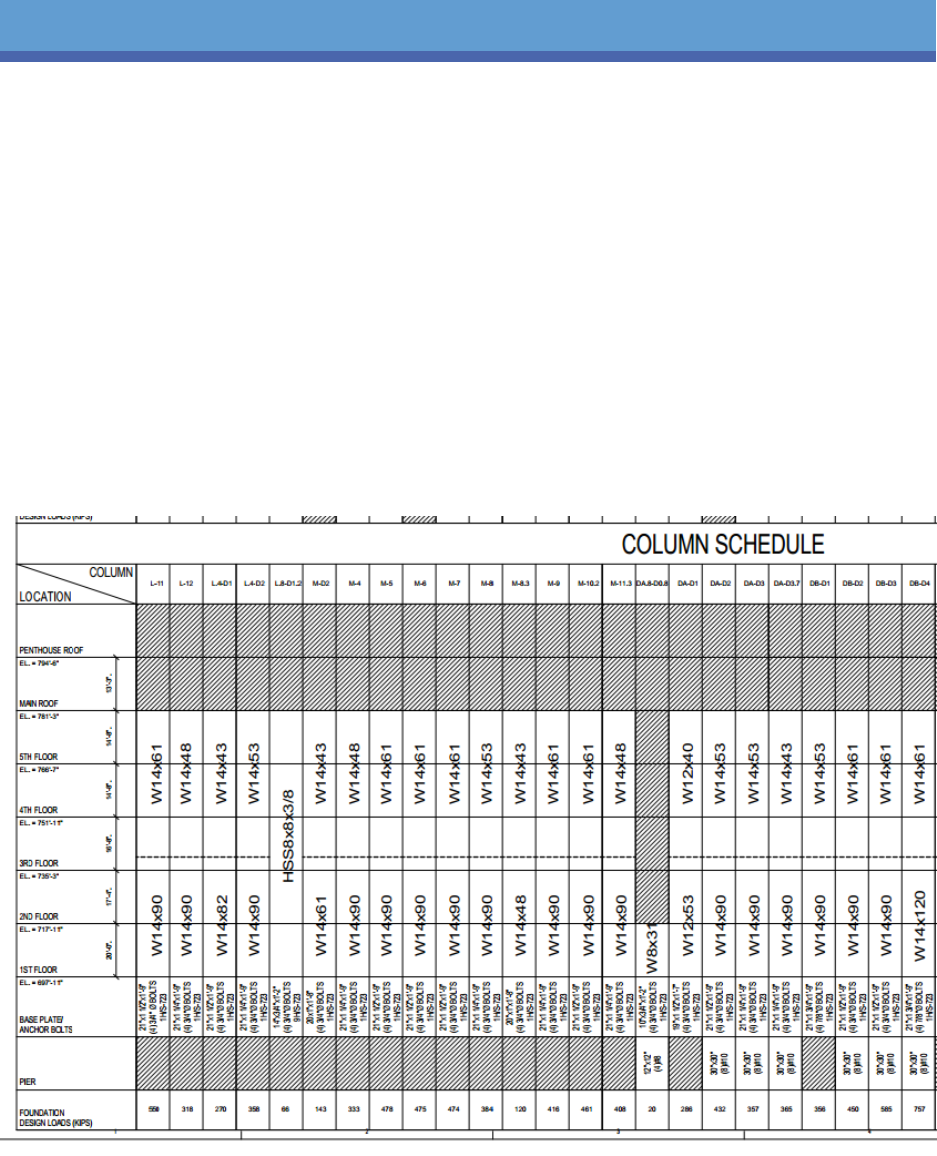

The primary structural framing of the building is composed of steel wide flange columns. All

columns are W14 or W12, with the majority of weights between 61 and 170. The one exception

to this is the lone HSS column that spans from the first floor to the roof. One feature that makes

the building unique is the number of column splices. Nearly every column in the building has a

column splice, and many of the spices are larger shapes on the bottom than the top. Every

combination of column splices varies slightly in size, with no predominant size majority. The

columns are typically spliced between level 2 and level 3, and several columns in the building

feature tension column splices.

FIGURE 5- COLUMN SCHEDULE

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 12

Lateral System

The lateral system of the Corporate Headquarters is made up of a series of braced frames near

the interior of the building. In six locations the braced frames rise from the first floor to the

roof, and in two locations the braced frames begin on the second floor level.

The brace legs are made of Hollow Structural Sections varying from HSS8x8x1/4 to HSS

16x16x5/8. In two locations, the bottom leg of the brace is made of a W14 shape. The braces

take the traditional diagonal shape in five locations, a chevron shape in one location, and an

inverted chevron shape in two locations.

The brace frames were used as the primary lateral force resistance method in their respective

areas due to their lightweight in comparison to shear walls and their ease of constructability.

The majority of the braced frames transfer their loads down to grade beams at the building’s

foundation level.

FIGURE 6- SAMPLE BRACED FRAME ELEVATIONS

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 13

Joint Details

The typical connections found in the Corporate Headquarters are column splices, floor

to curtain wall, and moment connections to columns. In the following section, each connection

type will be briefly described and accompanied by an image from the structural drawings.

Column Splices

Column splices typically occur between floor 2 and floor 3 within the corporate

headquarters. The columns are attached using welding or bolted splice plates and must

be developed to have a minimum of 10% of the tensile capacity of the column flanges.

FIGURE 7- TYPICAL COLUMN SPLICE

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 14

Floor to Curtain Wall Connection

The floor system is connection to the curtain wall via a gravity and lateral connection

piece that sits in the middle of the curtain wall channel. The connection utilizes a bent

plate with long headed studs for extra support.

FIGURE 8-TYPICAL FLOOR TO CURTAIN WALL CONNECTION

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 15

Moment Connection to Columns

To achieve the moment connection to the column web, the members are welded in

place using a weld plate. The stiffener plates used in the connection process are

required to have the same yield strength and thickness as the flange of the beam, which

is typically ¼”. Additionally, each bolted connection used will be slip critical due to the

possibility of oversized holes within the members.

FIGURE 9- TYPICAL MOMENT CONNECTION TO COLUMN

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 16

Design Codes and Standards

The following design codes and standards used during the structural design of the

Corporate Headquarters.

International Code Council

International Building Code 2009

o Incorporated by 2011 Ohio Building Code

American Society of Civil Engineers

ASCE 7-05: Minimum Design Loads for Buildings and Other Structures

o Referenced by IBC 2009

American Concrete Institute

ACI 530: Building Code Requirements for Masonry Structures

o ACI 530.1: Specifications for Masonry Structures

American Institute of Steel Construction

AISC 360-05: Specifications for Structural Steel Buildings

o Supersedes the Load Resistance Factor Design Specification for

Structural Steel Buildings, as given on drawings

American Welding Society

AWS D1.1: Structural Welding Code- Steel

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 17

Design Loads

The focus of this section are the load values used during the structural design of the

Corporate Headquarters. Dead, live, snow, wind, and seismic loads were calculated using the

2011 Ohio Building Code, which adopts IBC 2009, which references ASCE 7-05.

National Code for Live Loads and Lateral Loadings

Live and Lateral loads for the Corporate Headquarters were calculated using 2011 Ohio Building

Code, which adopts IBC 2009 and references ASCE 7-05.

Gravity Loads

Live Loads:

The live loading schedule for this project is listed on sheet S-001. Nearly every

value listed in the drawings can be found in ASCE 7-05, Table 4-1, except for Kitchen

Refrigerator and Freezer Area, and Typical and RTU Roof Areas. The loads not able to be

determined by ASCE 7-05 are explained in greater detail in the table below.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 18

Load

Determination of Load

Kitchen Refrigerator and Freezer Area

Due to heavy traffic during the lunch hour as

well as the weight of the equipment and its

ability to move, the space was designed for

a heavier load than a typical “light storage

warehouse.”

Typical Roof

A typical flat roof requires only 20 psf LL, but

this was upsized by 5 psf since no live load

reduction was utilized.

RTU Roof Areas

No live load reduction utilized, therefore

higher initial live load.

Dead Loads:

The dead load values for this project can be found on sheet S-001 and are based

on industry standards as well as the engineering judgment of the structural design

engineer. Certain dead load values, such as ceiling weight, MEP, and insulation are

based off assumptions.

Snow Loads

The design snow loads are based on the snow load maps found in IBC 2009, which reference

ASCE 7-05. The design loads and factors are listed on sheet S-001 and include the provisions for

drifting snow.

Lateral Loads

Wind Loads:

The design wind loads for this building were split up into two different sets of

criteria: wind loading for the main wind-force resisting system and wind loading for

components and cladding. The overall design criteria for the building’s structural design

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 19

are in accordance with the 2011 Ohio Building Code, which incorporates the 2009 IBC,

which adopted ASCE 7-05. Section 6 of ASCE 7-05 describes the procedure for

determining wind loads with given factors. Those factors, as well as the basic wind

speed, can be found in the design criteria on sheet S-001.

Seismic Loads:

Seismic design loads were determined based on ASCE 7-05, Section 12: Seismic

Design Requirements for Building Structures. The factors needed to determine exact

seismic loading can be found in the design criteria on sheet S-001.

Soil Loads

Soil loads for the building were calculated using the geotechnical report provided by Geo-Sci,

Inc. as well as the 2011 Ohio Building Code, Section 1806.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 20

Load Paths

Gravity Load Path

As loads are applied to a floor, the composite floor decking will carry the load and transfer it

onto the beams and girders in the floor framing. Once the load is taken by the framing, it is

shifted down the columns and is transferred onto the column footings, grade beams, and piers.

At that point, the foundation dissipates the load into the soil below.

The roof and courtyard green space follow a similar load path, taking loads and carrying them

through the deck onto the framing until they hit columns, the foundation, and eventually, the

soil.

Lateral Load Path

The building’s façade takes the distributed wind load and transfers it through the floor system.

The floor carries the load to the brace frames throughout the building and send the force down

to the foundation, where the load is dissipated into the soil.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 21

Conclusion

Technical Report 1 described the existing structural conditions of the Corporate

Headquarters. The report included detailed descriptions of the foundations, floor systems,

framing systems, lateral systems, typical joint conditions, design codes and standards, and

loading.

The architectural design of the Corporate Headquarters was inspired by the surrounding

existing buildings in the retail park just to the north of the site. Since the new building will serve

as a south entrance to the park, it was determined that the architecture should blend and have

a fluid feel as a guest walked from one end of the park to the other. The architectural design

and precedent buildings will have an impact on future assignments since changes made to the

building façade will have to keep the same basic architectural style of face brick and glass.

A major challenge in the building design was the poor soil quality and the request for

the interior courtyard. The poor soil quality required that aggregate piers be placed down in the

soil for column spread footings and piers to brace on. The interior courtyard also provided a

challenge since gravity loads from the upper floors had to take a different load path. The poor

soil quality could be a challenge and must be considered in future assignments.

The braced frame system will be challenging in future assignments due to its placement.

The braced frames lie near the core of the building, rather than on the perimeter, so designing

around them will be challenging. Additionally, the brace frames must be more fully considered

in future load paths. Since the interior composition of the space is so important to the

company, the braced frame must be completely hidden from view in future design and analysis.

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 22

Appendices

Appendix A: Typical Building Floor Plans

Building Key Plan

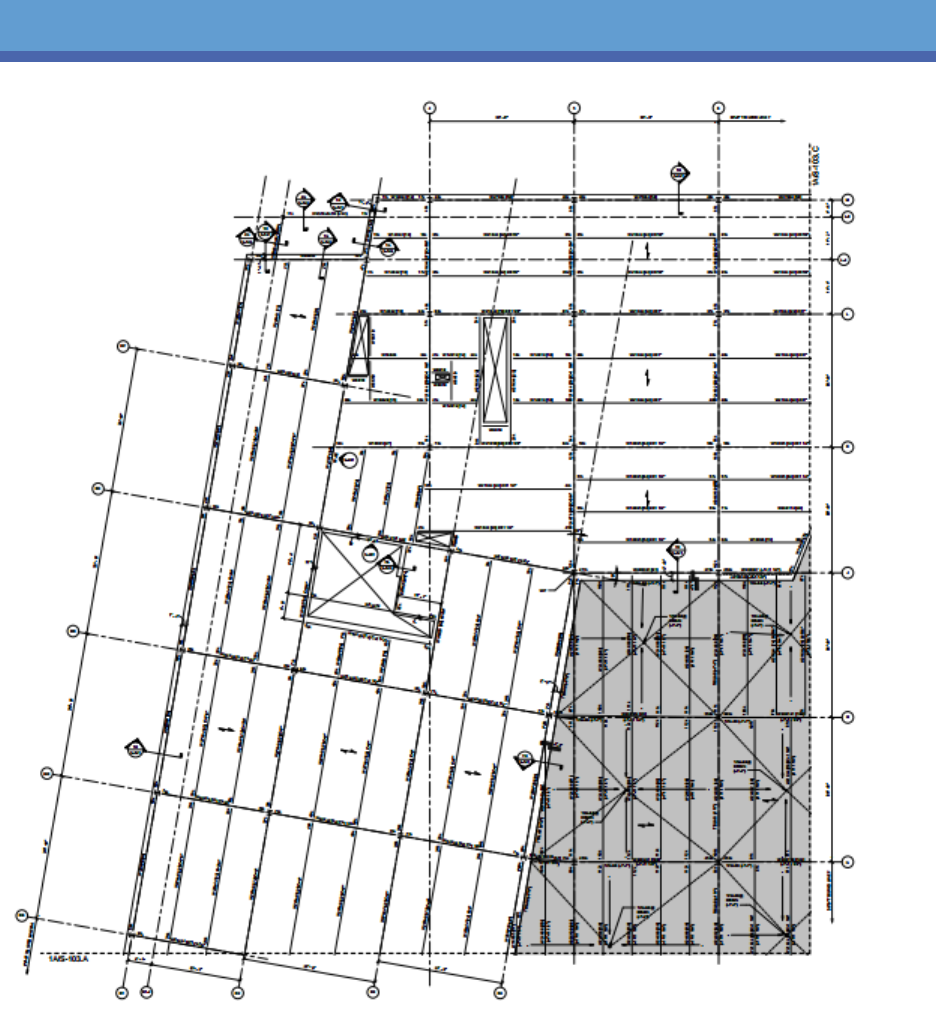

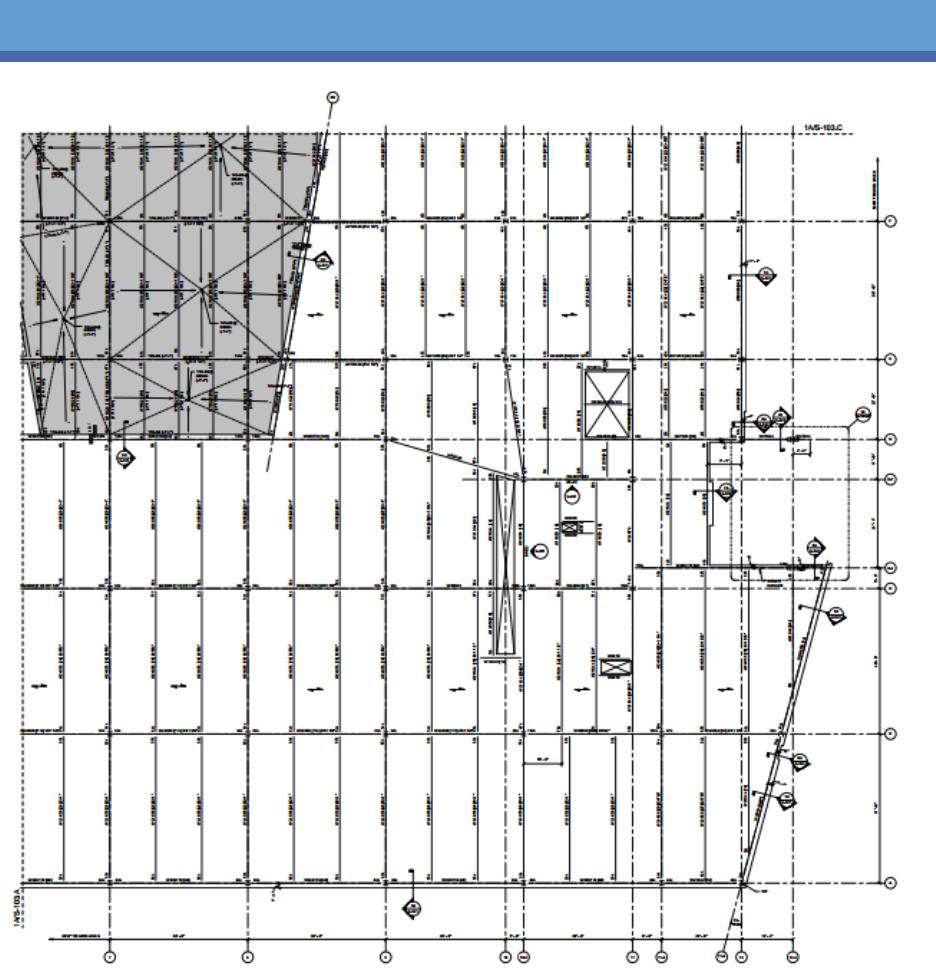

FIGURE 10- TYPICAL SEGMENT A FLOOR FRAMING PLAN

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 23

FIGURE 11- TYPICAL SEGMENT B FLOOR FRAMING PLAN

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 24

FIGURE 12-TYPICAL SEGMENT C FLOOR FRAMING PLAN

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 25

FIGURE 13-TYPICAL SEGMENT D FLOOR FRAMING PLAN

CORPORATE HEADQUARTERS

M. JULIA HAVERTY | STRUCTURAL OPTION

TECHNICAL REPORT 1 26

Appendix B: Building Elevations

FIGURE 14- BUILDING ELEVATIONS, FROM TOP DOWN: SOUTH, WEST, NORTH, EAST