BY ORDER OF THE

SECRETARY OF THE AIR FORCE

AIR FORCE INSTRUCTION 21-101

16 JANUARY 2020

AIR MOBILITY COMMAND

Supplement

03 AUGUST 2020

JOINT BASE MCGUIRE DIX LAKEHURST

Supplement

29 March 2021

Maintenance

AIRCRAFT AND EQUIPMENT

MAINTENANCE MANAGEMENT

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY

ACCESSIBILITY: Publications and forms are available for downloading or ordering on the

e-Publishing website at www.e-publishing.af.mil.

RELEASABILITY: There are no releasability restrictions on this publication.

OPR: AF/A4LM

Supersedes: AFI 21-101, 01 May 2015;

AFI 21-110, 16 Jun 2016;

AFI 21-123, 03 Feb 2017;

AFI 21-124, 12 Jan 2017; and

AFI 21-136, 03 Feb 2017

Certified by: SAF/AQD

(Ms. Angela L. Tymofichuk)

Pages: 439

OPR: AMC/A4MP

Supersedes: AFI21-101_AMCSUP,

09 February 2016;

AFI21-123_AMCSUP,

25 April 2019

(AMC)

Certified by: AMC/A4M

(Lieutenant Colonel Jeffery D. Johns)

Pages: 89

OPR: 305 MXG/MXQ

(JBMDL)

Certified by: 305 MXG/CC

(Colonel Mary R. Teeter)

Supersedes: AFI21-01_AMCSUP_JBMDLSUP,

18 January 2018

Pages: 28

2

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

This publication implements Air Force Policy Directive (AFPD) 21-1, Maintenance of Military

Materiel. It is the basic Air Force Instruction (AFI) for all weapon system and support equipment

maintenance management guidance. It provides the minimum essential guidance and procedures

to safely and effectively maintain, service, and repair weapon systems and support equipment.

This publication applies to all military and civilian members of the Regular Air Force (RegAF),

Air Force Reserve (AFR) and Air National Guard (ANG) and those with contractual obligation to

comply with Air Force publications. Supplements and addendums are written in accordance with

(IAW) AFI 33-360, Publication and Forms Management. Supplements must identify and

document Major Command (MAJCOM), AFR, and ANG required deviations (applicability,

variance, exception and differences in organizational placement of responsibilities/processes) in

their supplement and addendums with the abbreviation “(DEV)”. Place the “DEV” entry after the

Paragraph number and directly preceding the affected text, such as (AMC) (DEV) Use the... or

(ADDED-AMC) (DEV) Use the...). All supplements and addendums are submitted to the Air

Force Maintenance Division (AF/A4LM) @ usaf.pentagon.af-a4.mbx.a4lm-maintenance-

policy@mail.mil for approval and are published in the e-Publishing website. The authorities to

waive wing and unit level requirements in this publication are identified with a Tier (“T-0, T-1, T-

2, T-3”) number following the compliance statement. See AFI 33-360 for a description of the

authorities associated with the Tier numbers. Submit requests for waivers through the chain of

command to the appropriate Tier waiver approval authority, or alternately, to the requestor’s

commander for non-tiered compliance items. For questions on interpreting this instruction, first

contact your MAJCOM maintenance functional activity. Refer recommended changes and

questions about this publication through your MAJCOM, AFR or ANG, to the Office of Primary

Responsibility (OPR) using the Air Force (AF) Form 847, Recommendation for Change of

Publication; route AF Forms 847 from the field through the appropriate functional chain of

command. Ensure all records created as a result of processes prescribed in this publication are

maintained in accordance with Air Force Manual 33-363, Management of Records, and disposed

of in accordance with the Air Force Records Disposition Schedule located in the Air Force Records

Information Management System. The use of the name or mark of any specific manufacturer,

commercial product, commodity, or service in this publication does not imply endorsement by the

AF.

(AMC) This supplement implements and extends the guidance of AFI 21-101, Aircraft and

Equipment Maintenance Management. This publication implements major command (MAJCOM)

policy by supplementing specific processes and procedures that are unique to Air Mobility

Command (AMC). This publication is applicable to all AMC units and Air Force Reserve

Command (AFRC) and Air National Guard (ANG) upon mobilization and/or AMC-led classic

AFRC and ANG associations. This publication may be supplemented at any level, but all direct

Supplements are not required to be sent to the OPR for review unless they have deviations. The

authorities to waive wing/unit level requirements in this publication are identified with a tier (“T-

0, T-1, T-2, T-3”) number following the compliance statement. See AFI 33-360, Publication and

Forms Management, for a description of the authorities associated with the tier numbers. Submit

requests for T-0, T-1, T-2, and non-tiered waivers through the chain of command to the appropriate

recommended changes and questions about this publication to the Office of Primary Responsibility

(OPR) using Air Force Form 847, Recommendation for Change of Publication; route AF Form

847s from the field through the appropriate functional’s chain of command. Ensure that all records

created as a result of processes prescribed in this publication are maintained in accordance with

3

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

0AFI 33-322, Records Management and Information Governance Program, and disposed in

accordance with Air Force Records Disposition Schedule, which is located in the Air Force

Records Information Management System. The use of the name or mark of any specific

manufacturer, commercial product, commodity, or service in this publication does not imply

endorsement by the Air Force.

(JBMDL) Air Force Instruction (AFI) 21-101 Air Mobility Command (AMC) Supplement (SUP),

Aircraft and Equipment Maintenance Management, 03 August 2020, is supplemented as follows:

This instruction supplements AFI 21-101, (16 January 2020) and AFI 21-101 AMCSUP,

(03 August 2020), and supersedes AFI 21-101 AMCSUP_JBMDLSUP (18 January 2018). It is the

basic Air Force directive for aircraft and equipment maintenance management. It provides the

extended guidance and procedures for safely and effectively maintaining, servicing, and repairing

aircraft and support equipment. It acknowledges the foundational contributions made to Agile

Combat Support (ACS) capabilities of Generating the Mission, and Supporting and Sustaining the

Mission, Forces, and Infrastructure. It applies to all agencies under the direction of the 305th Air

Mobility Wing (AMW), and the 514th Air Mobility Wing (AMW) along with their subordinates.

Ensure that all records created as a result of processes prescribed in this publication are maintained

In accordance with (IAW) Air Force Manual (AFMAN) 33-363, Management of Records, and

disposed of IAW Air Force Records Information Management System (AFRIMS) Records

Disposition Schedule (RDS). Refer recommended changes and questions about this publication to

the Office of Primary Responsibility (OPR) using the Air Force (AF) Form 847, Recommendation

for Change of Publication; route AF Form 847s from the field through the appropriate functional’s

chain of command.

4

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

SUMMARY OF CHANGES

This publication has been substantially revised and must be completely reviewed in its entirety.

Significant changes include the addition of Maintenance Cyber Discipline requirements,

Decentralized Materiel Support, incorporation of four AFIs superseded above and establishes a

Wing Avionics Manager Position requirement. Additionally, eTool and World Wide Identification

(WWID) management procedures were expanded to provide standardized enterprise requirements.

MAJCOMs/ANG designated to establish Special Certification Roster (SCR) prerequisites to

optimize workforce alignment to mission requirements.

(AMC) This publication has been substantially revised and must be completely reviewed. The

major changes in the supplement are as follows: En Route reorganization, flying crew chief duty

day guidance, hangar queen, MAJCOM prerequisites for special certification roster, ramp

inspection, AFREP, aircraft ground deice, maintenance scheduling effectiveness, and maintenance

human factors.

(JBMDL) This publication has been substantially revised and must be completely reviewed. The

major change in this supplement pertains to the incorporation of the JBMDL/305 AMW FOD

Walk/Prevention policy.

Chapter 1—MANAGEMENT OVERVIEW, SUPPORTING CONCEPTS AND

REQUIREMENTS.

15

1.1. Introduction. ........................................................................................................... 15

1.2. Organization. .......................................................................................................... 15

1.3. Maintenance Concept. ........................................................................................... 15

1.4. Aircraft Maintenance Tactics, Techniques and Procedures (TTP). ....................... 16

1.5. Aircraft and Equipment Readiness. ....................................................................... 16

1.6. Maintenance Discipline. ........................................................................................ 17

1.6. (AMC) Maintenance Discipline. ............................................................................ 17

1.7.

Communications Security (COMSEC)/Controlled Cryptographic Item (CCI)

Accountability. ........................................................................................................

18

Table 1.1. Tiered Interface Examples. ..................................................................................... 19

1.8. Environmental Compliance. .................................................................................. 22

1.9. Publications. ........................................................................................................... 23

1.10. Maintenance Training. ........................................................................................... 23

1.10. (AMC) Maintenance Training. .............................................................................. 23

1.11. Modification Management. .................................................................................... 23

1.12. Maintenance Information Systems (MIS). ............................................................. 23

1.12.

(AMC) Maintenance Information Systems (MIS). ................................................

24

5

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

1.13.

General Safety Guidance. ......................................................................................

24

1.14. Duty Shifts and Rest Periods. ................................................................................ 24

1.15. Communications. ................................................................................................... 25

1.16. Maintenance Repair Priorities. ............................................................................... 26

Table 1.2.

Maintenance Repair Priority Designators. ..............................................................

26

1.17. Associate Unit Program/Total Force Integration (TFI). ........................................ 28

1.18. Performance-Based Activities. .............................................................................. 28

1.19. Changes to Technical Orders. ................................................................................ 29

Chapter 2—ROLES AND RESPONSIBILITIES 30

2.1.

General. ..................................................................................................................

30

2.2. Wing Commander (WG/CC) Responsibilities. ...................................................... 30

2.2. (AMC) Wing Commander (WG/CC) Responsibilities. ......................................... 30

2.3. Wing Vice Commander (WG/CV) Responsibilities. ............................................. 32

2.4. Maintenance Group Commander (MXG/CC) Responsibilities. ............................ 32

2.4. (AMC) [DEV] Maintenance Group Commander (MXG/CC) Responsibilities. ... 32

2.5. Deputy Maintenance Group Commander (MXG/CD). .......................................... 40

2.5. (AMC) Deputy Maintenance Group Commander (MXG/CD) will: ...................... 40

2.6. MXG Superintendent Responsibilities. ................................................................. 41

2.6. (AMC) MXG Superintendent Responsibilities. ..................................................... 41

2.7. Wing Weapons Manager (WWM). ........................................................................ 42

2.8. Squadron Commander (SQ/CC) Responsibilities. ................................................. 46

2.9. Maintenance Supervision Responsibilities. ........................................................... 47

2.9. (AMC) Maintenance Supervision Responsibilities. ............................................... 47

2.10. Flight Supervision. ................................................................................................. 50

2.11. Production Superintendent (Pro Super). ................................................................ 53

2.12. Section NCOIC/Chief. ........................................................................................... 53

Table 2.1. Military Grades and Non-ART Civil Service Grade Equivalents........................... 56

Table

2.2.

AFSC Levels and Non-ART Civil Service AFSC Level Equivalents. ...................

56

6

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

Chapter 3—AIRCRAFT MAINTENANCE SQUADRON (AMXS). 57

3.1.

General. ..................................................................................................................

57

3.1. (AMC) General. ..................................................................................................... 57

3.2. Maintenance Supervision Responsibilities. ........................................................... 57

3.3. Aircraft Maintenance Unit (AMU). ....................................................................... 57

3.4. AMU OIC/SUPT Responsibilities. ........................................................................ 57

3.5. Production Superintendent (Pro Super). ................................................................ 58

3.6. Flightline Expediter. .............................................................................................. 59

3.7. Aircrew and Maintenance Debrief Section. ........................................................... 60

3.7. (AMC) Aircrew and Maintenance Debrief Section. .............................................. 60

Table 3.1. Landing Status Codes. ............................................................................................ 62

Table 3.2. System Capability Codes ........................................................................................ 63

Table 3.3. Deviation Cause Codes ........................................................................................... 64

Table 3.4. Function With Primary Responsibility for Loading WWNDB and

TAWS/EGPWS. ......................................................................................................

64

3.8. Aircraft Section. ..................................................................................................... 65

3.9. Specialist Section. .................................................................................................. 66

3.9. (AMC) Specialist Section. ..................................................................................... 66

3.10. Weapons Section. ................................................................................................... 67

3.11. Support Section. ..................................................................................................... 74

3.12. AMU Decentralized Materiel Support (DMS). ...................................................... 74

3.12. (AMC) AMU Decentralized Materiel Support (DMS). ......................................... 74

3.13. En Route Operations. .............................................................................................. 75

3.14.

Contingency Response Wing (CRW) Maintenance Operations. ............................

77

Chapter 4—MAINTENANCE SQUADRON (MXS) 80

4.1. General. .................................................................................................................. 80

4.2. Maintenance Supervision Responsibilities. ........................................................... 80

4.3. MXS Production Superintendent (Pro Super). ....................................................... 80

4.4. Accessories Flight. ................................................................................................. 81

7

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

4.5. Aerospace Ground Equipment (AGE) Flight. ....................................................... 86

4.6. Armament Flight. ................................................................................................... 89

4.7. Avionics Flight. ..................................................................................................... 90

4.8. Fabrication Flight. .................................................................................................. 93

4.9. Maintenance Flight. ............................................................................................... 96

4.10. Munitions Flight. ................................................................................................... 99

4.11. Propulsion Flight. ................................................................................................... 100

4.12. Test, Measurement, and Diagnostic Equipment (TMDE) Flight. .......................... 107

Chapter 5— MAINTENANCE OPERATIONS (MXO). 110

5.1.

General. ..................................................................................................................

110

5.1. (AMC) [DEV] General. .......................................................................................... 110

5.2. Maintenance Operations. ....................................................................................... 110

Table 5.1. AMC Definitions and Formulas if not identified in Chapter 5 (T-2)...................... 126

5.3. Maintenance Training (MT). .................................................................................. 131

5.3. (AMC) Maintenance Training (MT) ...................................................................... 131

5.4.

Programs and Resources (P&R). ...........................................................................

131

Chapter 6— QUALITY ASSURANCE (QA) 133

6.1. General. .................................................................................................................. 133

6.1. (AMC) General. ..................................................................................................... 133

6.2. Responsibilities. ..................................................................................................... 133

6.2. (AMC) Responsibilities. ........................................................................................ 133

6.3. QA Superintendent (QA SUPT) Responsibilities. ................................................. 135

6.4. Chief Inspector Responsibilities. ........................................................................... 137

6.5. Quality Assurance Inspector Responsibilities. ....................................................... 139

6.6. Quality Assurance Inspector Training. .................................................................. 139

6.7. Maintenance Standardization and Evaluation Program (MSEP). .......................... 140

6.8. LEAP QA Database. .............................................................................................. 153

6.9. QA Product Improvement Programs (PIP). ........................................................... 155

6.10. Technical Order Distribution Office (TODO). ...................................................... 156

8

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

6.11.

One-Time Inspections (OTI) program. ...................................................................

159

6.12.

Functional Check Flights (FCFs) to include Operational Check Flights (OCFs)... 159

6.13.

Inflight Operational Checks. ................................................................................... 161

6.14.

High Speed Taxi Checks......................................................................................... 162

6.15.

Weight and Balance (W&B) Program. ................................................................... 162

6.15.

(AMC) Weight and Balance (W&B) Program. ..................................................... 162

Chapter 7—

IMPOUNDMENT PROCEDURES 164

7.1. Aircraft and Equipment Impoundment. ................................................................. 164

7.2. Specific Guidance. ................................................................................................. 164

7.3. Impoundment Authorities. ..................................................................................... 165

7.4. Impoundment Official Responsibilities. ................................................................ 165

7.5. Mandatory Impoundments. ..................................................................................... 165

7.6. Impoundment Procedures. ...................................................................................... 166

7.7. Rules of Impoundment Specifically for Explosive-Related Events/Mishaps. ........ 168

Chapter 8—

TOOL AND EQUIPMENT MANAGEMENT 170

8.1. Tool and Equipment Management........................................................................... 170

8.2. Guidelines for Program Management. .................................................................... 170

8.2. (AMC) Guidelines for Program Management. ....................................................... 170

8.3. General Program Guidelines................................................................................... 172

8.4. TMDE Management Guidelines. ............................................................................ 175

8.5. Tool Accountability. ............................................................................................... 176

8.6. Tool and Equipment Marking and Identification. .................................................. 178

Table 8.1. JBMDL WWID Listing. ......................................................................................... 180

8.7. Locally Manufactured, Developed, or Modified Tools and Equipment ................ 181

8.8. Tool Room Operations and Security. ..................................................................... 182

8.9.

Lost Item/Tool Procedures. ....................................................................................

183

Chapter 9—MATERIEL MANAGEMENT SUPPORT 185

9.1.

General. ...................................................................................................................

185

9

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

9.2. Decentralized Materiel Support. ............................................................................. 185

9.3. Supply Discipline.................................................................................................... 186

9.4. Readiness Spares Package Review. ....................................................................... 186

9.5. Bench Stock. .......................................................................................................... 186

9.6. Consumable Readiness Spares Package. ................................................................ 186

9.7. Shop Stock. ............................................................................................................ 187

9.8. Operating Stock. ..................................................................................................... 187

9.9. Work Order Residue................................................................................................ 187

9.10. Adjusted Stock Levels. .......................................................................................... 187

9.11. Shelf Life Items. .................................................................................................... 187

9.12. Equipment Items. ................................................................................................... 188

9.13.

Special Purpose Recoverable Authorized Maintenance (SPRAM). ...................... 188

9.14.

Supply Assets Requiring Functional Check, Calibration, or Operational Flight

Programming ................................................................................................................. 188

9.15.

Time Compliance Technical Order (TCTO) Kit Procedures. ................................. 188

9.16. Supply Points. ........................................................................................................ 188

9.17. Local Manufacture. ................................................................................................. 189

9.18. DIFM Management................................................................................................. 189

9.19. Tail Number Bins (TNB). ....................................................................................... 191

9.20. CANN Actions. ....................................................................................................... 191

9.21. Bench Check and Repair Policy. ............................................................................ 191

9.21. (AMC Bench Check and Repair Policy. ................................................................ 192

9.22. Maintenance Turn-Around Record Update Processing. ......................................... 192

9.22. (AMC) Maintenance Turn-Around (TRN) Record Update Processing. ................ 192

9.23. Buildup Items. ........................................................................................................ 192

9.23. (AMC) Buildup Items. ........................................................................................... 192

9.24. DR Exhibits. ........................................................................................................... 192

9.25. Destruction of TOP SECRET Material. ................................................................ 192

9.26. Certifying Items Associated With Explosives ...................................................... 193

Chapter 10—MUNITIONS POLICY AND WEAPONS LOAD CREW PROGRAM 194

10.1. AF Munitions Policy. ................................... ........................................................ 194

10

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

10.2.

Unit Committed Munitions List (UCML), Test/Training Munitions List

(TTML). ..................................................................................................................

194

10.3. Weapons Load Crew Training Program (WLCTP). .............................................. 195

10.4. Loading Standardization Crew (LSC). .................................................................. 197

10.5. Weapons Academic Instructor. .............................................................................. 198

10.6. Squadron Lead Crews. ........................................................................................... 198

10.7. Training Facilities/Aircraft. .................................................................................... 198

10.8. Weapons Academics. .............................................................................................. 199

10.9. Practical Training. .................................................................................................. 200

10.10. Task Assignment List. ........................................................................................... 200

10.11. Munitions Aircraft Loading Certification/Decertification. ..................................... 201

10.12. Proficiency Review Period. ................................................................................... 204

10.13. Minimum Required Proficiency Load. .................................................................. 204

10.14. Load Crew Semi-Annual Evaluations (SAE). ....................................................... 204

10.15. Documenting Load Crew Certification/Decertification/Qualification.................... 205

10.16. Weapons Task Qualification. ................................................................................. 206

10.17. Munitions Load Time Standards. ........................................................................... 207

Table 10.1.

Fighter Aircraft Munitions Family Group and Munition Load Time Standards (in

minutes). ..................................................................................................................

208

Table 10.2. Bomber Aircraft Munitions Family Group and Munition Load Time Standards. .. 210

Table 10.3.

Remote Piloted/Special Mission Aircraft Munitions Family Group and Munition

Load Time Standards ...............................................................................................

211

Chapter 11—ADDITIONAL MAINTENANCE REQUIRMENTS AND PROGRAMS 213

11.1. Facility Housekeeping and Contamination Control. .............................................. 213

11.2. Personal Wireless Communications Systems Management. .................................. 213

11.3. MAJCOM/ANG Special Certification Rosters (SCR). .......................................... 213

11.3. (AMC) Special Certification Roster (SCR). .......................................................... 213

Table 11.1. Mandatory Special Certification Roster and Prerequisites. .................................... 216

Table 11.1. (AMC) Mandatory Special Certification Roster and Prerequisites. ....................... 218

11.4.

Aircrat Grounding. ................................................................................................

223

11

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

11.5. Ramp Inspection Program. ..................................................................................... 224

11.6. Red Ball Maintenance. ........................................................................................... 228

11.7. Maintenance Recovery Team: ............................................................................... 228

11.7. (AMC) Maintenance Recovery Team (MRT): ...................................................... 228

11.8 Foreign Object Damage (FOD) Prevention Program. ........................................... 228

11.9. Dropped Object Prevention (DOP) Program. ........................................................ 238

11.9. (AMC) Dropped Object Prevention (DOP) Program. ........................................... 238

11.10. Aircraft Structural Integrity Program (ASIP). ....................................................... 240

11.11. Identification Friend or Foe (IFF) Program. ........................................................... 241

11.12.

Radar Warning Receiver/Radar Threat Warning Testing .............................................. 241

11.13.

Cannibalization Program ................................................................................................ 242

11.14. Hangar Queen Aircraft.............................................................................................. 243

11.15. Ground Instructional Trainer Aircraft (GITA). ........................................................ 245

11.16. Aircraft Inlet/Intake/Exhaust Certification. ............................................................ 248

11.17. Engine Run Training and Certification Program. ................................................... 248

11.18.

Engine Blade Blending Training and Certification Program. ................................ 257

11.19.

Engine Flexible Borescope Inspection Training and Certification Program. .......... 258

11.20. Flying Crew Chief (FCC) Program. ....................................................................... 259

11.21. Maintenance of Flash Blindness Protective Devices. ............................................. 271

11.22. WRM External Nestable Fuel Tank Build-Up. ...................................................... 271

11.23. Protective Aircraft Shelters (PAS). ........................................................................ 272

11.24. Combat Sortie Generation. ..................................................................................... 272

11.25. Hot Refueling Procedures. ..................................................................................... 273

11.26. Aircraft Rapid/Hot Defueling. ................................................................................ 277

11.27.

406 MHz Emergency Locator Transmitter Systems Program. .............................. 277

11.28.

Crashed, Damaged or Disabled Aircraft Recovery (CDDAR) Program. .............. 278

11.29. 11.29. Aircraft Battle Damage Repair (ABDR). .................................................. 281

11.30. 11.30. Egress/Cockpit Familiarization Training. .................................................. 283

11.31. 11.31. Aircraft Defensive Systems Loading Program. .......................................... 284

12

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

11.32. Aircraft and Equipment Decontamination. ............................................................. 289

11.33. End-of-Runway (EOR) Inspection. ........................................................................ 289

11.34. Wing Avionics Manager (WAM). .......................................................................... 290

11.35. Fire Extinguisher Requirements. ............................................................................. 291

11.36. Air Force Repair Enhancement Program (AFREP). ............................................... 291

11.37. Calibration Limitation Approval Certification Program......................................... 297 11.38.

Oil Analysis Program (OAP). ................................................................................. 298

11.39. Air Force Engineering and Technical Services (AFETS)....................................... 303 11.40.

Senior Leader Mission Generation (SLMG) Course. ............................................. 308 11.41.

(AMC) KC-135 MPRS Manager. .......................................................................... 309

11.42. (AMC) Mobile Crane Operation Training and Qualification Program. ................. 309

11.43. (AMC) Tow Team Supervisor Certification Program. ............................................ 310

11.44. (AMC) Graduate Assessment Program. .................................................................. 310

11.45. (AMC) Aircraft Ground Deice ....................................................................................... 311

Chapter

12—MAINTAINING

COMMERCIAL

DERIVATIVE AIRCRAFT (CDA).

313

12.1. Background Information, Objective and Roles and Responsibilities. ................... 313

12.2. AF/A4L will:........................................................................................................... 313

12.3. The Program Manager (PM) will:...........................................................................

313

12.4. Lead Commands will: ............................................................................................. 314

12.5. Units will: ............................................................................................................... 314

12.6. Maintenance Personnel Requirements. .................................................................. 315

12.7. Deviations/Changes to Inspection Requirements, Time Change Intervals, and

Component/Aircraft Overhaul. ............................................................................... 315

12.8. Air Force Modifications to CDA and Components. .............................................. 315

12.9. Certification Basis for CDA. .................................................................................. 315

Chapter 13—CENTRALIZED REPAIR FACILITIES (CRF). 316

13.1. Introduction. ........................................................................................................... 316

13.2. Organization. .......................................................................................................... 316

13.3. CRF Production Requirements. ............................................................................. 316

13

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

13.4. MGN Support. ........................................................................................................

316

13.5. CRF Enterprise Information Management. ............................................................ 317

13.6. Documentation. ...................................................................................................... 317

13.7. Metrics. .................................................................................................................. 317

Chapter 14—MAINTENANCE PLANS, SCHEDULING AND DOCUMENTATION

(PS&D).

318

14.1. Responsibilities:...................................................................................................... 318

14.2. Data Documentation. .............................................................................................. 321

14.3. Configuration, TCTO, SI and TCI Management. ................................................... 330

14.4. ENGINE MANAGEMENT (EM). ......................................................................... 344

14.5. Maintenance and FHP Planning Cycle. .................................................................. 352

Table 14.1. (AMC) Scheduled Look Phase Times. ................................................................... 362

Table 14.2. (AMC) Maintenance Scheduling Effectiveness Computation................................ 363

14.6. Contingency and Expeditionary Responsibilities. .................................................. 364

14.7. Aircraft Schedule Effectiveness (ASE) Computation............................................. 366

Table 14.3. (AMC) Deviation Type Codes................................................................................ 367

Table 14.4. (AMC) Deviations Type Codes Not Included in ASE............................................ 369

Table 14.5. (AMC) AMC Approved Deviation Cause Codes. .................................................. 369

Table 14.6. (AMC) AMC Definitions and Formulas if not identified in Chapter 14. ............... 371

Chapter 15—AIRCRAFT SUN SHADE SUSTAINMENT 373

15.1. Purpose: ................................................................................................................. 373

15.2. Scope: ..................................................................................................................... 373

15.3. Definitions. ............................................................................................................. 373

15.4. Headquarters Air Force........................................................................................... 374

15.5. MAJCOM A4s will:................................................................................................ 374

15.6. Owning Organization.............................................................................................. 375

15.7. New Procurements. ................................................................................................. 375

15.8. Design Criteria/Standards of New or Replacement Aircraft Sun Shades............... 378

15.9. Current Aircraft SunShades. ..................................................................................

380

14

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

15.10. Sustainment and Accountability. ........................................................................... 381

15.11. Allied Support (Electricity, Water, Communications, Lighting)............................ 382

15.12. Crew Shelters and Portable/Inflatable Shelters....................................................... 383

Chapter 16—MAINTENANCE HUMAN FACTORS 385

16.1. Maintenance Human Factors. ................................................................................ 385

16.2. Program Requirements. ......................................................................................... 385

16.3. Responsibilities. ..................................................................................................... 386

Attachment 1—GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION 390

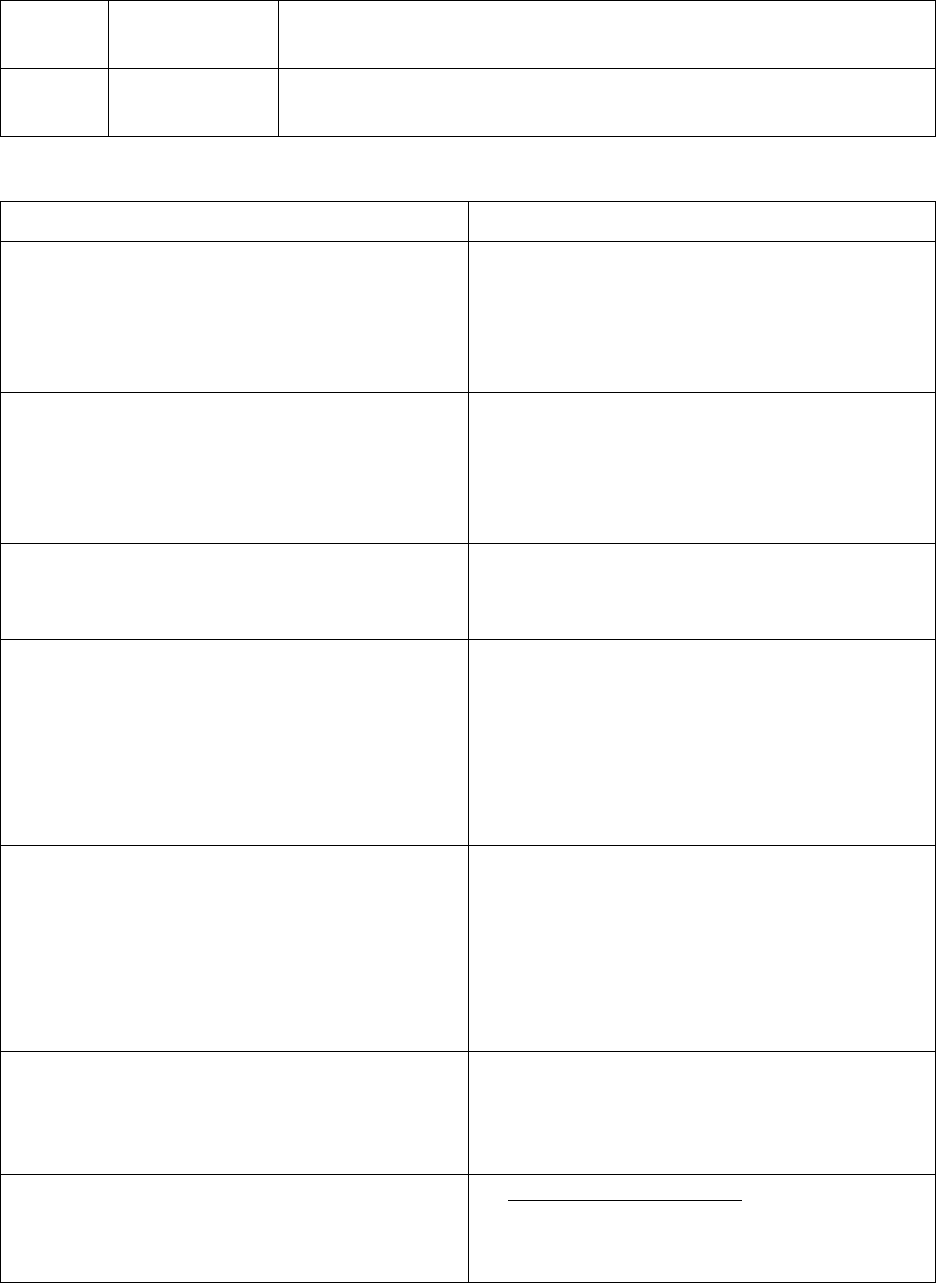

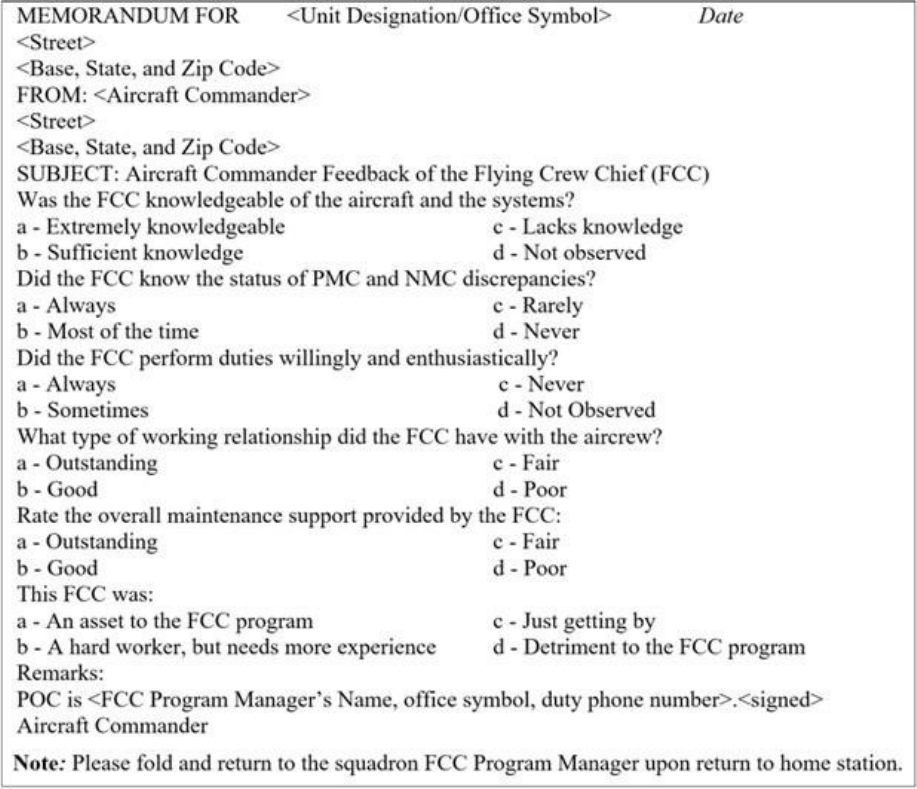

Attachment 2—AIRCRAFT COMMANDER FEEDBACK ON FCC 424

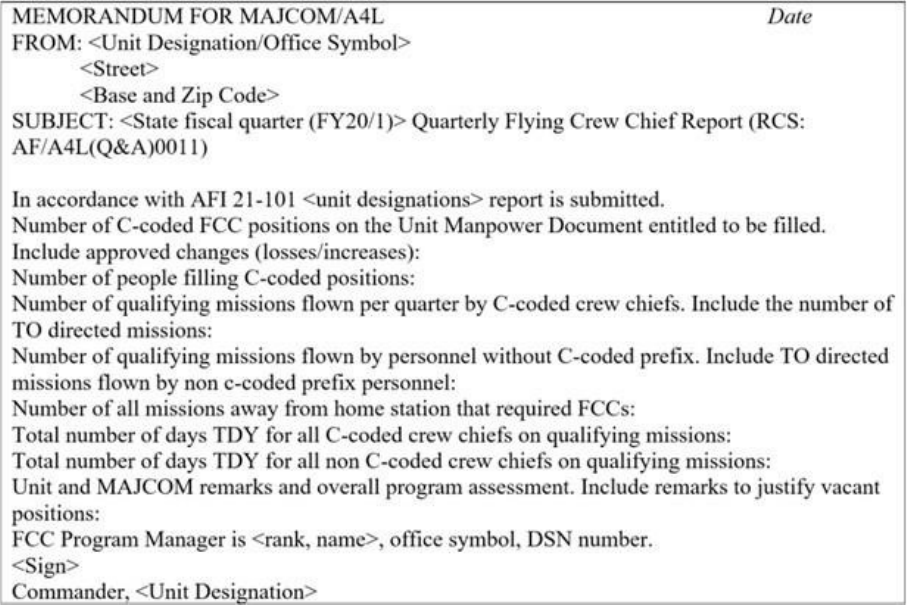

Attachment 3—QUARTERLY FCC REPORT FORMAT 425

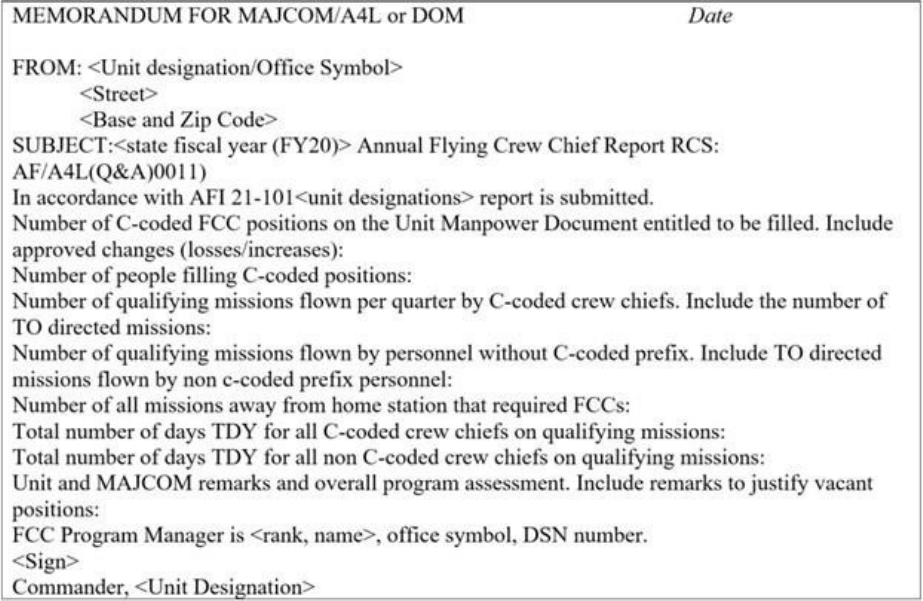

Attachment 4—ANNUAL FCC REPORT 426

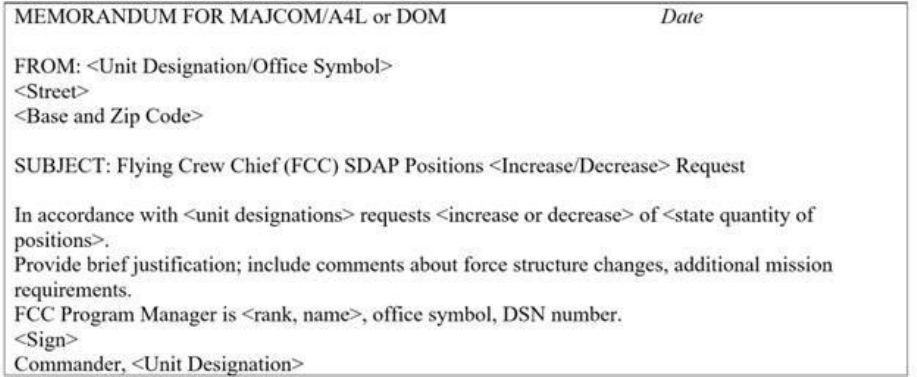

Attachment 5—FCC SDAP REQUEST 427

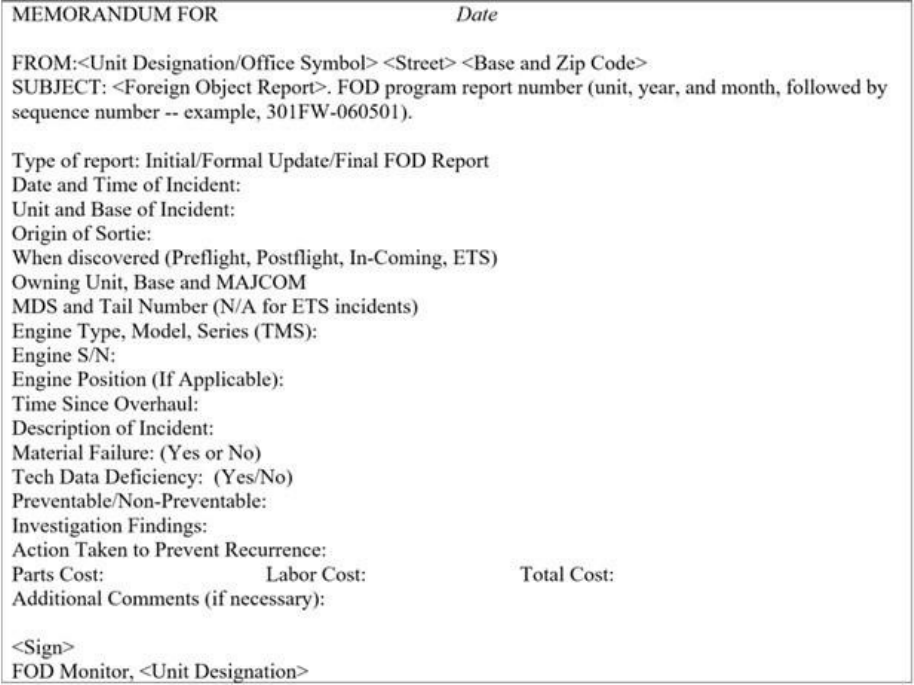

Attachment 6—FOREIGN OBJECT DAMAGE (FOD) REPORT 428

Attachment 7—CRITICAL APPLICATION ITEMS & CRITICAL SAFETY ITEMS 429

Attachment 8—DROPPED OBJECT PROGRAM (DOP) REPORTING FORMAT 430

Attachment 9—FCC PERFORMANCE FEEDBACK FORM 432

Attachment 10—FCC ORM WORKSHEET 434

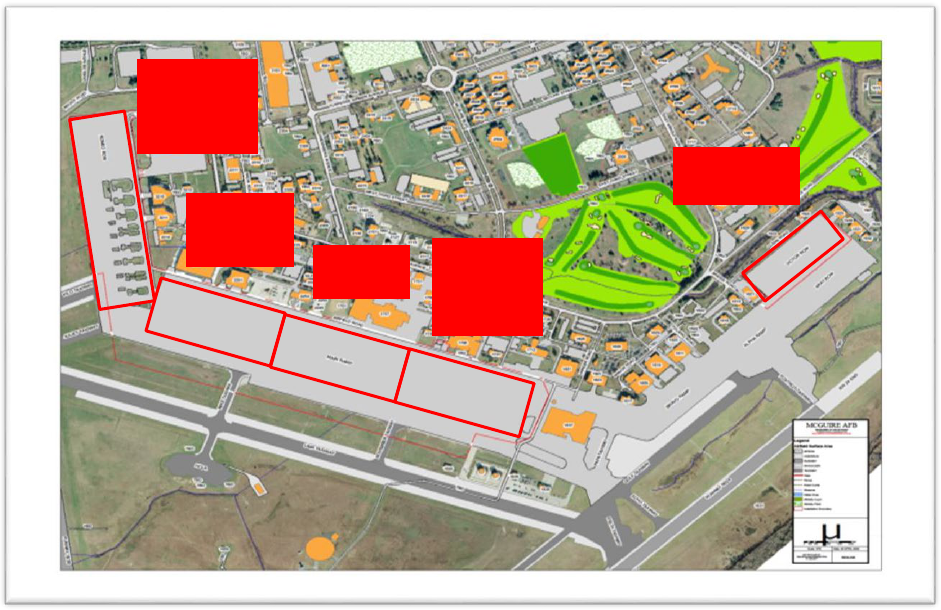

Attachment 11—(JBMDL) FOD PREVENTION GUIDANCE 436

Attachment 12—(JBMDL) FOD PREVENTION WALK AREAS OF RESPONSIBILITY 439

15

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

Chapter 1

MANAGEMENT OVERVIEW, SUPPORTING CONCEPTS AND REQUIREMENTS.

1.1. Introduction. This instruction prescribes basic aircraft and equipment maintenance

management policy implementation and procedures used throughout the United States Air Force

(USAF) to perform Mission Generation (MG) functions.

1.2. Organization. AF organizations are structured according to AFI 38-101, Air Force

Organization, or as authorized by the Director of Manpower, Organization & Resources

(AF/A1M). Contracted maintenance functions are not required to organize IAW AFI 38-101, but

will implement the organization as outlined in their proposal as accepted by the government. For

the definition of “Lead Command” see AFPD 10-9, Lead Command Designation and

Responsibilities for Weapon Systems.

1.3. Maintenance Concept. Per AFPD 21-1, organizational, intermediate and depot maintenance

capabilities for operational readiness shall be maintained to ensure effective and timely response

to peacetime operations, mobilizations, national defense contingencies and other emergencies.

Note: Guidance for the use of Additive Manufacturing to build replacement parts is prescribed in

AFI 63-101/20-101, Integrated Life Cycle Management.

1.3.1. As a minimum each capability will be able to:

1.3.1.1. Organizational: launch and recover sorties, maintain and repair materiel coded for

organizational level repair.

1.3.1.2. Intermediate: repair materiel coded for organizational and intermediate level

repair in back shops, centralized repair facilities, or both.

1.3.1.3. Depot-level Maintenance: Provides the capability to maintain materiel coded for

organizational, intermediate and depot levels of maintenance. Includes maintenance

requiring the overhaul, upgrading, or rebuilding of parts, assemblies, or subassemblies, and

the testing and reclamation of equipment as necessary.

1.3.2. Organizational and intermediate-level maintenance is organized into two mutually

exclusive networks, the Mission Generation Network (MGN) and the Repair Network (RN).

The MGN is optimized for mission generation at the wing level and consists of authorized “on-

equipment” and “off-equipment” maintenance capabilities required to launch, recover,

configure, inspect and repair AF systems and equipment. The RN supports the MGN by

providing the maintenance required to fulfill operational needs outside the capability or

capacity of MGN activities. The interface between the two networks takes place when the

MGN activity relinquishes control of reparable assets to the RN activity (such as, supply

counter turn-in) or changing an end item Purpose Identifier Code (PIC) from an operational

activity to a repair network activity (such as, depot maintenance).

1.3.2.1. Most MGN units possess a complement of equipment and supplies necessary to

perform on-equipment and off-equipment maintenance.

1.3.2.2. RN units may reside at bases that perform mission generation. RN requirements

and processes are identified in AFI 20-117, Repair Network Management.

16

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

1.3.3. MAJCOMs assigned combat coded fighter aircraft will coordinate with Mission Design

Series (MDS) lead and using commands and the MAJCOM Operations Directorate

(MAJCOM/A3) to develop and document standardized MDS and Primary Aerospace Vehicle

(Aircraft) Authorized (PAA) specific utilization rate standards in their supplements to this

instruction. At a minimum the rates will:

1.3.3.1. Consider aggregated and analyzed unit generation capability data to identify and

document standard MDS turn patterns by PAA in their supplements to Chapter 14.

1.3.3.2. Account for standard avionics and weapons training configurations.

1.3.3.3. Account for standard Technical Order (TO) driven turn time inspections and

Average Sortie Duration.

1.3.3.4. Include a process for supporting units in assessing shortfalls and developing action

plans.

1.3.4. Requests for Assistance. If a maintenance activity requires assistance for evaluation,

repair, or both, beyond unit capability, requests are made IAW AFI 21-103, Equipment

Inventory, Status and Utilization Reporting; TO 00-25-107, Maintenance Assistance; and TO

00-20-14, AF Metrology and Calibration Program, or automated process as approved by the

MDS Program Manager (PM) (for example, C-130 Automated Inspection, Repair, Corrosion

and Aircraft Tracking (AIRCAT), F-16 Technical Assistance Request). All requests for

assistance must be coordinated through the originating MAJCOM and Lead Command as

applicable. (T-2).

1.4. Aircraft Maintenance Tactics, Techniques and Procedures (TTP). TTPs are developed

from lessons learned and best practices that provide valuable reference documents to improve

maintenance processes and procedures. Maintenance leaders should utilize the maintenance

fundamentals TTP volumes (Aircraft, Munitions and Missile) to effectively and efficiently support

mission generation. Maintainers who attend the USAF Advanced Maintenance and Munitions

Operations School are trained in advanced operational, expeditionary and tactical maintenance

management concepts stemming from the alumni’s development and formalization of TTPs.

Maintenance Group Commander (MXG/CC) should identify their Advanced Maintenance and

Munitions Operations School graduates and utilize them as advisors and instructors to enhance

mission capability. AFTTP 3-4.21V1, Aircraft Maintenance, can be found at:

https://cs2.eis.af.mil/sites/10070/Documents/AFTTP3-4.21V1ACMX.pdf. For additional

information on Advanced Maintenance and Munitions Operations School and TTP development

see Air Force Manual (AFMAN) 21-111, Advanced Maintenance and Munitions Operations

School.

1.5. Aircraft and Equipment Readiness. Aircraft and equipment readiness is the maintenance

mission. The maintenance function ensures assigned aircraft and equipment are safe, serviceable,

and properly configured to meet mission needs. Maintenance actions include, but are not limited

to, inspection, repair, overhaul, modification, preservation, refurbishment, troubleshooting,

testing, analyzing condition, performance and maintenance documentation. All levels of

supervision need to place emphasis on safety, quality, and timeliness in the performance of

maintenance. The concept of quality maintenance must be fostered by each supervisor and

technician to ensure the integrity and skill of each maintainer is not degraded. To the greatest extent

possible, maintenance is accomplished on a preplanned scheduled basis. Planningprovides

17

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

the most effective and efficient use of people, facilities, and equipment, reduces unscheduled

maintenance, and allows for progressive actions toward maintaining and returning aircraft and

equipment to safe operating condition. Exploiting repair network capability and maintaining

visibility of repair cycle assets throughout the maintenance cycle are also critical elements of the

equipment maintenance program.

1.5.1. Preventive Maintenance. AF units implement and manage the tasks specified in the

scheduled recurring maintenance program for their assigned aircraft and associated support

equipment (SE). Preventive maintenance is achieved through the inspection requirement

concepts described in TO 00-20-1, Aerospace Equipment Maintenance Inspection,

Documentation, Policy, and Procedures, and applicable weapon system -6 TO

1.5.2. MAJCOMs that conduct Mission Generation Assessments or similar weapon system

logistic evaluations in order to validate unit readiness will:

1.5.2.1. Provide units a standardized assessment report containing, at a minimum, positive,

negative and areas for improvement feedback to facilitate crosstell to like units.

1.5.2.1.1. Analyze unit generation processes to capture and communicate best

practices.

1.5.2.1.2. Analyze unit generation performance to identify and communicate

noteworthy trends.

1.5.2.2. Directorates of Logistics, Engineering & Force Protection (MAJCOMs A4s) will

semi-annually report their top three trends and causal factors to the Logistics Board to

facilitate debate to identify and mitigate potential limiting factors. Submit MAJCOM top

three trends to the AF/A4LX workflow no later than 30 days prior to each Logistics Board

meeting for consolidation at: usaf.pentagon.af-a4.mbx.a4-elg-[email protected]il.

1.6. Maintenance Discipline. It is the responsibility of all maintenance personnel to comply with

all written guidance to ensure required repairs, inspections, and documentation are completed in a

compliant, safe, timely, and effective manner. Supervisors are responsible for enforcing and

establishing a climate that promotes maintenance and supply discipline. Unless expressly stated

otherwise in a particular instruction, waiver, or deviation in this AFI granted by the appropriate

authority, all Airmen must follow AFIs. (T-1). AFIs do not provide optional guidance, and failure

to comply with AFIs can result in disciplinary action as described in AFI 1-1, Air Force Standards.

Civilian personnel who violate punitive publications may also be subject to disciplinary action. See

AFI 33-360 for more detailed information on the use of punitive language in publications.

1.6. (AMC) Maintenance Discipline. HQ AMC/A4 Subject Matter Experts (SMEs) will, in

conjunction with AMC/IG and in accordance with AFI 90-201, The Air Force Inspection System,

verify and validate compliance through continual evaluation using tools such as, but not limited

to, Management Internal Control Toolset (MICT), metrics, Maintenance Information Systems

(MIS), Training Business Area (TBA), Maintenance Standardization and Evaluation Program

(MSEP) data, and site visits within the Air Force Inspection System (AFIS) construct.

1.6.1. Compliance Terminology. For the purposes of this instruction, the following definitions

apply:

18

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

1.6.1.1. Shall, Must, Will - Indicates mandatory requirements. Note: “Will” is also used

to express a declaration of purpose for a future event.

1.6.1.2. Should - Indicates a preferred method of accomplishment.

1.6.1.3. May - Indicates an acceptable or suggested means of accomplishment.

1.6.2. Use of TOs and TO Supplements. All personnel will enforce compliance with technical

data. (T-1). Use of prescribed technical data to maintain aircraft and equipment is mandatory

and will be conducted and managed IAW TO 00-5-1, Air Force Technical Order System. (T-

1).

1.6.3. AFTO Form 492, Maintenance Warning Tag. The Air Force Technical Order (AFTO)

Form 492, Maintenance Warning Tag, is used as prescribed in technical data, local procedures,

or both, to flag a condition that could cause damage or injury if ignored. Refer to TO 00-20-1

for additional guidance. Note: The AFTO Form 492 is replacing the AF Form 1492, Warning

Tag referenced in AFMAN 91-203, Air Force Occupational Safety, Fire, and Health Standards.

Use of the AF Form 1492 is authorized until supplies are exhausted.

1.7. Communications Security (COMSEC)/Controlled Cryptographic Item (CCI)

Accountability. The Air Force COMSEC/Central CCI Authority is the Cryptologic and Cyber

Systems Division, Joint Base San Antonio-Lackland, Texas.

1.7.1. Installed COMSEC/CCI accountability will be accomplished IAW AFMAN 17-1302-

O, Communications Security (COMSEC) Operations and AFI 23-101, Air Force Material

Management. (T-1). Ensure all serially controlled and serially tracked COMSEC/CCI

information is entered into the Maintenance Information System (MIS) IAW TO 00-20-2,

Maintenance Data Documentation. (T-1).

1.7.1.1. Maintain serial number inventory accountability for all COMSEC/CCI issued or

removed to Facilitate Other Maintenance (FOM) in Tail Number Bin (TNB) IAW

Paragraph 9.19. Tail Number Bins.

1.7.1.2. Questions concerning COMSEC/CCI accountability can be directed to the

Cryptologic and Cyber Systems Division’s COMSEC Policy Office Air Force Life Cycle

Management Center (AFLCMC/HNCLS).

1.7.2. Maintenance Cybersecurity Discipline.

1.7.2.1. Maintaining positive maintenance cyber discipline practices of Department of

Defense (DoD) Information Technology (IT) is critical to sustaining the mission.

Department of Defense Instruction (DoDI) 8500.01, Cybersecurity, definesboth hardware

and software that is physically part of, dedicated to, or essential in real-time to the mission

assurance of special purpose weapon systems. DoD IT is the most common IT encountered

in flightline environments, and includes (but is not limited to) electronic tools (eTools),

aircraft and associated support equipment. The culture of positive cybersecurity awareness

and actions necessary to sustain cyber resiliency is required by all maintenance personnel

to mitigate allusive cyber threats and optimize enduring mission generation capabilities.

1.7.2.1.1. All users perform an integral role in prevention, detection, and reporting

suspected corrupted software of DoD IT which includes Information Systems (IS) and

Platform Information Technology (PIT), which is an electronic platform with

information technology for a specific function. See Table 1.1

19

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

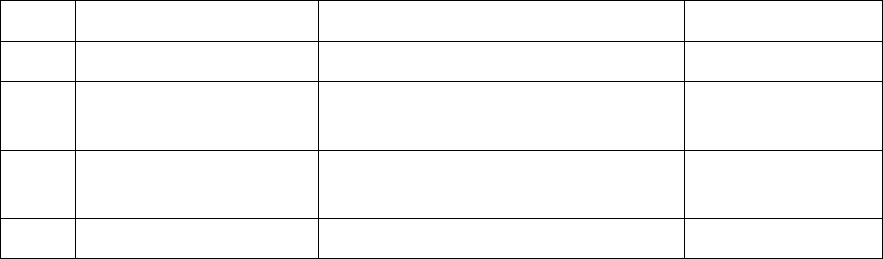

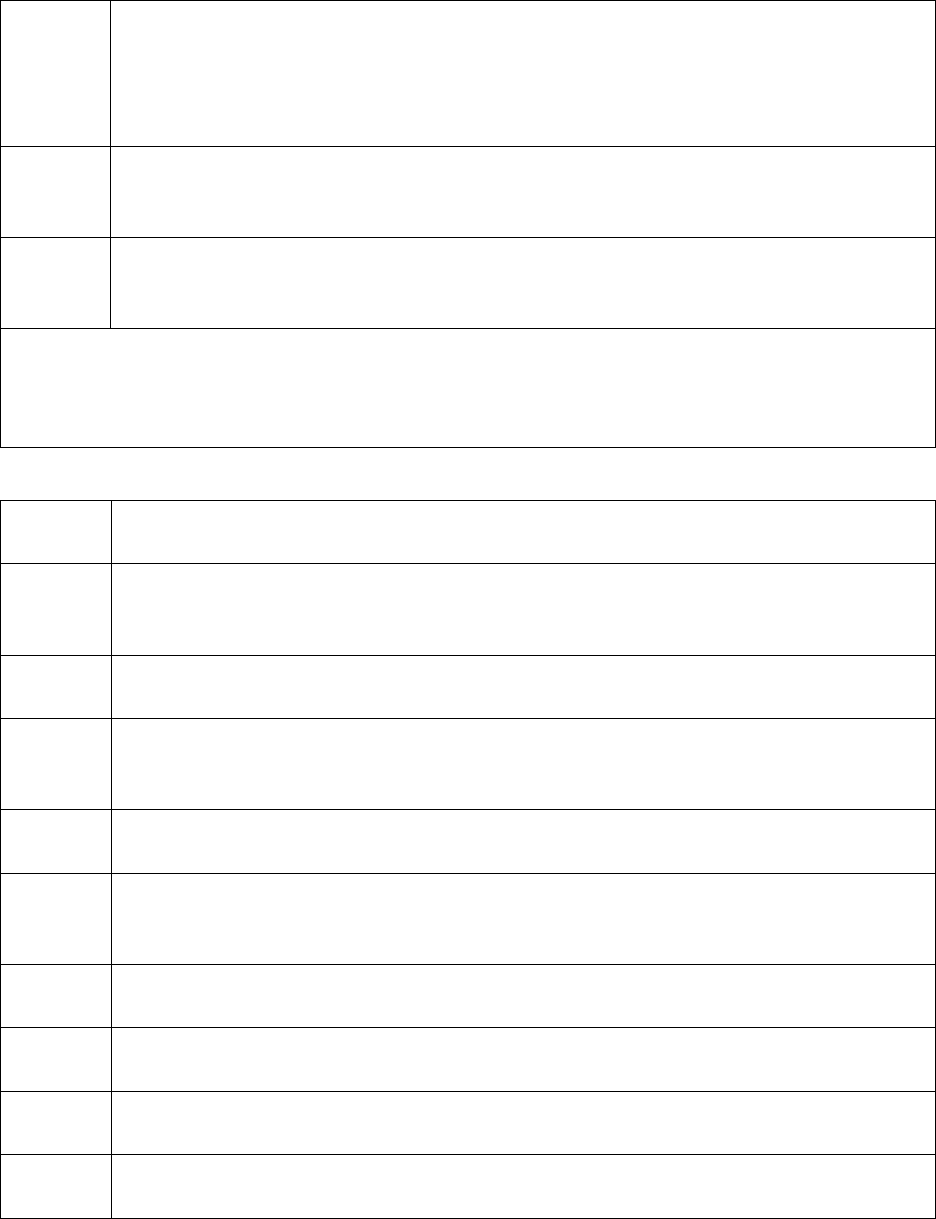

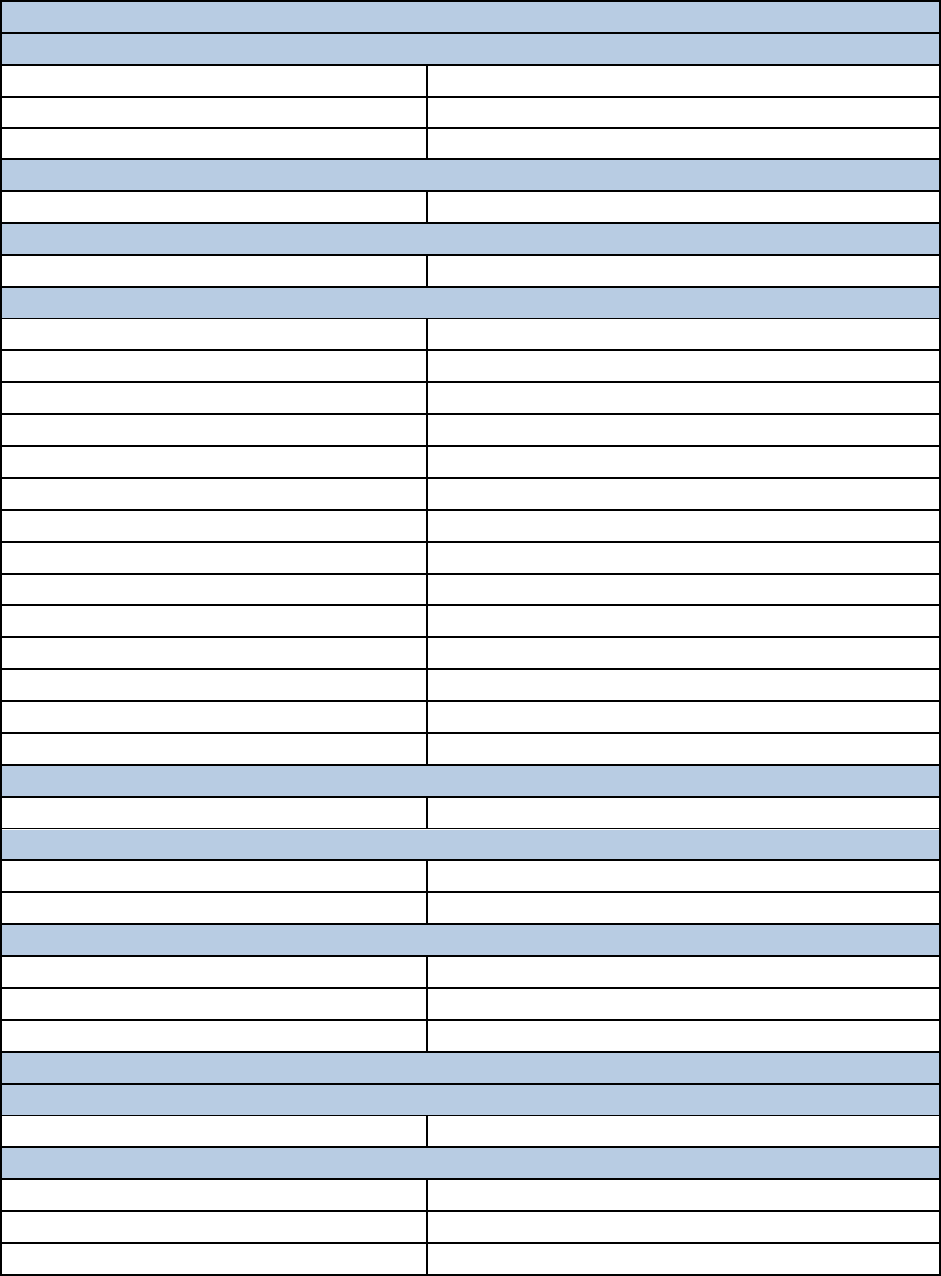

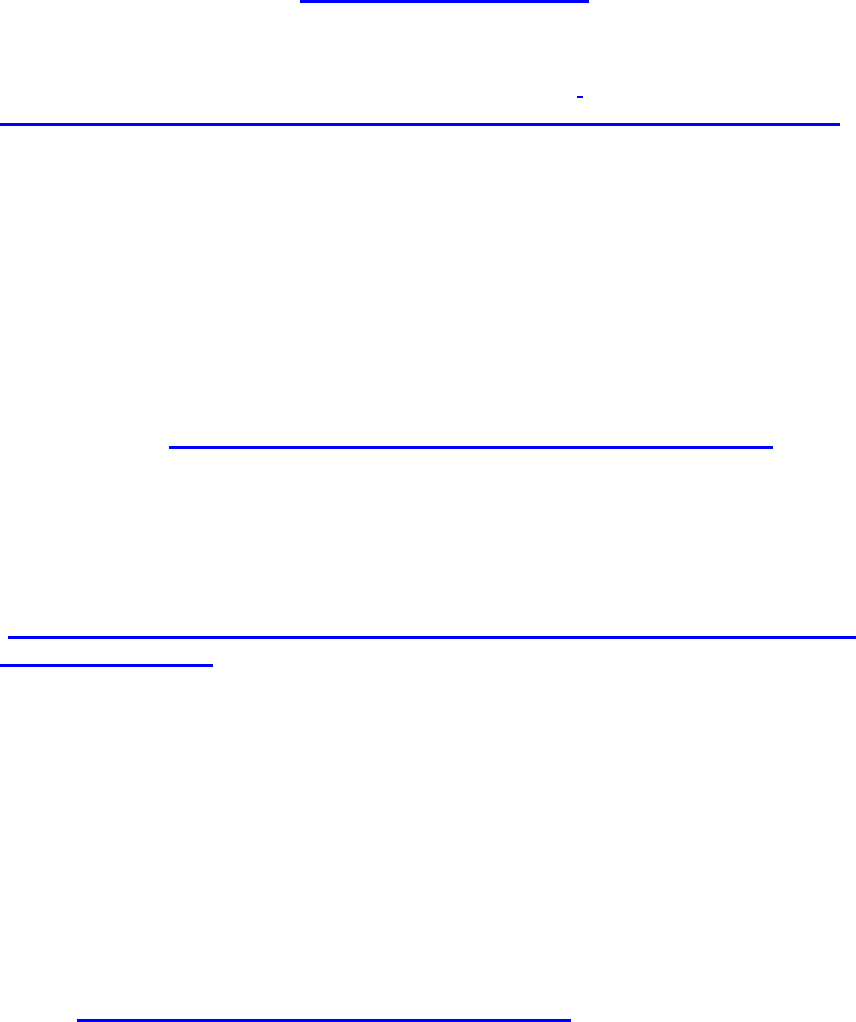

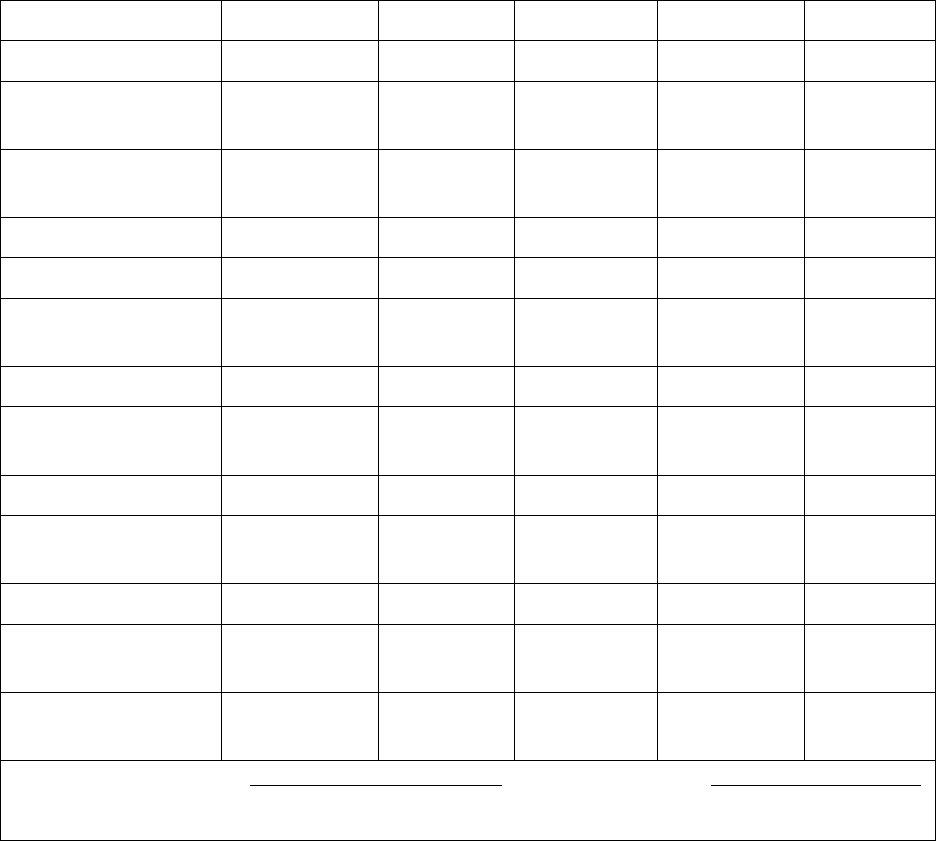

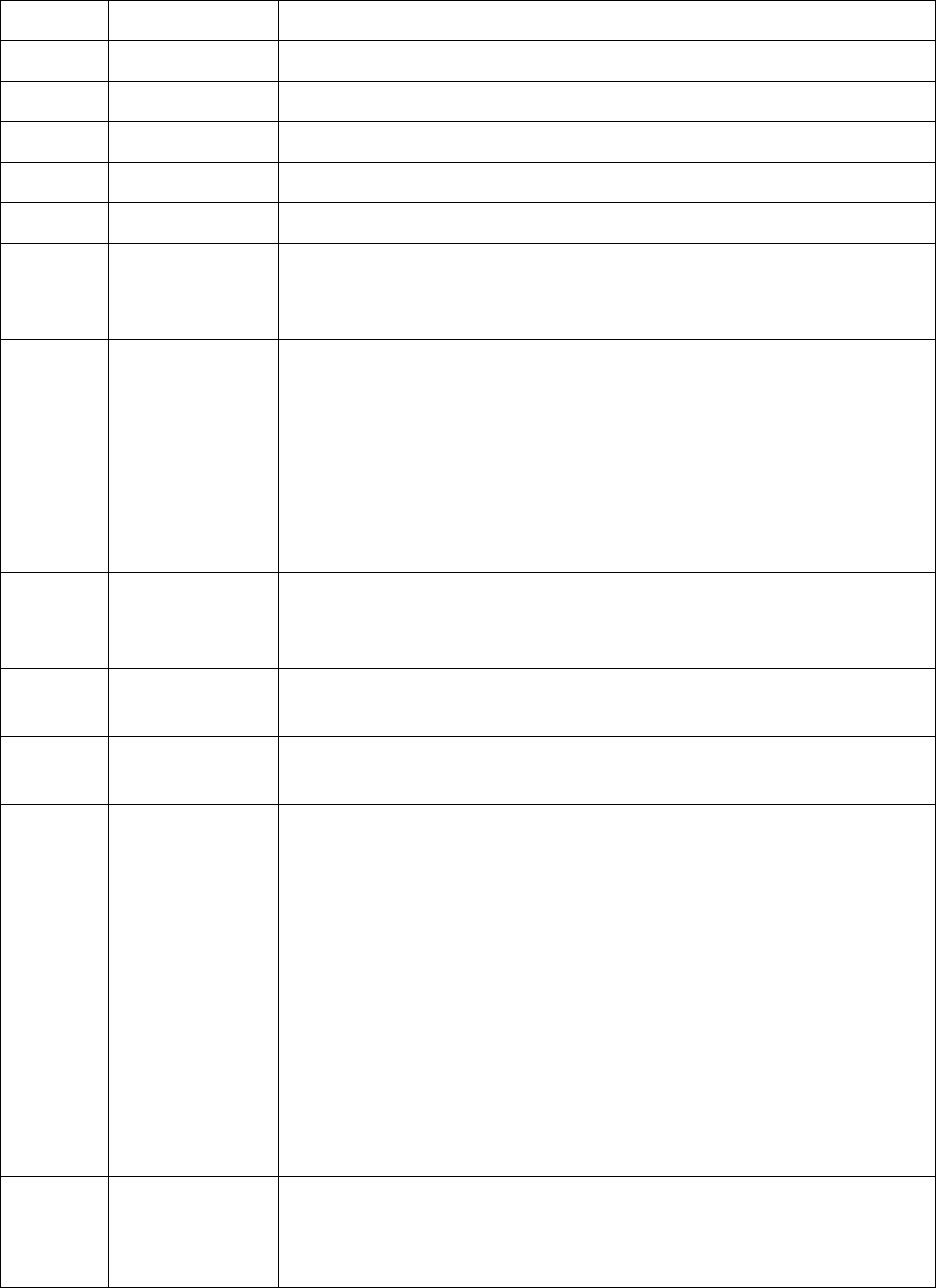

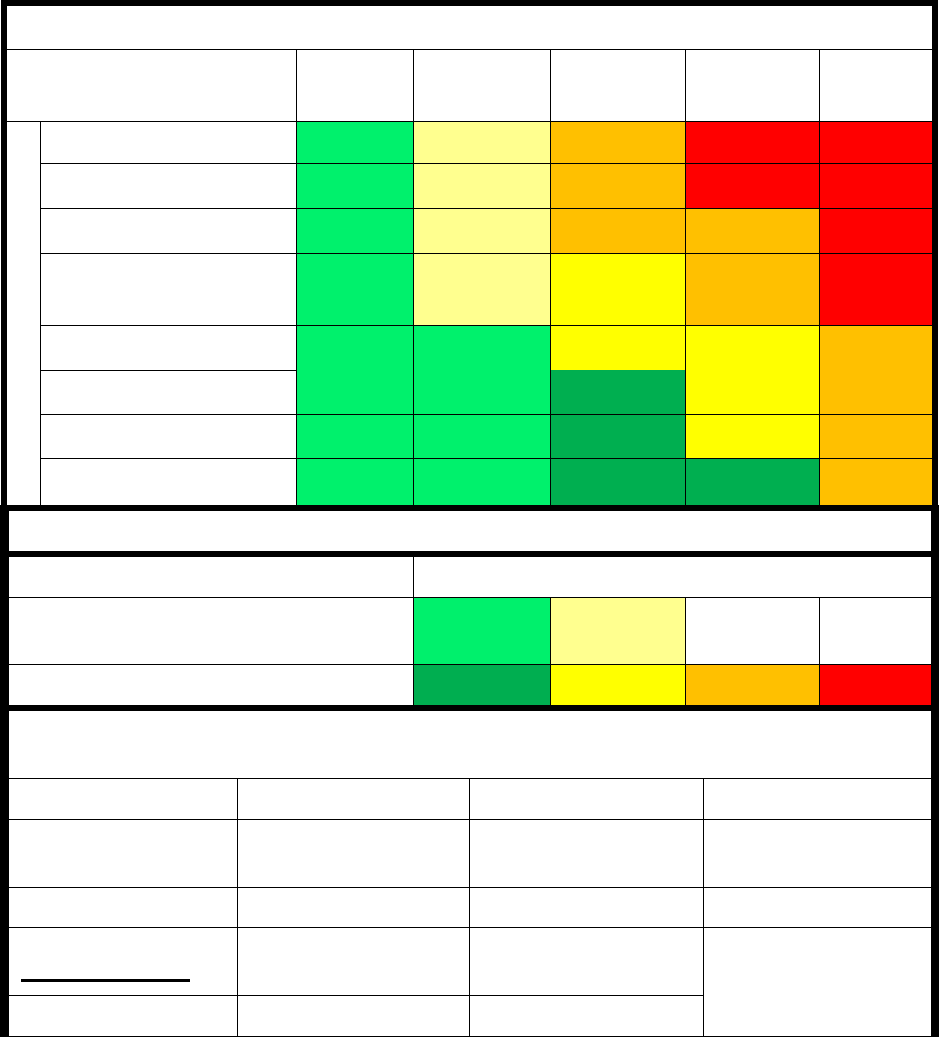

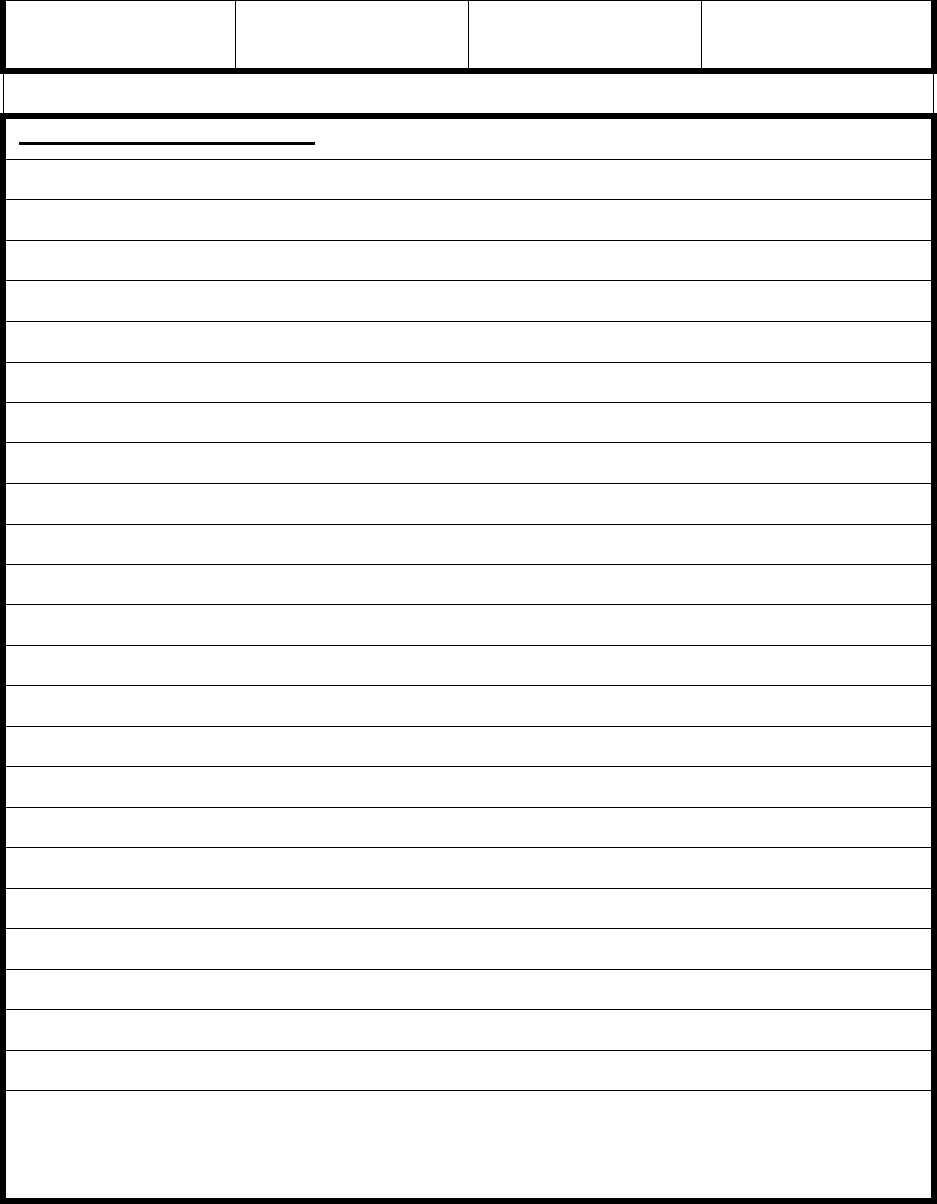

Table 1.1. Tiered Interface Examples.

TIER

Type of Interface

Examples

Applicable TOs

1

On-Board

EC-130, XX-135, E-3, E-8

Device TO

2

Directly Connected

F-22 PMA, F-35 PMA, Viper

MLV, CAPRE, CETS, DTADS

Device TO

3

Indirectly Connected

Test Eqpt., Support Eqpt., ATS,

ATE, AIS, VDATS

TO 33-1-38

4

Not Connected

eTools

TO 00-5-1

1.7.2.1.1.1. All users must consult airframe Security Classification Guides, TO 33-

1-38, Cybersecurity for Automatic Test Equipment and Support Test Equipment

(ATE/STE). TO 33-1-38 provides guidance for Cybersecurity Incident Reporting

and refers users to applicable technical manuals, instructions and publications when

determining the classification of cybersecurity incidents and vulnerability

documents. (T-1).

1.7.2.1.2. Authorized and unauthorized uses of IT and PIT. All users must have the

ability to distinguish between authorized and unauthorized uses. (T-1).

1.7.2.1.2.1. Authorized uses must be vetted through a formal cybersecurity

assessment process and be directed in specific TO guidance. (T-1). The governing

TOs or equivalent publications specifically define authorized uses.

1.7.2.1.2.2. Unauthorized uses include: connecting any hardware, uploading or

downloading software, or media not explicitly defined by TOs. This includes but is

not limited to: personal devices, phones, tablets, computers, Universal Serial Bus

drives, and similar devices.

1.7.2.1.2.3. DoD IT, derivative AF Publications, and TOs provide users guidance

on Automated Computer Program Identification Number System devices acquired

from local Communications Squadrons and media obtained from DoDcontractors.

1.7.2.1.2.4. All users will follow the applicable TO when directly or indirectly

connecting computers and equipment to the aircraft or support equipment, and

when uploading or downloading data. (T-1).

1.7.2.1.2.5. All users will immediately discontinue use, report, and turn into the

appropriate functional authority IT and PIT (WAM, Wing Cybersecurity Office,

and the Mission Defense Teams/Cyber Squadron, if assigned) that are suspect for

containing malicious software, malicious code, software bugs or unauthorized use.

(T-1).

1.7.2.1.2.6. All users will complete Maintenance Cyber Discipline Training

annually in Advanced Distributed Learning Service (ADLS) or equivalent training

method. (T-1).

1.7.2.1.3. MDS Lead Commands in coordination with the applicable PM will develop

MDS and Support Equipment (SE) cyber threat mitigation methods and procedures for

Organizational and Intermediate level maintenance activities. The methods and

20

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

procedures must detect malicious code, report cyber incidence and issues, and

remediate the incidence and issue affecting the MDS or SE. Note: Mitigation plan

should be developed per DoDI 8500.01; TO 33-1-38, DoD 8570.01M, Information

Assurance Workforce Improvement Program; Military Standard (MIL-STD)-38784A,

General Style and Format Requirements For Technical Manuals; 17- series AFIs.

1.7.2.1.3.1. The cyber threat mitigation methods must include MDS and SE

specific training requirements. (T-1). Note: Training requirements could include

training aids, for example, computer-based training on how the flightline

maintainer should scan support equipment for malicious software.

1.7.2.1.3.2. Lead Commands must ensure current MDS and SE specific malicious

code definitions are available to ensure positive cyber threat mitigation management

support is available. (T-1).

1.7.2.1.3.2.1. MAJCOM and ANG will report system-specific cyber incidents

to the applicable MDS Lead Command.

1.7.2.1.3.2.2. MAJCOM and ANG will follow airframe Security Classification

Guides, TOs, and applicable technical manuals when providing “cross tell” to

inform their subordinate units about system-specific cyber incidents, threats,

and issues.

1.7.3. eTools.

1.7.3.1. eTools are portable electronic devices (such as laptop computer, handheld device)

that operate in a disconnected mode and, are certified to inter-operate on AF networks.

eTools are mission critical; the primary purpose is for viewing electronic technical

publications and in some cases are used to exchange maintenance data with approved MIS

at the point of maintenance. eTools are procured IAW AFMAN 17-1203, Information

Technology (IT) Asset Management (ITAM). Note: eTools do not include electronic

devices and test equipment issued and configuration managed by a system PM (aircraft test

and support equipment).

1.7.3.2. MAJCOM/ANG A4s, will develop and implement standardized guidance on the

management, use, storage, configuration, content update, security and cyber hygiene

processes necessary to support the approved use of all assigned eTools consistent and IAW

the weapon system MDS specific technical orders and threat specific Air Force and DoD

cyber publications.

1.7.3.3. The MAJCOM/ANG A4 guidance will include any assigned command-wide

cyber threat awareness and mitigation strategies with reference to supporting publications,

technical orders, and MAJCOM eTool OPR contact information in their supplement or

addendum to this AFI.

1.7.3.4. (Added-AMC) eTools are procured by AMC/A4PI and sustained under the AMC

Logistics Network (LOGNET) contract.

1.7.3.5. (Added-AMC) eTools are used for official purposes to view TOs, and connect to

services on the Air Force network (e.g. Global Reach, email, etc.).

21

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

1.7.3.6. (Added-AMC) eTools are configured as standard desktop configuration (SDC)

devices by the LOGNET contractor to meet security requirements in accordance with 17-

series instructions.

1.7.3.7. (Added-AMC) eTools are to be able to connect to the DoD network.

1.7.3.8. (Added-AMC) Exceptions to use non-SDC devices as eTools will be

coordinated/approved by HQ AMC/A4 (T-2).

1.7.3.9. (Added-AMC) eTool TO Library management will be performed by TODO in

accordance with Chapter 6 (T-3).

1.7.3.10. (Added-AMC) Coordinate with local government LOGNET POC to determine

AMC eTool storage requirements.

1.7.3.11. (Added-AMC) Refresh cycle.

1.7.3.11.1. (Added-AMC) Remove eTools from service 12 months after warranty

expiration date (T-2). Note: This reduces cyber threats.

1.7.3.11.1.1. (Added-AMC) The eTool(s) will be removed from TCMax

accountability and the ETOV OU and ETOV_ETOOLS security groups (T-2).

1.7.3.11.1.2. (Added-AMC) Devices one year outside the warranty period

typically reach obsolescence due to advanced hardware and outdated software

applications.

1.7.3.11.2. (Added-AMC) AMC/A4PI will refresh AMC eTools annually based on

warranty expiration to maintain readiness and technology updates (T-2).

1.7.3.12. (Added-AMC) All eTools utilized in aircraft classified processing areas (CPAs)

and classified storage areas (CSAs) must have wireless capability (e.g. Wi-Fi, cellular,

Bluetooth, etc.), camera, microphone, and recording capabilities administratively disabled

(T-2). The eTool must also be marked to be readily identified as disabled (T-2).

1.7.3.12.1. (Added-AMC) The Communication Squadron Cyber Security Liaison and

the aircraft CPA/CSA owner must grant approval for the administratively disabled

device to be utilized in the CPA/CSA (T-2).

1.7.3.13. (Added-AMC) Prior to operating in disconnected mode/bare-base

environments, personnel must log into eTools while connected to the AF Network to ensure

functionality.

1.7.3.13.1. (Added-AMC) AMC eTools cache the last 50 personnel who have logged

into the device.

1.7.3.13.2. (Added-AMC) Follow deployed eTool technical order update

requirements outlined in TO 00-5-1.

1.7.3.14. (Added-AMC) Logistics Network (LOGNET).

1.7.3.14.1. (Added-AMC) LOGNET is a HQ AMC/A4PI managed contract to sustain

eTools and logistics IT infrastructure in accordance with 17 series AFIs.

1.7.3.14.1.1. (Added-AMC) Contact your local LOGNET POC or HQ AMC/A4PI

at ORG.AMCA4-46@us.af.mil or DSN 779-2633 for assistancewith

22

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

LOGNET matters.

1.7.3.14.2. (Added-AMC) LOGNET provides services that include: coordinating with

the MXG/CC and HQ AMC/A4PI for wireless LAN (WLAN) and eTool

requirements/funding, coordinating with local Communication Squadron for

hardware/software requirements, processing eTools received during initial purchase or

technical refresh into Automated Data Processing Equipment (ADPE) accounts, and

managing hardware/software warranties.

1.7.3.14.2.1. (Added-AMC) The MXG/AMOW will appoint a LOGNET POC

who will serve as a government liaison between assigned LOGNET contractors and

other government entities (T-2).

1.7.3.14.2.1.1. (Added-AMC) The MXG/AMOW will provide via

memorandum for record the LOGNET POCs name to the HQ AMC/A4PI

organizational email address (T-2).

1.7.3.14.2.2. (Added-AMC) Tenant units that do not have LOGNET contract

personnel assigned, the LOGNET POC will coordinate with host base network

managers and small computer managers to provide and maintain LOGNET service

support capabilities (T-2).

1.7.3.14.3. (Added-AMC) All eTool software and hardware failures will be reported

to LOGNET (T-2).

1.7.3.14.3.1. (Added-AMC) Non-computer support personnel will not repair,

rebuild, or update any eTool software or hardware (with the exception of electronic

TO updates) (T-2).

1.7.3.14.4. (Added-AMC) Units must receive approval from HQ AMC/A4PI before

purchasing any information technology infrastructure equipment (T-2).

1.7.3.14.5. (Added-AMC) The wireless WLAN provides user an extension of the AF

Network by providing access to aircraft maintenance information systems (e.g., G081,

SBSS).

1.7.3.14.5.1. (Added-AMC) Units will use the WLAN where available and

authorized to enhance mission accomplishment (T-3).

1.7.3.14.5.2. (Added-AMC) LOGNET is contracted to ensure wireless eTools are

available for maintenance technician use and assist WLAN users on proper use and

procedures.

1.7.3.14.6. (Added-AMC) LOGNET is the only approved office for

installing/maintaining current version of TCMax® software as approved by HQ

AMC/A4M and HQ AMC/A4PI.

1.8. Environmental Compliance. It is the responsibility of all maintenance personnel to comply

with all written guidance to ensure compliance with hazardous material, hazardous waste

management and air emissions record keeping as required for environmental compliance IAW AFI

90-821, Hazard Communication (HAZCOM) Program, installation Environment, Safety, and

Occupational Health Management System/Environment Management System (ESOHMS/EMS)

policy/guidance and applicable environmental requirements and guidance. (T-1).

23

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

1.9. Publications. Units may tailor procedures to the unique aspects of their own maintenance

operation and publish directives, instructions, supplements, addendums, and, for functional areas,

Operating Instructions (OI) IAW AFI 33-360.

1.9.1. Develop, control, and maintain functional and emergency action checklists. At a

minimum, each checklist is titled, dated and coordinated with the wing safety office. Functional

checklists are not to be used in place of or to circumvent technical data for operation, servicing,

inspection or maintenance of aircraft, aircraft systems, munitions, and all other equipment

supporting aircraft and munitions maintenance.

1.9.2. Methods and Procedures Technical Orders (MPTOs): Due to the close relationship

between MPTOs and this AFI, all changes and revisions to the MPTOs cited in Attachment

1, will be routed from Air Force Material Command (AFMC) to AF/A4LM for content review

for conflicts and policy gaps identification and mitigation prior to submission for publication.

1.10. Maintenance Training. Maintenance training provides initial, recurring and advanced

proficiency, qualification, or certification skills needed by a technician to perform duties in their

primary Air Force Specialty Code (AFSC), Civilian Job Series, or equivalent. Maintenance

training includes combat and sortie generation skills not normally integrated into peacetime

operations (such as, munitions handling, and external fuel tank build-up, hot refueling).

Maintenance training carries an equal priority with the operational training mission. For

maintenance training policy and guidance, refer to AFI 36-2650, Maintenance Training and

MAJCOM supplements.

1.10. (AMC) Maintenance Training. ARC maintenance personnel in associate units should refer

to their MAJCOM supplements as required for training guidance.

1.11. Modification Management. A modification proposal is a recommendation to change the

operation, use, or appearance of AF equipment. Modifications (temporary, permanent, or safety)

to AF aircraft or equipment are expressly prohibited without PM approval. Note: PM is used in

this publication as defined in AFPD 63-1, Integrated Life Cycle Management. Refer to AFI 63-

101/20-101, for modification management procedures.

1.11.1. Modifications to Munitions. All proposed modifications to aircraft-carried munitions

include AFI 63-101/20-101 and SEEK EAGLE certification IAW AFI 63-101/20-101and Air

Force Pamphlet (AFPAM) 63-129, Air System Development Process and Procedures. All

modifications to AF nuclear munitions or their associated support and training equipment are

nuclear certified IAW AFI 91-103, Air Force Nuclear Safety Design Certification Program and

AFI 63-125, Nuclear Certification Program. All modifications to AF conventional munitions

or their associated support and training equipment are certified IAW AFI 91-205, Non-Nuclear

Munitions Safety Board.

1.12. Maintenance Information Systems (MIS). MIS refers to automated maintenance

information systems that support and enable maintenance business processes. MIS is used to

document maintenance actions and track fleet health. The information entered into the MIS is

accomplished IAW TO 00-20-2 and matches the content of the aircraft forms. MIS data entries do

not have to be accomplished by the same individual who documented the aircraft forms, but

employee numbers, man numbers, and User IDs of individuals accomplishing the actual work are

entered into the MIS. Red Ball maintenance is documented IAW Chapter 11. Data integrity is the

24

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

responsibility of every member of the unit. All personnel are responsible for ensuring accuracy

and completeness.

1.12. (AMC) Maintenance Information Systems (MIS). Abbreviations may be used as long as

it does not alter the content.

1.12.1. Units use the approved MIS for their assigned weapon system.

1.12.2. Serial numbers will be documented in the MIS for all serially-controlled and tracked

assemblies that are identified by an asterisk in the Work Unit Code (WUC) or Logistics Control

Number (LCN) manual IAW TO 00-20-2.

1.13. General Safety Guidance. Maintenance personnel are exposed to a large variety of

hazardous situations, machinery, equipment, and chemicals. Most hazardous situations can be

avoided by following approved procedures, asking for assistance when needed, and using all

required personal protective equipment (PPE).

1.13.1. Safety “Knock It Off” and Risk Management. Due to the inherent danger to life, limb,

and property associated with maintenance operations, personnel are empowered to terminate

an operation or situation which they perceive is unsafe or too dangerous. When supervisors or

crew leaders become task-focused, junior personnel are often better able to assess the danger;

however, deferring to the experience and judgment of the supervisor or crew leader, they may

choose to remain silent, missing an opportunity to break the mishap sequence chain.

Maintenance commanders and supervisors are responsible for fostering a culture in their units

so that a simple, but recognizable “audible” from anyone can prevent a potential mishap. Note:

See AFI 90-802, Risk Management, and AFPAM 90-803, Risk Management (RM) Guidelines

and Tools for additional information.

1.13.2. Visitors. Unit Commanders shall not permit visitors to operate any AF equipment

unless they are qualified to operate such equipment and are doing so in the performance of

their assigned official duties. (T-1). Visitors will not be allowed in the flightline area if

munitions operations are present IAW AFMAN 91-201, Explosive Safety Standards. (T-1).

1.14. Duty Shifts and Rest Periods. MXG/CC or equivalent will establish minimum

requirements that ensure units (home station or deployed) maintain an equitable distribution of

supervision (Officer and Senior Non-Commissioned Officer (SNCO)) across all on-duty shifts in

their supplement to this AFI. (T-2).

1.14.1. During normal operations, maintenance personnel are scheduled for duty based on a

40-hour work week. Maintenance personnel duty hours are aligned to provide optimal mission

support.

1.14.2. Personnel will not be scheduled for more than 12 hours of continuous duty time. (T-

1). Duty time begins when personnel report for duty and ends when their supervisor releases

them. Time spent in exercise or contingency deployment processing lines and in-transit counts

toward the total duty day. Exception: MXG/CCs are the final approval authority for duty time

extensions exceeding the 12-hour limit up to a maximum of 16 hours. Note: Aircraft or

detachment commanders assume this responsibility in Temporary Duty (TDY)/travel status.

1.14.2. (AMC) CRG/CC is the approval authority for duty time extensions exceeding 12- hour

limit up to maximum of 16 hours. CRE commanders may assume this responsibility while

deployed.

25

AFI21-101_AMCSUP_JBMDLSUP 29 MARCH 2021

1.14.3. Commanders and supervisors will provide a rest period after each shift. (T-1). A rest

period is a block of time that gives a person the opportunity for 8 hours of uninterrupted sleep

in a 24-hour period. Note: This rest period also applies during exercises or inspections.

1.14.4. Personnel will not handle, load or perform maintenance on nuclear weapons,

conventional munitions, or egress explosives beyond a 12-hour continuous duty period. (T-1).

This requirement may not be waived for exercises or inspections; however, the 12-hour

continuous duty period may be exceeded for shift turnover or administrative actions only and

will be avoided to the maximum extent possible. The MXG/CC or equivalent may waive this

requirement during advance defense readiness conditions, actual emergencies as defined in

DoD Directive 3150.02, Department of Defense Nuclear Weapons Surety Program, or to

resolve an unexpected event (such as disabled vehicle, Weapons Storage and Security System

fault, hoist failure).

1.14.5. In alert force or standby duty situations where facilities are available for resting,

established norms may be exceeded. Adjust rest periods to allow for 8 hours of uninterrupted

sleep.

1.14.6. Commanders and supervisors will ensure individuals are afforded adequate duty rest

periods and breaks to prevent fatigue or thermal injury. (T-1). Stop anyone if fatigue may

jeopardize safety. In all cases, aircraft commanders or supervisors ensure aircraft maintenance

personnel are not required to perform duty when they have reached the point of physical or

mental fatigue rendering them incapable of performing their assigned duties safely and reliably.

1.14.7. MAJCOM Commanders will assume the risk for any Flying Crew Chief (FCC)

deviations from normal duty shifts, rest periods, and exceedance of the 16-hour maximum duty

day. MAJCOM Commanders will publish risk-mitigation procedures in order to meet critical

mission requirements.

1.14.7.1. (Added-AMC) FCC duty day will be managed in accordance with detailed

guidance in Chapter 11 (T-2).

1.15. Communications. Commanders shall develop communication plans according to AF

mission requirements. (T-2). See Chapter 11 for detailed communication requirements.

1.15.1. Effective maintenance accomplishment requires the ability to efficiently and

effectively communicate across all facets of the maintenance operation. Communication