FactoryTalk Alarms and Events

System Configuration Guide

Version 6.40.00

Technical Publications

Original Instructions

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this equipment before you install,

configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions in addition to requirements of all

applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried out by suitably trained

personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular

installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING:

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

ATTENTION:

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT:

Identifies information that is critical for successful application and understanding of the product.

These labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD:

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD:

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD:

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and for

Personal Protective Equipment (PPE).

The following icon may appear in the text of this document.

Tip:

Identifies information that is useful and can help to make a process easier to do or easier to understand.

Rockwell Automation recognizes that some of the terms that are currently used in our industry and in this publication are not in alignment with the movement toward

inclusive language in technology. We are proactively collaborating with industry peers to find alternatives to such terms and making changes to our products and content.

Please excuse the use of such terms in our content while we implement these changes.

2 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Contents

What you need to get started.................................................................................................................................................................................................................9

Required software...................................................................................................................................................................................................................................................................9

Recommended hardware and supported operating systems.........................................................................................................................................................................................9

Studio 5000 controllers............................................................................................................................................................................................................................................. 10

Compatible firmware.................................................................................................................................................................................................................................................. 12

Other controllers..........................................................................................................................................................................................................................................................13

How to get the information you need............................................................................................................................................................................................................................... 13

Overview of FactoryTalk Alarms and Events services......................................................................................................................................................................... 14

Migrating HMI tag alarms..................................................................................................................................................................................................................................................... 15

Where to start........................................................................................................................................................................................................................................................................ 16

FactoryTalk Alarms and Events components................................................................................................................................................................................................................... 17

About monitoring for alarm conditions.............................................................................................................................................................................................................................19

About device-based alarm monitoring....................................................................................................................................................................................................................19

Device-based alarm monitoring workflow..................................................................................................................................................................................................20

About server tag-based alarm monitoring.............................................................................................................................................................................................................21

Server tag-based alarm monitoring workflow............................................................................................................................................................................................22

About OPC UA alarm monitoring..............................................................................................................................................................................................................................23

OPC UA alarm monitoring workflow............................................................................................................................................................................................................. 23

Choose a suitable type of alarm monitoring...................................................................................................................................................................................................................24

Graphic objects in FactoryTalk Alarms and Events........................................................................................................................................................................................................24

Plan your system...................................................................................................................................................................................................................................25

Decide what type of application you are building..........................................................................................................................................................................................................25

Decide what type of alarm monitoring you need...........................................................................................................................................................................................................26

Follow these steps................................................................................................................................................................................................................................................................ 26

What you need.......................................................................................................................................................................................................................................................................26

Install and activate FactoryTalk software........................................................................................................................................................................................................................26

Typical stand-alone system......................................................................................................................................................................................................................................27

Install FactoryTalk software..................................................................................................................................................................................................................................... 27

Install SQL Server for logging.................................................................................................................................................................................................................................. 28

Define device-based alarms in Studio 5000 controllers......................................................................................................................................................................29

Alarm buffering during loss of connection to the controller........................................................................................................................................................................................29

Before you begin...................................................................................................................................................................................................................................................................30

What you need.......................................................................................................................................................................................................................................................................30

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 3

Follow these steps................................................................................................................................................................................................................................................................30

Define a Logix tag-based alarm......................................................................................................................................................................................................................................... 31

Create an alarm definition........................................................................................................................................................................................................................................ 31

Download the program to controller and test the alarm....................................................................................................................................................................................32

Define an instruction-based alarm: digital......................................................................................................................................................................................................................32

Configure the digital alarm and download to the controller..............................................................................................................................................................................32

Define an instruction-based alarm: analog..................................................................................................................................................................................................................... 35

Configure the analog alarm and download it to the controller......................................................................................................................................................................... 35

Add a device server for Studio 5000, SLC 500, or PLC-5 controllers..................................................................................................................................................38

Before you begin...................................................................................................................................................................................................................................................................38

What you need.......................................................................................................................................................................................................................................................................38

Follow these steps................................................................................................................................................................................................................................................................38

Add a device server..............................................................................................................................................................................................................................................................38

Add an OPC data server for third-party controllers............................................................................................................................................................................ 45

Before you begin...................................................................................................................................................................................................................................................................45

What you need.......................................................................................................................................................................................................................................................................45

Follow these steps................................................................................................................................................................................................................................................................45

Add an OPC data server to an application.......................................................................................................................................................................................................................45

Add a tag-based alarm server for Studio 5000, SLC 500, PLC-5, or third-party controllers.............................................................................................................. 48

Before you begin...................................................................................................................................................................................................................................................................48

What you need.......................................................................................................................................................................................................................................................................48

Follow these steps................................................................................................................................................................................................................................................................48

Create an application...........................................................................................................................................................................................................................................................49

Add a data server.................................................................................................................................................................................................................................................................50

Add a Tag Alarm and Event Server....................................................................................................................................................................................................................................52

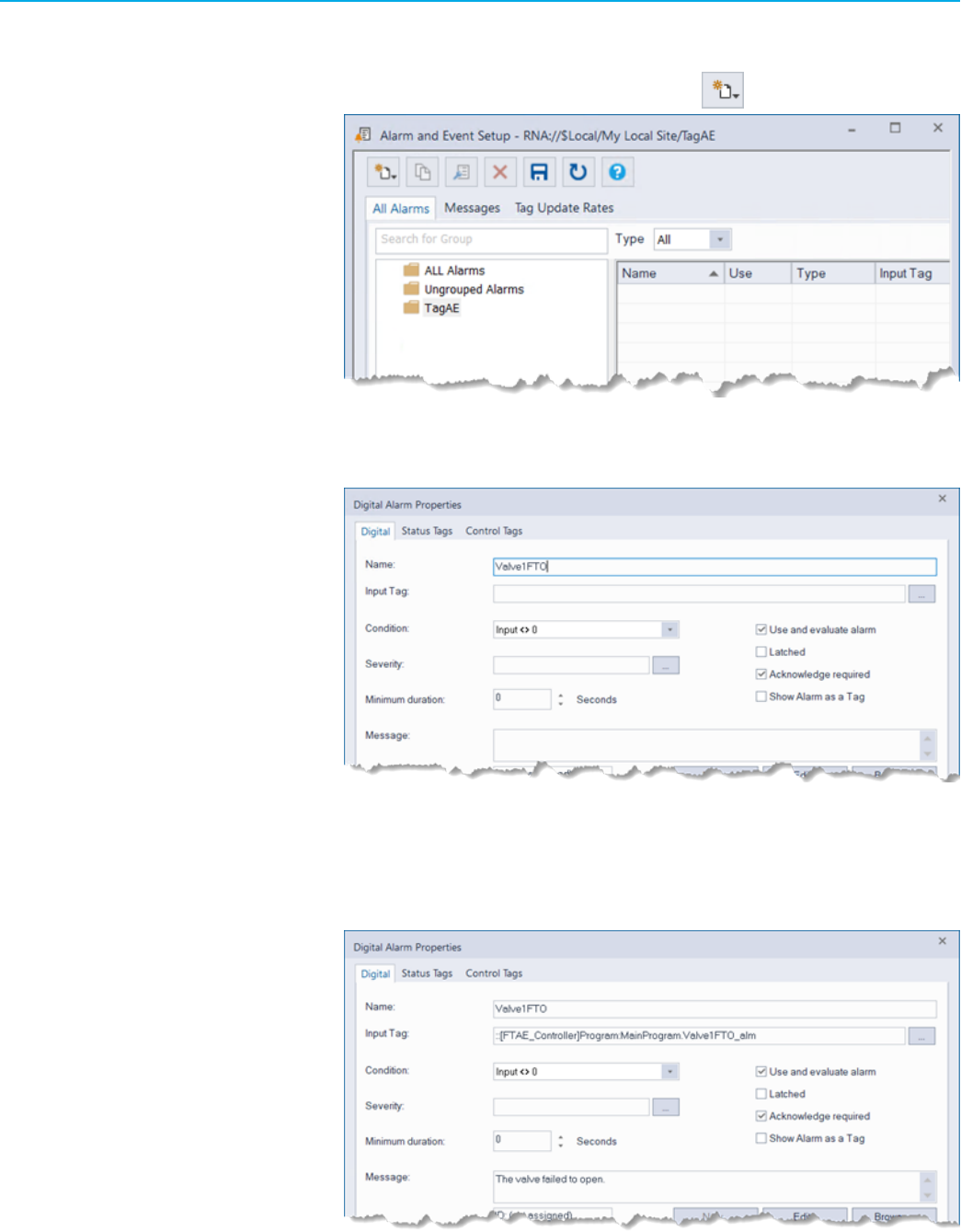

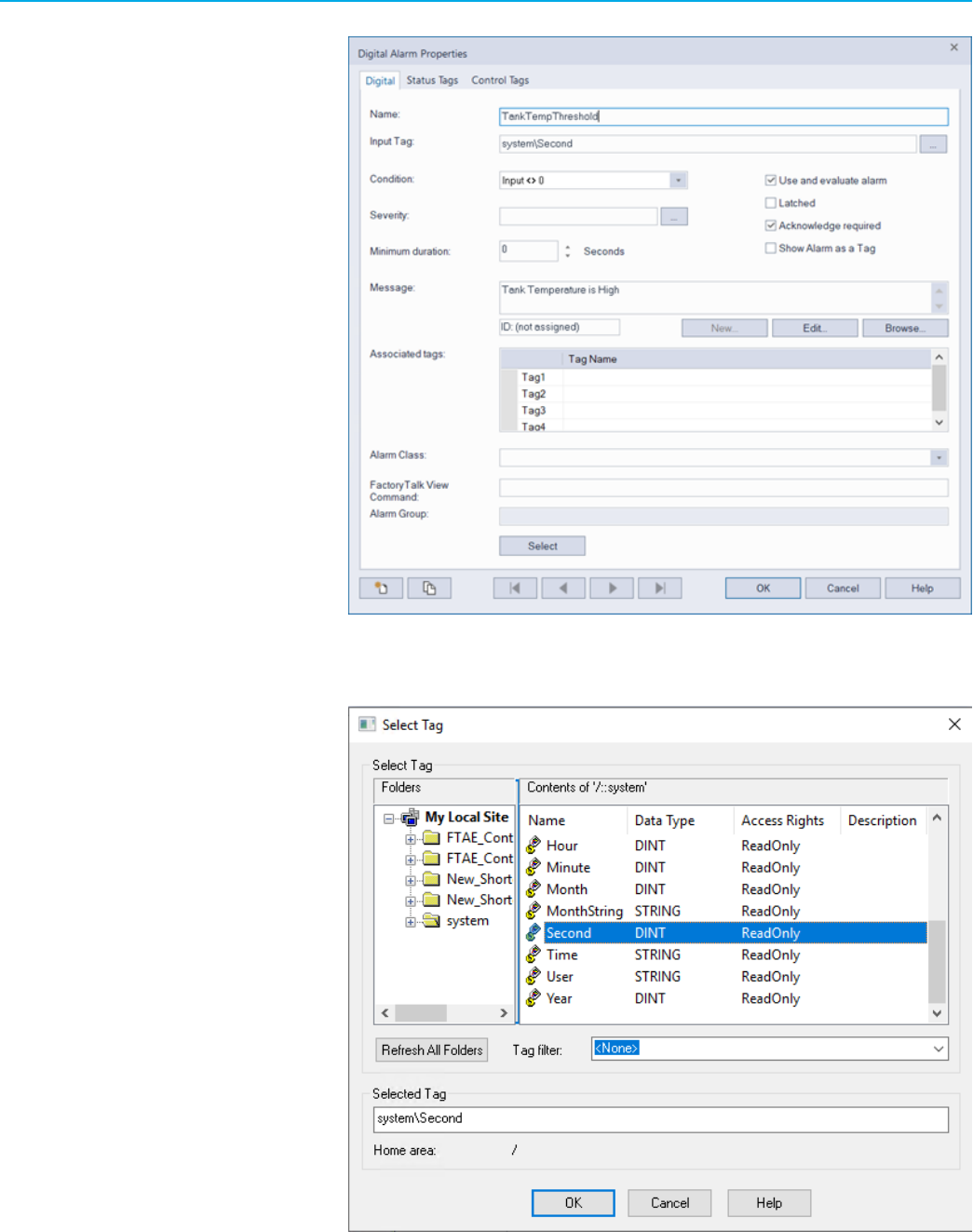

Define alarm conditions...................................................................................................................................................................................................................................................... 52

Next steps...............................................................................................................................................................................................................................................................................54

Add FactoryTalk Linx OPC UA Connector for third-party OPC UA servers........................................................................................................................................... 55

Before you begin...................................................................................................................................................................................................................................................................55

What you need.......................................................................................................................................................................................................................................................................55

Follow these steps................................................................................................................................................................................................................................................................55

Add FactoryTalk Linx OPC UA Connector..........................................................................................................................................................................................................................55

Set up graphic displays.........................................................................................................................................................................................................................58

Before you begin...................................................................................................................................................................................................................................................................58

What you need.......................................................................................................................................................................................................................................................................58

4 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Follow these steps................................................................................................................................................................................................................................................................58

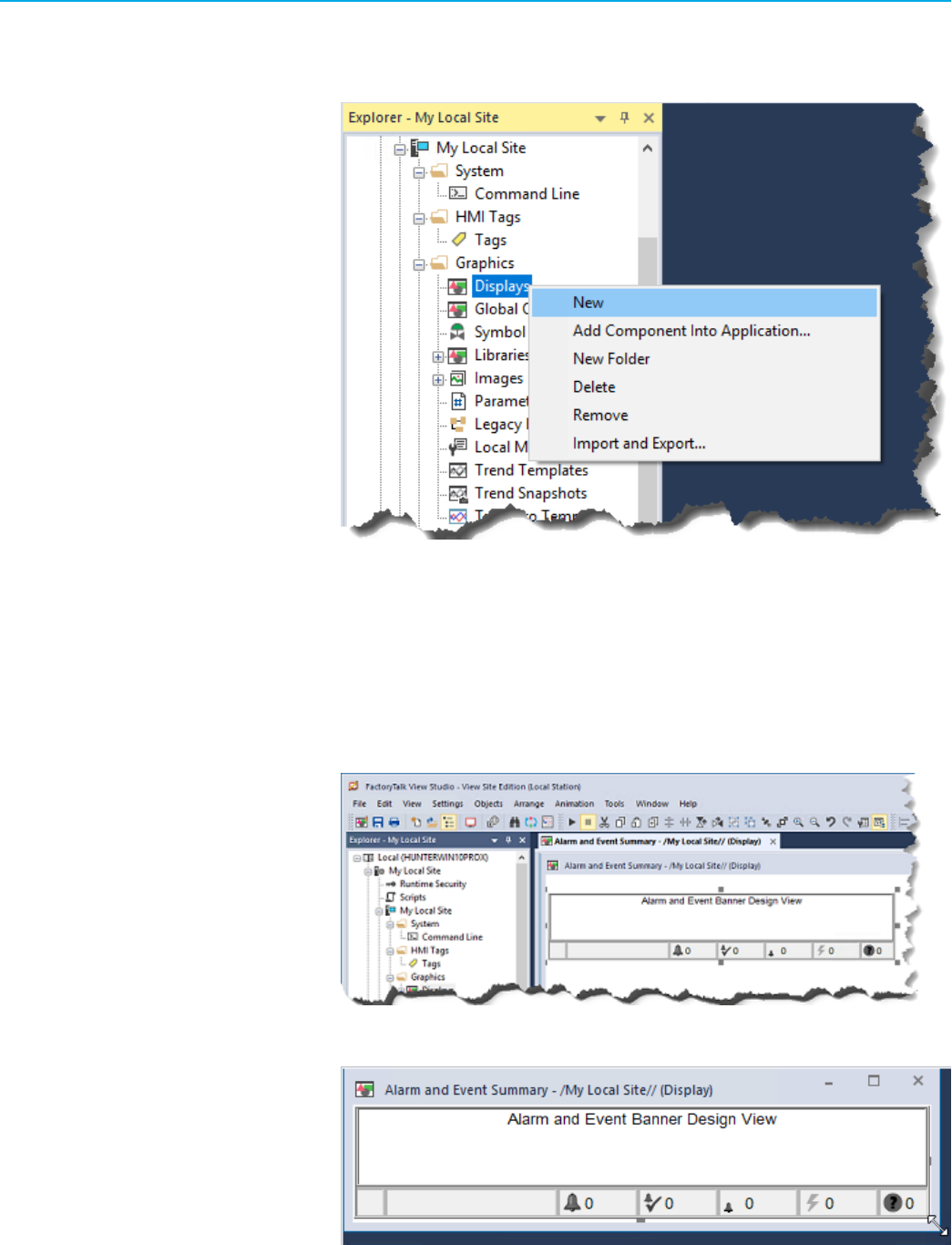

Create a graphic display..................................................................................................................................................................................................................................................... 59

Create an Alarm and Event Summary...............................................................................................................................................................................................................................60

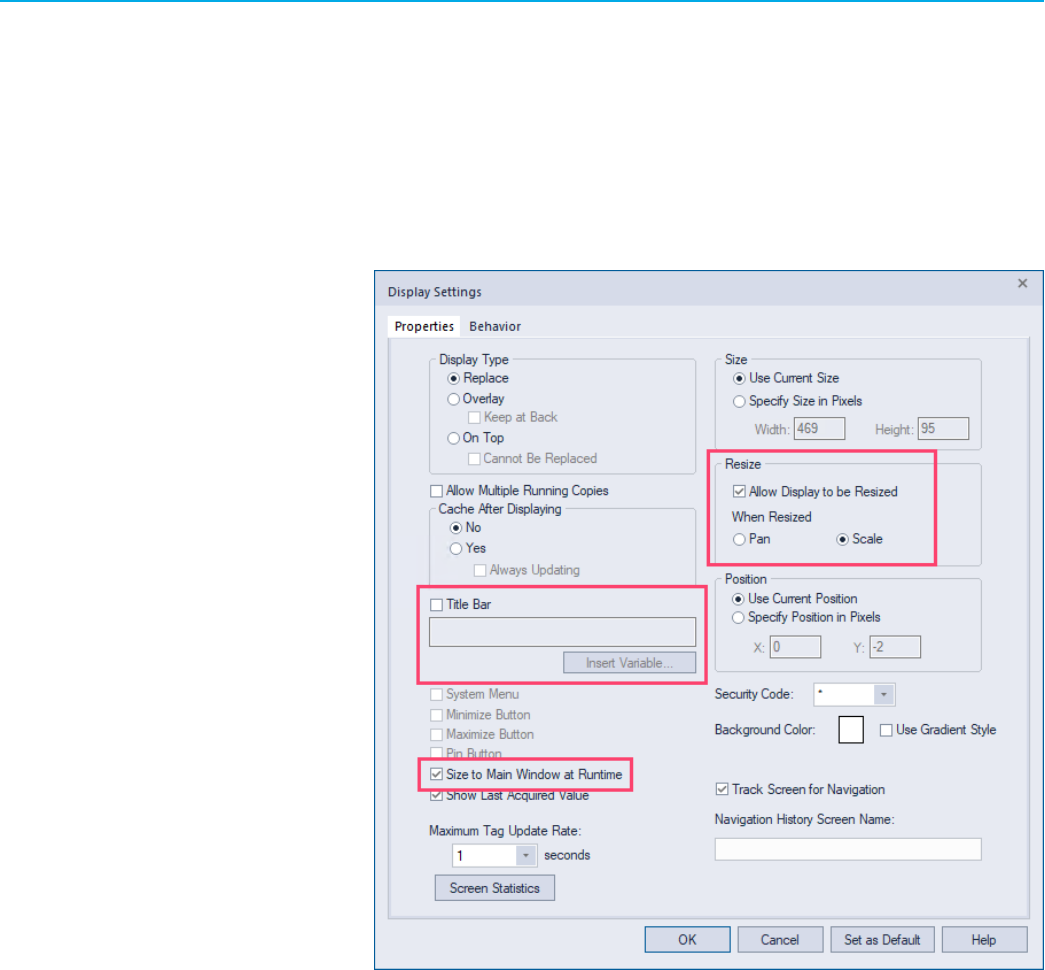

Create an Alarm and Event Banner display.....................................................................................................................................................................................................................63

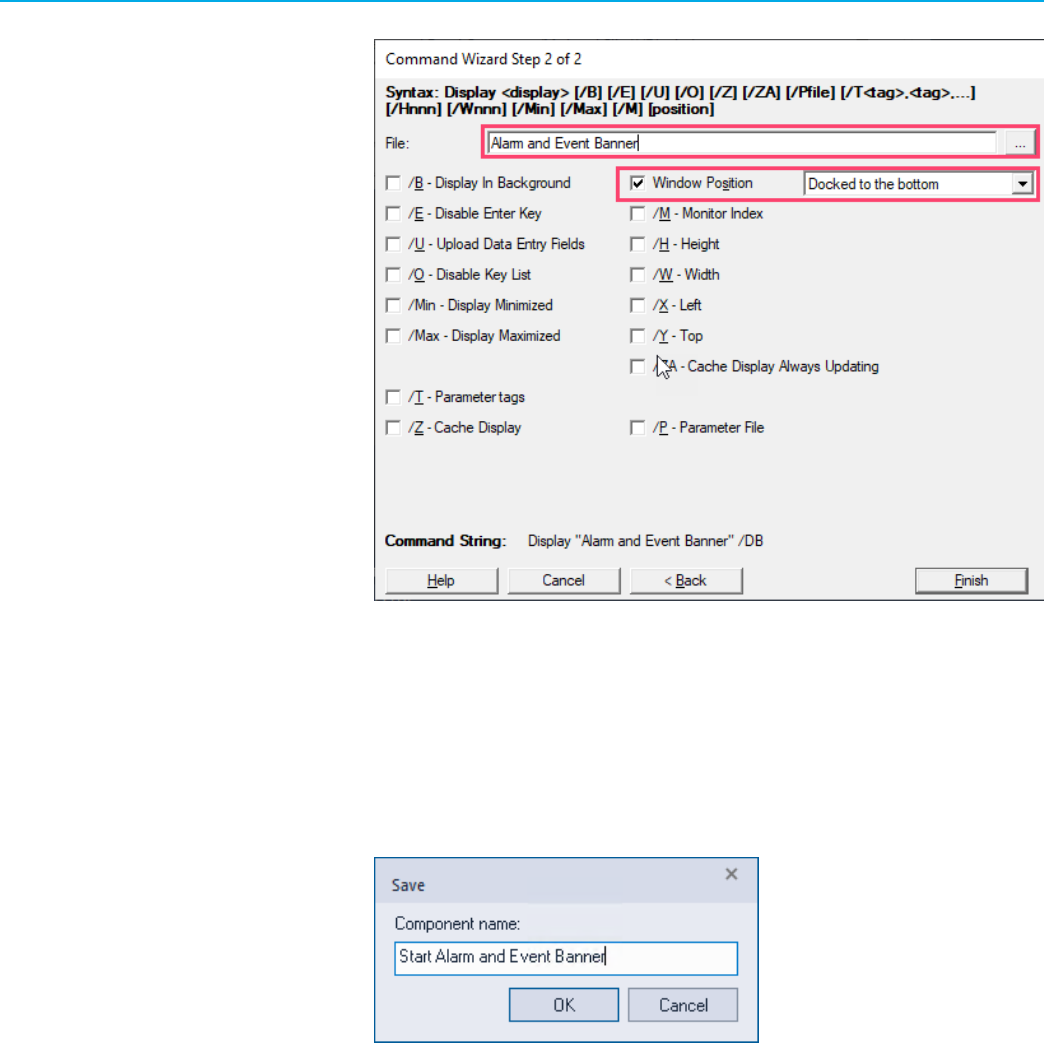

Create a startup macro for the Banner display............................................................................................................................................................................................................. 68

Create an Automatic Diagnostic Event Summary...........................................................................................................................................................................................................70

Use color animation to indicate alarm state changes.................................................................................................................................................................................................. 73

Next steps............................................................................................................................................................................................................................................................................... 81

Monitor and interact with alarms at runtime.......................................................................................................................................................................................82

Before you begin...................................................................................................................................................................................................................................................................82

What you need.......................................................................................................................................................................................................................................................................82

Follow these steps................................................................................................................................................................................................................................................................82

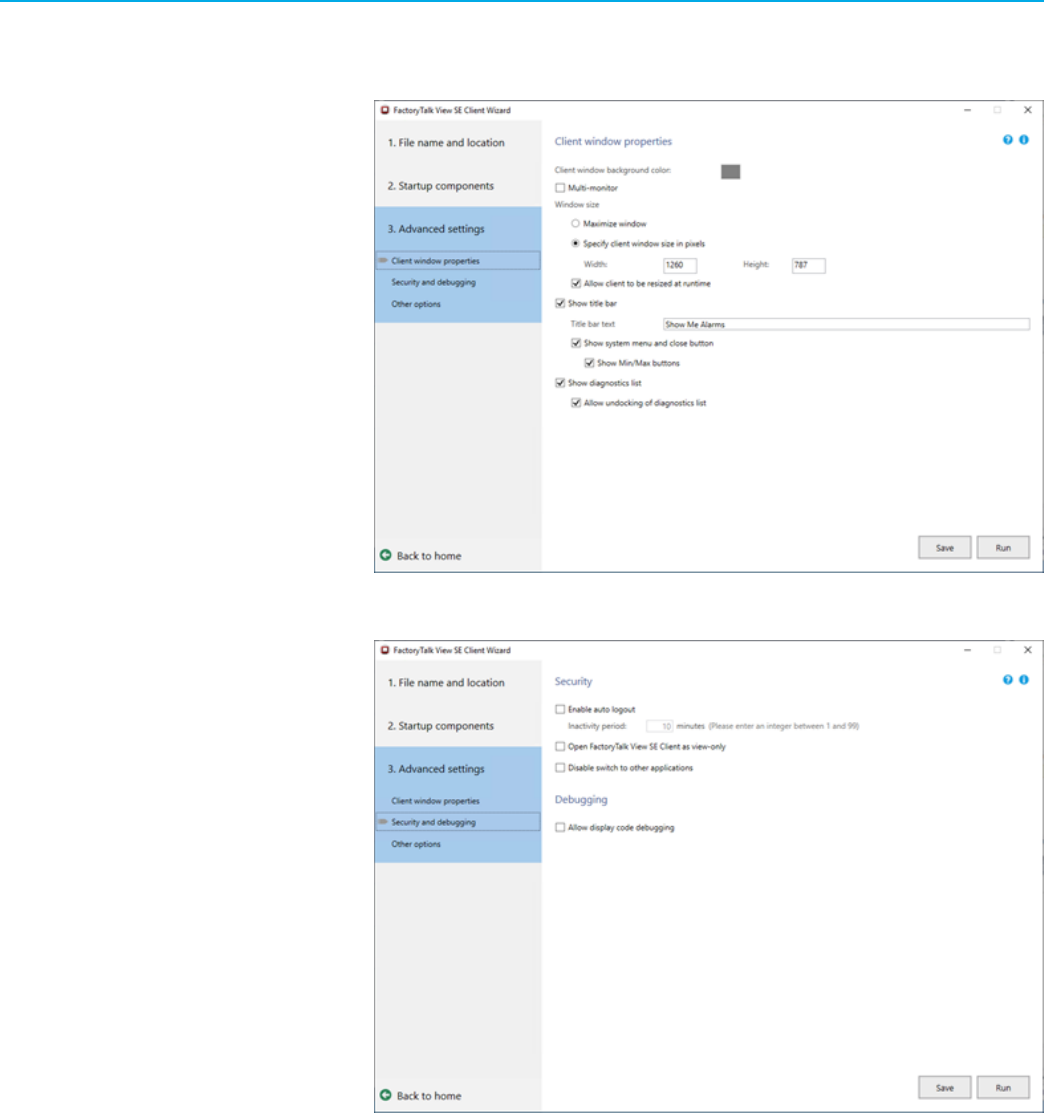

Create and then run a FactoryTalk View Client configuration.....................................................................................................................................................................................82

Monitor alarms and events................................................................................................................................................................................................................................................. 86

Security for alarms and events...............................................................................................................................................................................................................................86

Acknowledge an alarm...............................................................................................................................................................................................................................................87

Acknowledge the selected alarm.................................................................................................................................................................................................................. 87

Acknowledge the selected alarm and enter a comment..........................................................................................................................................................................88

Acknowledge all of the alarms displayed on the page.............................................................................................................................................................................89

Acknowledge all of the alarms in the event list........................................................................................................................................................................................ 89

Disable or enable an alarm......................................................................................................................................................................................................................................90

Disable selected alarms.................................................................................................................................................................................................................................. 91

Enable selected alarms...................................................................................................................................................................................................................................92

Suppress or unsuppress an alarm.......................................................................................................................................................................................................................... 92

Suppress an alarm...........................................................................................................................................................................................................................................93

Unsuppress an alarm...................................................................................................................................................................................................................................... 93

Shelve or unshelve an alarm....................................................................................................................................................................................................................................95

Shelve an alarm................................................................................................................................................................................................................................................96

Unshelve an alarm...........................................................................................................................................................................................................................................98

Set up historical alarm and event logging..........................................................................................................................................................................................100

Before you begin.................................................................................................................................................................................................................................................................100

What you need.....................................................................................................................................................................................................................................................................100

Follow these steps............................................................................................................................................................................................................................................................... 101

Confirm that the SQL Server software is installed........................................................................................................................................................................................................101

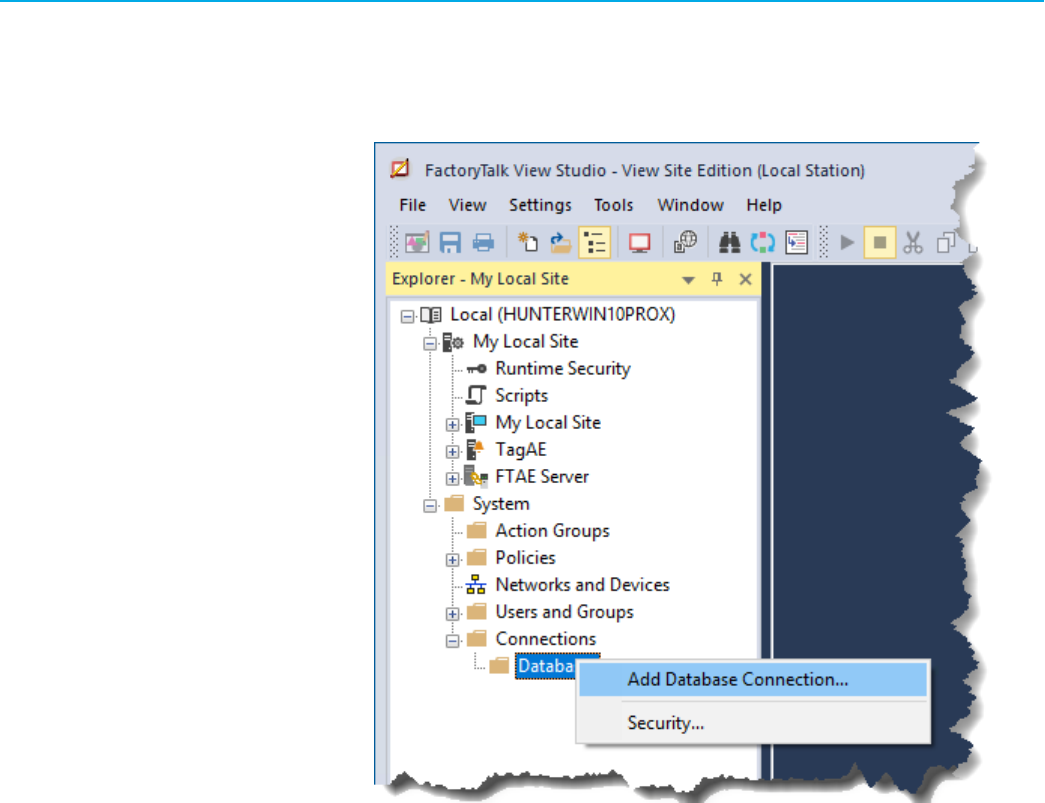

Add a database definition to your FactoryTalk system................................................................................................................................................................................................101

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 5

Associate a database definition with an alarm server................................................................................................................................................................................................105

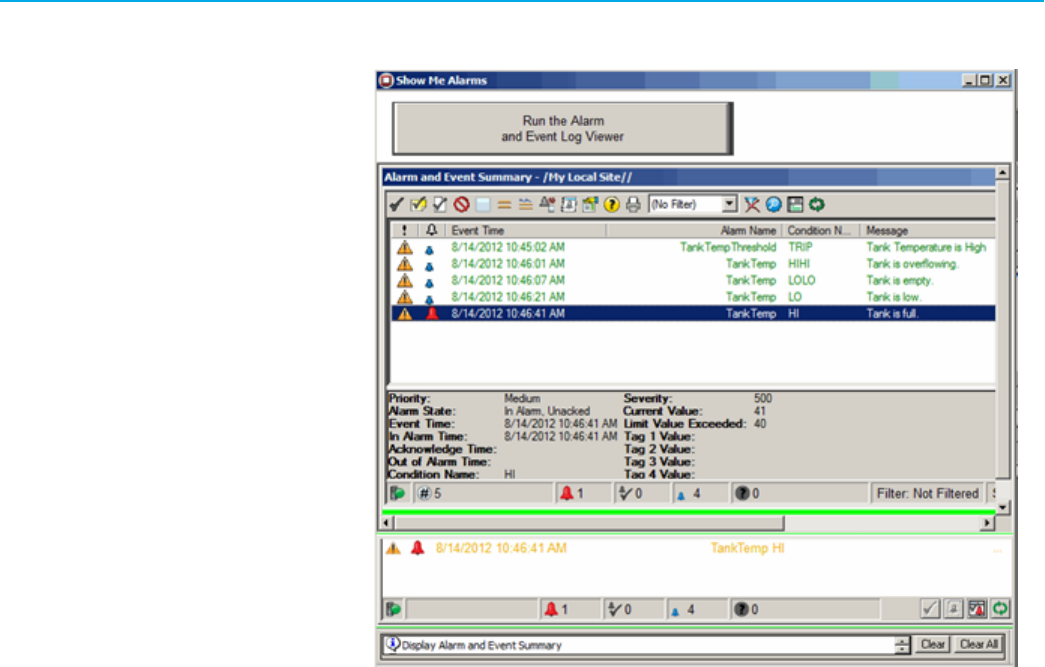

Create an Alarm and Event Log Viewer display............................................................................................................................................................................................................ 108

Create a button to open the Alarm and Event Log Viewer display...................................................................................................................................................................111

Create a startup macro for the Menu Bar display.........................................................................................................................................................................................................115

View historical alarm data in a FactoryTalk View SE Client........................................................................................................................................................................................ 117

Run the application....................................................................................................................................................................................................................................................117

Start the FactoryTalk View SE Client from within FactoryTalk View Studio.........................................................................................................................................117

Configure redundancy for alarms and events.....................................................................................................................................................................................120

FactoryTalk server redundancy........................................................................................................................................................................................................................................ 120

Develop and test your application without redundancy.............................................................................................................................................................................................. 120

Before you begin.................................................................................................................................................................................................................................................................. 121

What you need...................................................................................................................................................................................................................................................................... 121

Follow these steps...............................................................................................................................................................................................................................................................122

Upgrade an existing device-based alarm server.......................................................................................................................................................................................................... 122

Upgrade an existing tag-based alarm server................................................................................................................................................................................................................ 124

Check the status of an alarm server.............................................................................................................................................................................................................................. 125

Get started with language switching...................................................................................................................................................................................................127

Before you begin..................................................................................................................................................................................................................................................................127

What you need......................................................................................................................................................................................................................................................................127

Follow these steps...............................................................................................................................................................................................................................................................128

Create device-based alarm messages............................................................................................................................................................................................................................ 128

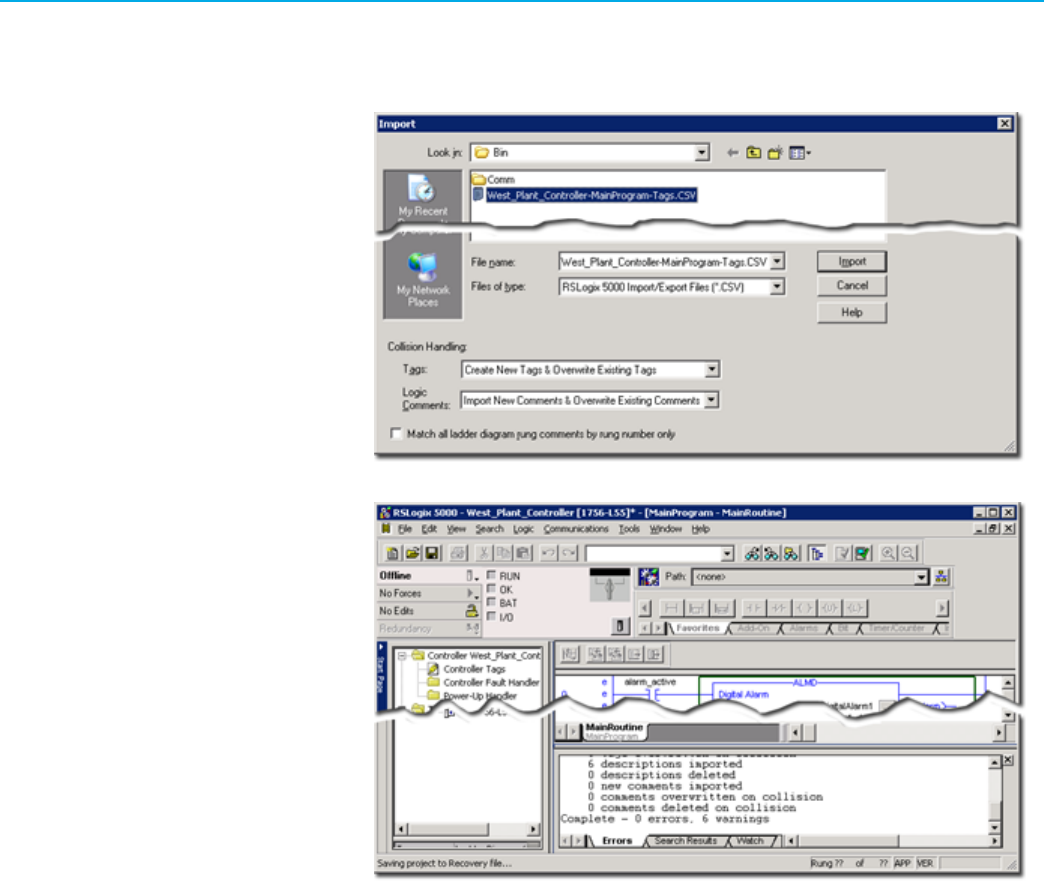

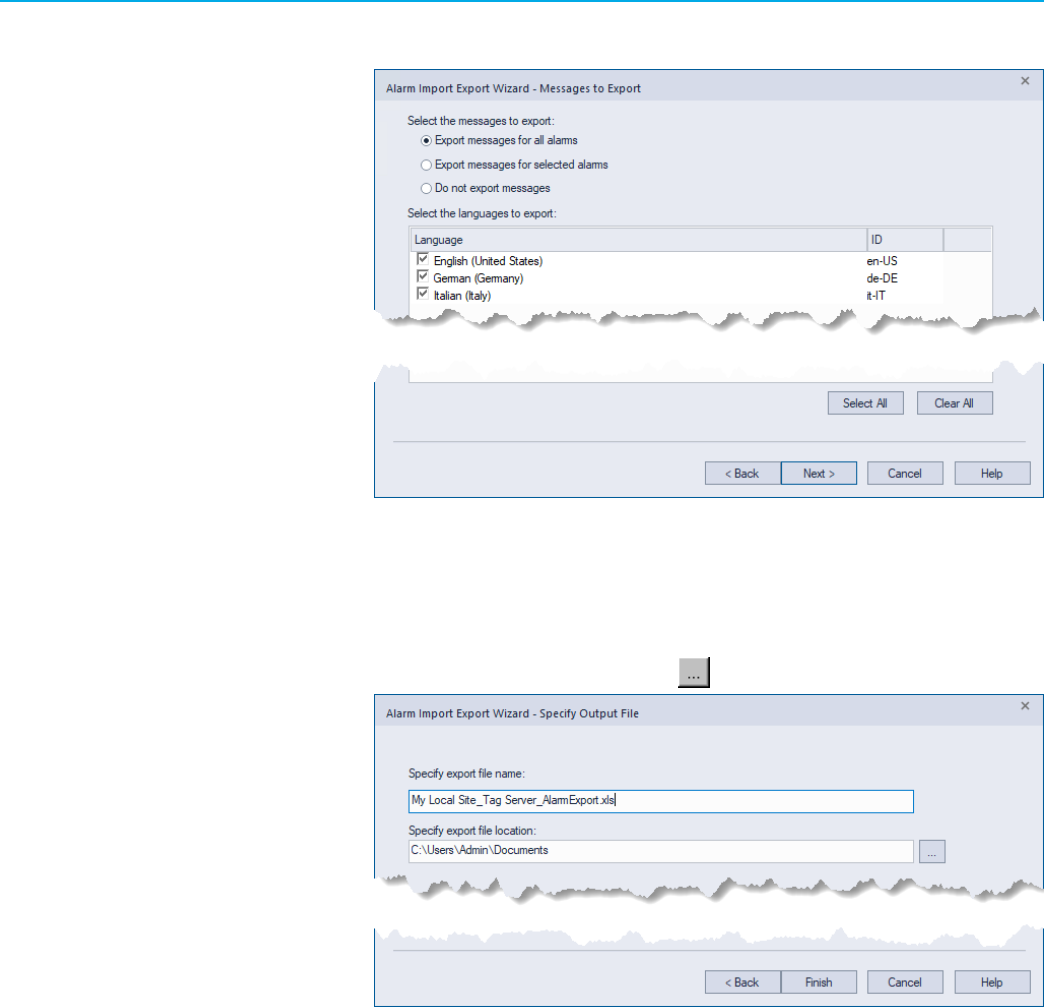

Translate alarm messages using import and export.........................................................................................................................................................................................128

Translate alarm messages in RSLogix 5000 version 16 or earlier........................................................................................................................................................ 129

Translate alarm messages using RSLogix 5000 version 17 or later...................................................................................................................................................... 131

Create tag-based alarm messages.................................................................................................................................................................................................................................. 134

Enter text strings in FactoryTalk View Studio.....................................................................................................................................................................................................134

Add languages to the application.....................................................................................................................................................................................................................................137

Add buttons to a graphic display to switch languages at runtime............................................................................................................................................................................138

Enter alarm messages in other languages.....................................................................................................................................................................................................................143

Create a Display Client configuration file to test alarm messages............................................................................................................................................................................151

Test alarm messages at runtime......................................................................................................................................................................................................................................153

Summary and tips for setting up language switching.................................................................................................................................................................................................156

Text that supports language switching................................................................................................................................................................................................................ 156

Text that does not support language switching................................................................................................................................................................................................. 156

Alarm and Event Summary and Alarm and Event Banner.................................................................................................................................................................................156

6 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Alarm and Event Log Viewer...................................................................................................................................................................................................................................157

System performance and limits...........................................................................................................................................................................................................158

Controller specifications.................................................................................................................................................................................................................................................... 158

Controllers with revision 31 and later................................................................................................................................................................................................................... 158

Controllers with revision 24 and later...................................................................................................................................................................................................................159

Controllers with revision 20 or earlier..................................................................................................................................................................................................................159

System sizing recommendations......................................................................................................................................................................................................................................160

Install FactoryTalk Alarms and Events manually................................................................................................................................................................................162

Summary of steps (manual installation).........................................................................................................................................................................................................................162

Confirm that FactoryTalk Services Platform is installed.............................................................................................................................................................................................162

Install FactoryTalk Alarms and Events............................................................................................................................................................................................................................ 163

Install Microsoft SQL Server................................................................................................................................................................................................................ 164

Summary of steps (new SQL Server)............................................................................................................................................................................................................................... 164

Step 1. Open the Redist folder.......................................................................................................................................................................................................................................... 164

Step 2. Install the .NET Framework..................................................................................................................................................................................................................................165

Step 3. Run the SQL Server install batch file (not the .exe)........................................................................................................................................................................................165

Step 4. Configure the Windows firewall..........................................................................................................................................................................................................................165

Use an existing SQL Server database..................................................................................................................................................................................................167

Supported SQL Server databases..................................................................................................................................................................................................................................... 167

Remote connections to the SQL Server database.........................................................................................................................................................................................................167

Summary of steps (existing SQL server).........................................................................................................................................................................................................................167

Step 1. Install SQL Server Management Studio.................................................................................................................................................................................................... 167

Step 2. Specify Mixed Mode authentication for the SQL Server database..................................................................................................................................................... 168

Step 3. Configure TCP/IP protocol for the database..........................................................................................................................................................................................168

Step 4. Enable the SQL Server Browser service................................................................................................................................................................................................. 168

Step 5. Configure the Windows Firewall...............................................................................................................................................................................................................168

Alarm time stamping............................................................................................................................................................................................................................170

Overview of time keeping..................................................................................................................................................................................................................................................170

Coordinated System Time (CST).............................................................................................................................................................................................................................170

Coordinated Universal Time (UTC)......................................................................................................................................................................................................................... 170

Local Time (Wall Clock Time)...................................................................................................................................................................................................................................171

ALMD and ALMA alarm blocks............................................................................................................................................................................................................................................172

Insert time stamps manually..................................................................................................................................................................................................................................173

Example..................................................................................................................................................................................................................................................................................174

Time synchronization........................................................................................................................................................................................................................... 175

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 7

Coordinate multiple controller wall clocks......................................................................................................................................................................................................................175

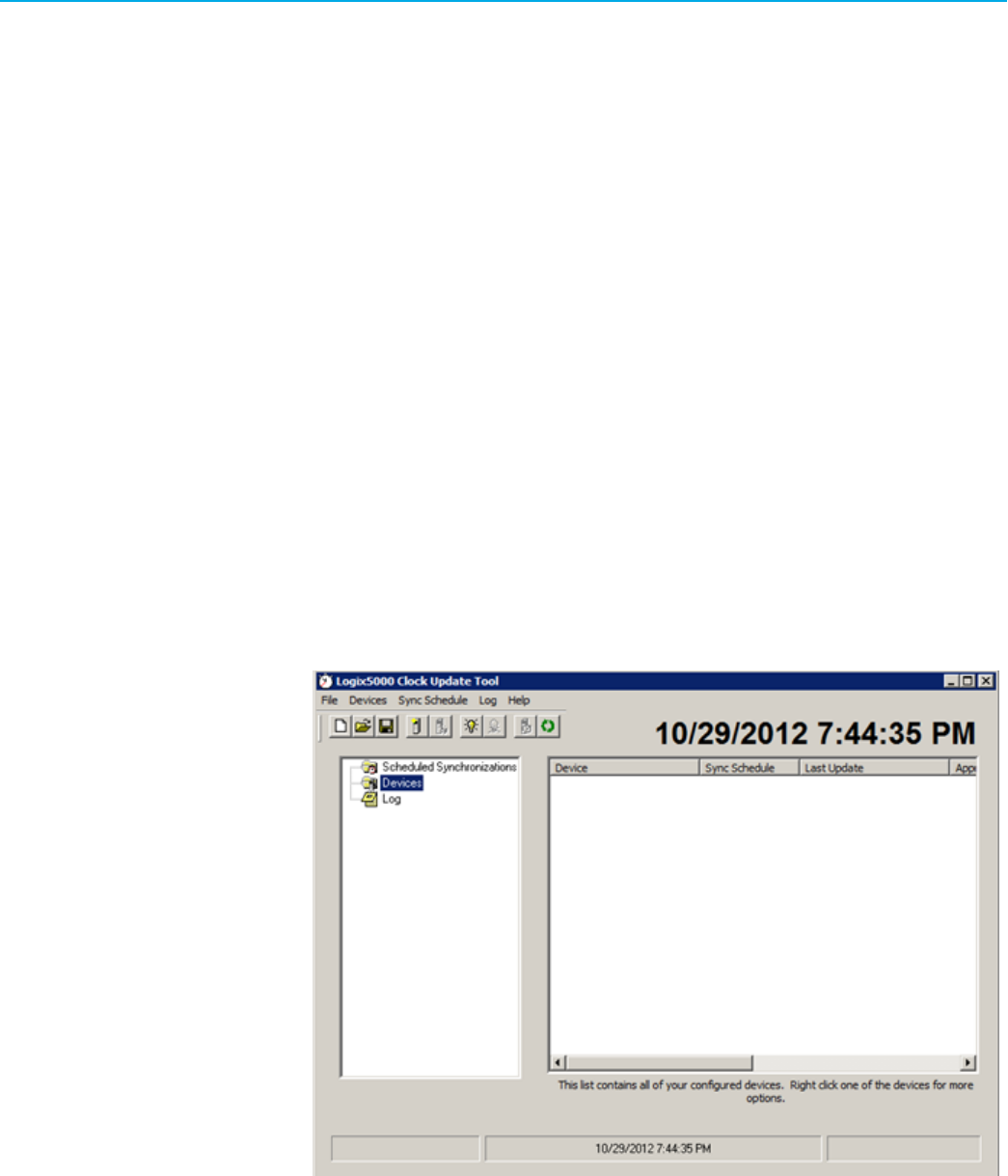

Install the Logix5000 Clock Update Tool.........................................................................................................................................................................................................................175

Start Clock Update Tool......................................................................................................................................................................................................................................................176

Start the Update Tool automatically......................................................................................................................................................................................................................176

Use the Logix5000 Clock Update Tool.............................................................................................................................................................................................................................176

Synchronize devices on a schedule................................................................................................................................................................................................................................. 177

Synchronization schedule........................................................................................................................................................................................................................................ 177

Create a synchronization schedule............................................................................................................................................................................................................. 177

Remove a synchronization schedule...........................................................................................................................................................................................................178

Modify a synchronization schedule.............................................................................................................................................................................................................178

Enable or disable a synchronization schedule..........................................................................................................................................................................................179

Add devices...........................................................................................................................................................................................................................................................................179

Add a device...............................................................................................................................................................................................................................................................179

Remove a device.......................................................................................................................................................................................................................................................180

View details about a device................................................................................................................................................................................................................................... 180

Assign devices to synchronization schedules.................................................................................................................................................................................................................181

Synchronize devices manually...........................................................................................................................................................................................................................................181

View the log file...................................................................................................................................................................................................................................................................182

Change the location of the log file........................................................................................................................................................................................................................182

Time stamps with tag-based alarms...............................................................................................................................................................................................................................183

Supported devices...............................................................................................................................................................................................................................................................184

Reference for building a distributed system.......................................................................................................................................................................................185

When installing FactoryTalk Alarms & Events............................................................................................................................................................................................................... 185

Typical distributed system on a network....................................................................................................................................................................................................................... 185

Language identifiers............................................................................................................................................................................................................................ 186

Language identifier list...................................................................................................................................................................................................................................................... 186

Legal Notices.........................................................................................................................................................................................................................................191

8 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Chapter 1

What you need to get started

The FactoryTalk® System Conguration Guide describes the tasks that are required to install, configure, and use

FactoryTalk Alarms and Events services as part of a FactoryTalk-enabled automation system. This guide also includes

references to additional documentation that provides more detail.

IMPORTANT:

This guide describes how to set up a local station application. However, the procedure

for setting up a network station application or network distributed application is similar. This guide

provides information about the latter two applications where it is necessary. See the Help included

with the individual software products used to configure and use Alarms and Events services.

Required software

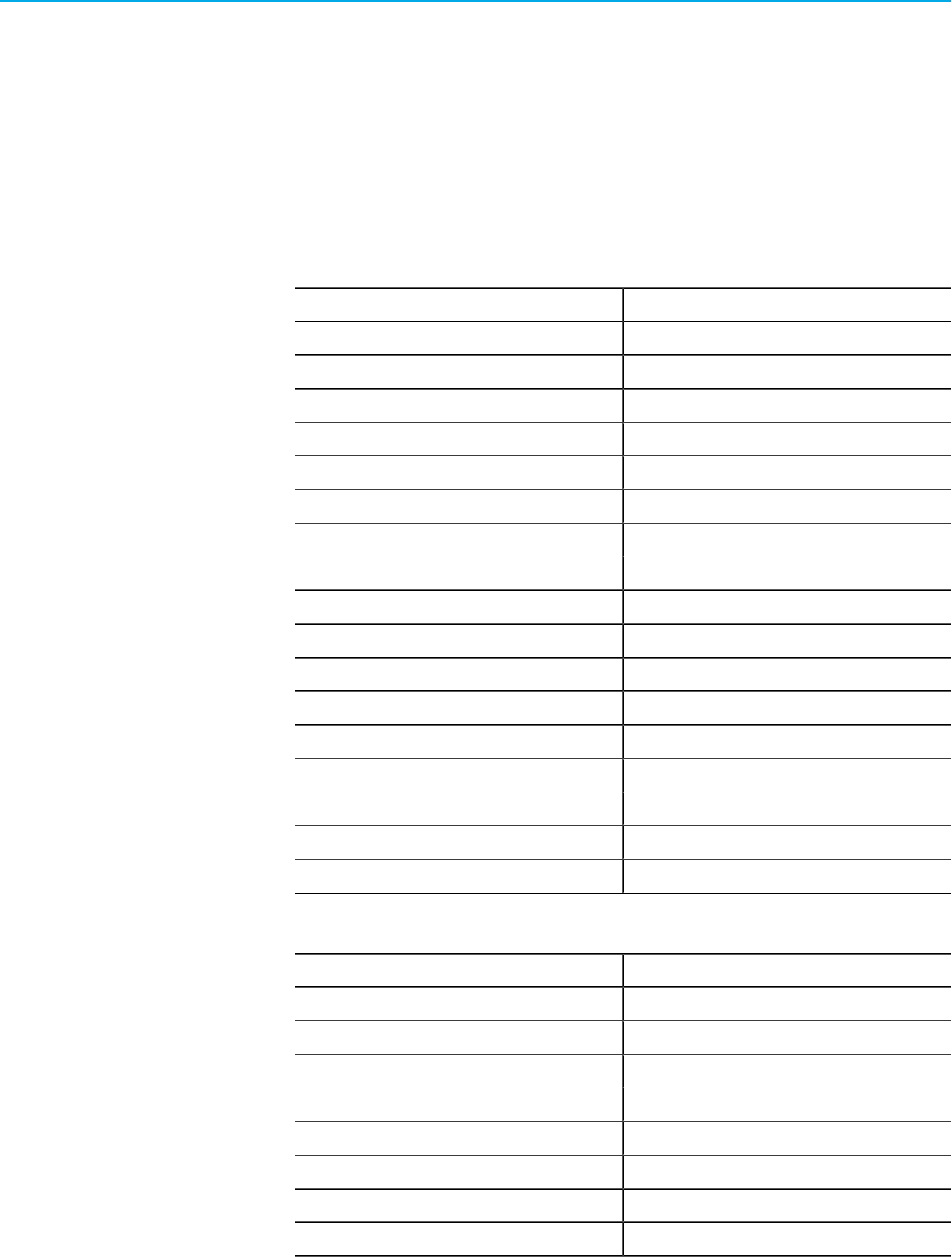

The following software is required to configure and operate FactoryTalk Alarms and Events services:

Software Version

FactoryTalk Services Platform 2.10 or later

FactoryTalk Alarms and Events 2.10 or later (included in FactoryTalk View SE and FactoryTalk

Services)

FactoryTalk® Linx™ 5.00 or later

RSLogix 5000® 16.05 or later (or the Studio 5000 Logix Designer® version

24.02 or later)

Studio 5000 Logix Designer 24.02 or later (or RSLogix 5000 version 16.05 or later)

RSLogix 500® Version that supports FactoryTalk Services Platform version

2.10 or later

RSLogix™ 5 Version that supports FactoryTalk Services Platform version

2.10 or later

FactoryTalk View SE 5.00 or later

FactoryTalk View Studio 5.00 or later

RSLinx® Classic (used forLogixprogramming) 2.50.20 or later

ControlFLASH™ 4.00.09 (used to download firmware)

ControlFLASH Plus® 1.00 or later (used to download firmware)

SoftLogix™ 16.03 or later

Microsoft® SQL Server® Version that supports FactoryTalk Alarms and Events historical

logging. For more information, see Supported SQL Server

databases on page 167.

Recommended hardware and supported operating systems

The hardware and supported operating systems that are recommended to run FactoryTalk Alarms and Events are

the same as those recommended to run FactoryTalk View Site Edition. For details, see the FactoryTalk View Site

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 9

Chapter 1What you need to get started

Edition Installation Guide. To access the guide, on the FactoryTalk View Studio toolbar, click Help > Online Books >

Installation Guide.

Studio 5000 controllers

The Studio 5000 controllers listed in the following table support FactoryTalk Alarms and Events services. When you

use built-in alarm instructions in Studio 5000 controllers, these controllers require a firmware update to revision

16.20 or later (excluding 21 to 23). If you do not want to update the firmware in your controllers, use a Tag Alarm and

Event Server for software-based alarms and events. See Decide what type of alarm monitoring you need on page

26.

Catalog number Name

1756-L61 ControlLogix Processor

1756-L62 ControlLogix Processor

1756-L63 ControlLogix Processor

1756-L64 ControlLogix Processor

1756-5555 5555 ControlLogix Processor

1768-L43 CompactLogix L43 Controller

1769-L31 CompactLogix L31 Controller

1769-L32C CompactLogix L32C Controller

1769-L32E CompactLogix L32E Controller

1769-L35CR CompactLogix L35CR Controller

1769-L35E CompactLogix L35E Controller

1794-L34 FlexLogix L34 Controller

1756-L61S ControlLogix Safety Processor

1756-L62S ControlLogix Safety Processor

PowerFlex700S 2 DriveLogix5370

1789-L60 SoftLogix5800

EMULATE RSLogix Emulate 5000

The following controllers with firmware revision 24 and later support FactoryTalk Alarms and Events services:

Catalog number Name

ControlLogix 1756-L71 Series B ControlLogix Processor

ControlLogix 1756-L71S Series B ControlLogix Safety Processor

ControlLogix 1756-L72 Series A ControlLogix Processor

ControlLogix 1756-L72 Series B ControlLogix Processor

GuardLogix1756-L72S Series B ControlLogix Safety Processor

ControlLogix 1756-L73 Series A ControlLogix Processor

ControlLogix 1756-L73 Series B ControlLogix Processor

ControlLogix 1756-L73XT Series B ControlLogix Processor

10 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Chapter 1What you need to get started

Catalog number Name

GuardLogix1756-L73S Series B ControlLogix Safety Processor

GuardLogix1756-L73SXT Series B ControlLogix Safety Processor

ControlLogix 1756-L74 Series A ControlLogix Processor

ControlLogix 1756-L74 Series B ControlLogix Processor

ControlLogix 1756-L75 Series A ControlLogix Processor

ControlLogix 1756-L75 Series B ControlLogix Processor

CompactLogix 1769-L16ER-BB1B CompactLogix L16ER-BB1BController

CompactLogix 1769-L18ER-BB1B CompactLogix L18ER-BB1B Controller

CompactLogix 1769-L18ERM-BB1B CompactLogix L18ERM-BB1BController

CompactLogix 1769-L24ER-QB1B CompactLogix L24ER-QB1B Controller

CompactLogix 1769-L24ER-QBFC1B CompactLogix L24ER-QBFC1BController

CompactLogix 1769-L27ERM-QBFC1B CompactLogix L27ERM-QBFC1BController

CompactLogix 1769-L30ER CompactLogix L30ERController

CompactLogix 1769-L30ER-NSE CompactLogix L30ER-NSEController

CompactLogix 1769-L30ERM CompactLogix L30ERMController

CompactLogix 1769-L33ER CompactLogix L33ER Controller

CompactLogix 1769-L33ERM CompactLogix L33ERM Controller

CompactLogix 1769-L36ERM CompactLogix L36ERM Controller

SoftLogix 1789-L60 SoftLogix5800

Tip:

Firmware revisions 21 through 23 do not support the new alarms functionality.

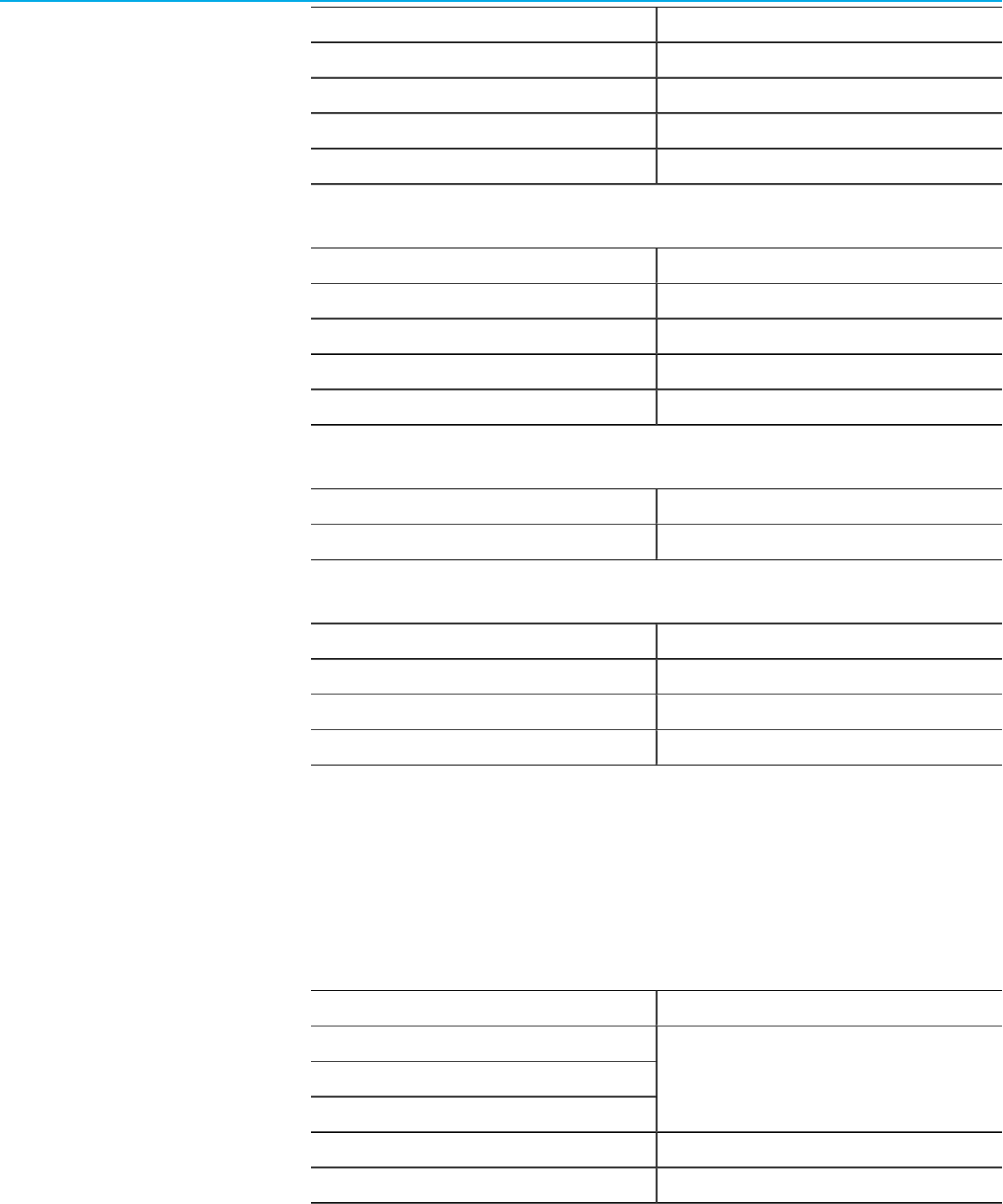

The following controllers with firmware revision 29 introduce support for FactoryTalk Alarms and Events services:

Catalog number Name

ControlLogix 1756-L81E ControlLogix Processor

ControlLogix 1756-L82E ControlLogix Processor

ControlLogix 1756-L83E ControlLogix Processor

ControlLogix 1756-L84E ControlLogix Processor

ControlLogix 1756-L85E ControlLogix Processor

CompactLogix 5069-L306ER CompactLogix L306ER Controller

CompactLogix 5069-L306ERM CompactLogix L306ERM Controller

CompactLogix 5069-L310ER CompactLogix L310ER Controller

CompactLogix 5069-L310ERM CompactLogix L310ERM Controller

CompactLogix 5069-L310ER-NSE CompactLogix L306ER-NSEController

CompactLogix 5069-L320ER CompactLogix L320ER Controller

CompactLogix 5069-L320ERM CompactLogix L320ERM Controller

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 11

Chapter 1What you need to get started

Catalog number Name

CompactLogix 5069-L330ER CompactLogix L330ER Controller

CompactLogix 5069-L330ERM CompactLogix L330ERM Controller

CompactLogix 5069-L340ER CompactLogix L340ER Controller

CompactLogix 5069-L340ERM CompactLogix L340ERM Controller

The following controllers with firmware revision 30 introduce support for FactoryTalk Alarms and Events services:

Catalog number Name

CompactLogix 5069-L380ERM CompactLogix L380ERM Controller

CompactLogix 5069-L3100ERM CompactLogix L3100ERM Controller

CompactLogix 1769-L37ERMO CompactLogix L37ERMO Controller

GuardLogix 1769-L37ERMOS CompactLogix Safety Processor

The following controllers with firmware revision 32 introduce support for FactoryTalk Alarms and Events services:

Catalog number Name

CompactLogix 5069-L46ERMW CompactLogix 5480 Controller

The following controllers with firmware revision 33 introduce support for FactoryTalk Alarms and Events services:

Catalog number Name

ControlLogix 1756-L81EP ControlLogix Processor

ControlLogix 1756-L83EP ControlLogix Processor

ControlLogix 1756-L85EP ControlLogix Processor

Automatic Diagnostics is supported only on Compact GuardLogix 5380, CompactLogix 5380, CompactLogix 5480,

ControlLogix 5580, and GuardLogix 5580 controllers, and the firmware revision must be 33 or later.

Compatible firmware

The controller firmware revisions listed in the following table are compatible with FactoryTalk Alarms and Events

services:

Controller Firmware revision

ControlLogix

CompactLogix L3x and L4x

DriveLogix

16.20 or higher (excluding 21 to 23)

ControlLogix Redundant Systems 16.60 or higher (excluding 21 to 23)

SoftLogix 16.03 or higher (excluding 21 to 23)

12 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Chapter 1What you need to get started

Other controllers

These controllers also support FactoryTalk Alarms and Events services:

•

Studio 5000 controllers that communicate with FactoryTalk Linx, using Tag Alarm and Event Servers.

• PLC-5® and SLC™ 500 controllers that communicate with FactoryTalk Linx (or RSLinx Classic to bridge from

Ethernet to DH+™ or DH-485 networks), using Tag Alarm and Event Servers.

•

Third-party PLCs that communicate with OPC® data servers such as KEPWare using Tag Alarm and Event

Servers.

How to get the information you need

For more information about the products and components discussed in this guide, the following manuals and Help

files are available:

• FactoryTalk Linx Help

• FactoryTalk Services Platform Help

•

Studio 5000 Logix Designer Help (for help with developing a controller project)

•

Studio 5000 Logix Designer online books

•

FactoryTalk View Site Edition Installation Guide (publication VIEWSE-IN003)

• FactoryTalk View Site Edition User Guide (publication VIEWSE-UM006)

•

FactoryTalk Linx Getting Results Guide (publication LIXENT-GR001)

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 13

Chapter 2

Overview of FactoryTalk Alarms and Events services

FactoryTalk Alarms and Events was introduced with FactoryTalk Services Platform 2.0 (CPR9) and FactoryTalk View

Site Edition 5.0 (CPR9) to provide a common, consistent view of alarms and events throughout a FactoryTalk system.

Starting from FactoryTalk Alarms and Events 2.30 (CPR9SR3), device-based and tag-based servers support

redundant server configuration. Starting from FactoryTalk Alarms and Events 6.30 (CPR 9 SR 13), OPC UA alarm

monitoring is supported.

IMPORTANT:

FactoryTalk View version 10.00 is the last release to support the legacy HMI tag alarms.

We highly recommend that you update your alarming strategy to use FactoryTalk Alarms and Events.

FactoryTalk Alarms and Events supports the following alarm monitoring:

• Device-based alarms, including:

◦

Logix instruction-based alarms

Alarm instructions are programmed and then downloaded into Studio 5000 controllers. The controller

detects alarm conditions and publishes the alarm information, which is routed to FactoryTalk Alarms

and Events.

◦

Logix tag-based alarms

Logix tag-based alarms associate alarm conditions with tags for Studio 5000 controllers. Logix tag-

based alarms monitor tag values to determine the alarm condition, but they are not part of the logic

program and do not increase the scan time for a project. Logix tag-based alarms are supported

only on Compact GuardLogix 5380, CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and

GuardLogix 5580 controllers.

•

Server tag-based alarms

Alarm conditions are defined and managed with software that monitors programmable controllers through

tags. Tag-based alarm monitoring is supported by Rockwell Automation controllers communicating through

Rockwell Automation device servers (FactoryTalk Linx), third-party controllers communicating through OPC

data servers, and HMI tags. Use server tag-based alarm monitoring if you do not want to use the pre-built

instructions in Studio 5000 Logix Designer, or do not have Studio 5000 controllers.

•

OPC UA alarms

Alarm conditions are provided by third-party OPC UA servers. The alarm data is then routed to FactoryTalk

Alarms and Events through FactoryTalk Linx OPC UA Connector.

FactoryTalk Alarms and Events:

•

Provides a single, integrated set of alarm information.

All participating FactoryTalk products work together to provide a consistent way to define, manage, log, and

view alarm and event information across a FactoryTalk application.

•

Streamlines alarm programming and eliminates polling with device-based alarm monitoring.

If your automation system includes Studio 5000 controllers, you can use pre-built alarms or alarm

instructions, available in the Logix Designer application (RSLogix 5000 software version 16 or later), to

simplify coding, and then download them to the controller. Device-based alarm monitoring eliminates the

need for duplicating alarm tags in an HMI server and requires fewer controller communication resources by

eliminating polling.

•

Supports other controllers in the integrated system with server tag-based alarm monitoring.

14 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Chapter 2Overview of FactoryTalk Alarms and Events services

If your automation system includes other Rockwell Automation controllers, such as PLC-5s or SLC 500s, or

if you prefer not to use the alarms or alarm instructions with Studio 5000 controllers, software-based tag

servers monitor controllers for alarm conditions and publish event information.

• Monitors alarms and events from third-party controllers.

Server tag-based alarm monitoring also makes it possible to monitor alarm conditions from third-party

controllers, which communicate through OPC data servers.

•

Provides accurate time stamps on alarm conditions that are generated from Studio 5000 controllers using

device-based alarm monitoring.

When you use device-based alarm monitoring, timestamps are applied immediately in the controller and

are not delayed until alarms reach an HMI server. To make sure that the timestamps on device-based

alarms are accurate, synchronize the clocks of all controllers that produce alarms. The event time is

propagated throughout the FactoryTalk Alarms and Events system, so inaccurate timestamps can affect

where alarms are displayed in the Alarm and Event Summary or the Alarm and Event Banner as well as

reports about the alarm and event history. For more information about synchronizing controller clocks, see

Time synchronization on page 175.)

•

Subscribes to and displays diagnostic events enabled by the Automatic Diagnostics feature of Studio 5000

Logix Designer.

Automatic Diagnostics is supported only on Compact GuardLogix 5380, CompactLogix 5380, CompactLogix

5480, ControlLogix 5580, and GuardLogix 5580 controllers, and the firmware revision must be 33 or later.

•

Sends process data with events and messages.

You can associate up to four tags with each alarm to include process data with event information and alarm

messages.

•

Secures access to alarm and event operations through integration with FactoryTalk Security.

•

Generates messages for logging.

Log messages include audit messages that track operator actions, system-related diagnostic messages, and

historical alarm and event messages.

•

Shows alarm messages and status information at runtime, in FactoryTalk View graphic displays.

Migrating HMI tag alarms

FactoryTalk View version 10.00 is the last release to support the legacy HMI tag alarms. We highly recommend that

you update your alarming strategy to use FactoryTalk Alarms and Events.

Use the FactoryTalk View Alarm Migration tool to migrate HMI tag alarms to FactoryTalk Alarms and Events.

Migrate to FactoryTalk Alarms and Events if you want to:

•

Use device-based alarm monitoring. You can use a Studio 5000 controller not only to detect alarms, but also

to monitor alarms. This keeps all alarm and event processing in the controller. To use device-based alarm

monitoring, add the built-in alarm instructions, available in the Logix Designer application (or RSLogix 5000

software version 16 or later), to a logic project and then download the project to a Studio 5000 controller. The

controller detects alarm conditions and publishes event information, which can be displayed and logged.

•

Use language-switching with alarm messages. For Logix instruction-based and Logix tag-based alarms, you

only need to translate once in Studio 5000 Logix Designer without having to translate within HMI servers.

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 15

Chapter 2Overview of FactoryTalk Alarms and Events services

• Take advantage of the richer feature set offered by FactoryTalk Alarms and Events, including:

◦

Redundant software-based Tag Alarm and Event servers that monitor controllers for alarm conditions

through data servers and publish event information that can be displayed and logged.

◦ Configurable Alarm and Event Summary that includes the ability to suppress alarms directly from the

summary, without the use of separate commands.

◦

Alarm and Event Banner, Alarm and Event Log Viewer, Alarm Status Explorer, and Automatic Diagnostic

Event Summary objects that are hosted on graphic displays. You can use the Alarm Status Explorer to

enable or disable alarms, suppress or unsuppress alarms, shelve or unshelve alarms, and view operator

comments.

◦

System-wide views in the Alarm and Event Banner, rather than just the alarms in a single HMI server.

Where to start

Here is an overview of the sections covered in this guide:

1.

Overview of FactoryTalk Alarms and Events services on page 14

2. Plan your system on page 25

◦

Set up device-based alarm monitoring

a. Define device-based alarms in Studio 5000 controllers on page 29

b. Add a device server for Studio 5000, PLC-5, or SLC 500 controllers on page 38

◦

Set up tag-based alarm monitoring

a. Add an OPC data server for third-party controllers on page 45

b. Add a tag-based alarm server for Studio 5000, PLC-5, SLC 500, or third-party controllers on page

48

◦

Set up OPC UA alarm monitoring

a. Define and configure alarms in the third-party OPC UA server on page 55

b. Add FactoryTalk Linx OPC UA Connector and enable alarms on page 55

3.

Set up graphic displays on page 58

4.

Monitor and interact with alarms at runtime on page 82

5.

Set up historical alarm and event logging on page 100

6.

Configure redundancy for alarms and events on page 120

16 FTAE-RM001P-EN-E - November 2023 Rockwell Automation, Inc.

Chapter 2Overview of FactoryTalk Alarms and Events services

FactoryTalk Alarms and Events components

The following diagram shows a high-level view of the components of the FactoryTalk Alarms and Events system. For

more detailed information, see FactoryTalk Alarms and Events Help.

Device-based alarm monitoring

With device-based alarm monitoring that are available with the Studio 5000 Logix Designer application, pre-built

alarms or alarm instructions are configured and then downloaded into a Studio 5000 controller. The controller

detects alarm conditions and notifies alarms and events services of alarm states. Software components publish this

information to a device server. From the device server, the information can be logged to a database and monitored

from FactoryTalk View graphic displays.

Use device-based alarm monitoring with Studio 5000 controllers, programmed with the Logix Designer application,

communicating through Rockwell Automation Device Servers (FactoryTalk Linx).

Server tag-based alarm monitoring

If you are not using Studio 5000 controllers, or if you do not want to use the pre-built alarming available with the

Logix Designer application, use server tag-based alarm monitoring. The server tag-based Alarm and Event servers

monitor controllers for alarm conditions through data servers and publish event information for display and logging.

These data servers serve tags, or data items, contained in OPC DA (Data Access) servers. Clients that need access

to data items, such as FactoryTalk View Studio and FactoryTalk Transaction Manager, use data server application

Rockwell Automation, Inc. FTAE-RM001P-EN-E - November 2023 17

Chapter 2Overview of FactoryTalk Alarms and Events services

elements referenced from the FactoryTalk Directory to locate the computers that are hosting OPC DA 2.0 compliant

data servers.

Use the server tag-based alarm monitoring for Studio 5000 controllers, PLC-5 devices, and SLC 500 devices

communicating through Rockwell Automation Device Servers (FactoryTalk Linx), or for third-party controllers

communicating through OPC DA data servers.

OPC UA alarm monitoring

OPC UA alarm monitoring captures alarm information originated from third-party OPC UA servers. FactoryTalk Linx

OPC UA Connector routes the alarm information to FactoryTalk Alarms and Events for display and logging.

FactoryTalk Alarms and Events services

Device-based alarms, tag-based alarms and events, and OPC UA alarms are published to FactoryTalk Alarms and

Events services, which then routes the information to FactoryTalk Alarms and Events objects hosted in FactoryTalk

View, the alarm and event history log, and to diagnostic logs and audit logs.

Alarm and Event Historian

The Alarm and Event Historian is a logging component that installs silently as part of the FactoryTalk Alarms and

Events software. It manages connections between alarm servers and databases and logs data from each alarm

server to an alarm history database. An Alarm and Event Log Viewer allows viewing and printing data from alarm

history databases. Third-party database tools can also retrieve, view, analyze, and print alarm history information.

To use alarm and event logging, install SQL Server separately, or use an existing SQL Server database. See the release

notes for FactoryTalk Alarms and Events for the latest qualified versions of SQL Server.

Diagnostic and audit logs

FactoryTalk Diagnostics routes messages generated by FactoryTalk Alarms and Events to Local logs on the computers

hosting FactoryTalk components, and optionally to a centralized database log. Audit messages are routed to the Local