power.cummins.com

©2017 Cummins Inc. | D-6203 (08/17)

Generator set data sheet

1000 kW continuous

Model:

C1000 N6C

Frequency:

60 Hz

Fuel type:

Natural gas MI 60 +

Emissions NOx:

0.5 g/hp-h

LT water inlet temp:

40 °C (104 °F)

HT water outlet temp:

90 °C (194 °F)

Measured sound performance data sheet:

MSP-1257

Prototype test summary data:

PTS-288

Generator set outline drawing:

A029E093 heavy duty air cleaner

A029U550 standard air cleaner

Fuel consumption (ISO3046/1)

100% load

90% load

75% load

50% load

Fuel consumption (LHV) ISO3046/1, kW (MMBTU/hr)

1,2,3,4,5,7

2438 (8.33)

2210 (7.55)

1867 (6.38)

1316 (4.49)

Mechanical efficiency ISO3046/1, percent

1,2,4,5,7

42.3%

42.0%

41.4%

39.2%

Electrical efficiency ISO3046/1, percent

1,2,3,4,5,7

41.0%

40.7%

40.2%

38.0%

Engine

Engine manufacturer

Cummins

Engine model

QSK60G

Configuration

V16

Displacement, L (cu.in.)

60 (3671)

Aspiration

Turbocharged (1)

Gross engine power output, kWm (hp)

1031 (1382)

BMEP, bar (psi)

17.2 (249)

Bore, mm (in.)

159 (6.26)

Stroke, mm (in.)

190 (7.48)

Rated speed, rpm

1200

Piston speed, m/s (ft/min)

7.6 (1496)

Compression ratio

12.7:1

Lube oil capacity, L (qt)

380 (400)

Overspeed limit, rpm

1500

Regenerative power, kW

N/A

Full load lubricating oil consumption,

g/kWe-hr (g/hp-hr)

0.18 (0.14)

Fuel system

Gas supply pressure to engine inlet, bar (psi)

8

0.2 (2.9)

Minimum methane index

60

power.cummins.com

©2017 Cummins Inc. | D-6203 (08/17)

Engine electrical system(s)

Electric starter voltage, volts

24

Ignition timing, deg before top dead center

18

Minimum battery capacity @ 40 °C (104 °F), AH

720

Genset dimensions

Genset length, m (ft)

6

5.12 (16.8)

Genset width, m (ft)

6

2.23 (7.30)

Genset height, m (ft)

6

2.77 (9.08)

Genset weight (wet), kg (lbs)

6

15625 (34,375)

Notes:

1. At ISO3046 reference conditions, altitude 1013 mbar (30 in. Hg), air inlet temperature 25 °C (77 °F).

2. Power output and efficiency include the effect of Cummins supplied engine driven LT coolant pump.

3. At electrical output of 1.0 power factor, 97% alternator efficiency.

4. Based on pipeline natural gas with LHV of 33.44 mJ/Nm

3

(905 BTU/ft

3

).

5. Subtract 3 °C ambient temperature capability for each 100 mm (4 in.) H

2

O back pressure above the information shown on

page 2.

6. Weights and dimensions represent a generator set with its standard features only. See outline drawing for other

configurations.

7. According to ISO3046/1 with fuel consumption tolerance of +5% -0%.

8. Minimum gas supply pressure dependant on LHV of fuel.

power.cummins.com

©2017 Cummins Inc. | D-6203 (08/17)

100% load

90% load

75% load

50% load

Energy data

Continuous generator electrical output kWe

1,5,6,7

1000

900

750

500

Continuous shaft power, kWm (bhp)

1,5,6,7

1031 (1382)

928 (1244)

773 (1036)

515 (690)

Total heat rejected in LT circuit, kW (MMBTU/h)

2

82 (0.28)

75 (0.26)

63 (0.21)

46 (0.16)

Total heat rejected in HT circuit, kW (MMBTU/h)

2

545 (1.86)

484 (1.65)

398 (1.36)

350 (1.19)

Unburnt, kW (MMBTU/h)

2

52 (0.18)

47 (0.16)

40 (0.14)

27 (0.09)

Heat radiated to ambient, kW (MMBTU/h)

2

158 (0.54)

143 (0.49)

120 (0.41)

83 (0.28)

Available exhaust heat to 105 °C, kW (MMBTU/h)

2

546 (1.86)

505 (1.72)

444 (1.51)

330 (1.13)

Intake air flow

Intake air flow mass, kg/s (lb/hr)

2

1.57 (12430)

1.41 (11170)

1.2 (9500)

0.83 (6570)

Intake air flow volume, m

3

/s @ 0 °C (scfm)

2

1.22 (2720)

1.09 (2430)

0.93 (2080)

0.64 (1430)

Max inlet restriction (after filter, limit for changing filters),

below 35 °C ambient temp, mm HG, (in H

2

O)

28 (15)

22.7 (12.1)

15.7 (8.4)

7 (3.7)

Max inlet restriction (after filter, limit for changing filters),

above 35 °C ambient temp, mm HG, (in H

2

O)

18.7 (10)

15.2 (8.1)

10.5 (5.6)

0 (2.5)

Exhaust air flow

Exhaust gas flow mass, kg/s (lb/hr)

2

1.62 (12830)

1.46 (11560)

1.24 (9820)

0.87 (6890)

Exhaust gas flow volume, m

3

/s (cfm)

2,9

3.18 (6730)

2.9 (6140)

2.5 (5290)

1.8 (3810)

Exhaust temp after turbine, °C (°F)

1

420 (788)

428 (802)

440 (824)

459 (858)

Max exhaust system back pressure, mm HG (in H

2

O)

8

38 (20)

31 (17)

21 (11)

10 (5)

HT cooling circuit

HT circuit engine coolant volume, l (gal)

181 (48)

181 (48)

181 (48)

181 (48)

HT coolant flow @ max ext restriction, m

3

/h (gal/min)

63 (277)

63 (277)

63 (277)

63 (277)

Max HT engine coolant inlet temp, °C (°F) reference

3

82 (180)

83 (181)

84 (183)

85 (185)

HT coolant outlet temp, °C (°F)

3

90 (194)

90 (194)

90 (194)

90 (194)

Max pressure drop in external HT circuit, bar (psig)

1.4 (20)

1.4 (20)

1.4 (20)

1.4 (20)

HT circuit max pressure, bar (psig)

5 (73)

5 (73)

5 (73)

5 (73)

Static head pump inlet, bar (psig)

.5-1.5 (7-20)

.5-1.5 (7-20)

.5-1.5 (7-20)

.5-1.5 (7-20)

LT cooling circuit

LT circuit engine coolant volume, l (gal)

34 (9)

34 (9)

34 (9)

34 (9)

LT coolant flow @ max ext restriction, m

3

/h (gal/min)

17 (75)

17 (75)

17 (75)

17 (75)

LT coolant inlet temp, thermostat controlled °C (°F)

4

40 (104)

40 (104)

40 (104)

40 (104)

LT coolant inlet temp max

4

50 (122)

50 (122)

50 (122)

50 (122)

Max pressure drop in external LT circuit, bar (psig)

1 (15)

1 (15)

1 (15)

1 (15)

LT circuit max pressure, bar (psig)

5 (73)

5 (73)

5 (73)

5 (73)

Static head pump inlet, bar (psig)

.5-1.5 (7-20)

.5-1.5 (7-20)

.5-1.5 (7-20)

.5-1.5 (7-20)

Notes:

1. At ISO3046 reference conditions, altitude 1013 mbar (30 in. Hg), air inlet temperature 25 °C (77 °F).

2. Production variation/tolerance ±5%.

3. Outlet temperature controlled by thermostat. Inlet temperature for reference only.

4. Inlet temperature controlled by thermostat to 40 °C but is allowed to go to 50 °C and ignition timing is retarded resulting in

efficiency loss of 0.4 - 0.6%.

5. Power output and efficiency include the effect of Cummins supplied engine driven LT coolant pump.

6. At electrical output of 1.0 power factor, 97% alternator efficiency.

7. Based on pipeline natural gas with LHV of 33.44 mJ/Nm

3

(905 BTU/ft

3

).

8. Subtract 3 °C ambient temperature capability for each 100 mm (4 in.) H

2

O back pressure above the information shown on

page 2.

9. At exhaust temperature and standard atmospheric pressure.

power.cummins.com

©2017 Cummins Inc. | D-6203 (08/17)

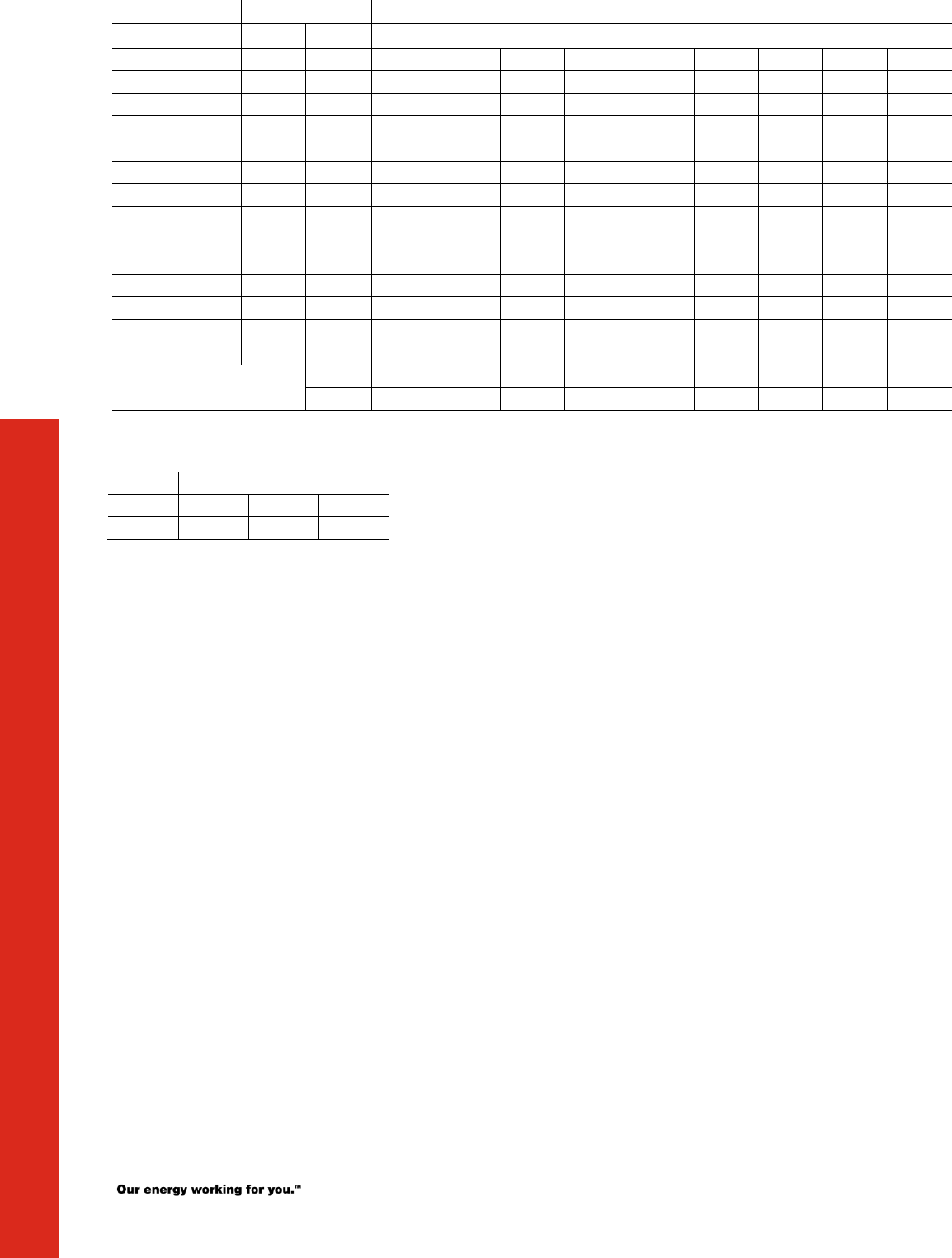

Altitude and temperature derate multiplication factor

1.2.3

Barometer

Altitude

Table A

In Hg

mbar

Feet

Meters

Derate multiplier for all operation modes

20.7

701

9843

3000

0.75

0.75

0.75

0.75

0.71

0.68

0.61

0.53

-

21.4

723

9022

2750

0.79

0.79

0.79

0.78

0.73

0.70

0.63

0.54

-

22.1

747

8202

2500

0.82

0.82

0.82

0.81

0.76

0.72

0.64

0.55

-

22.8

771

7382

2250

0.86

0.86

0.86

0.84

0.80

0.74

0.65

0.55

-

23.5

795

6562

2000

0.89

0.89

0.89

0.88

0.83

0.78

0.67

0.56

-

24.3

820

5741

1750

0.93

0.93

0.93

0.91

0.86

0.81

0.68

0.56

-

25.0

846

4921

1500

0.96

0.96

0.96

0.94

0.90

0.85

0.69

0.57

-

25.8

872

4101

1250

1.00

1.00

1.00

0.97

0.93

0.89

0.71

0.57

-

26.6

899

3281

1000

1.00

1.00

1.00

1.00

0.97

0.93

0.72

0.58

-

27.4

926

2461

750

1.00

1.00

1.00

1.00

1.00

0.96

0.74

0.58

-

28.3

954

1640

500

1.00

1.00

1.00

1.00

1.00

1.00

0.75

0.59

-

29.1

983

820

250

1.00

1.00

1.00

1.00

1.00

1.00

0.75

0.59

-

29.5

995

492

150

1.00

1.00

1.00

1.00

1.00

1.00

0.75

0.59

-

30.0

1012

0

0

1.00

1.00

1.00

1.00

1.00

1.00

0.75

0.59

-

Air filter inlet temperature

°C

0

15

20

25

30

35

40

45

50

°F

32

59

68

77

86

95

104

113

122

Methane number capability table B

Load (percent of rated)

100%

90%

75%

50%

60

60

60

60

power.cummins.com

©2017 Cummins Inc. | D-6203 (08/17)

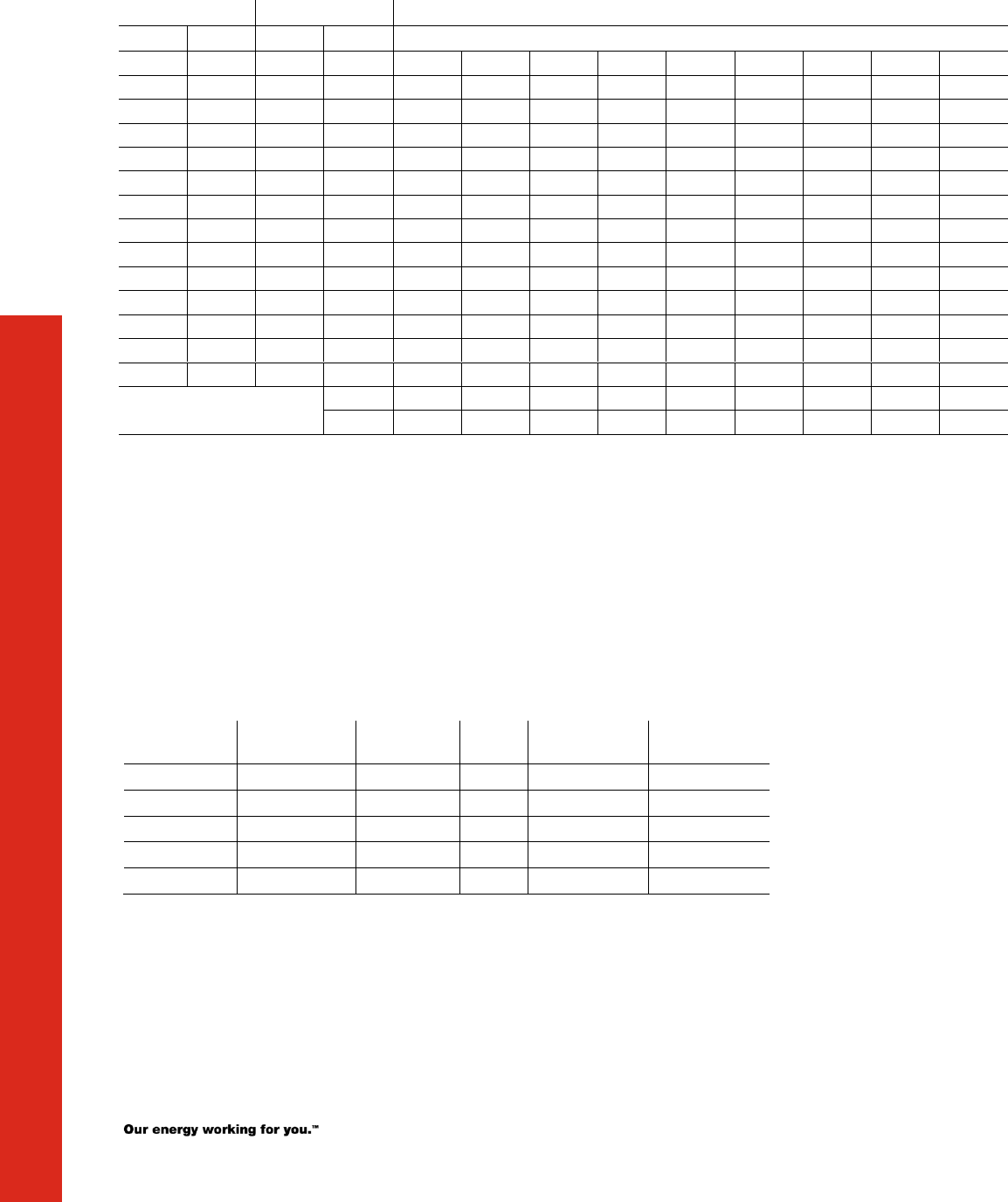

Table C altitude and ambient heat rejection factor adjustment for HT and LT circuits

LT & HT circuit heat rejection calculation procedure

1. Determine derate multiplier vs. temp derate from table A.

2. Using the multiplier from #1 above as the percent load factor, determine the heat rejection.

3. From table C find the HT and LT circuit multiplier.

4. Multiply the result of step 2 by the result of step 3 to obtain the heat rejection at your altitude and temperature.

Barometer

Altitude

In Hg

mbar

Feet

Meters

Multiplier for HT & LT heat rejection vs alt & temp.

20.7

701

9843

3000

1.06

1.10

1.11

1.13

1.14

1.15

1.17

1.18

1.19

21.4

723

9022

2750

1.05

1.09

1.10

1.12

1.13

1.14

1.15

1.17

1.18

22.1

747

8202

2500

1.04

1.08

1.09

1.10

1.12

1.13

1.14

1.16

1.17

22.8

771

7382

2250

1.03

1.07

1.08

1.09

1.11

1.12

1.13

1.14

1.16

23.5

795

6562

2000

1.02

1.06

1.07

1.08

1.09

1.11

1.12

1.13

1.15

24.3

820

5741

1750

1.01

1.04

1.06

1.07

1.08

1.10

1.11

1.12

1.14

25.0

846

4921

1500

0.99

1.03

1.05

1.06

1.07

1.09

1.10

1.11

1.12

25.8

872

4101

1250

0.98

1.02

1.04

1.05

1.06

1.07

1.09

1.10

1.11

26.6

899

3281

1000

0.97

1.01

1.02

1.04

1.05

1.06

1.08

1.09

1.10

27.4

926

2461

750

0.96

1.00

1.01

1.03

1.04

1.05

1.07

1.08

1.09

28.3

954

1640

500

0.95

0.99

1.00

1.02

1.03

1.04

1.05

1.07

1.08

29.1

983

820

250

0.94

0.98

0.99

1.00

1.02

1.03

1.04

1.06

1.07

29.5

995

492

150

0.94

0.97

0.99

1.00

1.01

1.03

1.04

1.05

1.06

30.0

1012

0

0

0.93

0.97

0.98

0.99

1.01

1.02

1.03

1.05

1.06

Air filter inlet temperature

°C

0

15

20

25

30

35

40

45

50

°F

32

59

68

77

86

95

104

113

122

Notes:

1. Ambient temperature is the same as air filter inlet temperature. LT inlet temperature is 40 °C, or 10 °C above ambient,

whichever is higher.

2. Table refers to the capability to run at continuous power level. For short periods of time the genset can run at 5 °C higher

temperature with reduced efficiency.

3. Subtract 3 °C ambient temperature capability for each 100 mm (4 in.) H

2

O back pressure above the information shown on

page 3.

4. This generator set is capable of operating for short periods of time under with the LT temperature and/or the fuel methane

number outside of the recommended limits with decreased performance. Operation in the green area will result in normal

performance. Operation in the yellow area is recommended only for short periods of time and will result in reduced efficiency

and shorter spark plug life. Operation in the red area is NOT recommended.

Alternator data

Voltage

range

Connection

configuration

Temp rise

degrees C

Duty

cycle

4

Phase

factor

Alternator

data sheet

380-480

Wye, 3 Phase

105

C

N/A

Note 5

440-480

Wye, 3 Phase

80

C

N/A

Note 5

600

Wye, 3 Phase

80

C

N/A

Note 5

4160

Wye, 3 Phase

80,105

C

N/A

Note 5

12470-13800

Wye, 3 Phase

80

C

N/A

Note 5

For more information contact your local Cummins distributor

or visit power.cummins.com

©2017 Cummins Inc. All rights reserved. Cummins is a registered trademark of Cummins Inc. PowerCommand, AmpSentry, InPower and “Our energy working for you.” are trademarks of

Cummins Inc. Other company, product, or service names may be trademarks or service marks of others. Specifications are subject to change without notice.

D-6203 (08/17)

Continuous rating definition

Applicable for supplying power continuously to a constant load up to the full output rating for unlimited hours. No

sustained overload capability is available for this rating. Consult authorized distributor for rating (equivalent to

continuous power in accordance with ISO8528, ISO3046, AS2789, DIN6271, and BS5514). This rating is not

applicable to all generator set models.

Emissions

100% load

90% load

75% load

50% load

NO

x

emissions dry, ppm

8

83

84

84

79

NO

x

emissions, mg/Nm

3

@ 5% O

2

(g/hp-h)

8

200 (0.5)

200 (0.5)

200 (0.5)

200 (0.5)

THC emissions wet, ppm

2

1212

1244

1287

1352

THC emissions, mg/Nm

3

@ 5% O

2

(g/hp-h)

2

1350 (2.6)

1380 (2.6)

1420 (2.6)

1460 (2.6)

NMHC emissions wet, ppm

2,3

182

187

193

203

NMHC exhaust emissions, mg/Nm

3

@ 5% O

2

(g/hp-h)

2,3

200 (0.4)

210 (0.4)

210 (0.4)

220 (0.4)

HCHO emissions (wet), ppm

6

70

70

70

70

HCHO exhaust emissions, mg/Nm

3

@ 5% O2, (g/hp-h)

6

150 (0.3)

150 (0.3)

150 (0.3)

140 (0.3)

CO emissions (dry), ppm

9

401

396

392

377

CO emissions rate, mg/Nm

3 9

@ 5% O

2

(g/hp-h)

700 (1.4)

680 (1.4)

670 (1.4)

630 (1.4)

CO

2

emissions (dry), percent

9

6.5

6.5

6.6

6.7

O

2

emissions (dry), percent

9

9.5

9.4

9.3

9.0

Particulates PM10, g/hp-h

9

< 0.03

< 0.03

< 0.03

< 0.03

Notes:

1. Production variation/tolerance ±5%.

2. Tolerance +/- 15%.

3. NMHC emission are an estimate. Actual NMHC emissions are a function of the non-methane hydrocarbons in the fuel.

4. Standby (S), Prime (P), Continuous (C) ratings.

5. Alternator model and data sheet information available on power.cummins.com.

6. Tolerance +/- 35%.

7. Maximum surge kVA or specific alternator data can be obtained by request if not published.

8. Tolerance ±10% for 1 g, ±14% for 0.7 g & ±20% for 0.5 g.

9. Tolerance +/- 10%.