“Dry Tomb” Landfills—The Past,

Present, and Possibilities

The implications of modern sanitary landfill technology has led to what are known

as “dry tombs” and presents a few possible alternatives that have the potential to

achieve the same results.

T

he promulgation of EPA’s

Subtitle D regulation (40 CFR

Parts 257 and 258—Solid Waste

Disposal Facility Criteria) has

significantly impacted sanitary landfill

design, construction, operation, and closure

over the past two decades. Developed under

the Resource Conservation and Recovery Act

(RCRA) of 1976, and in response to 1984

Hazardous and Solid Waste Amendments to

RCRA, the rule sets minimum criteria for

modern solid waste landfill in seven basic

areas: location restrictions, facility design,

operations, environmental monitoring,

financial assurance, corrective action, and

closure and post-closure care. The facility

design provisions provide prescriptions for

the makeup, installation, and operation of

key landfill design features, including a com-

posite bottom liner and leachate collection

system to minimize leakage of leachate, and

a final cover system at the time of closure to

minimize infiltration of precipitation and

other liquids into the waste mass.

A relevant consequence of the Subtitle D

regulations was that restricting liquids from

infiltrating into the waste mass—includ-

ing precipitation, stormwater runoff, and

leachate—created conditions in which the

organic waste components decomposed,

compressed, and generated gas much more

slowly than compared to a “wet landfill.”

Waste in a dry tomb landfill takes more time

to decompose (stabilize), thereby extending

the post-closure management and monitor-

ing period by several years, or even decades.

Questions and concerns relating to the

potential downsides of dry tomb landfills

have been raised by landfill owners, opera-

tors, regulators, and designers since Subtitle

D was promulgated. In response to these

concerns, and with appreciation for the

advances that have taken place in landfill

technology, EPA promulgated the Research,

Development, and Demonstration (RD&D)

rule in 2004 under Subtitle D. RD&D was

an interim measure that allowed for an

introduction of liquids and recirculation

of leachate on alternative bottom liners, as

well as other waste treatment approaches, to

facilitating waste degradation, accelerating gas

generation, minimizing leachate treatment

efforts, increasing the rate of waste settlement,

and reducing post-closure activities.

Weaver Boos

S16 LFG 2016 MSW MANAGEMENT

BY ROBERT H. ISENBERG AND DARRIN D. DILLAH

However, as of March 2014, EPA indicated

that there were only were 30 active RD&D

projects in 11 approved states, and one

project on tribal land. This statistic suggests

that dry tomb landfilling is still practiced

widely, despite the apparent disadvantages

and concerns raised by numerous parties.

Fortunately, EPA proposed in the November

13, 2015 Federal Register to allow directors of

states with EPA-approved RD&D programs

to increase the maximum term for RD&D

permits from 12, to 21 years at 40 CFR

258.4(e)(1), to provide more time to support

research into the performance of bioreactors,

alternative covers, and run-on systems.

Remembering the Past: Subtitle D

(Did the “D” Mean Dry Tomb?)

Under the original Subtitle D rule, state

regulatory agencies were required to adopt

the prescriptive facility design approach or

something no less restrictive, with some

flexibility to consider the influence of local

conditions such as climate and hydrogeol-

ogy. The vast majority of new landfills

and landfill expansions in the US adopted

regulations similar to Subtitle D, including a

composite bottom liner (or equivalent) and

a relatively impervious final cover system.

As described in Subparts C, D, and F

to 40 CFR Part 258, the prescriptive bot-

tom liner and final cover components and

features of a Subtitle D landfill include the

following (from bottom to top):

• Composite bottom liner (dual components

in direct and uniform contact)

• Lower compacted soil layer 24-in.

thickness with a hydraulic conductivity

(K) <1x10

-7

cm/sec, or geosynthetic

clay liner (GCL) alternative

• Upper (primary) Flexible Membrane

Liner (FML), 30-mil thickness, or

60-mil if HDPE

• Leachate collection system (LCS)

• Designed to maintain a maximum

30-cm depth of leachate over the liner

• Waste mass cover material

• Minimum 6 in. of earthen material

(daily cover) or alternative thickness to

control disease vectors, fires, odors,

blowing litter, and scavenging

• No liquid waste, except for leachate and

gas condensate, which are allowed as

exclusions

• Final cover (under Closure and Post-

Closure Care) to minimize infiltration

and erosion

• Minimum 6-in. “erosion” layer for

supporting plant growth

• Minimum 18-in. “infiltration” layer

with hydraulic conductivity less than

or equal to bottom liner system or

natural subsoils, or no greater than

K<1x10-5cm/sec, whichever is less

• Begin closure activities within 30 days of

final receipt of waste; complete within

180 days following beginning of closure

Avoid the “Bathtub Effect”

One of the main reasons EPA included a rela-

tively impervious cover system is described

in the Federal Register dated October 9, 1991.

Basically, comments provided to EPA prior to

finalization of the Subtitle D rules indicated

it was important to avoid the “bathtub effect,”

wherein leachate could infiltrate through

the cover at a higher rate than it could be

removed. This requirement was interpreted

to require a flexible membrane liner (FML)

component in the final cover similar to the

FML component in the bottom liner.

LFG SUPPLEMENT

[

www.mswmanagement.com

]

MSW MANAGEMENT S17

S18 LFG 2016 MSW MANAGEMENT

In addition to the material

and performance requirements,

the composite bottom liner and

final cover were often physically

or mechanically connected at or

near the waste boundary so as to

essentially encapsulate or entomb

the waste. Encapsulation of the

waste mass had the positive effect

of virtually eliminating the poten-

tial for exposure of waste to the

environment, as well as the poten-

tial for leachate to leak through

the bottom liner system. It also

had the negative effect of reduc-

ing the amount of liquid, whether

in the form of precipitation and/

or stormwater runoff, that might

otherwise infiltrate into the waste

mass and either flow through the

waste to be collected as leachate,

or be absorbed by the waste itself.

Encapsulation restricted moisture

content changes in the waste

mass from external influences, creating a

“dry tomb.”

Far from waste being technically dry

(zero moisture content), most sanitary land-

fill waste includes significant organic matter

and other moist materials, and may receive

direct precipitation during active filling

phases. Results of field testing of municipal

solid waste in non-arid regions generally

finds moisture contents in the approximate

range of 10 to 30% (wet weight basis), which

is below field capacity (F’c), and well below

saturation (S), which means that most waste

has the capacity to absorb additional liquid.

Therefore, the term dry tomb is relative and

merely suggests that the moisture content is

lower than it would otherwise be if the waste

were not encapsulated below and above, and

did not include daily soil cover layers that

tend to compartmentalize the waste.

The Present: Current Industry

Practice

Subtitle D allows for disposal of leachate and

gas condensate on the prescriptive bottom

liner (i.e., recirculation), and the RD&D

rule expands upon this by allowing leachate

recirculation on alternative bottom liners.

But, many solid waste facilities have chosen

not to practice recirculation, and some have

terminated recirculation for various practical

and/or economic reasons. Despite numerous

technical articles and papers addressing the

downsides of the dry tomb landfill, little has

changed since 1991; the standard Subtitle

D bottom liner and final cover system as

described above are still widely followed by

the states and the solid waste industry, with

some variations and adaptations.

Complicating the situation, as noted

above, is that conventional practice often

includes welding the final cover to the bot-

tom liner system, or alternatively, the cover

FML is extended laterally to beyond the

lateral limits of the bottom liner (such as in

perimeter anchor trenches). This techni-

cal detail prevents stormwater runoff from

backflowing into the landfill and keeps

landfill gas from escaping at the perimeter

or edges. It also precludes moisture content

changes over time to the following sources:

• direct precipitation or runoff that might

leak through the final cover through

pinholes or small defects,

• water that is consumed and/or produced

as part of methanogenesis/waste

degradation processes,

• moisture removal from landfill gas

collection (gas condensate), and

• leachate and gas condensate that is dis-

posed (recirculated) within the waste.

Under these conditions, the waste mass

will theoretically lose moisture over time,

and the waste will become drier than at

the time of placement unless the moisture

losses are replenished from infiltration, or

from recirculation of liquids back into the

waste mass. Given the importance of liquids

in maintaining conditions necessary for

anaerobic decomposition of organic matter

in the waste, and which directly impacts gas

generation, reducing the moisture content

over time has potential downsides:

• the waste decomposition process slows

down and as such, the time needed to

achieve waste stabilization is lengthened

indefinitely;

• landfill gas production is slower which

may have ill effects on its utilization;

• post-closure care periods may have to be

extended; and

• landfill settlement is slower.

The rate of gas generation from a Subtitle

D covered “dry tomb” landfill would be

expected to slow down over time compared

to generation at landfills not so encapsu-

lated. This would not only have ill effects on

gas utilization; it lengthens the time needed

to achieve biological or chemical waste

stabilization indefinitely, extending the post-

closure period for decades.

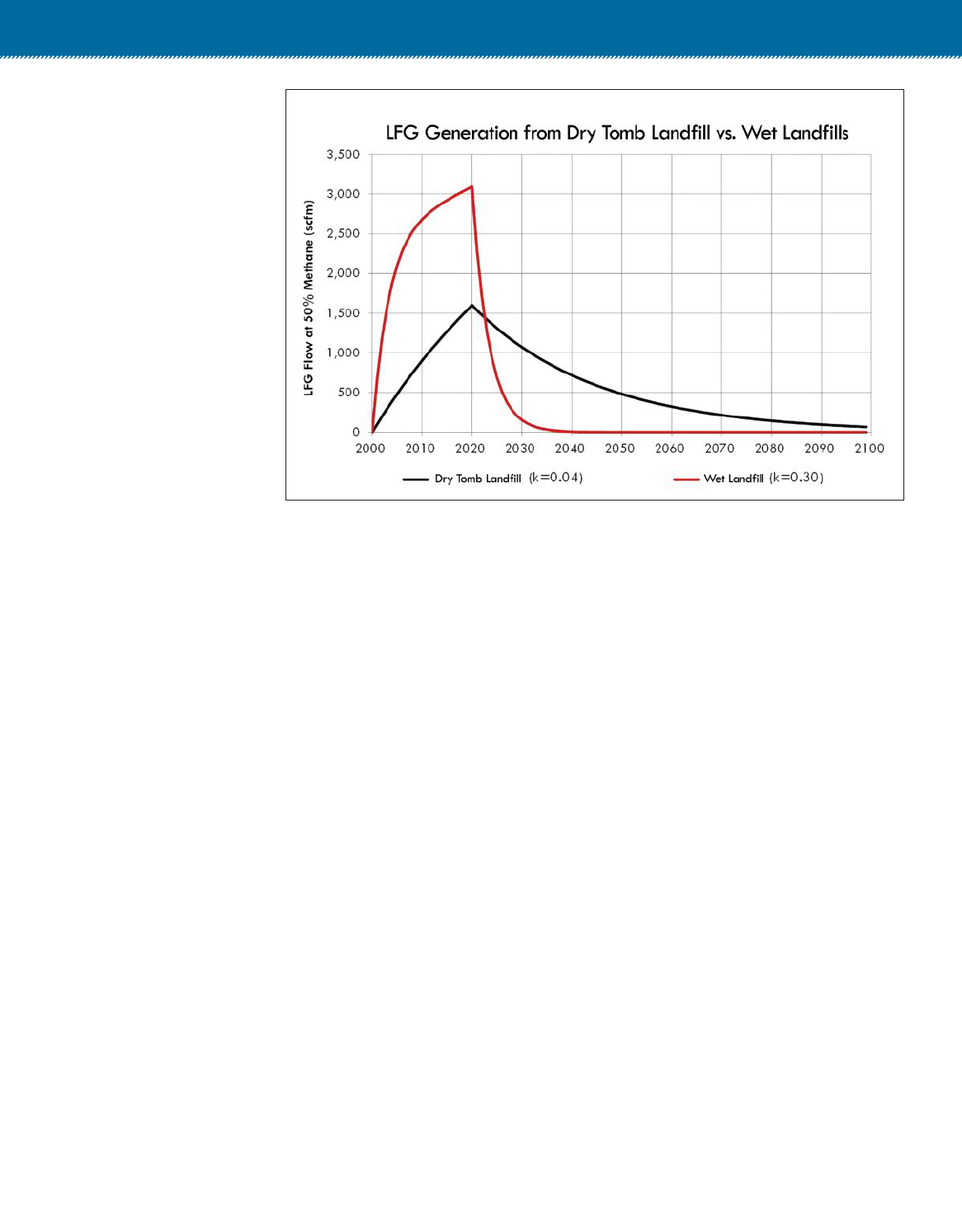

The latter point is suggested by conven-

tional Landfill Gas (LFG) generation mod-

els, including EPA’s Landfill Gas Emissions

Model (LandGEM), which allow a waste

decay rate variable (k value) to be adjusted

to account for the effect of moisture on

LFG generation rates. Gas curves for a mod-

erately sized MSW landfill under standard

(k = 0.04) and RD&D Rule bioreactor

(k = 0.30) conditions are shown in Figure

1 and which clearly show the period of gas

Figure 1

generation for a dry tomb landfill extending

for decades beyond a wet landfill. Unfortu-

nately, LandGEM does not have a mecha-

nism to account for changing moisture

conditions over time using a varying rate

of waste decay (k value), and the effects of

changing waste moisture on LFG generation

at individual sites’ are poorly understood

and difficult to quantify.

The Future: Alternative

Possibilities

With the proposed time extension of the

RD&D rule from 12 to 21 years, and the

clear economic advantages of stabiliz-

ing the waste mass more quickly with the

introduction and management of liquids,

why are we still building so many dry tomb

landfills? Why are we not taking advantage

of the RD&D rule or Subtitle D’s allowance

for recirculation? Is it because we have not

yet reached the 30-year post closure care

endpoint to realize that the waste has not

stabilized, and that post closure care may

be extended?

The answers, in part, are that design-

ing, constructing and operating a dry tomb

landfill is relatively straightforward, widely

accepted as standard practice and carries

limited risk—it is the comfortable approach.

Designing a landfill to promote faster

stabilization of waste by allowing liquids

introduction, or applying alternative design

and operational approaches requires more

thought and effort, more documentation,

technical demonstrations, operational evalu-

ations, and some degree of experimentation.

However, the benefits of accelerated gas

generation/collection, additional recoverable

airspace, and more rapid waste stabilization

leading to a shorter post-closure period are

certainly desirable and achievable.

In the interest of moving landfill technol-

ogy one more step forward to replace the dry

tombs, below are just a few broad concepts

that can be adopted with minimal changes

to currently accepted landfill design and

operations practices.

Apply for RD&D Project

First and foremost, the waste disposal

industry should take advantage of the

existing RD&D Rule as it currently stands,

and consider the alternative design and

operational concepts that will facilitate waste

stabilization. The RD&D Rule is flexible and

already allows for a wide variety of options

including the introduction of leachate and

liquids on alternative bottom liners as well as

the introduction of other materials or special

waste processing, to enhance the degrada-

tion of organic matter contained in the

solid waste. The program requires technical

justification and monitoring and is currently

available for a period of up to 12 years.

It is therefore timely that EPA is propos-

ing to extend the duration of an RD&D

project from 12 to 21 years, which is a

positive step forward and will allow landfills

more time to develop and adopt operational

and design changes that might facilitate waste

stabilization. Whether through recirculation

of leachate, stormwater runoff/run-on man-

agement, or by other means, RD&D is open-

minded and has limited restrictions provided

that the methods are well engineered,

monitored, and the results are measured and

evaluated over time. More facilities should

take advantage of the RD&D rule to not

simply to reduce their post-closure period, or

enhance degradation, but to experiment with

technologies that might add to the body of

knowledge for other facilities to consider and

apply at their sites.

Let Some Leakage In

(Without Taking a Bath)

As noted, Subtitle D rules were written to

address concerns over the bathtub effect,

which led to the requirement for a relatively

impervious final cover. However, since

the leachate collection system (LCS) must

be designed and operated to maintain a

maximum 30-centimeter hydraulic head

over the liner under all conditions—includ-

ing a fully open cell/no waste condition,

through each active filling phase, at the

time of final closure, and through the post-

closure period—the probability of creating

a bathtub seems to be relatively low. If the

amount of leakage allowed to enter the

waste can be reasonably estimated from

available water balance models, and con-

trolled and monitored effectively, allowing

some leakage should pose limited risk, and

positive measurable benefits, even if it is

limited to the capacity to absorb the liquid

before reaching field capacity.

Table 1 provides a theoretical guide to

how much liquid can be added to sanitary

waste (assuming different initial moisture

contents) to achieve final moisture contents

of 30, 40, and 50%. Other factors may also

be considered in arriving at realistic values:

the impact of daily cover soils on infiltra-

tion, type, and characteristics of the waste,

LFG

SUPPLEMENT

Continued on S22

including hydraulic conductiv-

ity, density, and organic content.

There are numerous articles and

case studies that provide such

information.

Under this category, incor-

porating final cover systems that

allow some amount of leak-

age, such as a soil-only cover,

or an evapotranspiration (ET)

cover, or even a hybrid cover that combines

separate areas of FML and soil components

should be considered, rather than the stan-

dard full-coverage geomembrane.

Limited Leachate Recirculation

Even with the flexibilities provided for in

Subtitle D and RD&D to allow recircula-

tion, the number of facilities that practice

recirculation successfully is rather limited;

some facilities have ceased doing so due

to operational challenges including odors,

seeps, stability, and settlement. But that was

then, this is now: with very recent chal-

lenges in managing leachate treatment and

the significant costs associated with leach-

ate disposal, there has been a renewed and

significant interest nationwide in leachate

evaporation and treatment technology to

reduce disposal costs.

While leachate evaporation technology

is still developing, why not reconsider recir-

culation as an option or complimentary

approach, even if on a limited basis? At the

very least, limited recirculation will reduce

the amount of leachate needing treatment,

should enhance gas generation and waste

stabilization, and create airspace. The

practice of spraying leachate directly on the

working face still works, and allowing run-

on to the waste (allowed under RD&D) and

similar simple, straightforward concepts

will not necessarily require significant

design or operational changes.

Delay Final Closure Capping

Even if a landfill is equipped with an FML

composite bottom liner, an FML final cover

does not practice recirculation, and is thus

relegated to the future as a dry tomb, the

simple process of delaying of the final

capping for several years may still pro-

vide significant benefits. Considering that

landfill settlement continues to occur many

years beyond the time filling is completed

(and is a surrogate measure of gas genera-

tion), allowing a more significant period

of time between the end of filling and final

capping than allowed for in Subtitle D, such

as three to five years or more, seems very

reasonable. This assumes that landfill gasses

and odors can be suitably managed, which

allows time for precipitation to enter the

waste and for a landfill to settle, enhancing

degradation and minimizing airspace loss

from early capping.

To this end, the Pennsylvania Depart-

ment of Environmental Protection

(PADEP) had the forethought to adopt a

rule in 2014 that allows facilities to overfill

waste above permitted grades, allowing

waste settlement to occur for up to five

years before final cover placement. Known

as the Settlement Accommodation Plan

(SAP), the state places various restric-

tions on overfilling slope angle, depth of

allowable waste overfill, and requires both a

technical evaluation of settlement coupled

with annual measurements to validate that

the overfill is performing well.

At the end of the five-year period, waste

that is still above permitted final grades

must be removed at the owners cost. The

SAP was born from the concerns of landfill

operators losing valuable airspace from

post-capping settlement, which cannot be

recovered, accommodates the understanding

that landfills settle over time, and also pro-

motes a form of wet landfilling by allowing

time for precipitation and runoff to enter

the waste, thereby accelerating waste decom-

position, gas generation, and settlement.

It seems well worth the cost and effort for

landfills in Pennsylvania to adopt a site-

specific SAP. Why not other states, too?

Closing

The waste industry, in general, knows more

about how waste responds to liquids addi-

tion from a variety of experiences, both

good and bad, over the past two decades;

but challenges and unknowns remain. We

also recognize the difficulties with manag-

ing leachate recirculation/bioreactor land-

fills, understand more fully the rates that

landfill gas is generated, how gas can be

collected most efficiently, and how

landfills settle over time, both with

and without recirculation.

Armed with this knowledge and

the desire to control operational

costs, reduce post-closure monitor-

ing, and still protect the environ-

ment, surely there are ways to

advance landfilling beyond the dry

tomb technology that was born in

the 1980s to a nationwide improvement in

landfill designs and operations for the next

generations. The only real question that

remains is: are we willing to try?

References

Environmental Protection Agency, Federal

Register, 40 CFR Parts 257 and 258,

Solid Waste Disposal Facility Criteria;

Final Rule, published Oct. 9, 1991.

Environmental Protection Agency, Federal

Register, Research, Development and

Demonstration (RD&D), Amendment

to 40 CFR Part 258, published

March 22, 2004.

Environmental Protection Agency, Federal

Register, Revision to Research, Develop-

ment and Demonstration (RD&D)

for Solid Waste Landfills, Amendment

to 40 CFR Part 258, published

November 13, 2015.

Gardner, R. B., “What Ever Happened

to the RD&D Rule? A Look at Where

Landfills Have Come From and Where

They Are Heading,” Pennsylvania

Department of Environmental Protec-

tion (PADEP, Settlement Accommoda-

tion Plan, Standard Operating Proce-

dure, October 2014.

Landfill Bioreactor Design & Operation,

Reinhart and Townsend, 1998.

The Bioreactive Landfill, Pacey, Augenstein,

Morck, Reinhart, and Yazdani, MSW

Management, September/October 1999.

“The Bioreactor Landfill—The Next Gen-

eration Landfill Management,” A White

Paper, Waste Management, Inc.

MSW

Robert H. Isenberg, P.E., CPG, is a Senior Vice

President, and Darrin D. Dillah, Ph.D., P.E.,

BCEE, a Vice President, both of SCS Engineers,

located in Reston, VA.

For related articles:

www.mswmanagement.com

S22

LFG 2016 MSW MANAGEMENT

LFG SUPPLEMENT

Initial Waste Moisture Content

(% wet)*----

15 20 25 30

Moisture Content Goal (% wet)

30

40**

50

Max. Liquids Addition in Gallons/Ton

52 34 17 0

100 80 60 40

167 144 120 96

**Assume wet waste density = 1,200 pcy

**Approximate Field Capacity, F’c

Table 1

Continued from S19