© 2015 Shaw, a Berkshire Hathaway Company

Shaw Corporate Headquarters PO Box 2128 | 616 E Walnut Ave | Dalton GA 30722-2128 | USA

Shaw

5900

Specification

ECOWORX

®

AND

ECOLOGIX

®

MODULAR CARPET

TI

LE

Any

variance

from these procedures will become the

responsibility

of the

installer

and not the

manufacturer.

See

Shaw’s Modular

Installation Guidelines

for

additional information. Installation guidelines

can be obtained by contacting

us at the number below. For

installation assistance please

contact Shaw Technical Support at 1.800.471.7429.

Shaw 5900

offers

a new

formulation

for

even greater performance. Faster

dry times and

enhanced,

more aggressive

tack make Shaw 5900 the perfect

choice

for fast-track carpet tile

installations.

Shaw modular products can be installed

into wet

adhesive

for

permanent

bonding or

allowed

to dry to its tacky phase for

releasable installations.

Shaw 5900

can be applied by

roller

or trowel

depending

on

installation

requirements.

FEATURES

AND BENEFITS

Aggressive

tack to hold carpet tile in place during

installation

and use

Permanent

or

releasable installation

system applications

Acrylic-based

for

superior

performance

Higher

moisture/pH tolerance

Mildew

resistant

and non-staining

CRI Green Label Plus certified

and

SCAQMD

compliant

Weight

Pallet

Qty.

Pallet

Weight

32.8 lbs. (4 gal) 48 1574 lbs

Laboratory Tests Results

Polymer

type

Acrylic

polymer

Percent

solids 58% to 60%

VOCs Rule

#1168 of

California’s

SCAQMD

Compliant

<50

g/L

Trowelability Use

Trowel

or Paint Roller

Density 8.2 lbs/U.S. gal (3.72 kg/3.79

L

)

Consistency Creamy

Color Off White

Tracer

Lime Hexagon

/

Silver

Squares

Shelf

life 2

years

when stored in

original packaging

at 73° F (23°C)

Storage

conditions 65°F to 95°F

(18°C

to

35°C

)

Flash

point

(ASTM

D56) > 212°F

(100°C

)

Protect from traffic 24 hours for light traffic, 72 hours for

heavy

traffic

Although the adhesive is freeze / thaw stable, protect containers from freezing in transit and storage. Provide for heated

storage on site and deliver all materials at least 24 hours before work begins.

© 2015 Shaw, a Berkshire Hathaway Company

Shaw Corporate Headquarters PO Box 2128 | 616 E Walnut Ave | Dalton GA 30722-2128 | USA

MR Credit 5,

Regional

Materials Up to 2 points

IEQ

Credit 4.1,

Low–emitting Materials, Adhesives

& Sealants 1 point

IEQ

Credit 4.3, Low-emitting

Materials, Flooring

Systems 1 point

LEED (VERSION 3.0)

CON

TRIBUTION

1-YEAR WARRANTY

This

product is covered by a

1-year limited warranty.

For

information

on this limited

warranty, please

ask your

authorized

Shaw

retailer

or contact the number below.

INSTALLATON INSTRUCTIONS FOR

ADHESIVE

For more

detailed instructions, refer

to Shaw’s Modular

Installation Guidelines

and the

CRI Installation Standard.

The

substrate

must be

structurally

sound, solid,

stable, level, even,

flat, smooth and dry.

1.

CHECK THE MOISTURE LEVEL

AND pH.

Do not begin the

installation

over concrete

substrates

that do not meet the

following MVER

moisture

vapor

emission

rate requirements.

Moisture: Conduct

Relative Humidity

testing and

results

must be below 95%

(ASTM F-2170).

In addition, concrete

substrate moisture must be tested by the current version of ASTM F1869 anhydrous calcium chloride test. Substrate

moisture vapor emissions cannot exceed 10.0 lbs. per 1000 square feet per 24 hours (4.54 kg/92.9m

2

/24

hours).

Alkalinity:

pH testing should be

performed

with

results ranging

between 8.0 and 10.0

(ASTM F-710).

Take

corrective measures

if the

results exceed

these limits.

This

product is for

interior installation

only.

2.

PREPARE THE FLOOR

The substrate

must be

structurally

sound, dry, solid and stable.

All substrates must be completely free of dust and dirt, paint, oil, curing or release agents, unapproved sealers or

existing adhesives, or anything that would interfere with the adhesive making a good bond directly to the substrate.

Refer to substrate preparation guidelines per current CRI 104.

Use only mechanical means to remove existing adhesives, then finish removal by sanding, grinding, or blasting

until the bare concrete surface is exposed. Do not utilize solvents or chemical cleaners on the substrate.

Suitable substrates

are:

Exterior-grade

plywood, Group 1, CC type

Other approved wood

underlayments (per manufacturer

recommendations)

Concrete

and

properly prepared

cement terrazzo

Cement-based self-leveling underlayments

and patching compounds

Embossing levelers applied

over

existing, properly

prepared and

fully

bonded ceramic tile, and sheet vinyl

A

single layer

of

properly prepared, fully

bonded

vinyl

composition tile (VCT)

Properly prepared

and primed gypsum

underlayments

that meet the

ASTM

F2419

requirements

for compressive

strength

Wood Association

approved wood underlayments

ENVIRONMENTAL

Meets the

requirements

of

California

South Coast Air

Quality Management District Rule

1168

Meets the

requirements

of

California Department

of Public

Health

Section 01350

CRI Green Label Plus Certified

#60125

© 2015 Shaw, a Berkshire Hathaway Company

Shaw Corporate Headquarters PO Box 2128 | 616 E Walnut Ave | Dalton GA 30722-2128 | USA

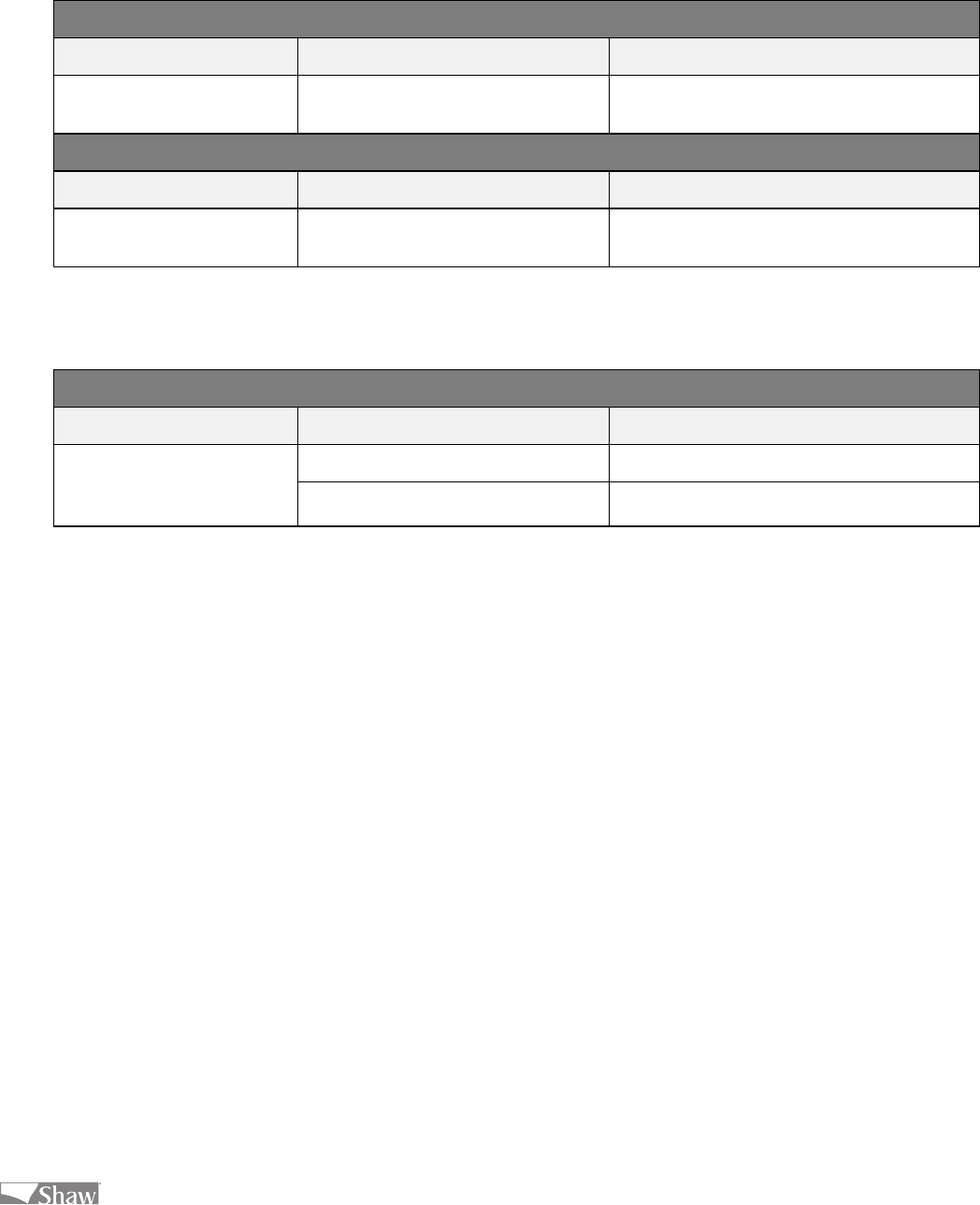

Flash

is the waiting time

required

before

installing flooring. Working

time is the window of time the

adhesive

will accept

the tile.

Flash

times and working times may

vary

based on

temperature, humidity, substrate

porosity, application

method and

jobsite

conditions.

Porous Substrates

Flooring

Type Flash Working Time

EcoWorx/EcoLogix

Tile

0

(permanent

bond); 30 minutes

or until dry (pressure-sensitive)

15

minutes (permanent

bond)

8 hours

(pressure

sensitive)

Non-porous Substrates

Flooring

type Flash Working Time

EcoWorx/EcoLogix

Tile

30

minutes

or until dry (pressure-

sensitive)

8 hours

(pressure sensitive)

Can be left overnight

4.

DETERMINE COVERAGE AND SELECT

APPLICATION METHOD.

Coverages

shown are for

estimating

purposes only. Actual jobsite

coverages

may

vary

according to substrate

conditions, type of trowel used and setting practices.

Trowel dimensions

are depth/width/space.

Application and Coverage

Flooring

Type Application Method Coverage

EcoWorx

Carpet Tile

EcoLogix Carpet Tile

(Attached

Cushion)

1/16" x 1/32" x 5/64" U - Notch 28-33 sy/U.S. gal

(250–300

sf/gal)

3/8’’ foam or medium nap roller 35–40 sy/U.S. gal (300-350

sf/gal

)

5.

APPLY ADHESIVE.

Spread

adhesive evenly

over the subfloor,

keeping

the trowel at a 45

angle

to the subfloor. For

releasable

applications,

wait until the

applied adhesive

has become

clear

and tacky with no

transfer.

Tack time will

vary

due to temperature,

humidity

and floor porosity. For

permanent-set applications, install

the product into semi-wet

adhesive.

Apply pressure

to the

entire surface

of the tile to

ensure

adhesion.

6.

ROLL THE FLOOR.

Roll

the width and length of the floor with a 75- to 100-pound roller.

7.

PROTECT FLOOR.

Protect floor with plywood if

heavy

objects are moved on top of

surface

within 24 hours.

8.

CLEAN UP.

Clean

tools with water while the

adhesive

is still fresh/wet.

Clean

with

mineral

spirits once dried. Use caution with

mineral

spirits, which may be

harmful

to some materials.

LIMITATION

S

Do not

install

over any

substrates containing

asbestos.

Install

in

interior installations

only.

Do not apply over any

active

cutback adhesive.

Do not

install

over concrete

substrates

where the

moisture

vapor

emission

rate

(MVER) exceeds

10 lbs/1,000

sf (4.54 kg/92.9 m

2

)

per 24 hours, when using the

anhydrous

calcium

chloride

test

(ASTM

F1869).

Do not

install

when

relative humidity

of concrete

slabs exceeds

95%

(ASTM

F2170) or pH readings exceeds 10.

Use only when the

substrate temperature

is between 50°F and 90°F

(10°C

and 32°C).

092015

3.

DETERMINE DRY

TIME.