SawStop

®

OWNER’S MANUAL

T-Glide

TM

Fence System-

Professional Series II

Model TGP2-FA

1. 1. You MUST install a rip fence before using your saw. Using the saw without a rip fence could result in

serious personal injury.

2. 2. Never perform a ripping operation freehand or a serious injury may result.

3. 3. Always use a push stick or push block when your hand comes within 6 inches of the blade. Attempting to use

the rip fence for narrow cuts without a push stick or push block could result in a serious injury.

4. 4. Do not use the miter gauge when making rip cuts.

5. 5. While making bevel cuts, use the fence only on the right side of the saw blade to prevent the blade from

possibly contacting the fence. The brake will activate if the spinning saw blade contacts the metal in the fence.

Safety

Warranty

SawStop warrants to the original retail purchaser of a new T-Glide Fence System - Professional Series II from

an authorized SawStop distributor that the fence system will be free from defects in material and workmanship

for ONE YEAR from the date of purchase. SawStop warrants to the original retail purchaser of a refurbished,

demonstration or oor model T-Glide Fence System - Professional Series II from an authorized SawStop distributor

that the fence system will be free from defects in material and workmanship for SIX MONTHS from the date of

purchase.

This warranty does not apply to defects arising from misuse, abuse, negligence, accidents, normal wear-

and-tear, unauthorized repair or alteration, or lack of maintenance. This warranty is void if the fence system or any

portion of the fence system is modied without the prior written permission of SawStop, LLC, or if the fence system

is located or has been used outside of the country where the authorized SawStop distributor from whom the fence

system was purchased resides.

Please contact SawStop to take advantage of this warranty. If SawStop determines the fence system is

defective in material or workmanship, and not due to misuse, abuse, negligence, accidents, normal wear-and-

tear, unauthorized repair or alteration, or lack of maintenance, then SawStop will, at its expense and upon proof

of purchase, send replacement parts to the original retail purchaser necessary to cure the defect. Alternatively,

SawStop will repair the fence system provided it is returned to SawStop, shipping prepaid, with proof of purchase

and within the warranty period.

SawStop disclaims any and all other express or implied warranties, including merchantability and tness for a

particular purpose. SawStop shall not be liable for death, injuries to persons or property, or incidental, consequential,

contingent or special damages arising from the use of the fence system.

This warranty gives you specic legal rights. You may have other rights which, in the United States, vary from

state to state.

Page 2

| SawStop T-Glide Fence System - Professional Series II

SawStop

SawStop

®

OWNER’S MANUAL

T-Glide

TM

Fence System-

Professional Series II

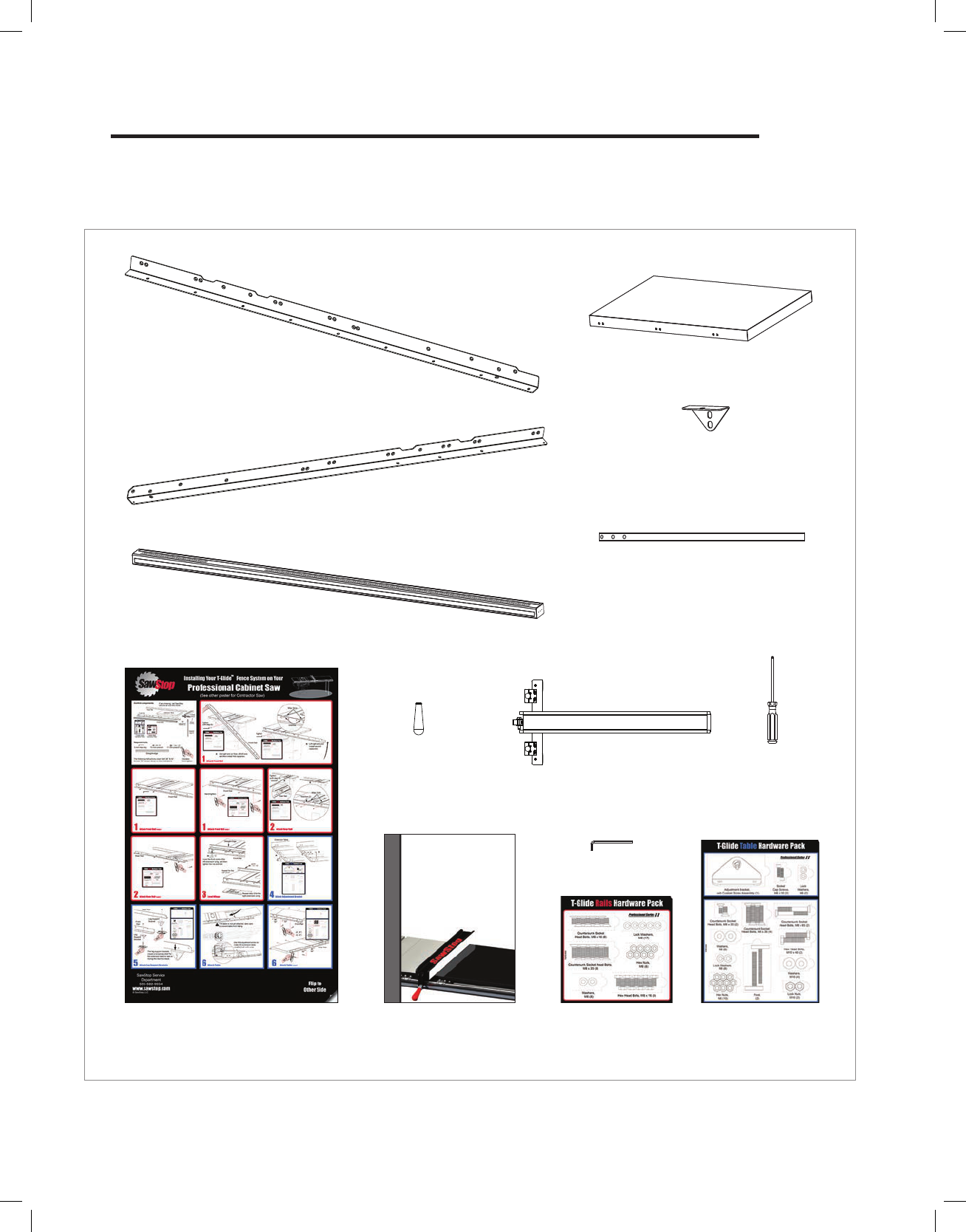

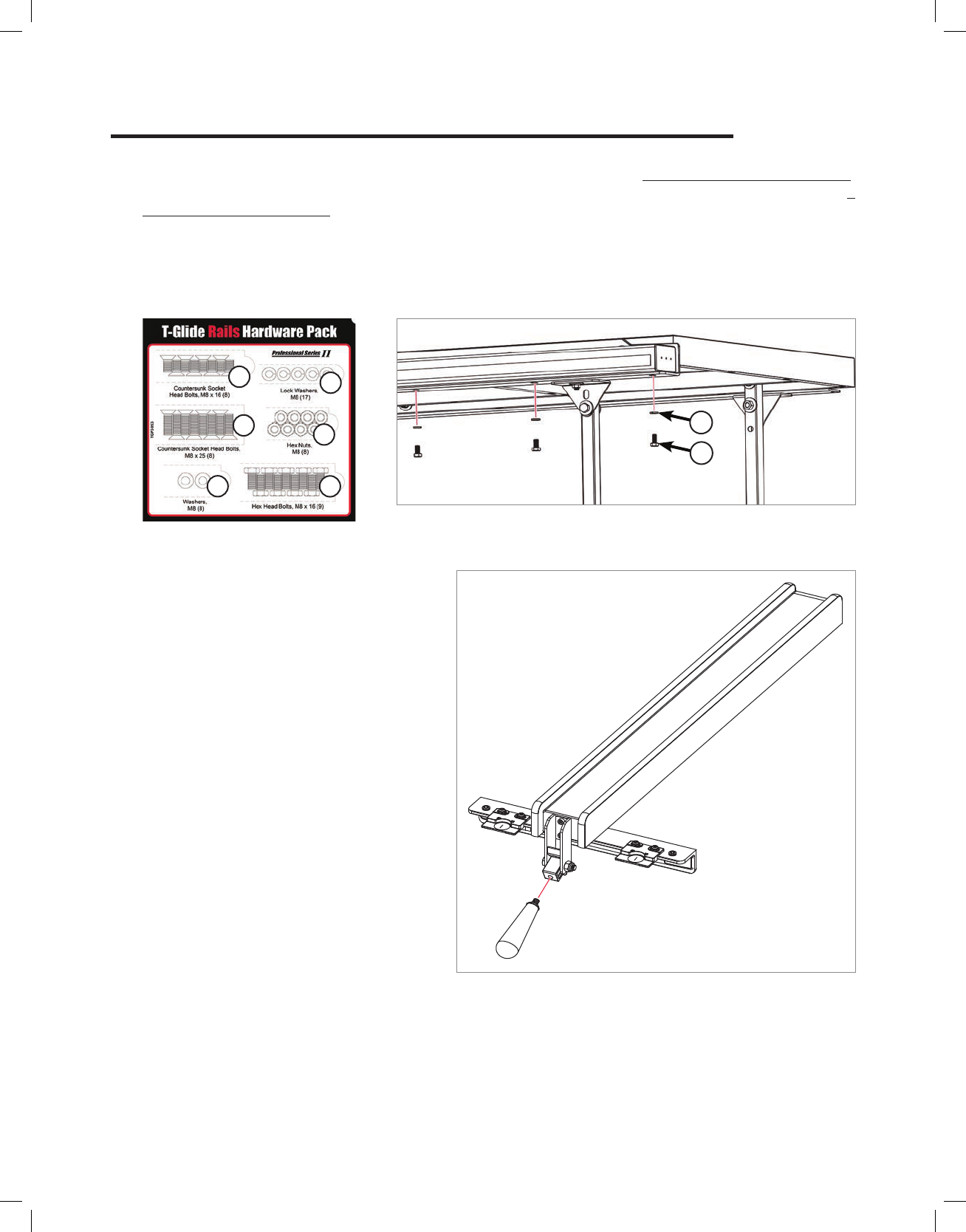

Unpacking Your T-Glide Fence System

While unpacking your saw, verify that you have all the components shown below for your specic fence system.

The T-Glide Fence System – Professional Series II is available in either a 52” system or a 36” system. Although the

components pictured below are from the 52” system, the components from the 36” system are similar.

Front Rail

Extension Table

Rear Rail

Support Leg (2)

Main Tube

Fence Handle

Owner’s Manual

T-Glide Fence

5 mm Hex Key

Leg Support

Bracket (2)

5 mm Ball-End

Hex Driver

T-Glide Rails

Hardware Pack

T-Glide Table

Hardware Pack

Installation Poster

(One for a Professional Cabinet Saw

and another for a Contractor Saw)

Fig. 1

Page 3

| SawStop T-Glide Fence System - Professional Series II

Note: Your saw must be fully assembled before installing the fence system.

Note: The drawings below show how to assemble both the 52” and 36” fence systems. Although the

components shown are from the 52” fence system, the components from the 36” system are similar.

Before you begin installing the fence system, locate the front rail, the rear

rail, and the T-Glide Rails Hardware Pack (). All of the hardware needed

to install the rails is located on the T-Glide Rails Hardware Pack and is

shipped in the T-Glide fence box. In order to easily identify the hardware

used in each of the following steps, the dierent pieces of hardware are

numbered on the hardware pack and in the gures. If you are missing the

T-Glide Rails Hardware Pack, the T-Glide Table Hardware Pack, or any

of the other fence system components shown in Fig. 1, call the SawStop

Service Department at 503-582-9934.

You will also need the following tools to complete the fence assembly:

• 13 mm wrench

• 17 mm wrenches (2) (or adjustable wrenches)

• 5 mm hex key

• Level or straight-edge

The instructions for installing rails on a SawStop Professional Cabinet Saw are dierent from the instructions for

a SawStop Contractor Saw. The instructions for installing the extension table are the same for the Professional

Cabinet Saw and the Contractor Saw.

If you have a SawStop Professional Cabinet Saw

- Begin on page 3.

If you have a SawStop Contractor Saw

- Begin on page 8.

Fig. 2

1

2

3

4

5

6

Page 4

| SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Installing Your T-Glide Fence System

Miter slots

Front rail

Use M8 x 16 bolts

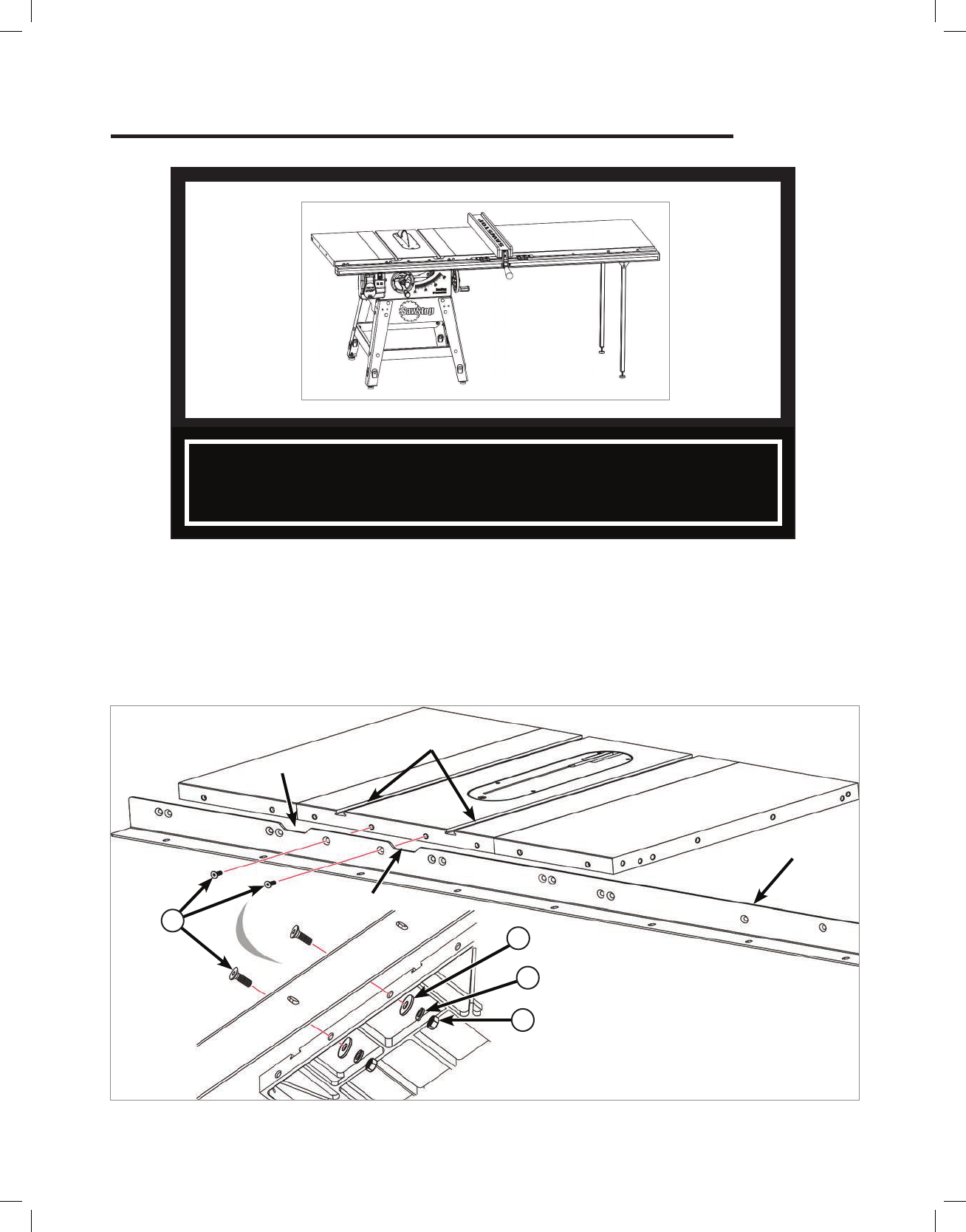

1. Begin mounting the front rail (the longer of the two rails) to the front edge of your saw by centering the notches

in the rail with the two miter slots in the table, aligning the two holes in the rail between the notches with the

two corresponding holes in the front edge of the table, and threading an M8 x 16 countersunk socket head bolt

(1) into each hole (See Fig. 3). Aligning the two holes between the notches aligns all the other holes used in

mounting the rail to your saw. Not all the holes are used to mount the rail to your saw; dierent holes are used

for dierent saws. Thread the bolts into the corresponding holes, and tighten them using a 5 mm hex key.

Notch

Notch

Fig. 3

Installing your T-Glide

TM

Fence System on your

SawStop

®

Professional Cabinet Saw

1

Page 5 | SawStop T-Glide Fence System - Professional Series II

2. Take two more M8 x 16 countersunk socket head bolts (1) and thread one into the hole to the right of the

notches and the other into the hole to the left of the notches (See Fig. 4). Tighten the bolts with a 5 mm hex

key.

Installing Your T-Glide Fence System

Professional Cabinet Saw

1

Fig. 4

Page 6

| SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Professional Cabinet Saw

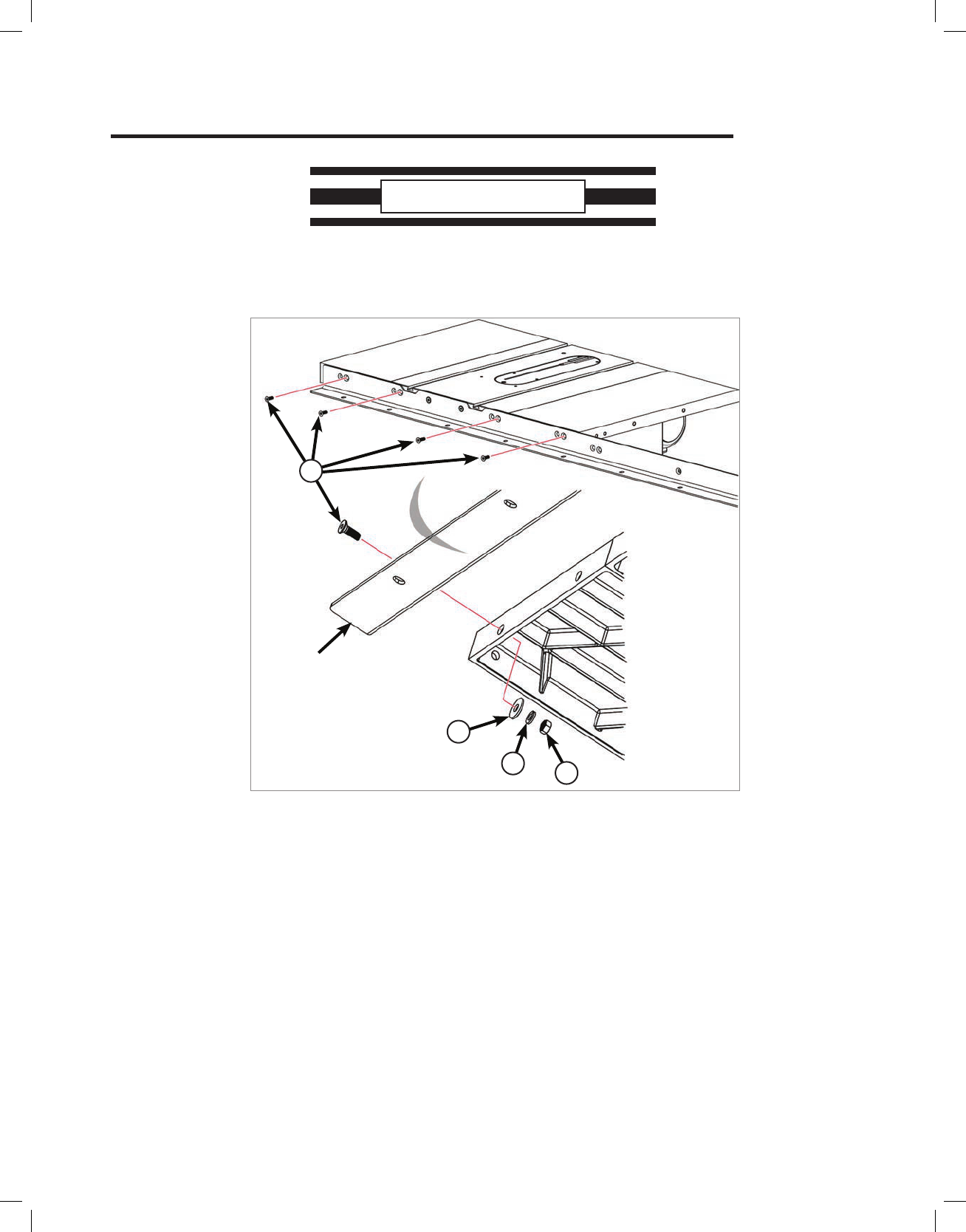

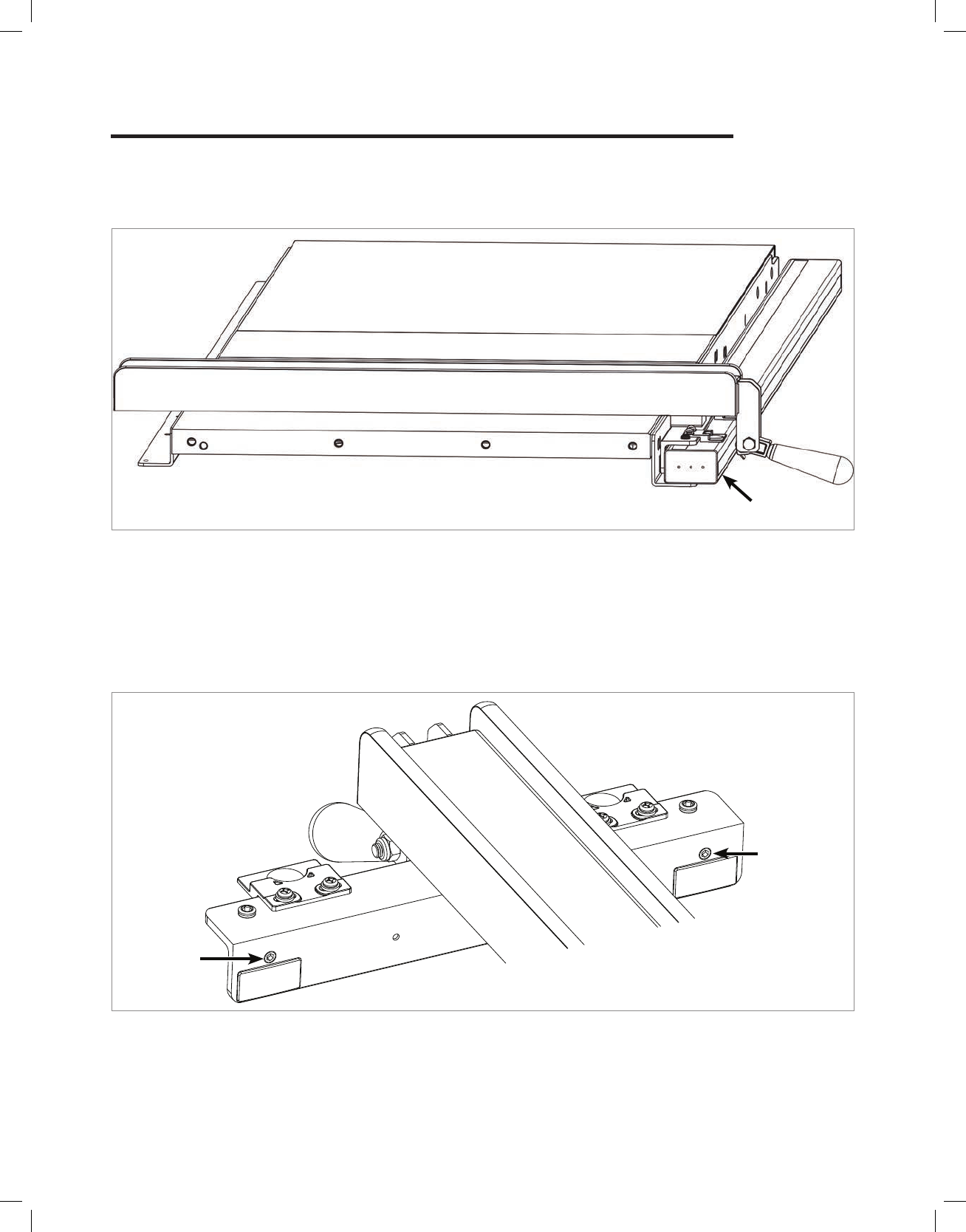

3. Take two M8 x 25 countersunk socket head bolts (2) and insert one bolt through the corresponding hole in the

end of each extension wing. Place an M8 washer (3), an M8 lock washer (4), and an M8 hex nut (5) on the

threaded end of each of the bolts (See Fig. 5). Hand tighten the nuts; do not fully tighten them.

2

Fig. 5

Front rail

2

5

3

4

Page 7

| SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Professional Cabinet Saw

Fig. 7

5. Finish mounting the rear rail to your saw by inserting an M8 x 25 countersunk socket head bolt (2) through the

open hole at the end of each extension wing, and placing an M8 washer (3), an M8 lock washer (4), and

an M8 hex nut (5) on the threaded end of each bolt (See Fig. 7). Hand tighten the nuts; do not fully tighten

them.

Rear rail

4. Begin mounting the rear rail (the shorter of the two rails) to the rear edge of your saw by centering the notches

in the rail with the two miter slots in the table and aligning the left-most hole between the notches with the

corresponding hole in the rear edge of the table (See Fig. 6). There are three holes in the rail between the

notches, one solitary hole and two holes paired together, and the left-most hole is the solitary hole. Not all the

holes are used to mount the rail to your saw; dierent holes are used for dierent saws. Aligning the left-most

hole aligns all the other holes used in mounting the rail to your saw. When the holes are aligned, mount the rail

to the saw by threading an M8 x 16 countersunk socket head bolt (1) into each of the four open holes in the

rear edge of the table and tighten the bolts using a 5 mm hex key.

Fig. 6

Rear rail

1

2

3

4

5

Page 8

| SawStop T-Glide Fence System - Professional Series II

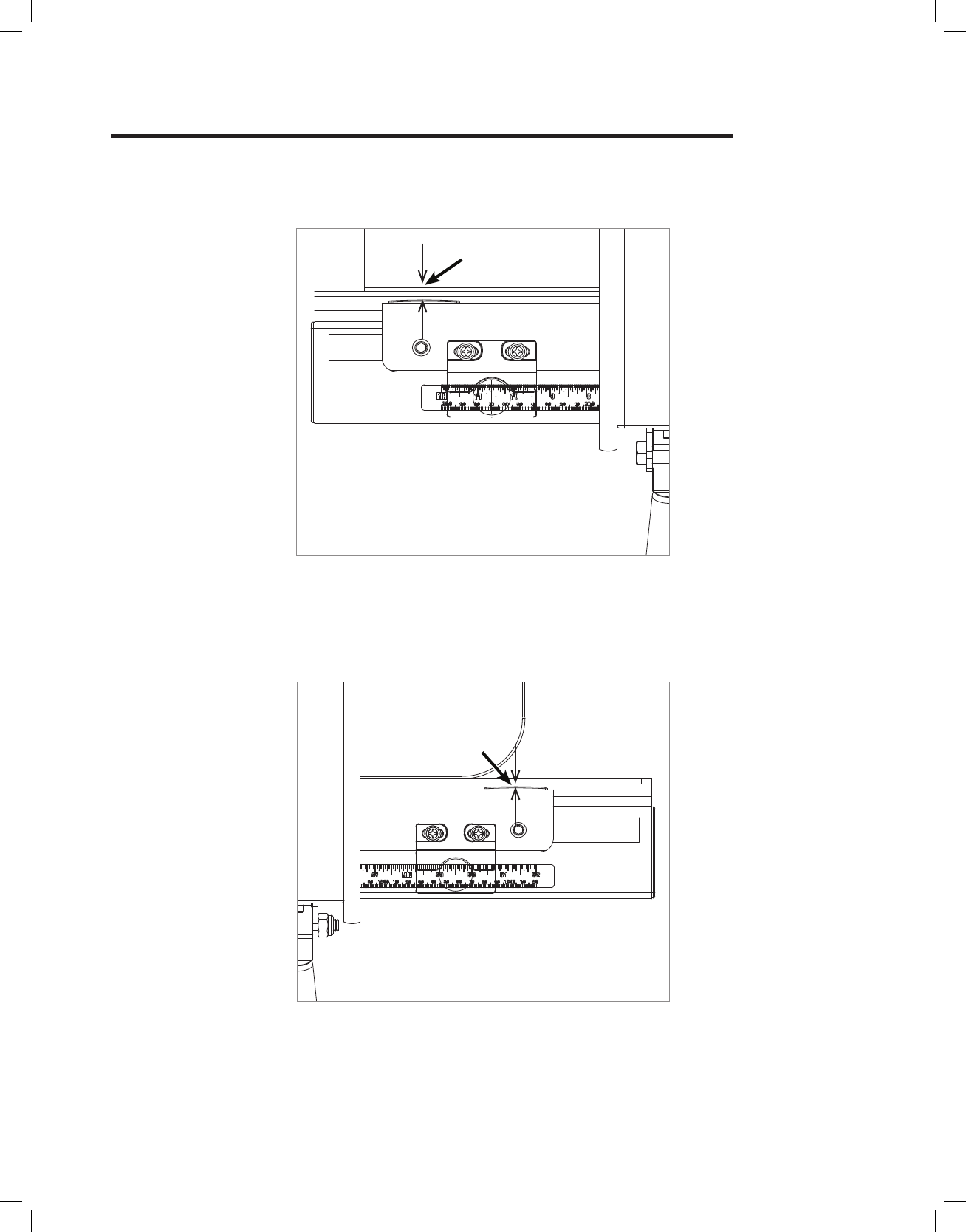

6. Use a straight-edge to level the front edge of the left extension wing to the cast iron table top (See Fig. 8). You

may have to pull up or push down on the outer edge of the extension wing to level it. Once the front edge of

the left extension wing is level, use a 5 mm hex key and a 13 mm wrench to fully tighten the nut on the bolt that

mounts the left extension wing to the front rail. Repeat this process to level the front edge of the right extension

wing and the rear edges of the left and right extension wings.

Level the extension wing

and tighten the nut on the

bolt that goes through the

extension wing

Fig. 8

Straight-edge

Installing Your T-Glide Fence System

Professional Cabinet Saw

Page 9 | SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Miter slots

1. Begin mounting the front rail (the longer of the two rails) to the front edge of your saw by centering the notches

in the rail with the two miter slots in the table, aligning the two holes in the rail between the notches with the two

corresponding holes in the front edge of the table, and inserting an M8 x 25 countersunk socket head bolt (2)

into each hole. Aligning the two holes between the notches aligns all the other holes used in mounting the rail

to your saw. Not all the holes are used to mount the rail to your saw; dierent holes are used for dierent saws.

Insert the bolts one at a time, placing an M8 washer and an M8 lock washer on the threaded end of each bolt

and then threading on an M8 hex nut (See Fig. 9). Hand tighten the nuts; do not fully tighten them.

Fig. 9

Front rail

Notch

Notch

Use M8 x 25 bolts

Installing your T-Glide

TM

Fence System on your

SawStop

®

Contractor Saw

5

4

3

2

Page 10

| SawStop T-Glide Fence System - Professional Series II

2. Take four more M8 x 25 countersunk socket head bolts and insert them through the four open holes in the front

rail and table. Place an M8 washer and an M8 lock washer on the threaded end of each of the bolts and then

thread an M8 hex nut on each bolt (See Fig. 10). Hand tighten the nuts; do not fully tighten them.

Contractor Saw

Fig. 10

Front rail

5

3

4

2

Page 11

| SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Rear rail

4. Begin mounting the rear rail (the shorter of the two rails) to the rear edge of your saw by centering the notches

in the rail with the two miter slots in the table and aligning the left-most hole between the notches with the

corresponding hole in the rear edge of the table. There are three holes in the rail between the notches, one

solitary hole and two holes paired together, and the left-most hole is the solitary hole. Not all the holes are used

to mount the rail to your saw; dierent holes are used for dierent saws. Aligning the left-most hole aligns all

the other holes used in mounting the rail to your saw. When the holes are aligned, mount the rail to the saw

by threading an M8 x 16 countersunk socket head bolt into each of the four open holes in the rear edge of the

table and tighten the bolts using a 5 mm hex key (See Fig. 12).

Fig. 12

Contractor Saw

1

Page 12 | SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Level the top of

the front rail with

the lower edge

of the bevel

Bevel

Tighten

Fig. 11

3. The holes in the front edge of the table and extension wings are slightly larger than the bolts they receive to

allow you to level the front rail and extension wings to the table top. Align the top of the front rail with the lower

edge of the bevel on the front edge of the table top (See Fig. 11). Use a 5 mm hex key and a 13 mm wrench

to fully tighten the nuts on the back of the four bolts that extend through the table top. Do not tighten the nuts

on the bolts that extend through the extension wings.

Installing Your T-Glide Fence System

Contractor Saw

5. Finish mounting the rear rail to your saw by inserting an M8 x 25 (2) countersunk socket head bolt through the

open hole at the end of each extension wing, and placing an M8 washer, an M8 lock washer, and an M8

hex nut on the threaded end of each bolt (See Fig. 13). Hand tighten the nuts; do not fully tighten them.

Level the extension

wing and tighten the

nut on the bolt that

goes through the

extension wing

Fig. 14

6. Use a straight-edge to level the front edge of the left extension wing to the cast iron table top (See Fig. 14). You

may have to pull up or push down on the outer edge of the extension wing to level it. Once the front edge of

the left extension wing is level, use a 5 mm hex key and a 13 mm wrench to fully tighten the nut on the bolt that

mounts the left extension wing to the front rail. Repeat this process to level the front edge of the right extension

wing and the rear edges of the left and right extension wings.

Straight-edge

Fig. 13

Rear rail

2

3

4

5

Page 13

| SawStop T-Glide Fence System - Professional Series II

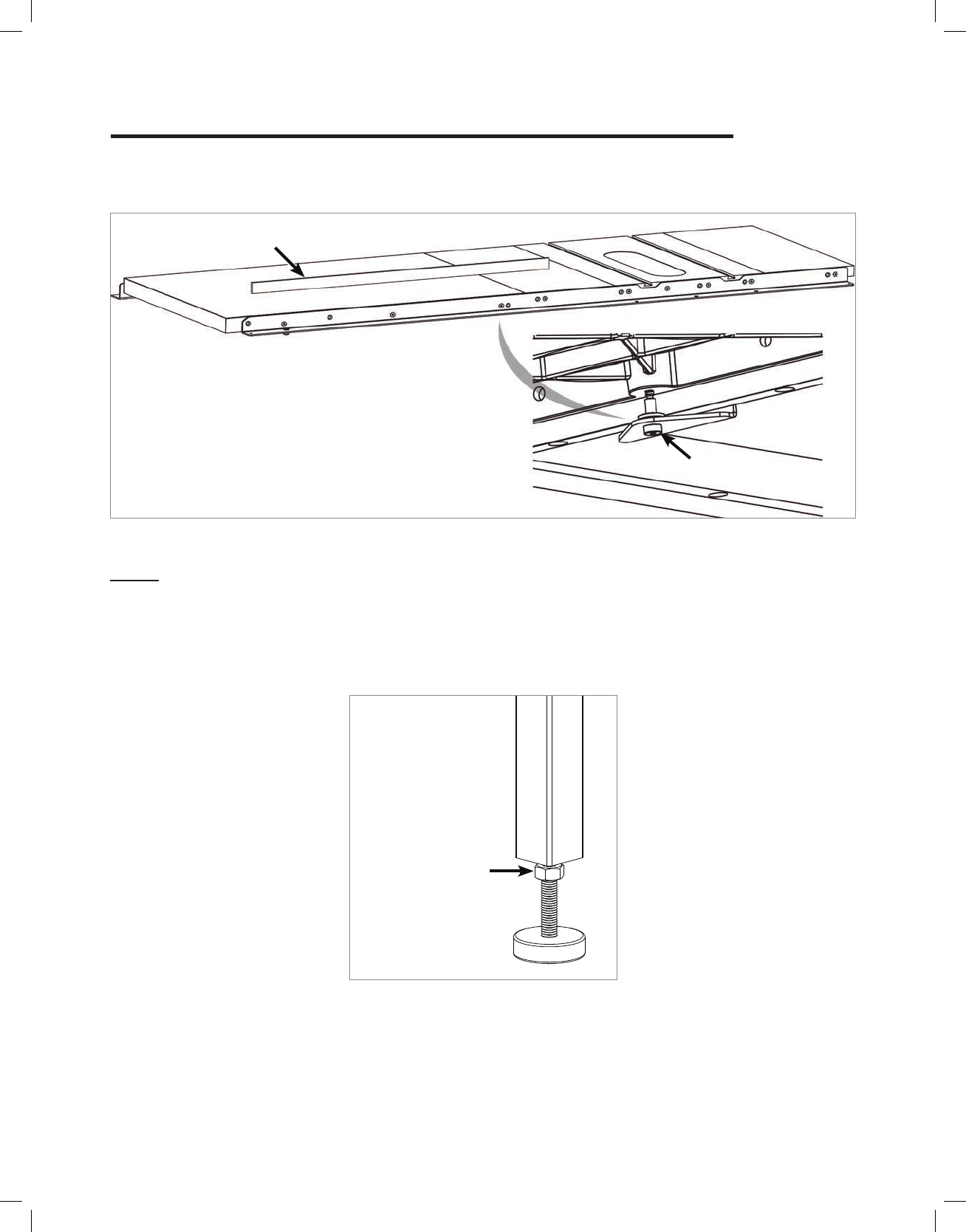

7. Once the rails are in place you can mount the extension table to the

rails. The hardware needed to mount the extension table to the rails is

in the T-Glide Table Hardware Pack (See Fig. 15).

The rst step in mounting the extension table is to install the adjustment

bracket (13) included in the T-Glide Table Hardware Pack. Remove

the adjustment bracket, two M6 x 18 socket cap screws (14), and two

M6 lock washers (15) from the T-Glide Table Hardware Pack, and

place a lock washer on each screw. One end of the extension table

includes two holes and the adjustment bracket has two corresponding

holes. Position the adjustment bracket against the inside edge of the

extension table, align the holes, and thread the screws into the holes

(See Fig. 16). Tighten the screws with a 5 mm hex key.

The instructions for installing the extension

table and the fence (steps 7-22) are the same

for both the Professional Cabinet Saw and the

Contractor Saw.

Fig. 16

Fig. 15

Fig. 17

13

NOTE: The adjustment

bracket is designed for

cast iron wings only.

If you have a Contractor

Saw with stamped wings,

you may skip this step

and go on to step 8.

Stamped

Wing

25

24

23

22

20

16

13

14 15

17

18

19

21

14

15

Page 14

| SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Installing Your T-Glide Fence System

8. Locate the two leg support brackets. Remove the two M8 x 20 countersunk socket head bolts (16) from the

T-Glide Table Hardware Pack along with two M8 washers (17), two M8 lock washers (18) and two M8 hex nuts

(19). Mount one leg support bracket to the underside of each of the rails (See Fig. 18). Hand tighten the nuts;

do not fully tighten them.

Once mounted, the brackets should create a shelf as shown in the detail view of Fig. 18.

9. Place the extension table between the rails and slide it towards the extension wing (See Fig. 19). Be careful

when positioning the extension table because it is not yet secured to the rails and could fall. You will need to tilt

the extension table slightly for the adjustment bracket to t under the extension wing. The adjustment bracket

includes a screw that extends upward and the underside of the extension wing includes a hole to receive the

screw. Fit the screw into the hole, and then turn the screw until the extension table is roughly ush with the

extension wing. The opposite end of the extension table will rest upon the leg support brackets but will not be

level because the leg support brackets are at dierent elevations and are not intended to support the extension

table once it is fully installed.

Fig. 19

Leg Support

Bracket

Fig. 18

16

19

18

17

Page 15

| SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

10. The extension table mounts to the rails with bolts that pass through holes in the rails and extension table (See

Fig. 20). If you have an extension table for a 36” fence system, take two M8 x 35 countersunk socket head bolts

and insert one through the hole in the front rail closest to the saw and the other through the hole in the rear

rail closest to the saw. If you have an extension table for a 52” fence system, take four M8 x 35 countersunk

socket head bolts and insert one bolt into each of the two holes in the front rail closest to the saw, and one

bolt into each of the two holes in the rear rail closest to the saw.

11. Locate the two support legs and remove the two feet from the T-Glide Table Hardware

Pack along with two M8 hex nuts. Thread an M8 hex nut onto the threaded shaft of

each foot so that the nut is close to the rubber base, and then thread the foot into the

bottom of the support leg as far as possible (See Fig. 21).

Fig. 21

12. The support legs attach to the outer ends of the rails and extension table with M8 x 65 countersunk socket

head bolts. Align the top hole in one support leg with the outermost hole in the front rail, and the top hole in

the second support leg with the outermost hole in the back rail. Make sure the legs are positioned against the

inside of the extension table. Insert an M8 x 65 bolt through the holes in the rails, extension table and legs.

Place an M8 washer and an M8 lock washer on the threaded end of each bolt and then thread an M8 hex nut

onto each bolt (See Fig. 22). Hand tighten the nuts; do not fully tighten them.

Support leg

Fig. 20

20

21

19

17

18

22

19

Fig. 22

Place an M8 washer,

an M8 lock washer, and

an M8 hex nut on the

threaded end of each

bolt and hand tighten the

nuts. Do not insert bolts

through the outermost

holes in the front and

rear rails at this time.

17

18

19

Page 16

| SawStop T-Glide Fence System - Professional Series II

13. Attach each support leg to the corresponding leg support bracket with an M10 x 40 hex head bolt, two M10

washers, and an M10 lock nut, as shown in Fig. 23, and fully tighten the bolts using two 17 mm wrenches. Note

that the leg support brackets align with dierent holes in the front and rear legs because the brackets are at

dierent elevations.

Installing Your T-Glide Fence System

Straight-edge

Fig. 24

Fig. 23

14. Use a straight-edge to level the front edge of the extension table to the saw table (See Fig. 24). You may have

to pull up or push down on the extension table to level it. Once the front edge of the extension table is level,

use a 5 mm hex key and a 13 mm wrench to fully tighten the nuts on the bolts along the front rail. Repeat the

process to level the rear edge of the extension table. Also fully tighten the bolts that attach the leg support

brackets to the front and rear rails (bolts in step 8).

16

Front

Rail

Make sure to tighten the bolts that

attach the leg support brackets to

the front and rear rails

16

23

24

24

25

23

24

24

25

Rear

Rail

Page 17 | SawStop T-Glide Fence System - Professional Series II

15. Place the straight-edge lengthwise across the middle of the table and level the middle of the extension table

by turning the screw in the adjustment bracket with a 5 mm hex key (See Fig. 25).

Installing Your T-Glide Fence System

16. Turn the foot on the bottom of each support leg to adjust its position until it is in solid contact with the ground.

Once the foot is in contact with the ground, fully tighten the hex nut against the bottom of the leg using a

13 mm wrench (See Fig. 26).

Fig. 25

Fig. 26

Straight-edge

Adjust the position of

the foot and tighten

the hex nut

Adjustment screw

NOTE: The adjustment bracket is designed for cast iron wings only. If you have a Con-

tractor Saw with stamped wings, you may skip this step and go on to step 16.

Page 18 | SawStop T-Glide Fence System - Professional Series II

SawStop

Installing Your T-Glide Fence System

18. Locate the fence and the red fence handle.

Thread the handle into the cam lock on the

front of the fence (See Fig. 29).

17. Locate the main tube and the T-Glide Rails Hardware Pack (See Fig. 27). If you have a 36” fence system,

remove seven M8 x 16 hex head bolts and seven M8 lock washers from the T-Glide Rails Hardware Pack. If

you have a 52” fence system, remove nine M8 x 16 hex head bolts and nine M8 lock washers from the T-Glide

Rails Hardware Pack. Position the tube on the front rail with the rulers facing up and the 12-inch ruler on the

left. The powder coated surfaces of the tube and rail can be slick, so be careful that the tube does not fall o

the rail. Align the holes in the rail with the holes in the bottom of the tube. Place an M8 lock washer on each

M8 x 16 hex head bolt and insert the bolts through the rail and into the threaded holes in the bottom of the tube

(See Fig. 28). Hand tighten the bolts; do not fully tighten them.

Fig. 28

Fig. 27

Fig. 29

4

6

Thread the handle into

the cam lock

1

2

3

4

5

6

Page 19

| SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Parallelism

adjustment

screw

Front tube

20. Press down on the fence handle to clamp the fence to the front tube. If the fence does not clamp tightly enough

to hold its position against a moderate amount of force, you can increase the clamping pressure by turning

both parallelism adjustment screws clockwise using a 5 mm hex key. Those screws are located in the vertical

portion of the fence cross-bracket (See Fig. 31). Alternatively, if too much force is required to push the fence

handle down to clamp the fence to the front tube, you can reduce the clamping pressure by turning both

parallelism adjustment screws counter-clockwise.

19. The holes in the bottom of the front rail are oversized to allow you to adjust the position of the tube on the rail.

To set the tube in the correct position, rst pull the front tube away from the table as far as possible. Next, place

your fence down on the tube near the left end (See Fig. 30).

Fig. 30

Parallelism

adjustment

screw

Fig. 31

Page 20 | SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

Gap

22. Next, move the fence to the right end of the tube, repeat the above process to position the tube, and tighten

the right-most screw (See Fig. 33). Once both ends of the tube are adjusted correctly, tighten the remaining

M8 x 16 hex head bolts to mount the front tube to the front rail. The fence should now slide smoothly along the

front tube without binding and without excessive play.

21. Once the fence is tightly clamped to the front tube, move the left end of the tube back toward the saw until

there is only a small gap (approximately 1/32 inch) between the front rail and the rear of the fence (See Fig.

32). Tighten the left-most M8 x 16 hex head bolt that holds the tube to the front rail using a 13 mm wrench.

Fig. 33

Fig. 32

Gap

Page 21 | SawStop T-Glide Fence System - Professional Series II

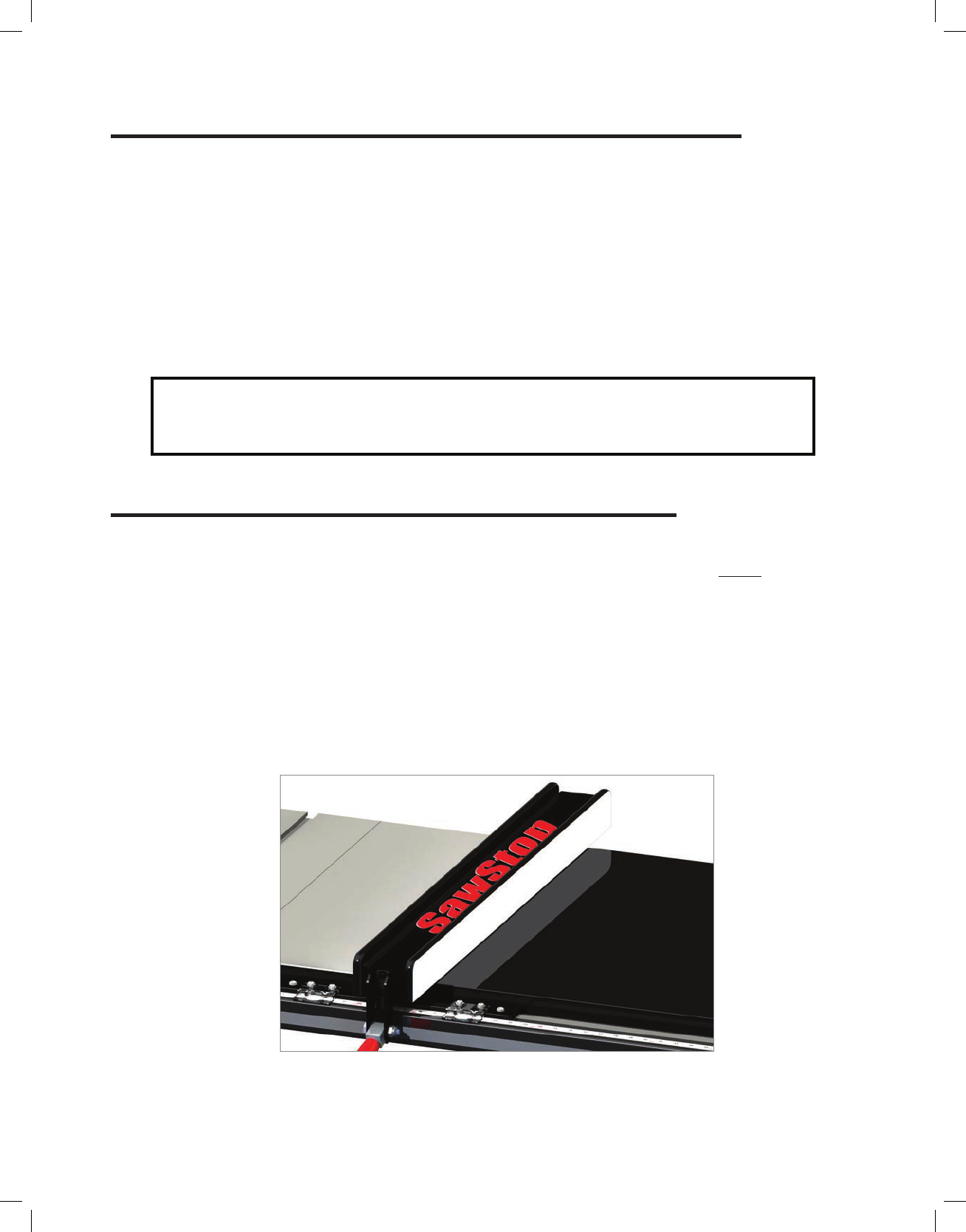

Adjusting Your T-Glide Fence System

Fig. 34

Right indicatorLeft indicator

i. The fence allows you to precisely set the width of your rip cuts (cuts that are length-wise along the grain of the

wood).The precise width of cut is shown by the indicator lenses on the front of the fence (

See Fig. 34). The

lens on the left indicates the width of cut when the fence is on the left side of the blade. The lens on the right

indicates the width of cut when the fence is on the right side of the blade. Each indicator lens is positioned

above a ruler on the front tube. Each lens has a red cursor line that indicates the precise width of cut. To read

the width of cut, look down at the cursor line. The mark on the ruler that is directly below the cursor line is the

width of cut.

i. Although the fence is factory-adjusted to nominal settings, it is usually necessary to make nal adjustments

once your rails and extension table have been installed on the saw.

Page 22 | SawStop T-Glide Fence System - Professional Series II

i. If necessary, you can adjust the position of the indicator lenses on the front of the fence. To verify the position

of each indicator lens, clamp the fence to the front tube and use a ruler to measure the distance from the blade

to the fence plate and compare it to the measurement shown on the proper indicator lens. If adjustment is

necessary, loosen the two Phillips screws shown in

Fig. 35 and slide the indicator lens to the right or left until

the cursor is directly over the correct measurement. Tighten the screws to lock the position of the indicator

lens.

Adjust the indicator

lens by loosening the

two Phillips screws

Fig. 35

Adjusting Your T-Glide Fence System

i. The next step is to align the face plates to be

parallel to the miter slots. Begin by sliding the

fence along the front tube until the left face

plate is ush with the right edge of the right

miter slot. Lock the fence handle and check

that the face plate is ush with the miter

slot edge along its whole length (

See Fig.

36). You can check this either visually or by

running your nger along the face plate and

miter slot edge. If there is any misalignment,

you can correct it by turning one of the two

parallelism adjustment screws in the vertical

edge of the fence cross-bracket (

See Fig.

31).

Fig. 36

Fig. 37

Leveling

screw

i. To adjust the angle of the face plates, place

a combination square on the table top and

against the left face plate (

See Fig. 38). Use

a 6 mm hex key to adjust the leveling screws

as necessary until the face plate is parallel to

the vertical edge of the combination square.

i. The next step is to adjust the face plates to

be perpendicular to the table top. The angle

between the face plates and the table is

set by the two plastic leveling screws in the

horizontal portion of the cross-bracket (

See

Fig. 37). The leveling screws raise and lower

each end of the horizontal portion of the fence

cross-bracket with respect to the main tube

while the two face plates remain parallel with

each other. Adjusting the leveling screws tilts

the fence cross-bracket as needed to make

the face plates perpendicular to the table.

Fig. 38

Page 23 | SawStop T-Glide Fence System - Professional Series II

Adjusting Your T-Glide Fence System

i. It is usually possible to adjust the position

of the face plates by placing a small block

of wood against the top or bottom edge of

the face plates, and then tapping the block

of wood with a plastic or wooden mallet.

However, if the face plates do not move when

tapped, you can loosen the mounting screws

as described below to adjust the face plates.

ii. You can access the screws that attach the

face plates to the fence through the slots on

the bottom of the fence. Insert a 5 mm ball-

end hex driver through the slot at the end

of the fence and into the screw head (

See

Fig. 41) with endcap removed). Loosen the

screw about one-quarter to one-half turn. Do

not loosen the screw too much. The screw

should be just loose enough to allow the plate

to move but still tight enough to hold the plate

temporarily in its new position. Continue this

process with each slot/screw pair. Once all

the screws on one face plate are loose, slide

the face plate toward the top of the fence.

i. The last step is to set the spacing between

the bottom of each face plate and the table.

The face plates are held in place by a series

of screws threaded into nuts embedded in the

face plates. The heads of the screws t into

key-hole slots in the sides of the fence (

See

Fig. 40 with endcap removed).

Key-hole

slot

Screw

head

Fig. 40

i. You may nd that after adjusting the face

plates the end of the cross-bracket has been

raised or lowered such that it is too close or

too far away from the main tube. If this is the

case, turn both plastic leveling screws the

same amount in order to ensure the position

indicator lenses are close to, but not touching,

the front tube or rulers (

See Fig. 44).

There should be a gap between the position

indicator lens and the ruler on the main tube.

Fig. 44

Page 24 | SawStop T-Glide Fence System - Professional Series II

Fig. 41

Adjusting Your T-Glide Fence System

i. Install the fence on the front tube and position the face plate as desired, making sure to leave at least a small

gap between the bottom of the face plate and the table so the face plate does not drag on the table. It may

be necessary to loosen and raise the other face plate as well if it is too low and interferes with the adjustment.

ii. Next, carefully lift the fence off the front tube and place it on the table with the newly adjusted face plate facing

down. Make sure not to move the face plate from the position you set. If necessary you can clamp the face

plate to the fence to keep the face plate from moving. Tighten each screw to lock the face plate in position.

Make sure not to over-tighten these screws as that may cause a slight concavity in the surface of the face

plate near the screw.

iii. Now adjust the position of the other face plate if necessary.

Congratulations, your fence system is now

installed and your saw is ready to use.

Using Your T-Glide Fence System

i. The rip fence included with your T-Glide Fence System is used to guide material parallel to the blade when you

make rip cuts (cuts that are length-wise along the grain of the wood). The fence must always be used when

making rip cuts.

ii. To use the rip fence, begin by placing it on the table so that the fence bracket is resting on the upper rear edge

of the front tube. You can use the fence on either the left or right side of the blade for non-bevel cuts. If you

plan to make bevel cuts, use the fence only on the right side to prevent the blade from possibly contacting the

fence. After placing the fence on the rails, lift the red handle up to the unlocked position and slide the fence to

the left or right until the distance between the blade and the fence is approximately equal to the desired width

of cut. Adjust the position of the fence until the cursor on the indicator lens is directly over the desired width

of the cut. Use the lens on the left when the fence is on the left side of the blade and use the lens on the right

when the fence is on the right side of the blade. Once the fence is in the correct position, push the red locking

handle down to the locked position (

See Fig. 42). The fence is now locked in place and ready for use.

Fig. 42

Page 25 | SawStop T-Glide Fence System - Professional Series II

ATT ENTION

ATT ENTION

Never touch the blade during

coast down until the blade

stops completely and the

green light stops blinking.

Always check that the spacing

between the brake and the

blade is at least 1/16” after

every blade or brake change.

Always check that the

spreader or riving knife is at

least 1/4” from the blade.

Always run the saw in Bypa ss

mode when cutting metal or

conductive material.

FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN

UNINTENDED BRAKE ACTIVATIONS.

CHECK OWNER’S MANUAL FOR DETAILS.

6

9

19

9

10

10

10

11

11

10

12

13

14

15

16

1

2

2

3

10

17

18

3

3

4

5

7

8

15

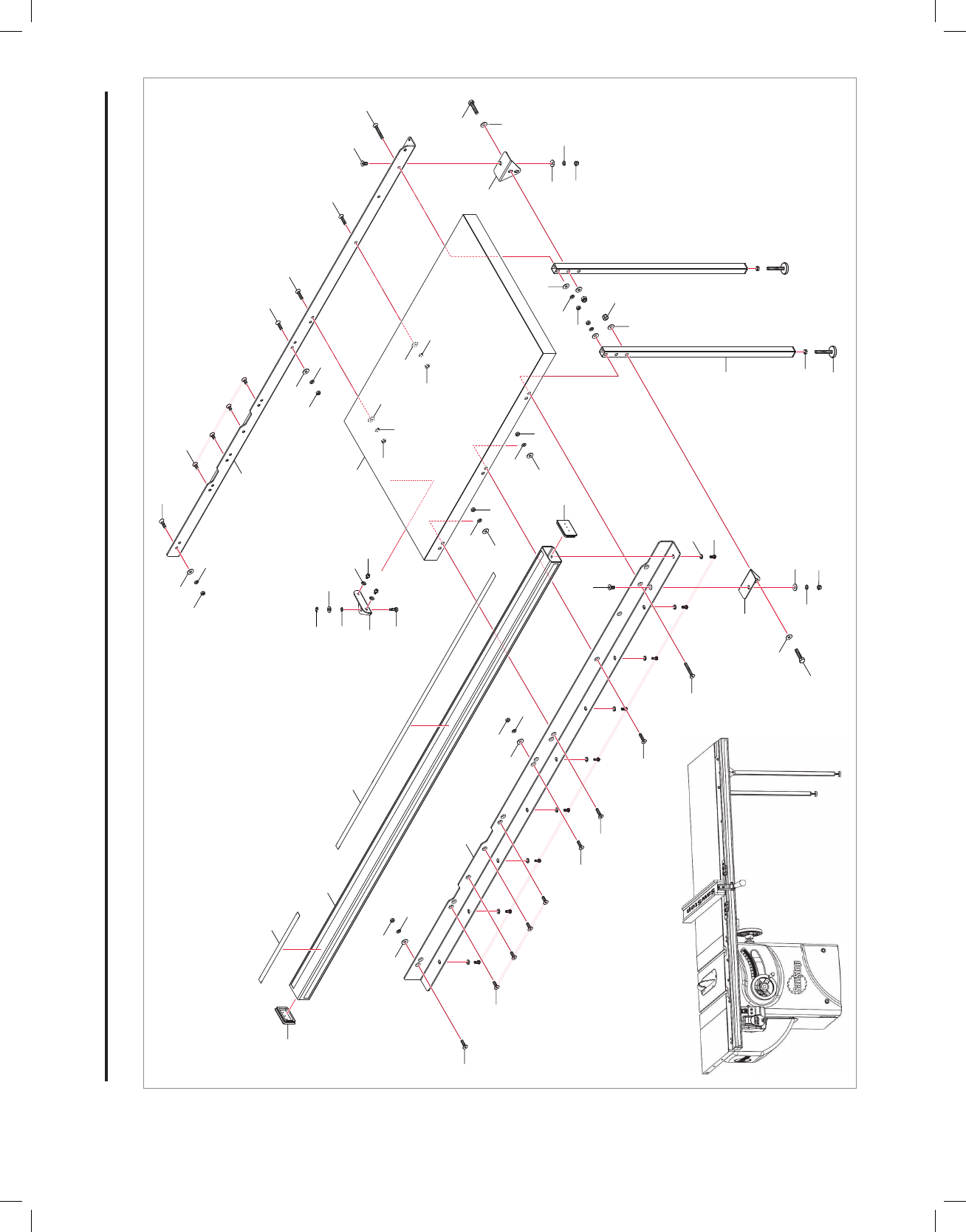

Fig. 43

Page 26

| SawStop T-Glide Fence System - Professional Series II

T-Glide Fence Exploded View

Page 27 | SawStop T-Glide Fence System - Professional Series II

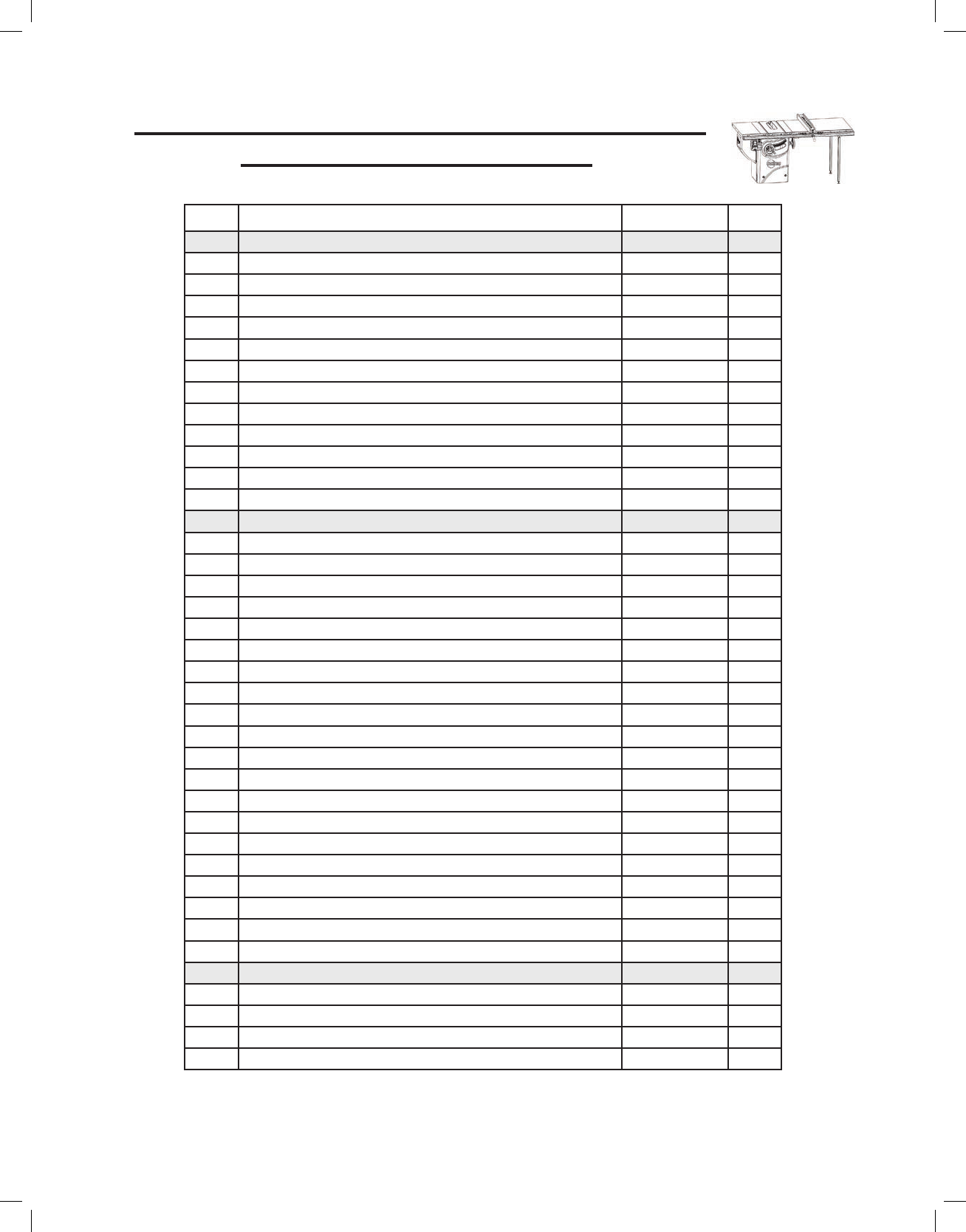

No. Description Part No. Qty.

Professional Series II T-Glide Fence Assembly (items 1-18) TGP2-FA 1

1 Fence Tube TGP2-001 1

2 Face Plate TGP2-002 2

3 M6x1.0x10 Socket Head Screw TGP2-003 20

4 Handle TGP2-004 1

5 Cam Lock TGP2-005 1

6 M10x1.5x45 Hex Head Bolt TGP2-006 1

7 M10x1.5 Lock Nut TGP2-007 1

8 Flex Plate TGP2-008 1

9 Leveling Adjustment Screw M12x1.75 TGP2-009 2

10 Glide Plate TGP2-010 5

11 M10x1.5x10 Set Screw TGP2-011 2

12 Position Indicator Lens TGP2-012 2

13 M6x1.0x10 Pan Head Phillips Screw TGP2-013 4

14 M6x13x1.5 Washer TGP2-014 4

15 M6x1.0x8 Flat Head Phillips Screw TGP2-015 2

16 Flex Arm TGP2-016 1

17 SawStop Label TGP2-017 1

18 Fence Endcap TGP2-018 1

19 Fence Attention Magnet TGP2-075 1

Accessories

N/A 5 mm Ball-end Hex Driver TGP2-019 1

N/A 6 mm Hex Key TGP2-020 1

T-Glide Fence Parts List

Fig. 44

Page 28 | SawStop T-Glide Fence System - Professional Series II

28

23

21

25

24

24

23

24

19

7

8

26

27

27

6

4

10

18

18

18

17

17

17

19

19

19

2

20

22

16

16

1

22

2

20

5

3

4

5

3

4

18

17

2

1

9

11

12

4

5

2

3

4

5

3

13

29

31

30

32

14

17

18

19

19

15

10

36” Fence System Rails and Extension Table Exploded View for a Cabinet Saw

Page 29 | SawStop T-Glide Fence System - Professional Series II

36” Fence System Rails and Extension Table

Parts List for a Cabinet Saw

No. Description Part No. Qty.

Professional Series II 36” T-Glide Fence Rails (items 1-12) TGP2-R36A 1

1 M8x1.25x16 Countersunk Socket Head Bolt TGP2-021 8

2 M8x1.25x25 Countersunk Socket Head Bolt TGP2-022 4

3 M8x23x2 Washer TGP2-023 4

4 M8 Lock Washer TGP2-024 11

5 M8x1.25 Hex Nut TGP2-025 4

6 M8x1.25x16 Hex Head Bolt TGP2-026 7

7 36” Front Rail TGP2-027 1

8 36” Rear Rail TGP2-028 1

9 36” Main Tube TGP2-029 1

10 Main Tube End Cap TGP2-030 2

11 12” Ruler TGP2-031 1

12 36” Ruler TGP2-032 1

Professional Series II 36” T-Glide Extension Table

(items 13-32) TGP2-T36A 1

13 Adjustment bracket TGP2-033 1

14 M6x1.0x18 Socket Cap Screw TGP2-034 2

15 M6 Lock Washer TGP2-035 2

16 M8x1.25x20 Countersunk Socket Head Bolt TGP2-036 2

17 M8x23x2 Washer TGP2-037 6

18 M8 Lock Washer TGP2-038 6

19 M8x1.25 Hex Nut TGP2-039 8

20 M8x1.25x35 Countersunk Socket Head Bolt TGP2-040 2

21 Foot TGP2-041 2

22 M8x1.25x65 Countersunk Socket Head Bolt TGP2-042 2

23 M10x1.5x40 Hex Head Bolt TGP2-043 2

24 M10x25x1.5 Washer TGP2-044 4

25 M10x1.5 Lock Nut TGP2-045 2

26 36” Table TGP2-046 1

27 Leg Support Bracket TGP2-047 2

28 Support Leg TGP2-048 2

29 Adjustment Screw TGP2-049 1

30 M9x18.3x2.3 Washer TGP2-050 1

31 M9 Wave Washer TGP2-051 1

32 M8 Retaining Ring TGP2-052 1

Accessories

N/A T-Glide Rails Hardware Pack TGP2-053 1

N/A T-Glide Table Hardware Pack TGP2-054 1

N/A Professional Cabinet Saw Fence System Installation Poster TGP2-055 1

N/A T-Glide Fence System Professional Series II Owner’s Manual TGP2-056 1

1

9

11

12

2

2

10

10

3

5

4

3

4

2

1

5

3

4

5

5

3

4

20

20

16

27

2

20

20

17

17

17

18

18

18

19

17

18

19

17

18

19

19

19

26

13

29

31

30

32

8

22

16

14

15

22

27

17

18

19

28

23

21

24

23

24

24

19

25

7

18

17

19

4

6

Fig. 45

Page 30 | SawStop T-Glide Fence System - Professional Series II

52” Fence System Rails and Extension Table Exploded View for a Cabinet Saw

Page 31 | SawStop T-Glide Fence System - Professional Series II

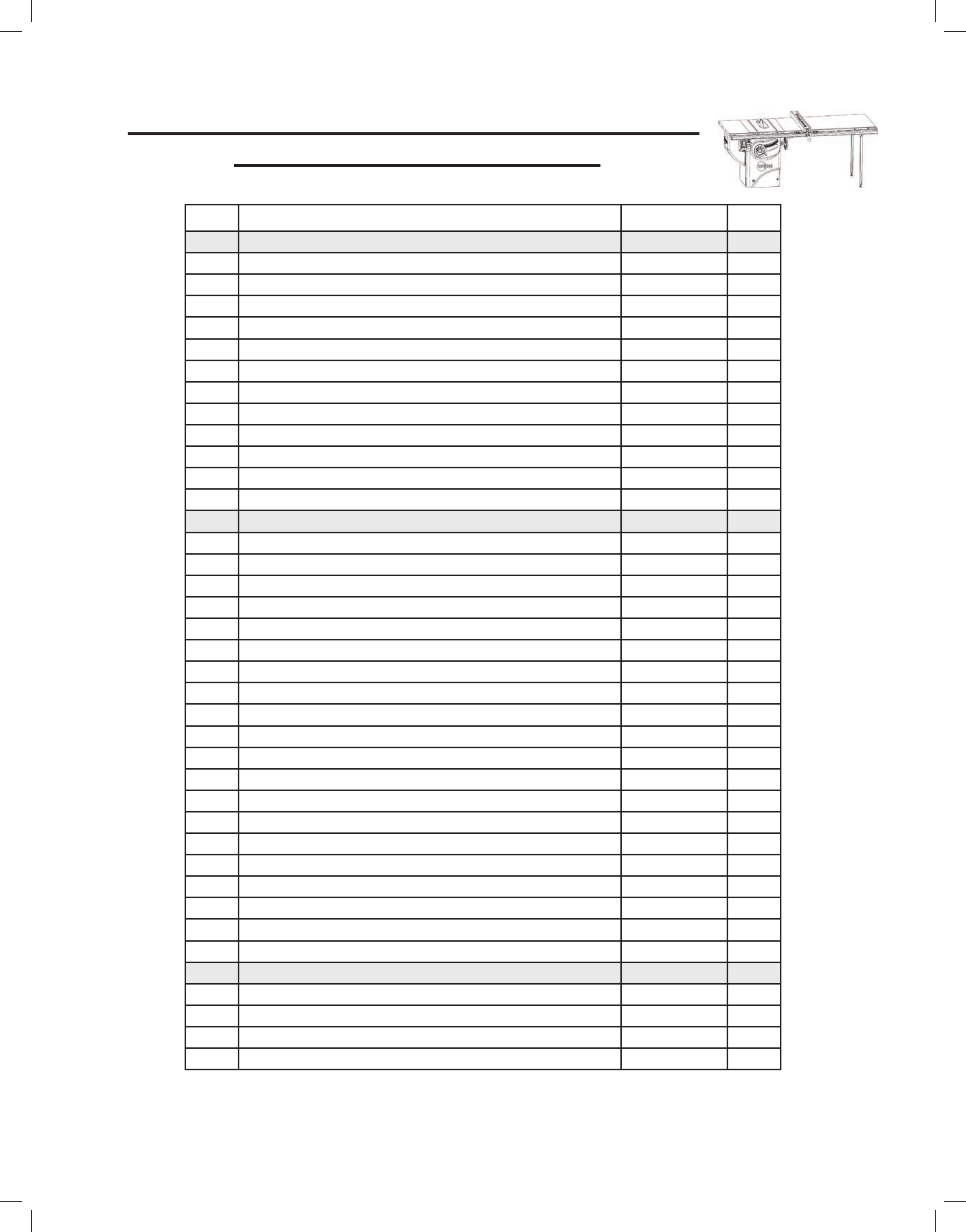

52” Fence System Rails and Extension Table

Parts List for a Cabinet Saw

No. Description Part No. Qty.

Professional Series II 52” T-Glide Fence Rails (items 1-12) TGP2-R52A 1

1 M8x1.25x16 Countersunk Socket Head Bolt TGP2-021 8

2 M8x1.25x25 Countersunk Socket Head Bolt TGP2-022 4

3 M8x23x2 Washer TGP2-023 4

4 M8 Lock Washer TGP2-024 13

5 M8x1.25 Hex Nut TGP2-025 4

6 M8x1.25x16 Hex Head Bolt TGP2-026 9

7 52” Front Rail TGP2-057 1

8 52” Rear Rail TGP2-058 1

9 52” Main Tube TGP2-059 1

10 Main Tube Endcap TGP2-030 2

11 12” Ruler TGP2-031 1

12 52” Ruler TGP2-060 1

Professional Series II 52” T-Glide Extension Table

(items 13-32) TGP2-T52A 1

13 Adjustment bracket TGP2-033 1

14 M6x1.0x18 Socket Cap Screw TGP2-034 2

15 M6 Lock Washer TGP2-035 2

16 M8x1.25x20 Countersunk Socket Head Bolt TGP2-036 2

17 M8x23x2 Washer TGP2-037 8

18 M8 Lock Washer TGP2-038 8

19 M8x1.25 Hex Nut TGP2-039 10

20 M8x1.25x35 Countersunk Socket Head Bolt TGP2-040 4

21 Foot TGP2-041 2

22 M8x1.25x65 Countersunk Socket Head Bolt TGP2-042 2

23 M10x1.5x40 Hex Head Bolt TGP2-043 2

24 M10x25x1.5 Washer TGP2-044 4

25 M10x1.5 Lock Nut TGP2-045 2

26 52” Table TGP2-061 1

27 Leg Support Bracket TGP2-047 2

28 Support Leg TGP2-048 2

29 Adjustment Screw TGP2-049 1

30 M9x18.3x2.3 Washer TGP2-050 1

31 M9 Wave Washer TGP2-051 1

32 M8 Retaining Ring TGP2-052 1

Accessories

N/A T-Glide Rails Hardware Pack TGP2-053 1

N/A T-Glide Table Hardware Pack TGP2-054 1

N/A Professional Cabinet Saw Fence System Installation Poster TGP2-055 1

N/A T-Glide Fence System Professional Series II Owner’s Manual TGP2-056 1

Fig. 46

Page 32 | SawStop T-Glide Fence System - Professional Series II

3

5

4

3

5

4

2

1

2

20

22

16

17

17

18

18

19

26

8

27

7

17

18

19

19

13

29

31

30

32

23

23

14

24

24

15

25

24

28

21

19

10

19

27

17

18

20

22

16

2

9

11

12

18

17

19

3

4

5

10

6

4

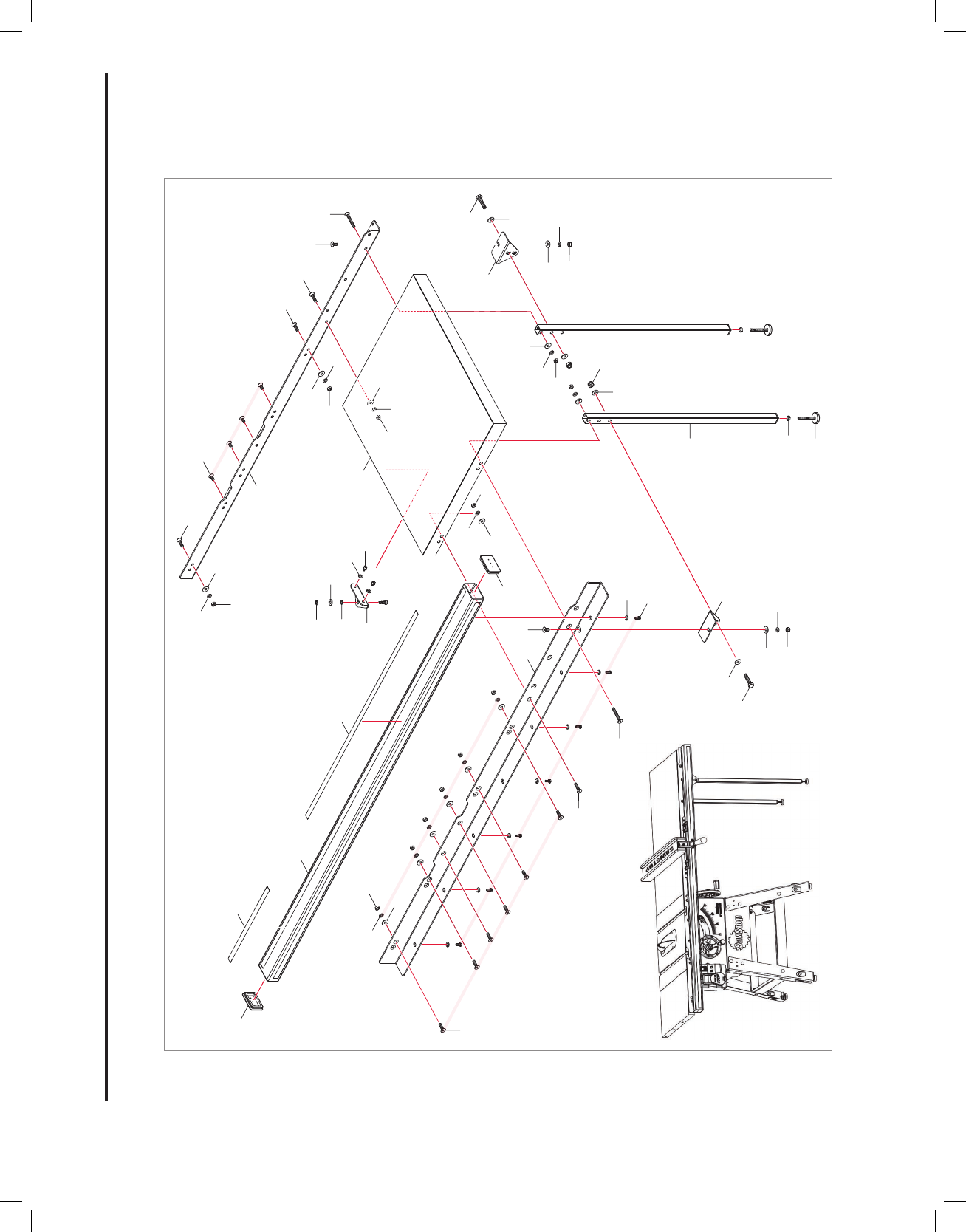

36” Fence System Rails and Extension Table Exploded View for a Contractor Saw

Page 33 | SawStop T-Glide Fence System - Professional Series II

No. Description Part No. Qty.

Professional Series II 36” T-Glide Fence Rails (items 1-12) TGP2-R36A 1

1 M8x1.25x16 Countersunk Socket Head Bolt TGP2-021 4

2 M8x1.25x25 Countersunk Socket Head Bolt TGP2-022 8

3 M8x23x2 Washer TGP2-023 8

4 M8 Lock Washer TGP2-024 15

5 M8x1.25 Hex Nut TGP2-025 8

6 M8x1.25x16 Hex Head Bolt TGP2-026 7

7 36” Front Rail TGP2-027 1

8 36” Rear Rail TGP2-028 1

9 36” Main Tube TGP2-029 1

10 Main Tube Endcap TGP2-030 2

11 12” Ruler TGP2-031 1

12 36” Ruler TGP2-032 1

Professional Series II 36” T-Glide Extension Table

(items 13-32) TGP2-T36A 1

13 Adjustment bracket TGP2-033 1

14 M6x1.0x18 Socket Cap Screw TGP2-034 2

15 M6 Lock Washer TGP2-035 2

16 M8x1.25x20 Countersunk Socket Head Bolt TGP2-036 2

17 M8x23x2 Washer TGP2-037 6

18 M8 Lock Washer TGP2-038 6

19 M8x1.25 Hex Nut TGP2-039 8

20 M8x1.25x35 Countersunk Socket Head Bolt TGP2-040 2

21 Foot TGP2-041 2

22 M8x1.25x65 Countersunk Socket Head Bolt TGP2-042 2

23 M10x1.5x40 Hex Head Bolt TGP2-043 2

24 M10x25x1.5 Washer TGP2-044 4

25 M10x1.5 Lock Nut TGP2-045 2

26 36” Table TGP2-046 1

27 Leg Support Bracket TGP2-047 2

28 Support Leg TGP2-048 2

29 Adjustment Screw TGP2-049 1

30 M9x18.3x2.3 Washer TGP2-050 1

31 M9 Wave Washer TGP2-051 1

32 M8 Retaining Ring TGP2-052 1

Accessories

N/A T-Glide Rails Hardware Pack TGP2-053 1

N/A T-Glide Table Hardware Pack TGP2-054 1

N/A Contractor Saw Fence System Installation Poster TGP2-062 1

N/A T-Glide Fence System Professional Series II Owner’s Manual TGP2-056 1

36” Fence System Rails and Extension Table

Parts List for a Contractor Saw

27

23

23

24

24

17

18

19

22

7

10

16

17

18

19

17

18

19

20

20

2

11

12

9

13

29

31

30

32

26

14

15

25

24

19

27

17

18

19

17

18

8

22

16

2

20

20

2

1

28

21

19

3

4

5

18

19

17

18

19

17

3

5

4

3

5

4

6

4

10

52” Fence System Rails and Extension Table Exploded View for a Contractor Saw

Fig. 47

Page 34 | SawStop T-Glide Fence System - Professional Series II

Page 35 | SawStop T-Glide Fence System - Professional Series II

No. Description Part No. Qty.

Professional Series II 52” T-Glide Fence Rails (items 1-12) TGP2-R52A 1

1 M8x1.25x16 Countersunk Socket Head Bolt TGP2-021 4

2 M8x1.25x25 Countersunk Socket Head Bolt TGP2-022 8

3 M8x23x2 Washer TGP2-023 8

4 M8 Lock Washer TGP2-024 17

5 M8x1.25 Hex Nut TGP2-025 8

6 M8x1.25x16 Hex Head Bolt TGP2-026 9

7 52” Front Rail TGP2-057 1

8 52” Rear Rail TGP2-058 1

9 52” Main Tube TGP2-059 1

10 Main Tube Endcap TGP2-030 2

11 12” Ruler TGP2-031 1

12 52” Ruler TGP2-060 1

Professional Series II 52” T-Glide Extension Table

(items 13-32) TGP2-T52A 1

13 Adjustment bracket TGP2-033 1

14 M6x1.0x18 Socket Cap Screw TGP2-034 2

15 M6 Lock Washer TGP2-035 2

16 M8x1.25x20 Countersunk Socket Head Bolt TGP2-036 2

17 M8x23x2 Washer TGP2-037 8

18 M8 Lock Washer TGP2-038 8

19 M8x1.25 Hex Nut TGP2-039 10

20 M8x1.25x35 Countersunk Socket Head Bolt TGP2-040 4

21 Foot TGP2-041 2

22 M8x1.25x65 Countersunk Socket Head Bolt TGP2-042 2

23 M10x1.5x40 Hex Head Bolt TGP2-043 2

24 M10x25x1.5 Washer TGP2-044 4

25 M10x1.5 Lock Nut TGP2-045 2

26 52” Table TGP2-061 1

27 Leg Support Bracket TGP2-047 2

28 Support Leg TGP2-048 2

29 Adjustment Screw TGP2-049 1

30 M9x18.3x2.3 Washer TGP2-050 1

31 M9 Wave Washer TGP2-051 1

32 M8 Retaining Ring TGP2-052 1

Accessories

N/A T-Glide Rails Hardware Pack TGP2-053 1

N/A T-Glide Table Hardware Pack TGP2-054 1

N/A Contractor Saw Fence System Installation Poster TGP2-062 1

N/A T-Glide Fence System Professional Series II Owner’s Manual TGP2-056 1

52” Fence System Rails and Extension Table

Parts List for a Contractor Saw

SawStop, LLC

11555 S.W. Myslony Street

Tualatin, Oregon 97062

www.sawstop.com

Main Phone - (503) 570-3200

Service - (503) 582-9934

Fax - (503) 570-3303

Email: [email protected]

January 2020

M PCS 18 0010 00

Patents Pending. Copyright SawStop, LLC. All Rights Reserved.

SawStop is a registered trademark and T-Glide is a trademark of SawStop, LLC.

Updates of this manual may be available at www.sawstop.com.