OPERATING &

MAINTENANCE

INSTRUCTIONS

KALC

Air Hoists

For Capacities:

1, 2, & 3 Ton

½, 1 & 2 Ton Spark

Resistant Models

Publication Part No. 117404-23

Published December 2007

IMPORTANT-CAUTION

To safeguard against the possibility of personal injury or property damage, follow the recommendations and instructions

of this manual. This manual contains important information for the correct installation, operation, and maintenance of

this equipment. All persons involved in the installation, operation, and maintenance of this equipment should be

thoroughly familiar with the contents of this manual. Keep this manual for reference and further use.

To prevent personal injury, do not use the equipment shown in this manual to lift, support or otherwise transport people,

or to suspend unattended loads over people.

WARNING

Page 2

INDEX

SECTION I GENERAL DESCRIPTION Page

Paragraph 1-1 General....................................................................................................................................................................................... 3

Paragraph 1-2 Basic Construction .................................................................................................................................................................... 3

Paragraph 1-3 Differences Between Models and Sizes .................................................................................................................................. 3

Paragraph 1-4 MAN-GUARD Overload Clutch ................................................................................................................................................. 3

SECTION II INSTALLATION

Paragraph 2-1 General....................................................................................................................................................................................... 3

Paragraph 2-2 Suspending Hoist ...................................................................................................................................................................... 3

Paragraph 2-3 Pre-Installation Checks ............................................................................................................................................................. 4

Paragraph 2-4 Connecting Hoist to Air Service ............................................................................................................................................... 4

SECTION III OPERATION

Paragraph 3-1 General....................................................................................................................................................................................... 5

Paragraph 3-2 Pre-Operational Hoist ................................................................................................................................................................ 5

Paragraph 3-3 Operating Hoist .......................................................................................................................................................................... 5

Paragraph 3-4 Upper and Lower Limit Stops ................................................................................................................................................... 5

Paragraph 3-5 MAN-GUARD Overload Clutch Operations.............................................................................................................................. 5

Paragraph 3-6 Load Chain................................................................................................................................................................................. 6

Paragraph 3-7 Pulling and Pivoting Hoist and Load ........................................................................................................................................ 6

Paragraph 3-8 Operating Precautions............................................................................................................................................................... 6

SECTION IV LUBRICATION

Paragraph 4-1 General ......................................................................................................................................................................................... 6

Paragraph 4-2 Service Air Line Lubricator ......................................................................................................................................................... 6

Paragraph 4-3 Lubricate Load Chain .................................................................................................................................................................. 7

Paragraph 4-4 Change Gearcase Oil .................................................................................................................................................................. 7

Paragraph 4-5 Lubricate Upper Hook and Lower Block Assembly ................................................................................................................... 7

SECTION V MAINTENANCE

Paragraph 5-1 General ......................................................................................................................................................................................... 7

Paragraph 5-2 Thirty-Day Inspection................................................................................................................................................................... 7

Paragraph 5-3 Six-Month Inspection ................................................................................................................................................................. 10

Paragraph 5-4 Annual Inspection ...................................................................................................................................................................... 10

Paragraph 5-5 Inspection - 5000 Hour or Five Year......................................................................................................................................... 11

SECTION VI TROUBLESHOOTING ....................................................................................................................................................................... 12

SECTION VII DISASSEMBLY AND REASSEMBLY

Paragraph 7-1 General ....................................................................................................................................................................................... 13

Paragraph 7-2 Disassembly of Hoist into Subassemblies ............................................................................................................................... 13

Paragraph 7-3 Rebuild of Hoist Frame, Sprocket Gear, Sprocket Shaft and Chain Guide ........................................................................... 15

Paragraph 7-4 Rebuild of Load Brake and Overload Clutch Assembly .......................................................................................................... 17

Paragraph 7-5 Rebuild of Lower Block and Load Chain Assembly ................................................................................................................ 19

Paragraph 7-6 Rebuild of Pendant Throttle Control Assembly ........................................................................................................................ 20

Paragraph 7-7 Rebuild of Supply Head Assembly ........................................................................................................................................... 20

Paragraph 7-8 Rebuild of Air Motor .................................................................................................................................................................. 21

Paragraph 7-9 Reassembly of Hoist From Subassemblies ............................................................................................................................. 21

Paragraph 7-10 Testing Hoist ............................................................................................................................................................................ 21

Paragraph 7-11 Test Procedure For Checking Operation of Overload Clutch ............................................................................................... 22

SECTION VIII REPLACEMENT PARTS................................................................................................................................................................. 23

FOREWORD

This book contains important information to help you install, operate

and maintain your new YALE KALC Air Hoist. We recommend that you

study its contents thoroughly before putting your hoist to use. Through

proper installation, application of correct operating procedures, and by

practicing the recommended maintenance suggestions you will be

assured maximum service from your hoist.

Complete inspection, maintenance and overhaul service is available

for YALE Air Hoists at authorized YALE Repair Stations. Refer to your

telephone directory yellow pages under "HOISTS". They are staffed

by qualified factory-trained service men and stock approved YALE

replacement parts.

Notice: Information contained in this book is subject to change without notice.

Replacement parts information is also included in this book for your

convenience. Since it will likely be a long time before parts information

is needed, we suggest that, after you have become familiar with

operation and preventive maintenance procedures, this book be

carefully filed for future reference.

EQUIPMENT ILLUSTRATED AND DESCRIBED HEREIN IS NOT

DESIGNED OR SUITABLE FOR LIFTING OR LOWERING PERSONS.

Page 3

SECTION I - GENERAL DESCRIPTION

1-1. GENERAL. These YALE KALC Air Hoists are precision

built chain type hoists which are built in three capacity sizes: 1,

2, and 3 ton. All models use coil type load chain and have

pendant throttle controls. There are model variations with hook

or lug type suspensions. Hoists are also provided in spark

resistant models and corrosion resistant models. (Note: Spark

resistant models have capacity ratings lower than standard

models).

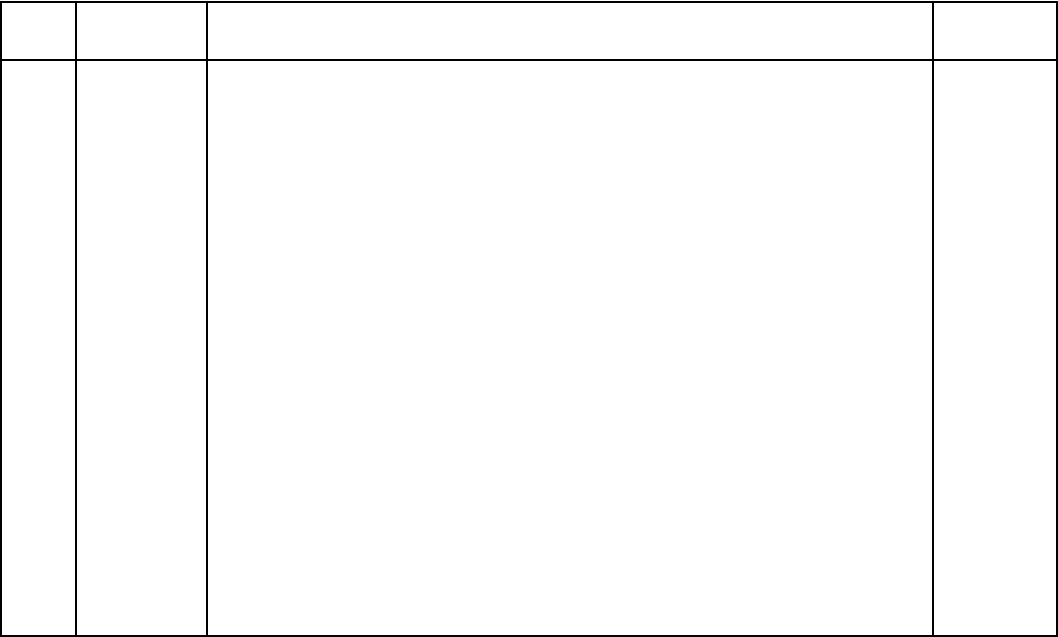

1-2. BASIC CONSTRUCTION. All sizes and models of these

YALE KALC Air Hoists are of the same basic design, having

many common and interchangeable parts. They consist primarily

of an aluminum alloy frame and gearcase cover which houses

an automatic load brake and gear train. An air motor is mounted

on the rear of the frame. An upper hook or lug bracket for

suspending the hoist is attached to the top of the frame. An

alloy steel coil load chain with lower block assembly is employed

to raise and lower loads. Upper and lower limits of hook travel

are limited by chain mounted limit stops. Hoist operation is

controlled by a pendant throttle control assembly.

1-3. DIFFERENCES BETWEEN MODELS AND SIZES. The

main differences between hoist models are in the reeving of

the load chain and the suspension employed. These are

described in Paragraphs a and b, below.

a.On standard 1 ton capacity hoists, the load chain is

single reeved (one part of chain); on standard 2 ton

capacities, the chain is double reeved (two parts of chain);

on standard 3 ton capacities, the chain is triple reeved

(three parts of chain). Coil type chain is full-flexing, electric

welded, link chain; carburized steel on standard and

corrosion resistant models and stainless steel on spark

resistant models. Both types are especially designed for

use in hoisting and have special calibrated pitch. (Note:

On corrosion resistant models, the load chain is zinc

plated).

b. Suspension differences include a conventional hook type

mounting and a lug type mounting. Hook suspension allows

portability permitting hoist to be easily moved from job to

job. Lug suspension permits hoist to be rigidly mounted to

overhead structure or attached to YALE Rigid Mount

Trolleys, affording unusual headroom advantage.

1-4. MAN-GUARD OVERLOAD CLUTCH. YALE KALC Air

Hoists have a MAN-GUARD label on the sides of the

counterweighted cover and are equipped with an overload clutch

that is designed to help guard against excessive overloads.

The clutch is built into the load brake gear. It is a cone-friction

clutch that connects the first reduction gear (load brake gear)

to the load brake output pinion shaft. A belleville disc spring

provides clutch pressure between the gear and its cone shaped

gear center. An excessive overload causes the load brake gear

to rotate without turning the gear center and output pinion

shaft. The clutch is located between the load brake and the

motor, thus allowing load brake to function in its normal manner.

See Paragraph 3-5 for operation.

SECTION II - INSTALLATION

2-1. GENERAL. YALE KALC Air Hoists are completely

lubricated and load tested before being shipped from the factory.

The hoist is shipped with pendant handle and hose assembly

packed loose in the shipping carton. See Paragraph 2-2.e for

attachment. To place hoist in service, attach to a suitable

overhead suspension (Paragraph 2-2) in area to be used;

perform pre installation check (Paragraph 2-3); and connect

hoist to air service (Paragraph 2-4).

2-2. SUSPENDING HOIST.

a.On hook suspended hoists, select a suitable overhead

support in area hoist is to be used (one capable of holding

combined weight of hoist and its capacity load) and hang

hoist up. Be certain that upper hook is firmly seated in

center of hook saddle and that the spring safety latch

is properly closed over hook opening. In some cases,

it may be necessary to first remove spring latch before

hook will fit over a support. Reinstall latch after hook is

engaged.

b. On lug suspended hoists, select a suitable overhead

support in area hoist is to be used (one capable of holding

combined weight of hoist and its capacity load). Mount

hoist using through bolts of appropriate size to fit mounting

holes in suspension lug at top of hoist. (See table below).

Use only suspension bolts provided by YaleLift-Tech.

Hoist Capacity

(tons)

Bolt Diameter

(in)

Distance Between

Holes

(in)Std. S.R.*

11/2 5/8 3-1/8

21 1 5

3 2 1-1/4 6

SUSPENSION LUG BOLTS SIZES AND SPACING

The structure used to suspend hoist must be of

sufficient strength to withstand reasonable forces to

which hoist and support may be subjected. Hoist must

be aligned with load to avoid side pulls.

WARNING

*S.R. = Spark Resistant Models

c. On lug suspended hoists, the suspension lug is factory

oriented to cross mount the hoist. This is the recommended

orientation. To rotate the lug 90

° for parallel mounting, follow

instructions below:

(1) On 1/4 through 1 ton hoists, remove the two screws securing

the anti-rotation bracket and remove the bracket. Rotate the

suspension lug in 90

° increments. Reinstall the anti-rotation

bracket and secure with two screws and lock washers.

Page 4

(2) On hoists with two parts of chain: remove hex socket

head screw in lower lock plate. Remove lower lock

plate. Rotate suspension lug to selected position and

replace lock plate and hex socket head screw.

(3) On hoists with three parts of chain: the hanger bracket

must first be removed from the hoist to provide access

to suspension nut per Section VII, Paragraph 7-2.a.(4)

and Figures 7-1 and 7-2.

To removed lug bolt, follow instructions in Section VII,

Paragraph 7-3.b.(3). With bolt removed lift lug from

hanger and reposition as desired. The lug is located and

prevented from turning by integral lugs on adjacent

surfaces of the lug and the hanger. Reinstall lug bolt,

spherical washers and nut. Align hole in nut and lug bolt.

Drive grooved pin through nut and suspension bolt to a

position flush with nut, or not more than 1/8" protruding.

Reassemble hanger bracket to hoist.

Be certain to replace grooved pin through nut and lug

bolt. Grooved pin must be tight.

WARNING

d. On rigid mount trolley suspended hoists, the trolley side

plates must be properly spaced so trolley will fit I-beam

on which hoist will operate. Adjustment for various I-beam

sizes is accomplished by rearrangement of spacer

washers on the through bolts which connect trolley side

plates to suspension lug on hoist. Refer to instruction

sheet furnished with YALE Rigid Mount Trolleys for

complete instructions.

If trolley is mounted on an open-end beam, end stops

must be installed to prevent trolley from running off

the end of the beam resulting in injury to operator and

others and damages to load and other property.

WARNING

e. To connect pendant throttle control, refer to Figure 8-8.

The hose with a straight connection at the top (Ref. No.

10) attaches to the left connection of the supply head as

shown. The hose with the long elbow at the top connects

to the upper right connection and the hose with the short

elbow at the top connects to the lower right connection of

the supply head. Assemble the parts at the upper end of

the strain relief cable as shown. Make the cable tight

enough to support the weight of the handle and hoses

before tightening the wire rope clips.

f. If chain container is to be used on hoist, install it following

instructions furnished with container.

2-3. PRE-INSTALLATION CHECK. Check Oil Level. (Figure

4-1) The gear case has been filled with oil, to the proper level

at the factory. However, the oil level should be checked before

hoist is operated. Remove pipe plug from oil filler on side of

hoist frame. Replace with supplied oil hole cover. Check oil

level by removing oil level plug (side of frame). Observe if oil

level is even with bottom of tapped hole. If it is not, add oil, as

specified in paragraph 4-4c. Also check load chain. Be sure it

is properly lubricated. See paragraph 4-3.

2-4. CONNECTING HOIST TO AIR SERVICE.

a Connect hoist to nearest filtered and lubricated air source

using 3/4" I.D. air hose (see Figure 2-1). Avoid use of

hose assemblies of smaller diameters that will cause air

flow restrictions and reduce hoist performance.

b. If hoist is suspended by trolley, provide sufficient hose to

reach from air source to farthest point of trolley travel.

YALE Hose Trolleys are recommended to keep hose

up out of the way.

Figure 2-1. Connecting Air Hose to Hoist

12424

c. A filter and lubricator unit (Figure 2-2) must be installed

between air source and hoist, as close to hoist as

possible. These keep air flowing to hoist free of dirt and

add lubricant to air so internal parts of motor are

constantly lubricated. Use a good grade of spindle oil,

approximate viscosity 180 ssu at 100° F., air powered

tool oil, or S.A.E. 10W machine oil. YaleLift-Tech

distributors can provide filter-lubricator units.

Figure 2-2. Air Filter and Lubricator Unit

10980

d. The recommended operating air pressure for all capacities

of YALE Air Hoists is 90 psi. When line pressure

exceeds 100 psi (at hoist when hoist is operating), it is

recommended that a pressure regulator valve be provided

in the air supply line to maintain proper pressure. Although

there is a wide range of pressures within which the hoists

will operate, motor efficiency may decrease more rapidly

than the drop in air pressure on a percentage basis.

Refer to "Performance Charts," See Figure 2-3.

Page 5

1 Ton Capacity Hoist

Load 500 lb. 1000 lb. 1500 lb. 2000 lb.

Air

Pressure

PSIG Up

Down

(max) Up

Down

(max) Up

Down

(max) Up

Down

Min Max

60 40 36 33 36 28 36 20 25 36

70 43 39 36 39 31 39 24 28 39

80 47 42 39 42 34 42 28 32 42

90 50 47 42 47 38 47 30 36 47

2 Ton Capacity Hoist

Load 1000 lb. 2000 lb. 3000 lb. 4000 lb.

Air

Pressure

PSIG Up

Down

(max) Up

Down

(max) Up

Down

(max) Up

Down

Min Max

60 19 17 16 17 14 17 10 12 17

70 21 19 17 19 15 19 12 14 19

80 22 20 19 20 16 20 14 16 20

90 24 22 20 22 18 22 15 18 22

3 Ton Capacity Hoist

Load 1500 lb. 3000 lb. 4500 lb. 6000 lb.

Air

Pressure

PSIG Up

Down

(max) Up

Down

(max) Up

Down

(max) Up

Down

Min Max

60 13 11 11 11 9 11 6 8 11

70 14 12 12 12 10 12 8 9 12

80 15 13 13 13 11 13 9 10 13

90 16 14 14 14 12 14 10 11 14

Figure 2-3. Hoist Performance Charts

Note: Hoist speeds are shown in feet per minute (f.p.m.)

SECTION III - OPERATION

3-1. GENERAL. Operation of YALE KALC Air Hoists is controlled

by a pendant throttle control. The Pendant Throttle Control has

a convenient lever type control valve handle (Figure 3-1)

suspended from the control manifold.

3-2. PRE-OPERATION CHECKS. Check the following before

operating hoist with load:

Check limit stops. Make sure the stop on the tail chain side is

securely fastened to the proper link (see chart.)

Never operate hoist with defective or missing limit stops,

defective hooks or load chain. See Paragraph 5-2 for aid in

checking load chain condition.

WARNING

b. When hoist is to be used without a chain container, check

that tail chain anchor screw is secure. When hoist is to be

used with a chain container, tail chain may be left unattached

PROVIDED LIMIT ACTUATOR IS IN PLACE IN ACCORDANCE

WITH ABOVE.

c. Check to see that limit stop is in proper position.

3-3. OPERATING HOIST. With hoist installed and air pressure

turned on, hoist is operated in the following manner:

a.Depress throttle valve lever marked

to raise load. See Figure 3-1.

b. Depress throttle valve lever marked

to lower load.

c. Release lever being depressed to stop

either lifting or lowering.

d.Speed of lifting and lowering is varied

by the position of the throttle valve lever

being depressed.

e.Speed of lowering can be reduced from

the maximum by adjusting a screw in

the upper fitting of the down valve

supply hose.

Figure 3-1.

Pendant Throttle

Control Handle

12425

3-4. UPPER AND LOWER LIMIT STOPS. Upper and lower

limit stops are provided to guard against overtravel of load in

either raising or lowering direction, which can cause damage

to hoist. When highest position is reached, the lower block will

cause the overload clutch to slip. When the lowest block position

is reached, the tail chain stop will cause the overload clutch to

slip. Limit stops are intended as safety devices and should not

be used on a routine basis to stop block travel. Lowering full

rated capacity load at full rated speed Into the limit stop is an

especially severe condition and must not be knowingly done at

any time.

3-5. MAN-GUARD OVERLOAD CLUTCH OPERATION. The

overload clutch is factory preset at assembly so that the hoist

will lift its full rated load but will refuse to lift overloads within a

range of 110 percent rated load to 200 percent rated load. If

the load to be lifted exceeds the clutch factory setting, the

motor will continue to run and will rotate the load brake gear

without lifting the load. Whenever this occurs, immediately

release the "UP" control to prevent overheating of the clutch

friction surfaces and motor.

Type Chain Size Chain

Number of

Chain Links

From End Link

Coil 1/4" Wire Dia. 12 Links (9½")

Coil 5/16" Wire Dia. 10 Links (9")

d. Check hooks. They should not be bent or distorted and

should not be opened beyond the correct opening sizes

given in Figures 5-5 and 5-6. Hook latches should not be

bent or damaged and springs not broken.

e. Check chain to make sure it is not twisted or kinked. Be

sure lower block on double reeved models has not been

capsized. Be sure load chain is lubricated. See Paragraph

4-3.

f. Check suspension bushing keeper. The keeper must

contact a flat on the suspension bushing. Be sure that

suspension bushing is screwed in all the way. Be sure

screw retaining suspension bushing keeper is tight.

Page 6

3-8. OPERATION PRECAUTIONS

Safe operation of an overhead hoist is the operator's

responsibility. Listed below are some basic rules that can make

an operator aware of dangerous practices to avoid and

precautions to take for his own safety and the safety of others.

Observances of these rules in addition to frequent examinations

and periodic inspection of the equipment may save injury to

personnel and damage to equipment.

a. Personnel not physical fit or properly qualified, shall

not operate hoist.

b. Operate hoist cautiously to become familiar with its

performance.

c. Do not lift loads greater than the hoist rated load.

d. Never lift or transport a load until all personnel are

clear. Never lift people on hook or load.

e. Stand clear of all loads and never travel loads over

people.

f. When lifting load make certain it is free to move and

will clear all obstructions.

g. Do not divert attention from load while operating hoist.

Never leave a suspended load unattended.

h. Do not operate hoist unless upper and lower limit stops

are operating properly.

j. Do not use limit stop as normal operating stop. This is

a safety device only.

k. Take up chain slack carefully to avoid jerking load,

possibly overloading hoist.

I. Never use hoist chain as a lifting sling around a load or

as an electrical ground for welding.

Equipment covered herein is not designed or suitable

as a power source for lifting or lowering persons.

WARNING

m. Always be sure there is no twist in coil load chain. On 2

& 3 line coil chain hoists, check to see that lower block

is not capsized between strands of chain.

n. Avoid operating hoist when hook is not centered under

hoist. Be sure that hoist trolley or other support

mechanism is correctly positioned for handling the load

before lifting.

o. Do not operate hoist with twisted, kinked, badly worn

or damaged chain.

p. Do not operate damaged or malfunctioning hoist.

q. Do not "Jog" unnecessarily.

r. Conduct regular visual inspections for signs of damage

or wear.

s. Observe recommended inspection and maintenance

procedures.

t. Never operate hoist with hooks that have opened up.

See Figure 5-5 and 5-6.

u. Do not remove or obscure warning labels.

v. The supporting structure or anchoring means shall have

a load rating at least equal to that of the hoist

w. Hoists shall not be used in locations that will not allow

operator movement to be free of the load.

x. The operator shall insure that he has firm footing or is

otherwise secured before operating the hoist.

y. The load sling or other approved devices shall be seated

properly in the saddle of the hook and the hook latch

shall be closed before operating hoist.

z. Before lifting a load the operator shall be certain that

load is not caught on any obstructions.

aa.When starting to lift or pull, the load should be moved

a few inches at which time the hoist should be checked

for proper load holding action. The operation shall be

continued only after the operator is assured that the

hoist is operating properly.

ab.The operator should not leave a loaded hoist unattended

at the end of a work shift or for extended periods during

the work shift. Where operations are such that this

condition cannot be avoided the operator must be

assured that the condition does not create a hazard to

personnel or property.

ac.Use common sense and best judgment whenever

operating a hoist. Observe American National Standard

Safety standard, ANSI B30.16, latest issue.

SECTION IV - LUBRICATION

4-1. GENERAL. The lubrication services outlined in Paragraphs

4-2 through 4-5 should be performed at regular intervals to

maintain top hoist performance and insure long life. The

frequency for lubrication services will depend on the type of

hoisting service that hoist is subjected to and should coincide

with periodic preventive maintenance inspection. See Section

V - Maintenance.

4-2. SERVICE AIR LINE LUBRICATOR. Servicing air line filter

and lubricator unit is of primary importance since it's the only

source of lubrication for control valves and air motor. Fill

lubricator with a good grade of light spindle oil or air powered

tool oil, and follow the manufacturer's recommended service

procedure.

NOTICE

Always know load to be lifted. Loads greater than rated

capacity are not to be lifted.

3-6. LOAD CHAIN. Make sure the load chain is lubricated

according to the requirements of Paragraph 4-3 before

operation. For hoists with stainless steel load chain carefully

inspect for unusual chain wear daily during the first week of

operation then return to the regular maintenance schedule of

Section V.

3-7. PULLING AND PIVOTING HOIST AND LOAD.

a. The Pendant Throttle Control handle is supported by a

strain cable that is suitable for pulling trolley suspended

hoists when empty or lightly loaded. Use a tag line or

pole to pull or push loads to traverse heavily loaded hoists.

Observe caution to stay clear of loads.

b. To pivot load, push on one corner of load. Lower hook

will swivel through 360° to permit load to be swung to the

desired position. The upper hook (hook suspension

models) is also designed to rotate so that hoist will swing

to face the load.

Page 7

Figure 4-1. Location of Oil Filler and Plugs

4-4. CHANGE GEARCASE OIL (Figure 4-1).

a. Remove drain plug from bottom of hoist frame and drain

oil from gearcase. Replace plug.

b. Remove oil level plug from side of hoist.

c. Refill gearcase through oil filler to proper level (bottom of

oil level plug hole) using Automatic Transmission Fluid -

DEXRON® Type. This is an all weather oil available from

all major oil companies. 1-1/2 pints of oil are required.

4-5. LUBRICATE UPPER HOOK AND LOWER BLOCK

ASSEMBLY.

a. Apply a few drops of graphite suspension oil on shank of

upper hook where it enters frame.

SECTION V - MAINTENANCE

5-1. GENERAL. Preventive maintenance services required on

YALE KALC Air Hoists are for the most part, simple periodic

inspection procedures to determine condition of hoist

components. Below are suggested inspection procedures,

based on daily average hoist usage.

5-2. THIRTY DAY INSPECTION. Hoist may be left suspended.

a. Inspect Load Chain.

(1) Operate hoist under load and observe operation of

chain over sprocket in both directions of chain travel.

Chain should feed smoothly into and away from the

sprocket. It chain binds, jumps or is noisy, first see

that it is clean and properly lubricated. If trouble

persists, inspect chain as outlined below.

(2) Clean chain for inspection. Examine visually for

gouges, nicks, weld splatter, corrosion or distorted

links. Slacken chain and check bearing surfaces

between links for wear, Figure 5-1. Greatest wear will

often occur at sprocket at high or low point of lift,

particularly when hoist is subjected to repetitive lifting

cycles. Case hardness of chain is about .015" deep.

Chain must be replaced before the case is worn

through. Also check chain for elongation using a vernier

caliper (Figure 5-2). Select an unworn, un-stretched

section of chain (usually at slack or tail end) and

measure and record the length over the number of

chain links (pitches) indicated in Figure 5-2. Measure

and record the same length of a worn section in the

load side of the chain. Obtain the amount of wear by

subtracting the measurement of the unworn section

from the measurement of the worn section. If the result

(amount of wear) is greater than the amount specified

in the "ALLOWABLE CHAIN WEAR" table, the chain

has elongated beyond the maximum allowable length

and must be replaced. Chain with excessively pitted,

corroded, nicked, gouged, twisted or worn links should

be replaced using only factory approved chain. Never

weld or attempt to repair coil chain.

Load chain for spark resistant models is made of

stainless steel. Surface hardness treatment is no more

than .001" deep and the core is lower in hardness

Before performing any internal work on hoist, be

certain air is shut off and pressure is released.

WARNING

4-3. LUBRICATE LOAD CHAIN. A small amount of lubricant

will greatly increase load chain life, therefore, chain should not

be allowed to run without lubricant. Chain should be cleaned

and lubricated as directed in Paragraph a, below. User should

set up a regular schedule for chain lubrication after observing

operating conditions for a few days.

a. Under ordinary conditions only weekly attention will be

necessary. Under hot and dirty conditions it may be

necessary to clean chain at least once a day and lubricate

it several times between cleanings. Thoroughly clean chain

with an oil solvent and relubricate by coating it lightly

with bar and chain oil (LUBRIPLATE or equal). Make

sure that lubricant coats wear surfaces between links.

b. YALE KALC spark resistant air hoist models

use stainless steel load chain that must be well lubricated

at all times and must be inspected daily when in use.

See Paragraph 5-2.a.(2).

b. Apply a few drops of graphite suspension oil on shank of

lower hook where it enters lower block. Hook rotation

bearing may be removed for cleaning and relubricating if

necessary. See Paragraph 7-5.

c. On lower block assemblies with 2 or 3 lines of load chain

also apply a good grade of bearing grease through

pressure fitting in end of sprocket pin to lubricate bearing

in chain sprocket.

d. On models with 3 lines of load chain lubricate sprocket in

hanger bracket with a few drops of graphite suspension

oil in hole provided in center of sprocket hub.

Page 8

Figure 5-2. Check Coil Chain Using Vernier Caliper

ALLOWABLE CHAIN WEAR - ELONGATION

When replacing coil load chain, use only factory

approved chain conforming to factory specifications

for material, hardness, strength and link dimensions.

Chain not conforming to YALE hoist specifications may

be dangerous as it will not fit in the load sprocket and

chain guide correctly, causing damage to hoist, and it

will wear prematurely, deform and eventually break.

WARNING

Figure 5-1. Check Chain Wear at Bearing

Surfaces Between Links

Lines of

Load Chain

Rated Capacity

For Standard Model

(tons)

Rated Capacity

For Spark Resistant Model

(tons)

11 1/2

22 1

33 2

(3) Removing and Replacing Coil Load Chain.

(a) Replacement coil load chain is installed by

attaching it to tail end of old chain, after

disconnecting old chain from side of hoist frame

and removing limit stop. New chain is then run

into hoist as old chain is run out. Use open "C"

links, Figures 5-3 and 5-4, for attaching chains.

Links must be identical in size to hoist chain -

5/16" wire size with .858" pitch length for all models.

Be certain that all welds on links of replacement

chain face away from center of load sprocket.

(b) Remove lower block assembly and actuator from

old chain and attach them to replacement chain at

end which was just run through hoist. Install limit

stop (as noted below) on other end of chain and

anchor chain to side of hoist frame.

Note: Install limit stop as shown in chart on page 5.

On double line models, also connect opposite end of chain

(from lower block) to load chain anchor inside of frame. On

triple line models, the opposite end of the chain is attached to

the lower block connecting link.

Chain Size

(wire dia.)

No. of

Pitches

to Measure

Maximum

Wear Limit

5/16" 11 .142"

than standard alloy steel load chain. For these reasons

the rated capacity of spark resistant models is lower

than that of standard models as follows:

Do not assume that load chain is safe because it

measures below replacement points given herein.

Other factors, such as those mentioned in visual

checks above, may render chain unsafe or ready for

replacement long before elongation replacement is

necessary.

WARNING

Figure 5-3. Open "C" Link for Removing and

Installing Link Load Chain

Use one or two "C" links to orient chain for chain

anchor screw. Position first link of new chain to be flat

against hoist housing without twisting the chain.

NOTICE

Page 9

(4) Check connection of chain to lower block on single

reeved and triple reeved hoists. Replace parts showing

evidence of damage, twisting or elongation.

(5) Check connection of chain to anchor inside hoist frame

on double-reeved hoists. Replace parts showing

evidence of damage, twisting or elongation. (Also see

Section VII, Paragraph 7-2.a.(2).

(6) Lubricate load chain before using hoist. See Paragraph

4-3, Section IV.

b. Inspect Lower Block.

(1) Check for bent or distorted hook. If hook is opened

beyond the dimension given in Figure 5-5, it must be

replaced. Also check to see that hook swivels and is

free to pivot. Lubricate these points if necessary.

When installing coil load chain do not attempt to hand

feed chain into hoist, or use a piece of wire In place of

the method described herein. To do so may result in

serious internal damage to hoist, as coil chain links

must be properly seated in chain sprocket before chain

Is run into hoist.

NOTICE

Note: In the event the old chain is to be removed from the

hoist and reinstalled, a short length of chain (about 18" long)

must be run into hoist when the old chain is removed. This

short length can then be used in the same manner as shown

in Paragraph 5-2.a(3). Be sure to use the proper number of

open "C" links in order to correctly position end link on tail end

of chain to fit anchor at side of hoist frame.

Figure 5-5. Lower Hook Opening

(Shown with latch removed for clarity.)

(2) On double and triple reeved hoists, check sprocket

and bearing in lower block for freedom of movement

and signs of damage. Lubricate if necessary. Replace

damaged parts.

(3) Check hook latches. Replace damaged or bent latches

or broken springs.

Hoist Capacity

(tons)

Hook Throat Opening

Normal

Opening

Replace Hook If

Opening is Greater thanStd. S.R.

1 1/2 1-1/4 1-7/16

2 1 1-3/8 1-9/16

3 2 1-1/2 1-11/16

Figure 5-4. Installing Coil Load Chain Using Two

"C" Links (1/4, 1/2 & 1 ton hoists)

Hooks, upper or lower, damaged from chemicals,

deformation or cracks or having more than 15 percent

in excess of normal throat opening or more than 10

degrees twist from the plane of the unbent hook, or

opened, allowing the hook latch to bypass hook tip

must be replaced.

Any hook that is twisted or has excessive throat

opening indicates abuse or overloading of the hoist.

Other load bearing components of the hoist should be

Inspected for damage. (See Section V, Paragraph 5-

2.d.(2) below).

WARNING

C. Inspect Upper Suspension.

All models utilize an upper suspension bushing to

attach the upper suspension to the hoist frame. The

bushing must be threaded all the way into the frame,

and the keeper must contact a flat on the suspension

bushing. The suspension bushing keeper screw must

be kept tight. Failure to do so could result in the

suspension separating from the hoist.

WARNING

Page 10

Figure 5-6. Upper Hook Opening

(Shown with latch removed for clarity.)

Hoist Capacity

(tons)

Hook Throat Opening

Normal

Opening

Replace Hook If

Opening is Greater thanStd. S.R.

1 1/2 1-1/4 1-7/16

2 1 1-3/8 1-9/16

3 2 1-1/2 1-11/16

(2) On lug suspended models, check condition of

suspension lug. Replace lug if damaged or cracked.

Check to see that lock plate is in place on lug and

screw holding it is tight.

(3) On double reeved hoists, check to see that upper lock

plate securing hook or lug bushing is in place and

screws holding it are tight. Lubricate hook shank.

(4) Check hook latch. Replace damaged or broken parts.

(5) Check suspension bushing, keeper and screw, make

sure bushing is screwed in all the way and keeper

screw is tight.

d. Inspect Motor and Frame.

(1) Check to see that bolts securing motor to frame are

tight. Also check for any visible damage to motor,

supply head or muffler, such as a cracked or dented

housing. Replace damaged parts.

(2) Check hoist frame for signs of visible damage. If frame

shows evidence of fracture, the hoist should be

disassembled and inspected for further signs of

damage from possible overloading. Replace damaged

parts. Also check condition of limit stop.

e. Check Oil Level. Remove oil level plug (Figure 4-1). If oil

level is not even with bottom of tapped hole, add Automatic

Transmission Fluid, DEXTRON® Type, to bring proper

level.

5-3. SIX-MONTH INSPECTION OR 500-750 HOURS OF

OPERATION. Hoist may be left suspended.

a. Check control cable wire strain reliever to see that it is in

good condition and securely attached to supply head

assembly.

b. Change Gearcase Oil. See Section IV, Paragraph 4-4.

c. Relubricate Load Chain. See Section IV, Paragraph 4-3.

d. Lubricate Upper Hook and Lower Block. See Section

IV, Paragraph 4-5.

5-4. ANNUAL INSPECTION. Hoist must be disconnected from

air service and removed from overhead suspension. Hoists

subjected to severe service or to adverse environments

should be examined weekly or as conditions warrant.

a. Hoist should be partially disassembled as necessary to

inspect hoist parts noted in Paragraphs b through e below.

Refer to Section VII for disassembly and reassembly

steps as noted.

b. Inspect Pendant Throttle Control Assembly. Remove

springs and valves (Paragraphs 7-6.a.(3) through 7-6.a.(5).

Check condition of springs and valves. Replace worn or

damaged parts.

c. Inspect Supply Head Assembly. Remove supply head

assembly (Paragraph 7-7.a) and disassemble it as

outlined. Check condition of valves. Replace worn or

damaged parts.

d. Inspect Air Motor. Remove air motor assembly (Paragraph

7-2.d) and disassemble it as outline (Paragraph 7-8).

Check for worn or damaged rotor vanes. Inspect ball

bearings and check condition of rotor, shaft, cylinder and

end plates. Any repairs beyond replacing vanes, springs,

and pins would best be done at an authorized YALE

repair station. Repair or replace defective parts as noted

in following steps:

(1) Rotor. Examine end faces for roughness and vane

slots for wear and burrs. A new vane should move in

and out without binding. Smooth roughness on end

faces and remove sharp edges or burrs at slot corners

using a hone. Replace motor if rotor and shaft

assembly is excessively worn or damaged.

(2) Cylinder. Examine surface of bore diameter for rough

circular grooves from scoring. If the cylinder is badly

scored, it must be replaced. A badly scored cylinder

cannot be restored by honing, since it will only enlarge

bore diameter, widening seal point between rotor and

cylinder, resulting in loss of speed and power. If

cylinder is replaced, new shim gaskets of the proper

thickness are required to maintain the original spacing

of the end plates.

(3) End Plates. Check faces of front and rear end plates

for wear of scoring. If wear depth is greater than .005

inch, end plates should be replaced. Light score marks

can be lapped out with 150-grit abrasive cloth on a

flat surface.

(4) Rotor Vanes and Springs. Inspect the rotor vanes for

wear, scoring, warpage, or other damage. Compare

the width of the old vane with a new one to determine

the amount of wear that has taken place on the width.

(1) On hook suspended models, check for bent or distorted

hook. If hook is opened beyond the dimension given

in Figure 5-6, it must be replaced. Also check to see

that hook pivots. Lubricate if necessary. Single reeved

hoists have a stop pin installed in frame adjacent to

hook to restrict hook rotation. Check to see that pin is

not sheared off and stop lug on hook shank is not

broken.

Page 11

Figure 5-7. Rotor Vane

(5) Motor Bearings. Check motor bearings, especially the

bearing at the extended shaft end of the motor, for

excessive looseness or binding. Do not, under any

circumstances, wash sealed bearings nor blow off with

a high pressure air hose. Replace damaged or worn

bearings. See Paragraph 7-8.

e. Reassemble and Test Hoist. Reassemble hoist as outlined

in Section VII, Paragraph 7-9. After reassembly, test

hoist in accordance with Paragraph 7-10.

5-5. INSPECTION: 5000 HOURS "ON" TIME OR 5 YEARS

ELAPSED TIME. Hoist must be removed from overhead

suspension.

If the old vane is more than 3/64" less than the new

vane (in width), it must be replaced. An old vane that

shows wear on the thickness must also be replaced.

Vanes worn in this manner will eventually, fail, cause

costly repairs, and unexpected down-time on the hoist.

Warped vanes must also be replaced as the vanes

must move in and out of the rotor slot without binding.

Inspect leaf springs and centering pins. Worn areas

on springs can cause eventual spring breakage and

motor lock up. Replace worn springs, particularly when

vanes are replaced.

a. Disassemble Hoist into Subassemblies. Follow procedure

outlined in Section VII, Paragraph 7-2.

b. Motor shaft oil seal and "0" ring, sprocket shaft bearing

and seal, all gaskets should be replaced.

c. Inspect Load Brake and Overload Clutch. Disassemble

load brake and clutch assembly as outlined in Paragraph

7-4. Friction discs should be discarded and replaced with

new discs. Check load brake friction surfaces on flange,

ratchet assembly and gear clutch cone. Replace parts if

badly scored or worn. Check condition of pawl and ratchet

assembly. If pawl, ratchet teeth or pawl spring are broken,

damaged or badly worn, replace complete assembly.

Check contact faces of load brake cam and gear center.

Brake gear and pinion teeth should be inspected for wear

or broken teeth. Clean parts thoroughly with an oil solvent

before reassembly.

Note: The overload clutch assembly should not be

disassembled as it is preset at the factory to provide

proper clutch pressure for a specific hoist capacity range.

If there is evidence of the clutch slipping or wear or

damage to the clutch components, the complete clutch

assembly should be replaced or sent to an authorized

YALE Hoist Repair Station to be rebuilt and properly

adjusted to factory specifications.

d. Inspect Sprocket and Intermediate Gears.

(1) Check condition of gear teeth on intermediate gear

and pinion shaft assembly. Replace worn or damaged

parts.

(2) Check condition of teeth or pockets on chain sprocket.

Replace worn or damaged parts.

e. Reassemble and Test Hoist. Reassemble hoist from

subassemblies following procedure outlined in Paragraph

7-9. After assembly is complete, test hoist as outlined in

Paragraphs 7-10 and 7-11.

NOTES

Page 12

6-1. Hoist does not operate. 1. Insufficient air pressure at source. 1. Check air pressure and adjust.

2. Insufficient air supply at hoist. 2. Use correct size supply hose.

3. Clogged air intake. 3. Shut off air - disconnect air hose -

clean air filter.

4. Excessive overload. 4. Reduce loading to rated capacity

of hoist, as shown on nameplate.

5. Clogged valve - pendant throttle 5. Disassemble and check pendant

throttle control. control. Refer to Section VII,

Paragraph 7-6.

6. Clogged or inoperative valve- 6. Disassemble and check supply

supply head assembly. head assembly, Refer to Section

VII, Paragraph 7-7.

7. Motor failure. 7. Disassemble motor and check

rotor vanes and springs. Replace

defective parts.

6-2. Hoist will not hold load 1. Load brake not holding. 1. Remove load brake and inspect

in suspension. parts. Refer to Section VII,

Paragraph 7-4.

6-3. Hook Will Raise But Not Lower. 1. Load brake locked up and overload 1. Consult Authorized YALE Hoist

clutch slipping (Caused by Repair Station.

excessive overload).

6-4. Hoist loses power. 1. Insufficient air pressure. 1. Check air pressure and adjust.

2. Clogged air intake. 2. See this Section, Paragraph 6-1.

3. Clogged muffler (Iced). 3. Remover muffler cover. Clean

screen and muffler. Reduce

frequency of lift to prevent icing.

4. Worn or broken rotor vanes, springs 4. Replace rotor vanes, springs, and

or pins. pins.

6-5. Cannot regulate speed by 1. Clogged valve - pendant throttle 1. See this section, Paragraph 6-1.

control handles. control.

6-6. Hoist lifting or lowering speed 1. Incorrect air pressure or inadequate . 1. Check pressure at hoist when

differs from rated speed at full load. air supply. hoist is operating.

2. Loss of power. 2. See this section, Paragraph 6-4.

SECTION Vl - TROUBLE SHOOTING

Trouble Probable Cause Remedy

Page 13

then the chain can be pulled through the hoist by

hand.

(3) On triple reeved chain hoists, remove retaining ring

and connecting link pin as shown in Figures 7-27 and

7-28. Remove connecting link with chain from lower

block. To remove connecting link from chain, take out

cotter key and push anchor pin from connecting link.

Chain can now be pulled through hanger bracket and

lower block. Unfasten tail chain from hoist frame,

remove limit stop, and if air is available, operate

hoist in lowering direction to remove chain. (See note

in Section V, Paragraph 5-2.a.(3) for inserting short

length of chain.) If hoist is inoperative see note below

but be sure to install short length of chain into hoist

before removing load chain.

Note: If hoist is inoperative it will be necessary to

remove load brake (Paragraph c, below) so chain can

be pulled through the hoist by hand.

(4) To remove hanger bracket from triple reeved hoist,

remove retaining ring and connecting rod pin (see

Figure 7-1). Rotate hoist approximately 45° (see Figure

7-2) and hanger will slip free from hoist frame.

Figure 7-1. 3 Ton Hanger Bracket

Connection Pin Removed

12427

Figure 7-2. Removing 3 Ton Hanger

Bracket from Hoist Frame

12428

SECTION VII - DISASSEMBLY AND REASSEMBLY

7-1. GENERAL.

a. The following disassembly and reassembly instructions

apply to all models of YALE KALC Air Hoists. Where

needed, variations to instructions are provided to cover

differences between models (suspensions, load chain,

reeving, capacity sizes) with applicable models specifically

noted.

b. A complete tear down procedure is given. However, if

only certain parts require repair or replacement, a partial

tear down may be performed, using applicable portions

of the instructions.

c. For easier handling during disassembly, the following

disassembly steps may, where conditions permit, be

completed before hoist is removed from its overhead

suspension or disconnected from its air supply: Remove

chain container, if hoist is so equipped. Remove lower

block and load chain assembly, following procedure

outlined in Paragraph 7-2.a. Drain and discard gearcase

oil, by removing plug at bottom of frame.

d. These hoists contain precision machined parts and should

be handled with care at disassembly and at reassembly.

When removing or installing parts with press fits, be

careful to apply pressure evenly. On ball bearings, apply

pressure to face of inner or outer race, whichever is

adjacent to mating part. This will avoid damage to bearing

races from brinelling by pressing through bearing balls.

Apply a thin film of sealant to parts having a press fit

when they are installed.

e. To remove hoist from overhead suspension:

(1) Turn off air at source.

(2) Operate control to bleed air from hoist.

(3) Disconnect air hose at inlet swivel.

(4) Remove hoist from overhead suspension.

7-2. DISASSEMBLY OF HOIST INTO SUBASSEMBLIES.

a. Removal of Lower Block and Load Chain Subassembly.

(1) On models with single reeved load chains disconnect

tail end of load chain from anchor at side of frame.

Remove fillister head screw holding end link to frame.

Remove screws and lockwashers from the limit stop

and remove from chain. With hoist connected to air

supply, run chain out of hoist by operating in "lowering"

direction. (See note following Paragraph (2) below and

note in Section V, Paragraph 5-2.a.(3) for inserting

short length of chain.)

(2) On models with double reeved load chains disconnect

tail end of load chain from anchor at side of hoist

frame and remove limit stop as in (1) above, run

chain out of hoist by operating it in "lowering" direction,

and disconnect opposite end of load chain from anchor

inside hoist frame. To disconnect this end of chain,

remove cotter pin from end of anchor pin, press pin

from anchor and withdraw chain.

Note: If hoist is inoperative it will be necessary to wait

until after load brake is removed (Paragraph c, below),

Page 14

Figure 7-3. View of Hoist with

Counterweighted Compartment Cover Removed

12429

(2) Remove eight hex socket head screws and

lockwashers securing gearcase cover to hoist frame.

Pry gearcase cover off hoist frame using screwdriver

at special notches provided at opposite corners of

cover (Figure 7-4). Gearcase cover can now be lifted

from frame (Figure 7-5). Discard gearcase cover

gasket.

Figure 7-4. Prying Gearcase Cover From Hoist Frame

12430

Figure 7-5. Gearcase Cover Removed From Hoist Frame

12431

c. Removal of Load Brake and Clutch Assembly and

Intermediate Gear Subassembly.

Pull load brake and clutch assembly and intermediate

gear assembly, including the thrust washers for each

unit, from hoist frame (Figure 7-7).

Figure 7-7. Removing Load Brake and Clutch and

Intermediate Gear Subassemblies

10315B

d. Removal of Motor and Supply Head Assembly.

Place hoist frame on wood blocks to protect integral

gear on motor shaft. Loosen four motor mounting bolts

and lift motor assembly from frame (Figure 7-8).

b. Removal of Counterweighted Compartment Cover and

Gearcase Subassembly.

(1) Disconnect hoist from air source. Remove three

cover retaining screws and lift off cover (Figure 73).

Cover screws have retaining rings which hold them

in cover. Use caution as cover contains a

counterweight.

Figure 7-8. Removing Motor Assembly

Page 15

Figure 7-9. Pulling Sprocket Gear from Sprocket Shaft

Using Common Puller

10322

(2) Unscrew four fillister head machine screws securing

sprocket bearing retaining plate and remove plate

(Figure 7-10). Remove and discard ring gasket from

groove around bearing or remove seal disk.

Figure 7-10. View of Sprocket Bearing Retaining Plate

10323

Figure 7-12. Removing Chain Guide Support Pins

(3) Remove "C" clips holding chain guide pins in place.

Pull guide pins out from motor side of frame. (Fig 7-

12)

(4) Remove sprocket shaft and front ball bearing assembly

from frame by lifting up on end of shaft while prying

up on sprocket as illustrated in Figure 7-13. The chain

guide will need to be repositioned in frame as sprocket

shaft is raised to allow the sprocket to pass through

hole of guide (Figure 7-14).

Figure 7-13. Removing Sprocket Shaft and Front Bearing

10326

7-3. REBUILD OF HOIST FRAME, SPROCKET GEAR,

SPROCKET SHAFT AND CHAIN GUIDE

a. Disassembly of Sprocket Gear, Shaft and Chain Guide.

(1) Remove retaining ring from end of sprocket shaft

and pull off sprocket gear using a common puller

(Figure 7-9). Remove Woodruff key from shaft.

Page 16

Note: Do not remove oil seal, ball bearings, and needle

bearings from their bores in the frame unless they show

evidence of wear or damage and require replacement.

When replacing rear sprocket ball bearing pack bearing

1/2 full with NLGI No. 2 grease.

b. Disassembly of Upper Hook (Hook Suspension Models.)

(1) On 1/4 through 1 ton models, remove screw securing

suspension bushing keeper. Unscrew suspension

bushing from frame to remove hook.

Figure 7-14. Chain Guide Being Removed From Frame

as Sprocket Shaft is Lifted Out

10327

(2) On double reeved models, unscrew two hex socket

head screws holding suspension bushing lock

assembly to upper block (Figure 7-16) and remove

lock. Unscrew suspension bushing from block to

Figure 7-16. View of Upper Hook Assembled to

Hoist Frame (Double Reeved Models)

Note: Hook and bushing assembly is not to be further

disassembled as nut securing bushing to hook shank is

welded in place at the factory. Only the assembly is

available for replacement.

(3) On tripled reeved models, remove retaining ring from

connecting rod pin and push connecting rod pin

through bracket and connecting rod, releasing

hanger (see Figure 7-1). Raise hanger above hoist

frame to provide access to hook nut. Rotate hook

until grooved pin in nut is visible from end of hanger

frame. Using a drift punch, drive grooved pin through

hook nut until it hits hanger pocket. Remove drift

punch far enough to hold nut from turning and

unscrew hook from nut. Thrust washer will fall free.

(4) To remove connecting rod (fig 7-2) on 3 ton hoist,

remove screw securing suspension bushing keeper.

Unscrew suspension bushing to remove connecting

rod from frame.

c. Disassembly of Suspension Lug (Lug Suspension

Models).

(1) On ¼ through 1 ton models, remove two screws

securing anti-rotation bracket and remove bracket.

Remove screw securing suspension bushing keeper,

and remove keeper. Remove suspension lug using

an extra thin 1-1/4" open end wrench to unscrew

suspension bushing from frame. (See fig. 7-17).

Figure 7-15. Removing Upper Hook and Hook Nut

from Hoist Frame (1/4 through 1 Ton Models)

remove hook. To disassemble block from frame

remove drive pin from nut inside frame and unscrew

nut from stud holding body to frame. Remove drive

pin securing threaded end of chain anchor in block

and unscrew anchor. Block can then be lifted off.

Page 17

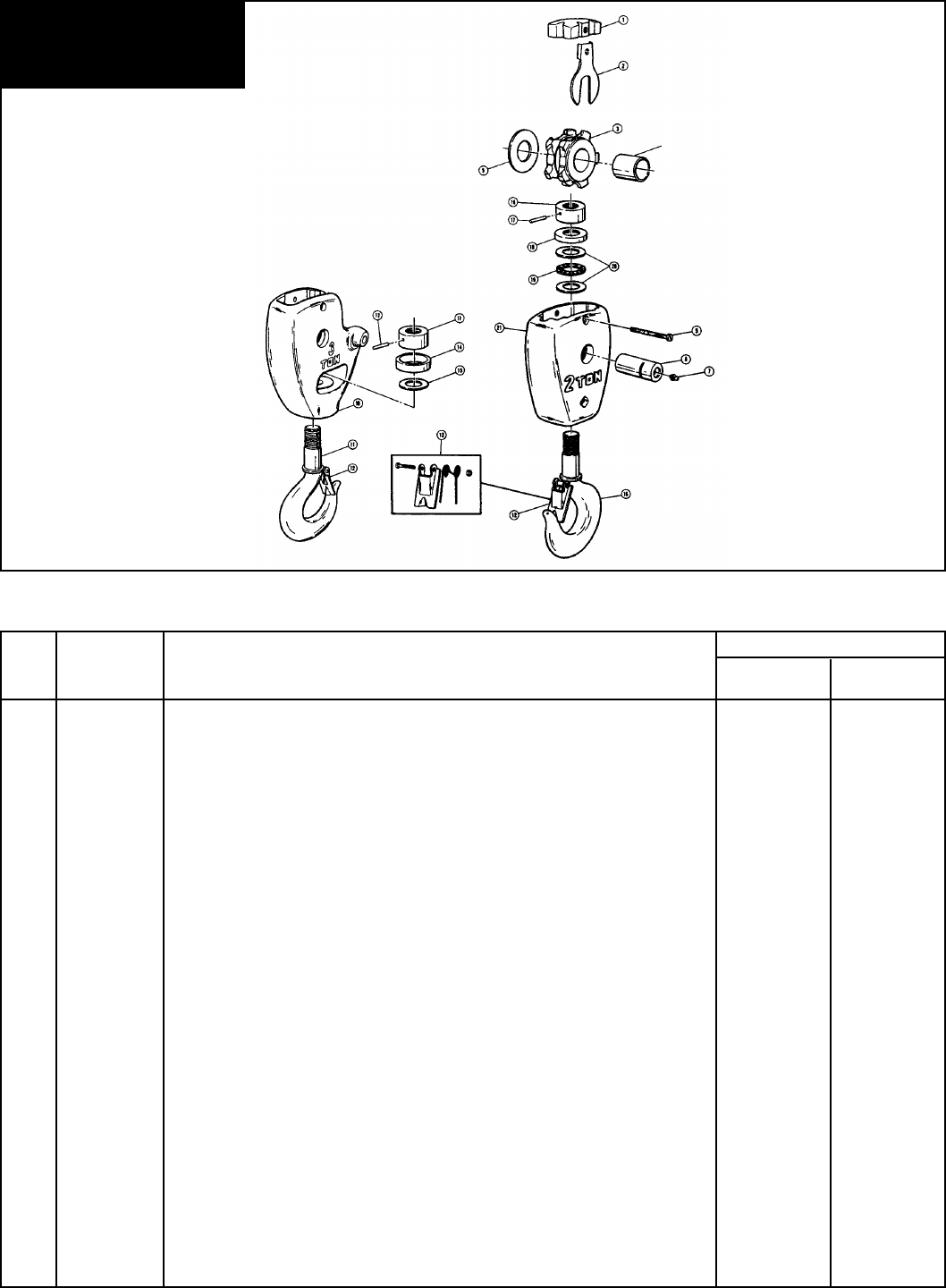

7-4. REBUILD OF LOAD BRAKE AND OVERLOAD CLUTCH

ASSEMBLY

a. Disassembly.

(1) Place load brake and clutch assembly, flange up, in

a vise equipped with brass or copper jaw plates to

protect pinion gear teeth. Remove snap ring from

end of load brake shaft (Figure 7-18).

Figure 7-18. Removing Snap Ring from Load Brake Shaft

10333

(2) Using a puller tool, remove brake flange from shaft.

A groove is provided around outer diameter for this

purpose. See Figure 7-19. Remove key from shaft

and lift off 2 friction discs, and the pawl and ratchet

assembly (Figure 7-20).

Figure 7-19. View Showing Load Brake Flange Removed

10334

(2) On 2 ton models, remove three hex socket head

screws securing the two lock plates to block at top of

frame and pull out locks. Remove suspension lug,

using an extra thin 1-1 /4" open end wrench to

unscrew suspension bushing from block. Instructions

for removing block from frame are given in paragraph

b. (2).

NOTE: The suspension lug is not to be further

disassembled, as nut securing suspension bolt and

bushing to lug is permanently secured in place at the

factory. Only the suspension lug assembly is available for

replacement.

(3) On 3 ton models lug bolt is removed in same manner

as hook. See paragraph 7-3. b. (3).

d. Reassembly.

(1) Before assembly, all parts should be thoroughly

cleaned and inspected to determine their

serviceability. Replace parts that are excessively

worn or damaged.

(2) Reassemble suspension hook or lug, chain guide,

sprocket shaft and sprocket gear to frame following a

reverse procedure of the disassembly steps listed in

Paragraphs a through c, above. If ball bearing is to

be reinstalled on sprocket be certain to position it so

that the seal side of bearing faces out, away from

sprocket. To help prevent oil seepage, apply sealant

on O.D. of sprocket bearing and in seat for the ring

gasket.

If groove pin securing nut to upper hook is loose,

replace hook-nut assembly and pin.

WARNING

Figure 7-17. Removing Suspension Lug

(1/4 through 1 Ton Models)

Page 18

(3) Remove load brake gear and overload clutch

assembly from output pinion shaft. Pull the spring

from its recess in clutch cone (Figure 7-21) but do

not further disassemble gear and clutch assembly.

See "Note" below.

Note: Disassembly of the load brake gear and

overload clutch assembly (Figure 7-21) is not

recommended. Clutch pressure is preset by the

factory at assembly to provide the correct torque to

allow the clutch to refuse loads within a specified

range (110% of rated load to 180% rated load). It is

suggested whenever there is a need to repair or

readjust the gear and clutch assembly that it be sent

to an authorized YALE Hoist Repair Station where

adequate tools, fixtures and appropriate test

equipment is available.

Figure 7-20. Removing Pawl and Ratchet Assembly

From Load Brake Shaft

10335

Figure 7-21. Load Brake Gear and Overload Clutch

Assembly Removed from Load Brake Shaft Showing

Brake Spring Installed in Clutch Cone

11927

(4) The load brake pawl and ratchet is a riveted

assembly and is not to be disassembled.

b. Reassembly.

(1) Before assembly, all parts should be cleaned and

inspected to determine their serviceability. Replace

parts that are excessively worn or damaged.

(2) Reassemble load brake parts following a reverse

procedure of the disassembly steps listed above,

observing the assembly steps (3) through (6) below.

(3) Before installing spring in its recess in center of

clutch cone (Figure 7-21) apply a good grade of ball

bearing grease to inside of recess. Spring must be

positioned exactly as illustrated, butted against pin.

(4) When installing pawl and ratchet assembly on load

brake shaft, be certain that teeth on ratchet face are

in the same direction as shown in Figure 7-20. The

ratchet assembly should rotate freely when turned

counterclockwise and the pawl should engage

ratchet teeth when unit is turned clockwise.

(5) When installing brake flange position it with chamfer

facing friction disc, Figure 7-19.

(6) The brake spring must be pre-loaded at assembly to

a torque of from 10 to 14 lb. ft. This is accomplished

using a plumber's strap wrench to wind (rotate) load

brake gear to set up spring (Figure 7-22) while

pressing brake flange into place using an arbor

press. Clamp pinion end of shaft into a portable vise

to keep brake from rotating in press. Use brass or

copper jaw plates on vise to protect pinion gear

teeth. Wind gear counterclockwise (viewing brake

from flange end) with plumber's strap wrench and

press down on flange until snap ring groove in shaft

is exposed allowing snap ring to be installed. Use

extreme care not to over wind spring as yield will

result and final spring torque will be reduced. Do not

wind gear beyond point necessary to install snap

*ring in groove.

Figure 7-22. Winding Load Brake Gear Using a Plumber's

Strap Wrench to Set Up Load Brake Spring.

10610

Page 19

7-5. REBUILD OF LOWER BLOCK AND LOAD CHAIN

ASSEMBLY

a. Disassembly (single reeved models).

(1) Separate load chain from lower block assembly.

Drive out small roll pin securing lower block pin in

lower block yoke and push lower block pin from yoke

to release chain.

(2) Unbolt and remove limit actuator(s). On a single line

hoist that has a bumper, remove the bumper also.

(3) Lower blocks are of a pinned construction, permitting

replacement of body, thrust bearing, or hook and nut

assembly. To disassemble, drive spring pin from hook

nut (Figure 7-23). With pin removed, hold hook nut

from turning with drift punch and rotate hook to

unscrew it from nut. Separate hook, bearing shield,

needle bearing and two thrust washers from body.

Hook and nut are drilled at assembly and are

replaced only as an assembly.

Figure 7-23. Removing Roll Pin Securing Hook Nut to

Hook Shank

11868

b. Disassembly (double reeved models).

(1) On double reeved models, remove fillister head

screw securing center guide in top of lower block

body and lift out guide (Figure 7-24) and sprocket

pin lock (Figure 7-25). Press sprocket pin from body

and pull out chain, sprocket and washer (Figure 7-

26). Do not remove bushing type bearing from

sprocket or pressure lube fitting from sprocket pin

unless replacement is necessary.

Figure 7-25. Removing Sprocket Pin Lock on Double and

Triple Reeved Lower Block Assembly.

12437

Figure 7-26. Removing Coil Chain and Sprocket on Double

and Triple Reeved Lower Block Assembly

12438

Figure 7-24. Removing Chain Center Guide from Double

and Triple Reeved Lower Block Assembly

12436

c. Disassembly (triple reeved models).

(2) To remove hook, drive grooved pin from hook nut

with drift punch. With pin removed, hold hook nut

from turning with drift punch and rotate hook to

unscrew it from nut. Separate hook, nut, bearing

shield, needle bearing two thrust washers from body.

Hook and nut are drilled at assembly and are

replaced only as an assembly.

(1) Remove chain sprocket from lower block following

procedure for double reeved models described in

Paragraph 7-5.b.(1) above.

(2) To disconnect end of chain anchored to lower block,

remove retaining ring from pin bore (Figure 7-27).

Push connecting link pin from bore by pressing

through hole provided in opposite side of block

(Figure 7-28). Chain connecting link is now free and

can be further disassembled for inspection.

(3) To remove hook from lower block body, first drive

grooved pin from hook nut. Then hold nut from

turning using drift punch and rotate hook to unscrew

it from nut. Separate hook, shroud and thrust washer

from body. Note that bearing surface of washer faces

nut.

(4) To remove chain sprocket from upper suspension

hanger, first remove hanger as outlined in Paragraph

7-2.a.(4). With hanger removed, push sprocket pin

from hanger and sprocket. Note: Sprocket pin must

Page 20

Figure 7-27. Removing Retaining Ring From Bore of

Connecting Link Pin - Triple Reeved Lower Block

Assembly

11752A

Figure 7-28. Removing Connecting Link Pin From Triple

Reeved Lower Block Assembly

11752B

d. Reassembly of Lower Blocks.

(1) Clean, inspect and replace worn or damaged parts.

(2) Lubricate and reassemble following a reverse

procedure of the disassembly steps above.

7-6. REBUILD OF PENDANT THROTTLE CONTROL

ASSEMBLY

a. Disassembly.

(1) Disconnect three air hoses from top of throttle

control assembly.

(2) Remove hex head cap screw and washer holding

wire rope thimble and strain cable to supply head

assembly.

(3) Remove two large hex head threaded caps from

throttle control assembly side opposite control levers.

(4) Remove spring from under each cap.

(5) Remove each spool valve by threading a #10-24

screw into tapped hole in valve and pulling valve out.

be removed toward side having small anti-rotation

pin slot in hanger.

b. Reassembly.

(1) Before assembly, all parts should be thoroughly

cleaned and inspected to determine their

serviceability. Replace all parts that are worn or

damaged.

(2) Reassemble parts in reverse of the disassembly

steps above.

7-7. REBUILD OF SUPPLY HEAD ASSEMBLY

a. Disassembly. (See Figure 8-6.)

(1) Disconnect three air hoses leading to the pendant

throttle control assembly.

(2) Remove hex head cap screw and washer holding

wire rope thimble and strain cable for pendant

throttle control assembly.

(3) Remove two long hex head cap screws, with

lockwashers, running from supply head to muffler

assembly and remove muffler assembly.

(a) Remove two pan head screws and remove muffler

cover.

(b) Remove muffling material and screen.

(4) Remove two hex socket cap screws and lockwashers

on side of supply head assembly and remove supply

head assembly from air motor body.

(5) To gain access to the valves, remove the retaining

rings and screens at the ports and pull out the

muffling material.

(6) Remove the two pan head screws on the side of the

supply head assembly to release the valves inside

the assembly.

(7) Pull valve sleeve, spring, and stem out of the supply

head assembly. Valve parts may be reached by using

needle nose pliers.

Early hoist models utilized a plastic valve and valve

base. When rebuilding supply head, replace these

with the new valve sleeve, spring, and stem.

b. Reassembly. (See Figure 8-6)

(1) Before assembly, all parts should be thoroughly

cleaned and inspected to determine their serviceability.

Replace all parts that are worn or damaged.

(2) Install muffler screen diagonally in cavity with square

end resting against back above circular contour and

notched end straddling bottom rib near opening.

(3) Install muffling material above screen and mount

gasketed cover with screws.

(4) Install valve springs and stems in sleeves and lubricate.

(5) Slide sleeves into position in supply head (small, single

hole on side of sleeves must align with retaining

screws) and reinstall retaining screws.

(6) Replace supply head gasket. Position gasket so that

no portion of ports is covered.

Page 21

7-8. REBUILD OF AIR MOTOR.

a. General. For removal of supply head assembly and muffler

assembly, see Paragraph 7-7.

b. Disassembly.

(1) Remove four hex socket cap screws and then remove

motor from hoist.

(2) Remove three fillister head screws, end cap and

gasket.

(3) Remove six hex head bolts holding rear end plate to

motor cylinder.

(4) Hold the shaft in a soft jawed vise and using a puller,

adapted to fit the three #10-32 bolt centers of the end

cap, remove rear end plate and shim gasket. Do not

try to pry the end plate from the motor.

(5) Remove six hex socket cap screws from front end

plate.

(6) Remove motor body exposing the rotor assembly while

leaving front end plate mounted on shaft. This

relationship should be maintained to eliminate the

necessity of adjusting the motor upon reassembly.

(7) Remove vanes, springs, and pins.

Note: Motors requiring further disassembly should be

sent to an authorized YALE repair station for repairs.

c. Reassembly.

(1) Before assembly, all parts should be thoroughly leaned

and inspected to determine their serviceability. Replace

all worn or damaged parts.

(2) Position assembly vertically with rotor facing upward.

Insert push pins in rotor. Place shim gasket and motor

body on end plate, using dowel pins for positioning.

Insert vanes and springs into rotor. Take care that

spring tab is positioned in slot of vane.

(3) Install six hex socket head screws through front end

plate.

(4) Place shim gasket and rear end plate on body, using

dowel pints for positioning. Press rear bearing onto

rotor shaft by pressing on inner race. Bearing outer

race should not be bottomed on rear end plate.

(5) Install six hex head bolts through rear end plate.

(6) Replace end cap and gasket and install three fillister

screws.

(7) Position motor in proper orientation on hoist and fasten

with four hex socket head screws.

7-9. REASSEMBLY OF HOIST FROM SUBASSEMBLIES.

a. General. The procedure to be followed to reassemble the

hoist from subassemblies is in reverse order of the

disassembly steps outlined in Paragraph 7-2. Listed below

are special precautions which should be observed to

assure proper assembly.

b. Assembly of Load Brake Thrust Washers. When

reinstalling load brake assembly be certain thrust washers

are properly installed at both ends of load brake shaft, as

noted below.

(1) A bronze thrust washer with a lug on one side belongs

on pinion end of shaft and must be installed so that

its lug engages the special slot located on spotface

surrounding bearing bore inside gearcase cover. Use

heavy grease to hold washer in proper position in

cover during assembly.

(2) A 5/8" I.D. steel thrust washer is to be installed on the

brake flange end (end opposite pinion) of load brake

assembly.

c. Assembly of Load Chain.

Note: Coil chain must be installed so welds on vertical

links face away from the load sprocket.

(1) Install load chain over sprocket

before load brake

assembly is installed.

Insert anchor end of chain (end

opposite lower block on single reeved models) into

chain guide opening on far side of hoist (viewing frame

from anchor screw side). Rotate sprocket gear by hand

counterclockwise as chain is fed into opening. When

sufficient chain has been run into hoist to reach anchor

position, plus a slack loop, install limit actuator on

anchor end of load chain (see (2) below) and attach

end of chain to frame with special fillister head screw.

Be certain chain is not twisted.

(2) When installing limit actuator on anchor end of load

chain attach it according to chart in Section 3-2.

(3) When installing limit actuator at lower block, single

line models only, actuator slides freely on chain. Place

urethane bumper above the limit actuator.